Mechanical Characteristics of High-Speed Railway Catenary Cantilever System

-

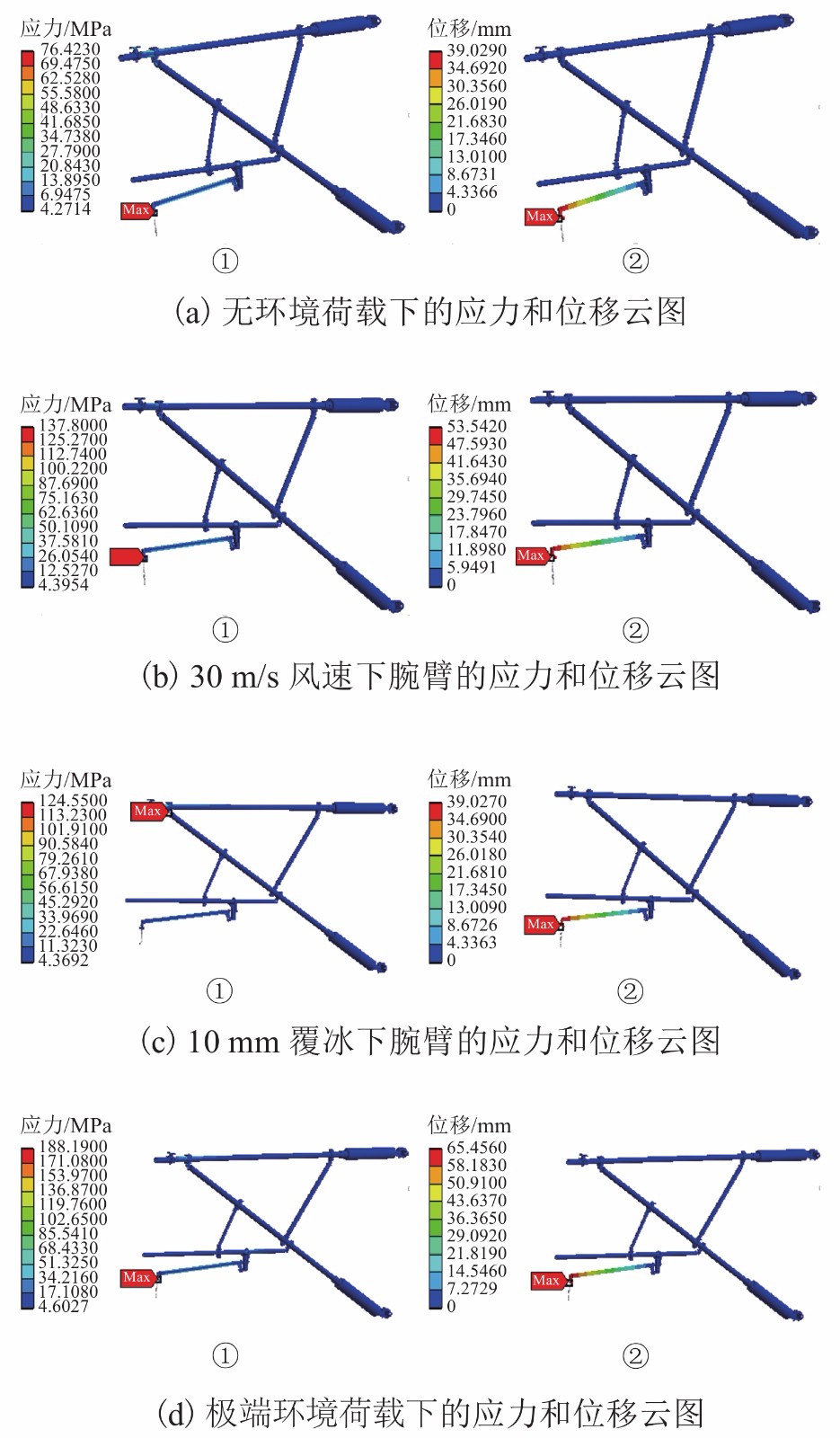

