Experimental Study on Flexural Capacity of PP-ECC Beam

-

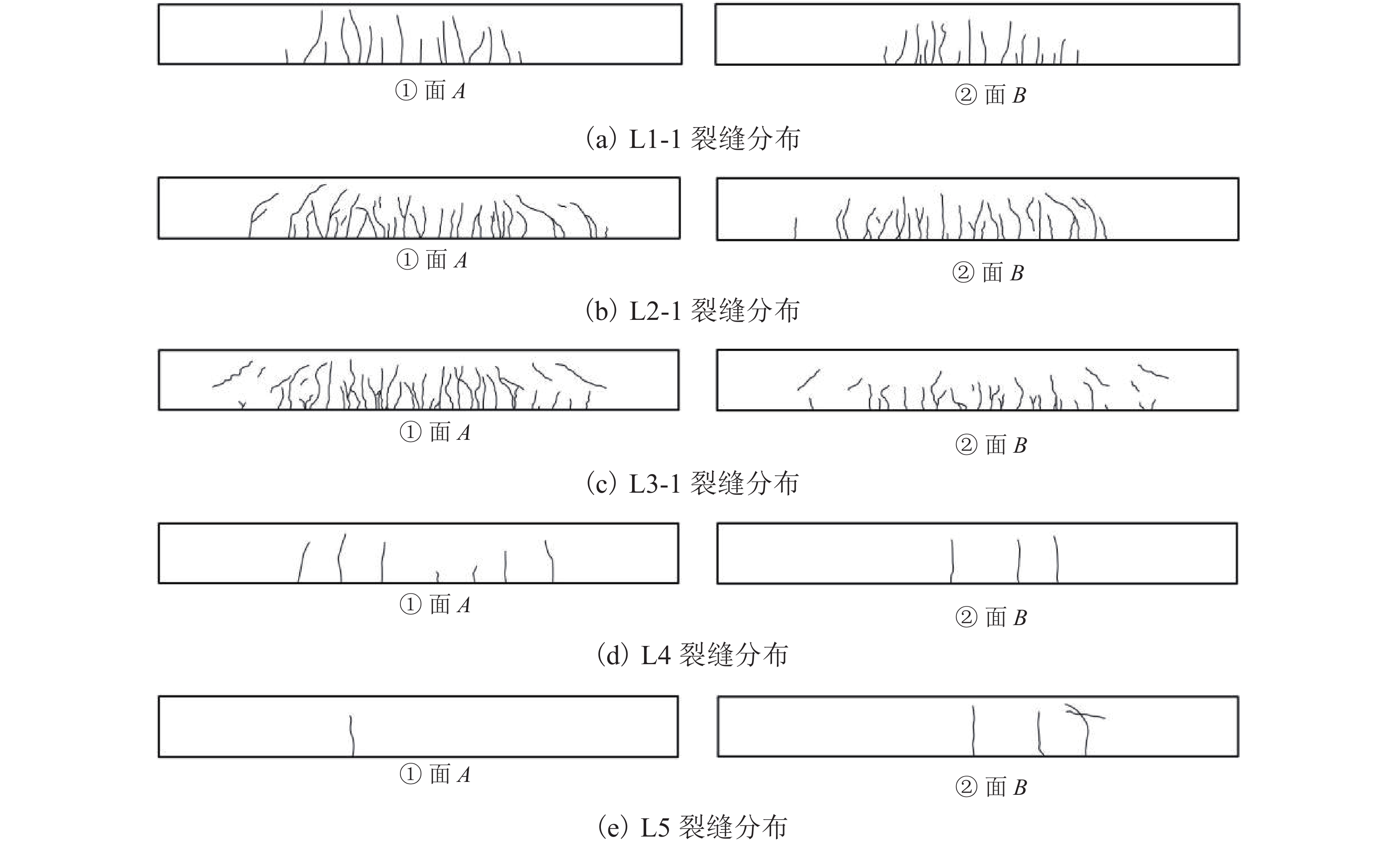

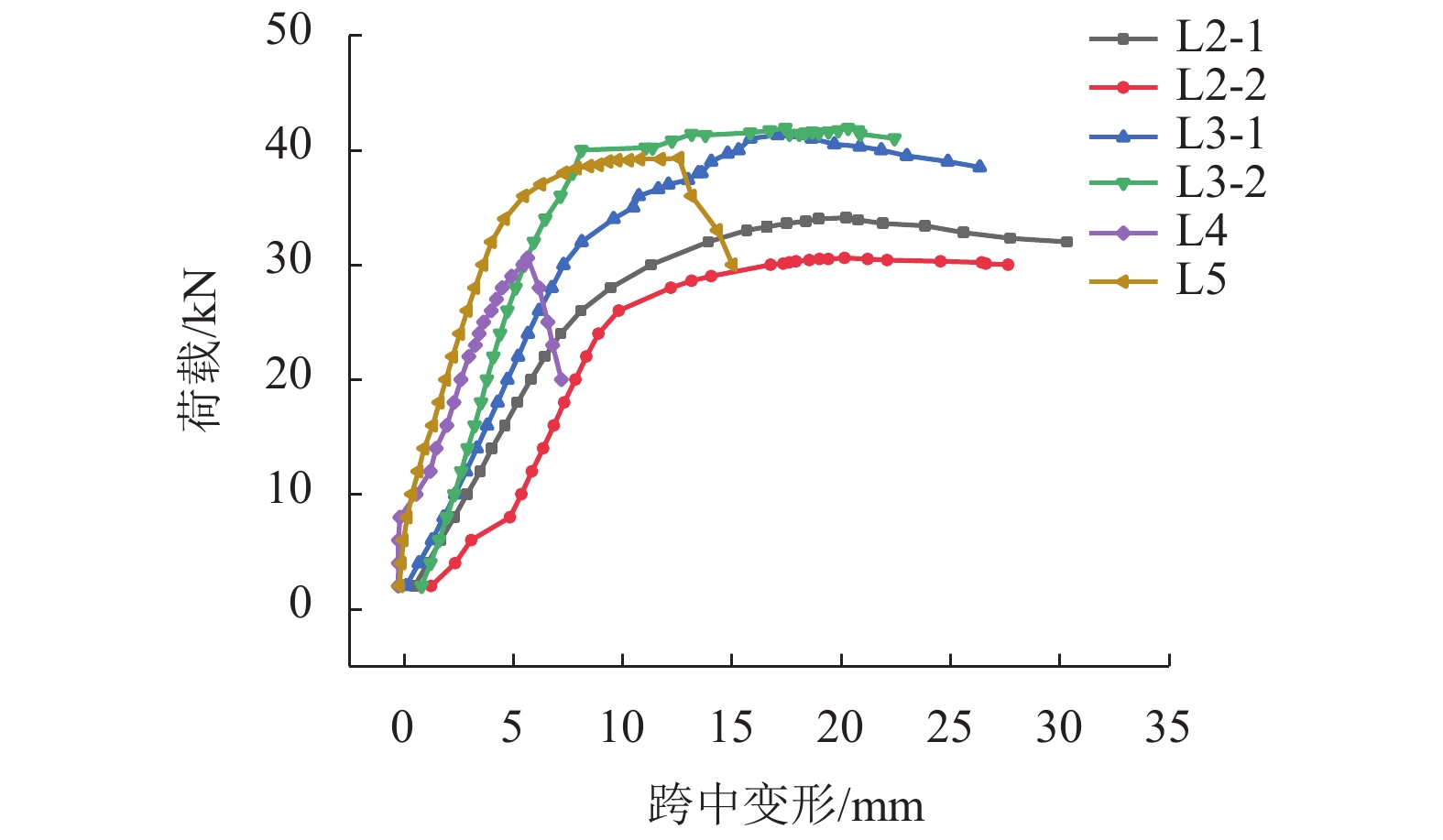

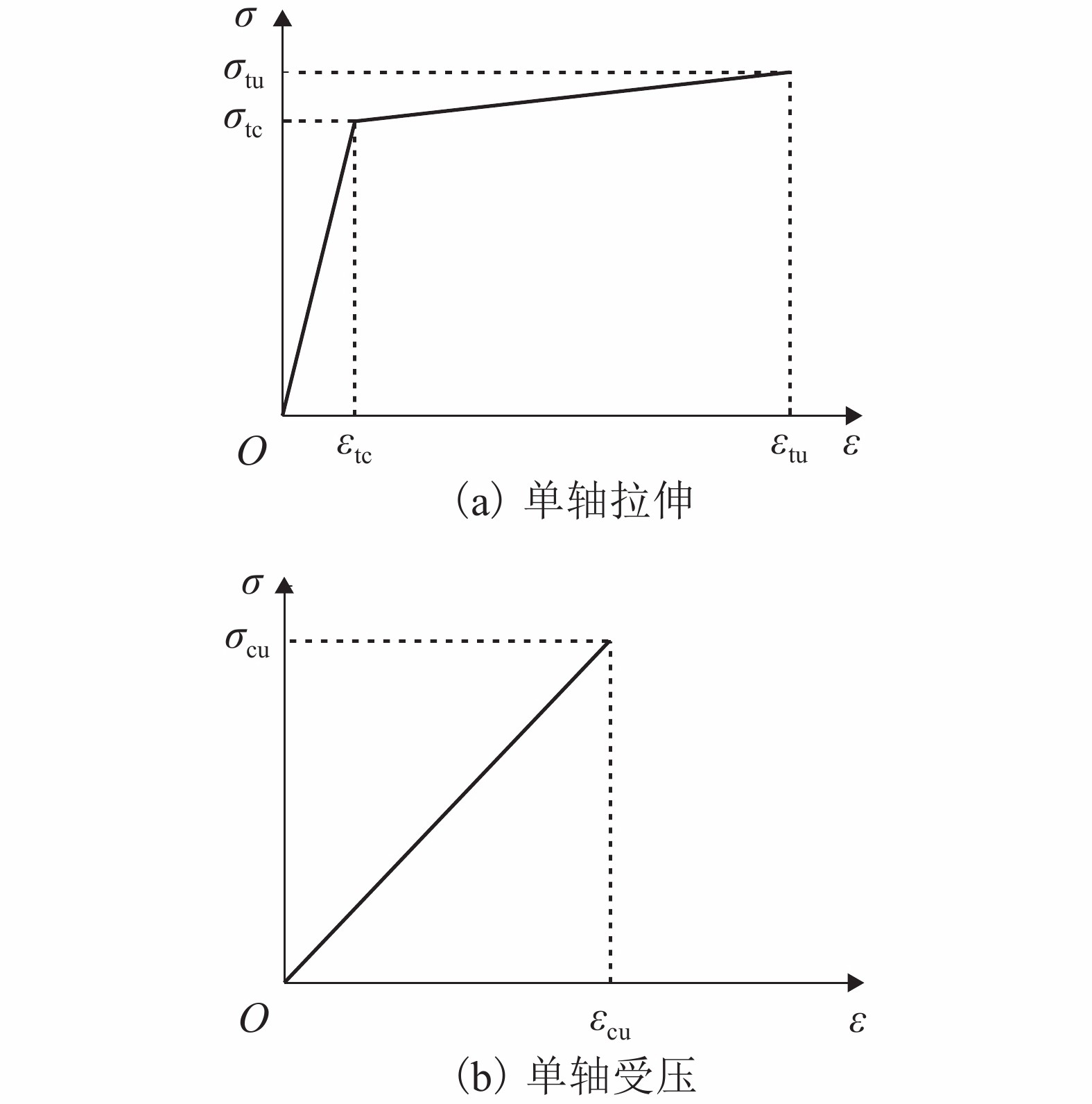

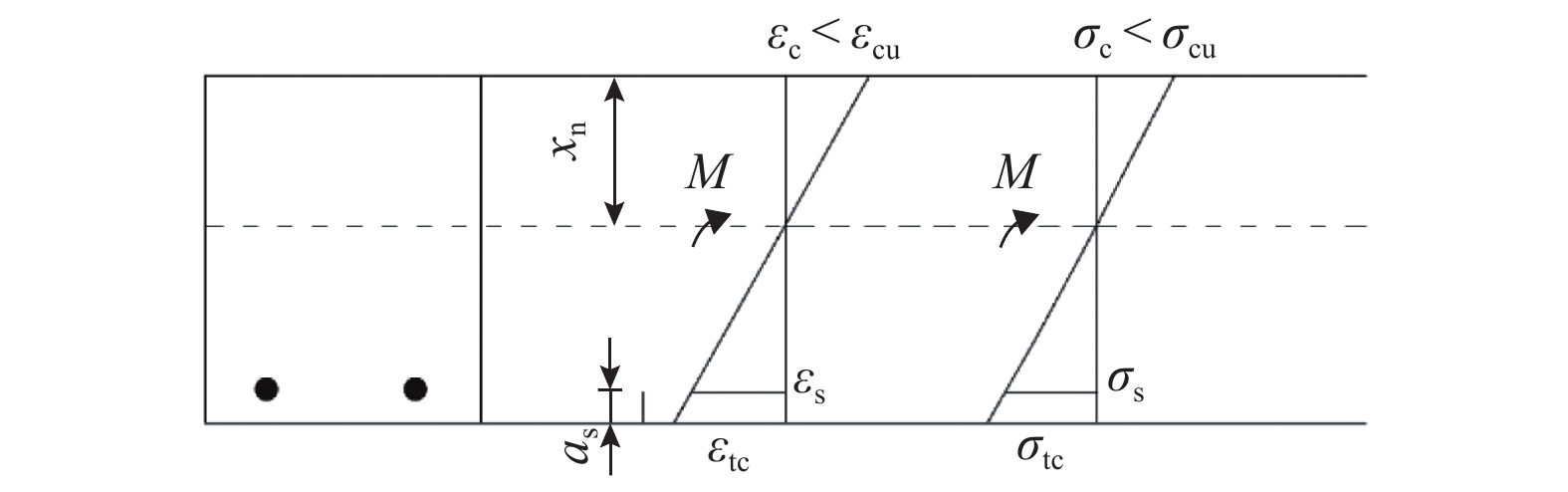

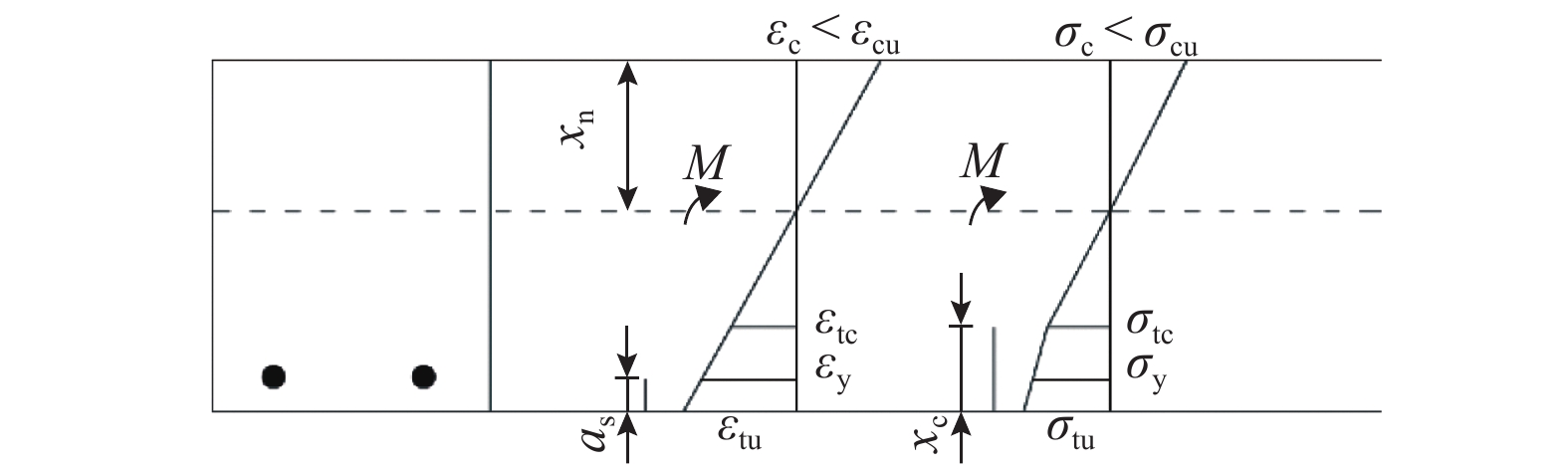

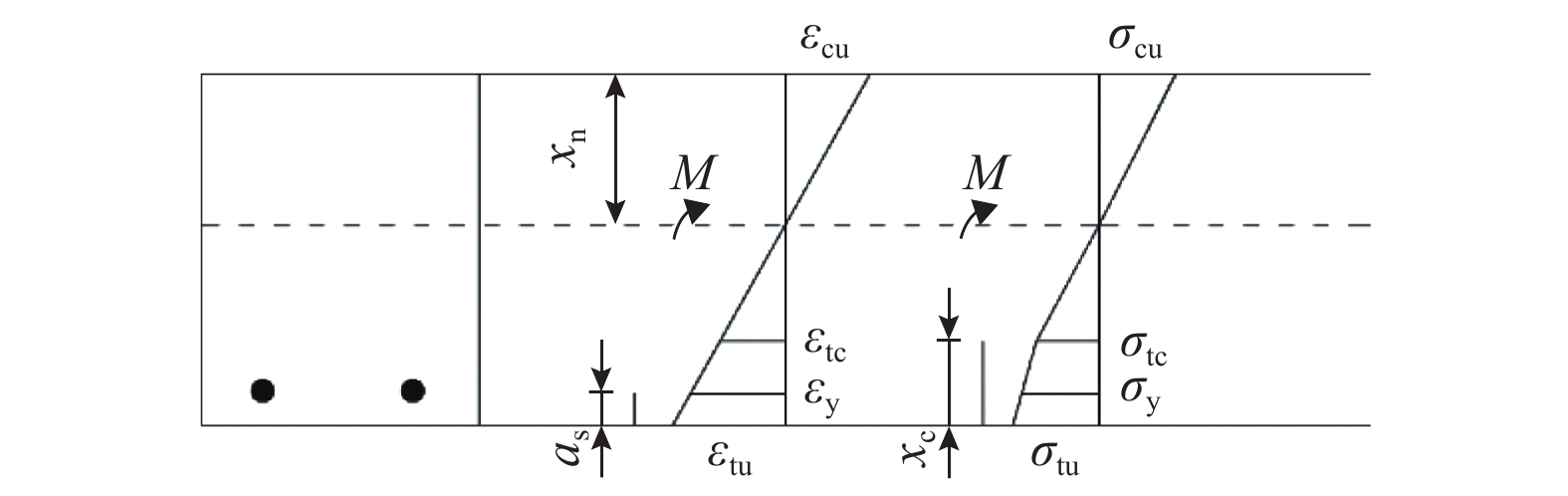

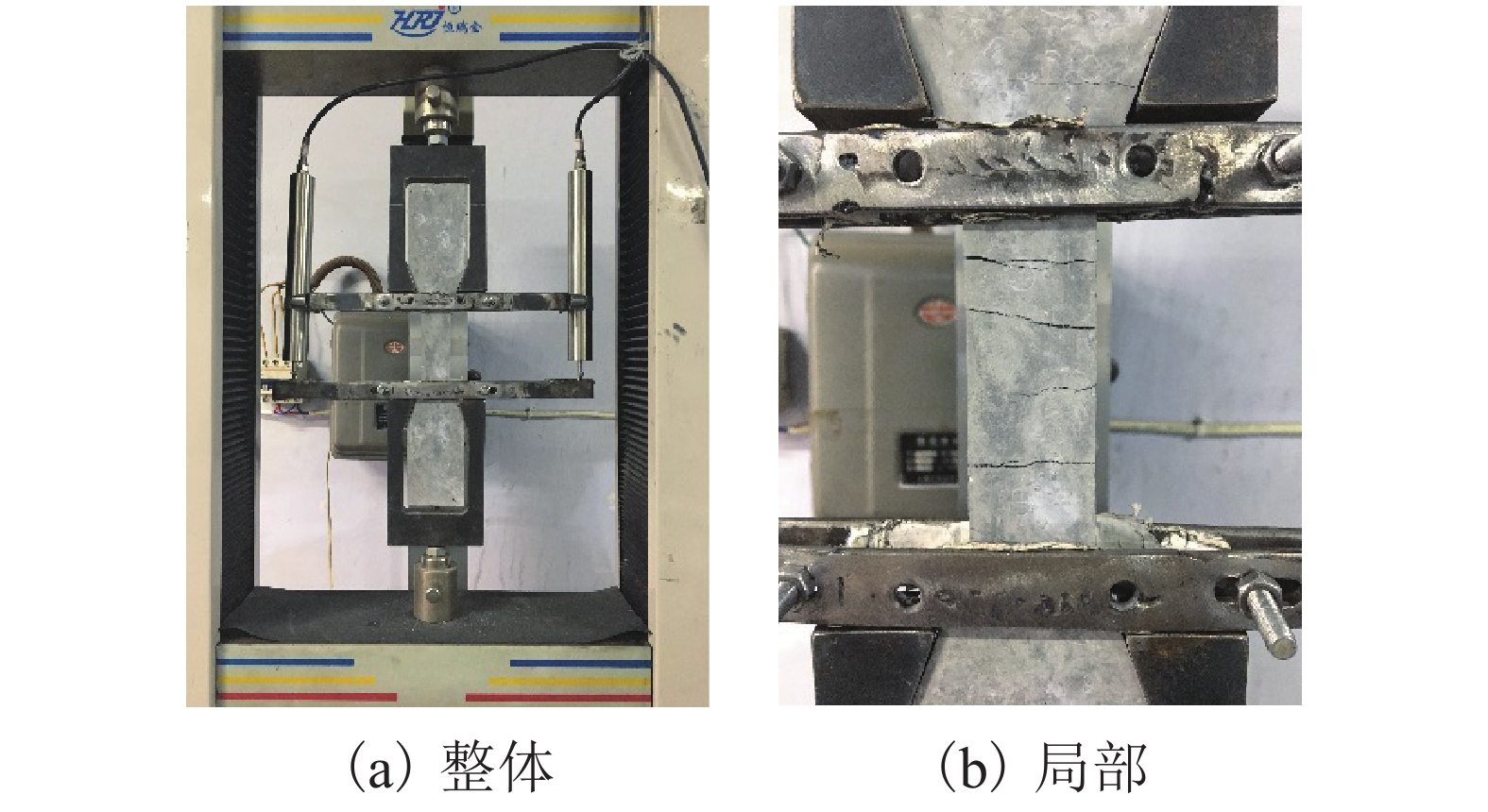

摘要: 为研究聚丙烯纤维水泥基复合材料(PP-ECC)梁与普通钢筋混凝土梁在弯曲荷载作用下力学性能的差异,通过四点弯曲加载,对PP-ECC梁的抗弯性能进行了试验探究. 对PP-ECC梁的弯曲破坏过程进行了阶段划分;基于计算假定和简化后的PP-ECC本构模型推导出PP-ECC梁各阶段的理论临界荷载;通过试验结果对计算模型进行验证,并对比相同配筋率下PP-ECC梁与普通钢筋混凝土梁在抗弯承载力、裂缝发展形态、跨中最大变形以及延性等方面的差异. 研究结果表明:受拉区PP-ECC材料开裂之后并不退出工作而是协同受拉钢筋参与全截面受力;使用简化本构模型计算的PP-ECC梁理论抗弯承载力计算模型精度达到0.83~1.17,具备较良好的精度;PP-ECC梁在达到极限状态时,受拉区呈多裂缝稳态发展,在达到80%极限承载力时,最大裂缝宽度小于0.2 mm;相同配筋率下,PP-ECC梁在每一加载级别的变形、跨中最大变形以及位移延性系数均高于普通钢筋混凝土梁(跨中最大变形和位移延性系数平均提高71.39%和42.84%),并且随着配筋率的提高,跨中最大变形和位移延性系数下降;配筋率相同时,PP-ECC梁的极限抗弯承载力较普通钢筋混凝土梁平均提高6.09%.

-

关键词:

- 聚丙烯纤维水泥基复合材料 /

- 抗弯性能 /

- 多裂缝发展 /

- 变形性能 /

- 延性

Abstract: To study the difference of mechanical properties between PP-ECC (polypropylene fiber cement-based composite) beam and ordinary reinforced concrete beam under bending load, the bending performance of PP-ECC beam was tested through four point bending load. Firstly, the bending failure process of PP-ECC beam was divided into stages. Secondly, the theoretical critical loads of each stage of PP-ECC beam were derived based on the calculation assumption and simplified PP-ECC constitutive model. Finally, the calculation model was verified by the test results, the differences of flexural capacity, fracture development, maximum mid-span deformation, and ductility between PP-ECC beam and ordinary