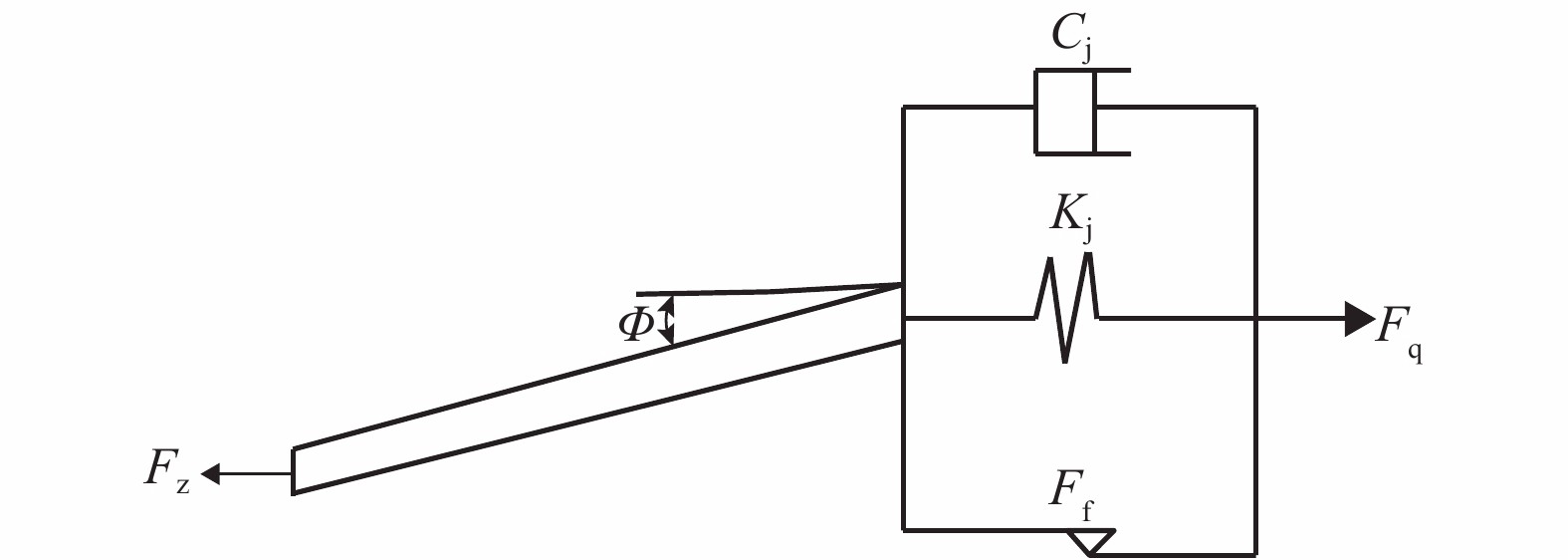

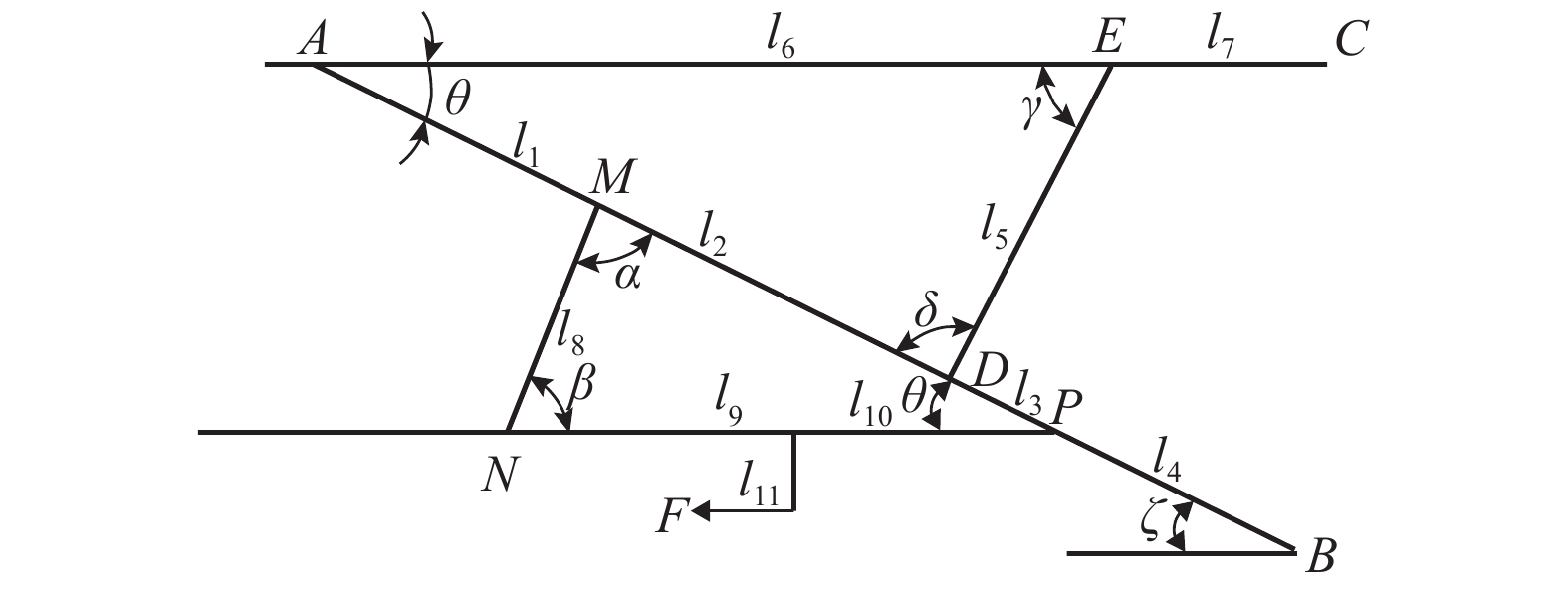