reinforced concrete beam were compared under the same reinforcement ratio. The results show that PP-ECC material in the tensile zone does not quit working after cracking, but cooperates with the tensile reinforcement to participate in the full section stress. The accuracy of the theoretical bending capacity calculation model of PP-ECC beam calculated by the simplified constitutive model reaches 0.83~1.17, which has a good accuracy. When PP-ECC beam reaches the ultimate state, the tensile zone presents the steady development of multiple cracks, when the ultimate bearing capacity reaches 80%, the maximum crack width is less than 0.2 mm. With the same reinforcement ratio, the deformation, maximum deformation, and displacement ductility coefficient of PP-ECC beam at each loading level are higher than those of ordinary reinforced concrete beam (the average increase of the maximum deformation and displacement ductility coefficient is 71.39% and 42.84%), and with the increase of reinforcement ratio, the maximum deformation and displacement ductility coefficient in the middle of span decrease. With the same reinforcement ratio, the ultimate bending capacity of PP-ECC beam is 6.09% higher than that of ordinary reinforced concrete beam. -

表 1 试件基本参数

Table 1. Basic parameters of specimens

试件编号 基体材料 受拉钢筋强度/MPa 受拉钢筋直径/mm 箍筋强度/MPa 箍筋直径/mm 试件个数/个 L1-1,L1-2 PP-ECC 2 L2-1,L2-2 PP-ECC HRB400 8 Q235 6 2 L3-1,L3-2 PP-ECC HRB400 10 Q235 6 2 L4 C30 混凝土 HRB400 8 Q235 6 1 L5 C30 混凝土 HRB400 10 Q235 6 1 表 2 PP纤维性能指标

Table 2. Performance index of PP fiber

长度/mm 密度/(kg•m3) 直径/μm 抗拉强度/MPa 拉伸弹模/GPa 拉伸率/% 12 0.91 20 480 5 15 表 3 HRB400钢筋性能指标

Table 3. Performance index of HRB400 reinforced bar

直径/mm 截面面积/mm2 屈服强度/MPa 极限强度/MPa 弹性模量/GPa 8 50.24 406 435 197 10 78.50 411 476 203 表 4 C30混凝土性能指标

Table 4. Performance index of C30 concrete

立方体抗压强度/MPa 极限压缩应变/% 弹性模量/GPa 33.47 0.09 24.8 表 5 位移延性系数

Table 5. Displacement ductility coefficient

试样编号 $\varDelta _{\rm{y}} $/mm $\varDelta _{\rm{u}} $/mm λ2 L2-1 10.87 31.30 2.88 L2-2 11.28 31.18 2.76 L3-1 8.45 22.30 2.64 L3-2 9.37 23.62 2.52 L4 3.12 6.62 2.12 L5 8.48 14.36 1.69 表 6 PP-ECC单轴拉伸试验参数

Table 6. PP-ECC uniaxial tensile test parameters

哑铃序号 σtc/MPa εtc/% σtu/MPa εtu/% 1 0.67 0.07 1.84 3.57 2 1.84 0.11 2.51 2.87 3 0.53 0.05 2.11 4.13 4 0.32 0.10 2.23 5.13 5 0.87 0.08 2.40 3.28 6 1.30 0.13 2.88 4.14 表 7 PP-ECC单轴拉伸本构参数

Table 7. PP-ECC uniaxial tensile constitutive parameters

σtc /MPa εtc/% σtu/MPa εtu/% 0.84 0.09 2.32 3.80 表 8 PP-ECC单轴压缩本构参数

Table 8. PP-ECC uniaxial compressive constitutive parameters

σcu/MPa εcu/% 弹性模量/GPa 32.09 0.41 13.35 表 9 抗弯承载力对比

Table 9. Comparison of flexural capacity

试件编号 开裂弯矩/(kN•m) 极限弯矩/(kN•m) ${\omega }_{1}$ ${\omega }_{2}$ xn/mm 理论值 试验值 理论值 试验值 L1-1 0.30 0.69 1.21 1.01 2.30 0.83 10.60 L1-2 0.30 0.57 1.21 1.17 1.90 0.97 10.60 L2-1 1.11 0.93 4.35 5.12 0.84 1.17 33.42 L2-2 1.11 0.89 4.35 4.59 0.81 1.06 33.42 L3-1 1.11 0.96 5.87 6.19 0.86 1.05 46.27 L3-2 1.11 0.93 5.87 6.29 0.84 1.07 46.27 L4 0.93 0.60 3.25 4.57 0.65 1.41 28.11 L5 1.45 1.26 4.59 5.89 0.87 1.28 43.92 -