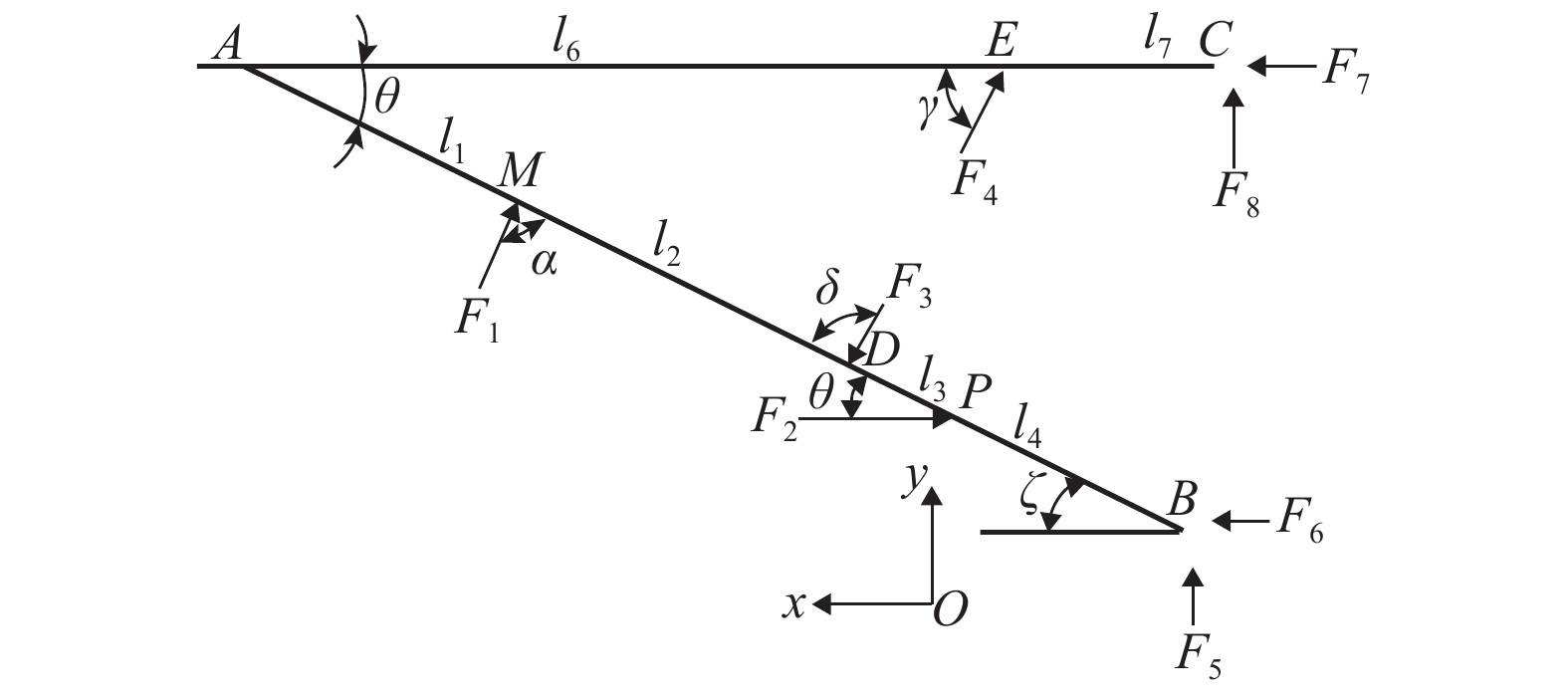

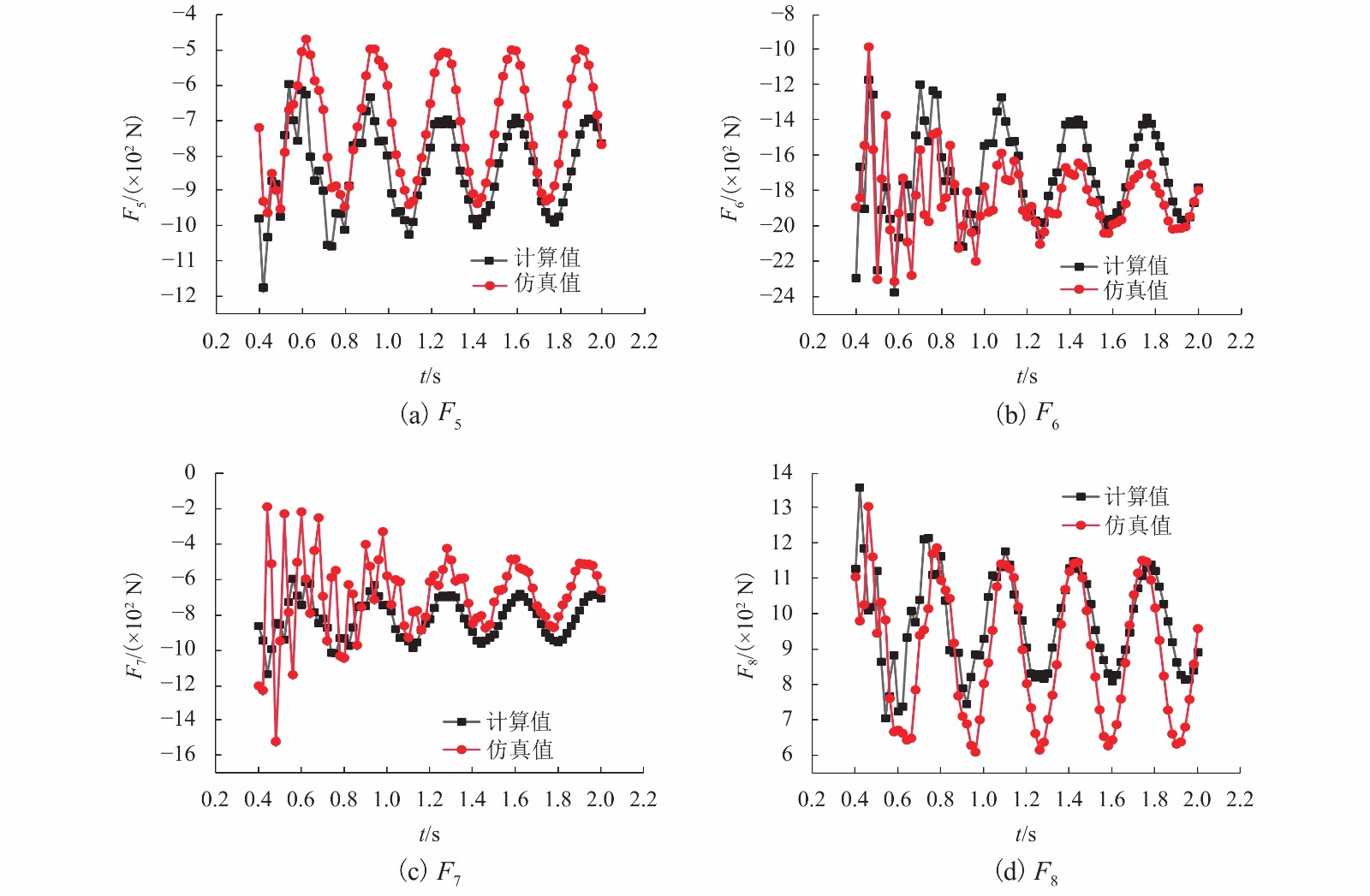

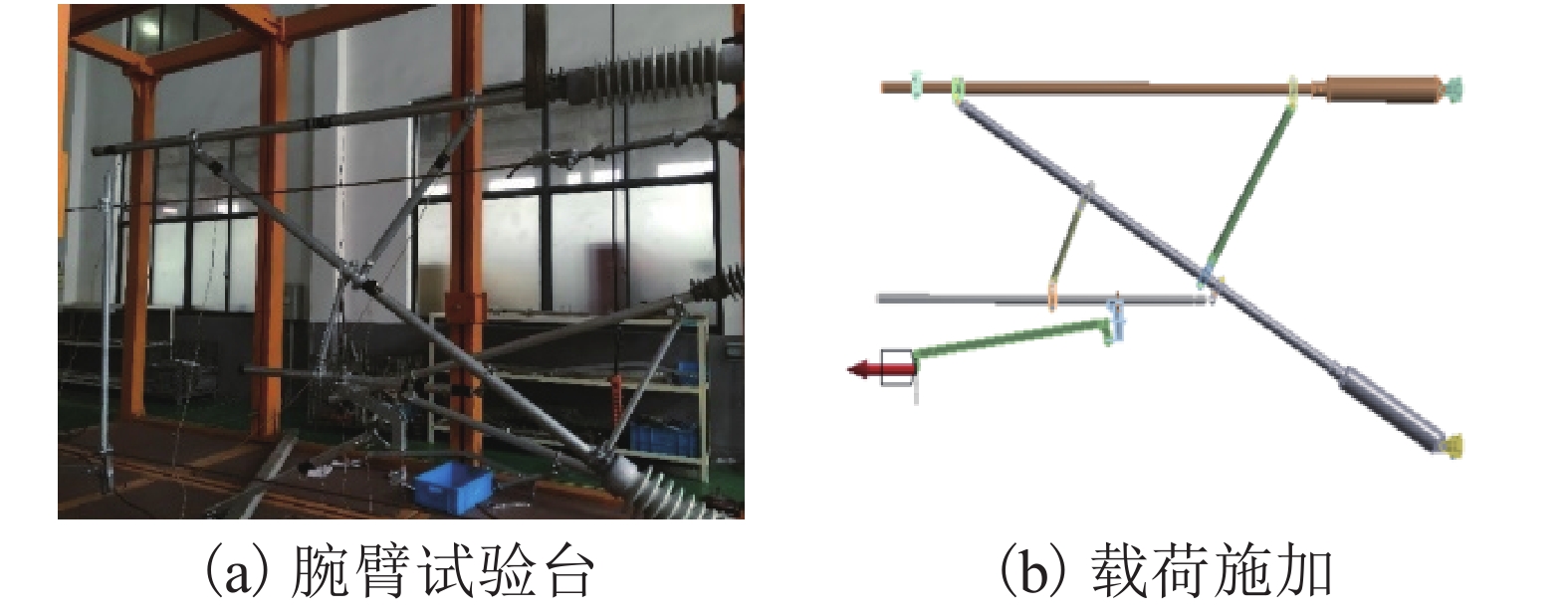