俞家欢. 超强韧性纤维混凝土的性能及应用[M]. 北京: 中国建筑工业出版社, 2012: 6-93. 袁方,陈梦成,王文波. 往复荷载下钢筋增强ECC梁的抗剪性能研究[J]. 铁道学报,2018,40(8): 146-153. doi: 10.3969/j.issn.1001-8360.2018.08.019YUAN Fang, CHEN Mengcheng, WANG Wenbo. Study on shear behavior of steel reinforced ECC beams under reversed cyclic loading[J]. Journal of the China Railway Society, 2018, 40(8): 146-153. doi: 10.3969/j.issn.1001-8360.2018.08.019 葛文杰,冯肖季,翔陈坦. 纤维增强复材筋增强工程用水泥基复合材料-混凝土复合梁受弯性能研究[J]. 工业建筑,2017,47(11): 23-27.GE Wenjie, FENG Xiaoji, XIANG Chentan. Experimental research on the flexural behavior of ECC-concrete composite beam reinforced with FRP bars[J]. Industrial Construction, 2017, 47(11): 23-27. 周双. 纤维增强水泥基复合材料试验研究及其桥梁无缝化改造中的应用[D]. 成都: 西南交通大学, 2017. IEVA P, GREGOR F. Phenomenological interpretation of the shear behavior of reinforced engineered cementitious composite beams[J]. Cement and Concrete Composites, 2016, 73: 213-225. doi: 10.1016/j.cemconcomp.2016.07.018 CHEN Y, YU J, LEUNG C K Y. Use of high strength strain-hardening cementitious composites for flexural repair of concrete structures with significant steel corrosion[J]. Construction and Building Materials, 2018, 167: 325-337. doi: 10.1016/j.conbuildmat.2018.02.009 SHIMIZU K, KANAKUBO T, KANDA T, et al. Shear behavior of steel reinforced PVA-ECC beams[C]//Proceedings 13th World Conference on Earthquake Engineering Conference. Vancouver: WCEE, 2004: 1-9. YAO D, KE Q, YU B, et al. Structural behaviors of ultra-high performance engineered cementitious composites (UHP-ECC) beams subjected to bending- experimental study[J]. Construction and Building Materials, 2018, 177: 102-115. doi: 10.1016/j.conbuildmat.2018.05.122 袁方,陈梦成. 钢筋增强ECC梁受弯性能评估[J]. 铁道建筑,2016(7): 17-21. doi: 10.3969/j.issn.1003-1995.2016.07.05YUAN Fang, CHEN Mengcheng. Evaluation on flexural performance of steel reinforced ECC (engineered cementitious composite) girder[J]. Railway Engineering, 2016(7): 17-21. doi: 10.3969/j.issn.1003-1995.2016.07.05 汪梦甫,徐亚飞,陈红波. PE-ECC短梁抗剪性能研究[J]. 湖南大学学报(自然科学版),2015,42(11): 10-16. doi: 10.3969/j.issn.1674-2974.2015.11.002WANG Mengfu, XU Yafei, CHEN Hongbo. Research on shear behavior of PE-ECC short beam[J]. Journal of Hunan University (Natural Sciences), 2015, 42(11): 10-16. doi: 10.3969/j.issn.1674-2974.2015.11.002 薛会青,邓宗. HRECC组合梁弯曲性能的试验研究与理论[J]. 土木工程学报,2013,46(4): 10-17.XUE Huiqing, DENG Zong. Experimental and theoretical studies on bending performance of HRECC beams[J]. China Civil Engineering Journal, 2013, 46(4): 10-17. 李碧雄,廖桥,章一萍,等. 超高强钢筋工程用水泥基复合材料梁受弯计算理论[J]. 吉林大学学报(工学版),2018,49(4): 1153-1161.LI Bixiong, LIAO Qiao, ZHANG Yiping, et al. Theoretical on flexural behavior of ultra high strength rebar reinforced engineered cementitious composites beam[J]. Journal of Jilin University (Engineering and Technology Edition), 2018, 49(4): 1153-1161. GE Wenjie, ASHRAF F A, JI Xiang, et al. Flexural behaviors of ECC-concrete composite reinforced with steel bars[J]. Construction and Building Materials, 2018, 159: 175-188. doi: 10.1016/j.conbuildmat.2017.10.101 DAN Meng, LEE C K. Flexural and shear behaviours of plain and reinforced polyvinyl alcohol-engineered cementitious composite beams[J]. Engineering Structures, 2017, 151: 261-272. doi: 10.1016/j.engstruct.2017.08.036 SHIMIZU K, KANAKUBO T, KANDA T, et al. Shear behavior of steel reinforced PVA-ECC beams[C]//Proceedings 13th World Conference on Earthquake Engineering Conference. Vancouver: WCEE, 2004: 1-9. PEERAPONG S, TAKASHI M, TETSUSHI K. Multiple cracking and fiber bridging characteristics of engineered cementitious composites under fatigue flexure[J]. Journal of Materials in Civil Engineering, 2004, 5: 433-443. 王必元. ECC力学性能及其增强钢筋/FRP筋-混凝土复合梁受弯性能研究[D]. 扬州: 扬州大学, 2016. ARISOY B, WU H C. Material characteristics of high performance lightweight concrete reinforced with PVA[J]. Construction and Building Materials, 2008, 22: 635-645. doi: 10.1016/j.conbuildmat.2006.10.010 QUDAH S, MAALEJ M. Application of engineered cementitious composites (ECC) in interior beam-column connections for enhanced seismic resistance[J]. Engineering Structure, 2014, 69: 235-245. doi: 10.1016/j.engstruct.2014.03.026 HOSSAIN K M A, ALAM S. High performance composite slabs with profiled steel deck and engineered cementitious composites-strength and shear bond characteristics[J]. Construction and Building Materials, 2016, 125: 227-240. doi: 10.1016/j.conbuildmat.2016.08.021 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB 50010—2010[S]. 北京: 中国建筑工业出版社, 2010. 张鹏,薛伟辰,唐小林,等. 纤维塑料筋混凝土梁延性分析的能量表示法[J]. 武汉理工大学学报,2005,27(8): 49-51. doi: 10.3321/j.issn:1671-4431.2005.08.015ZHANG Peng, XUE Weichen, TANG Xiaolin, et al. An energy expression method of ductility analysis of concrete beam reinforced with fiber reinforced plastics bars[J]. Journal of Wuhan University of Technology, 2005, 27(8): 49-51. doi: 10.3321/j.issn:1671-4431.2005.08.015 -

下载:

下载: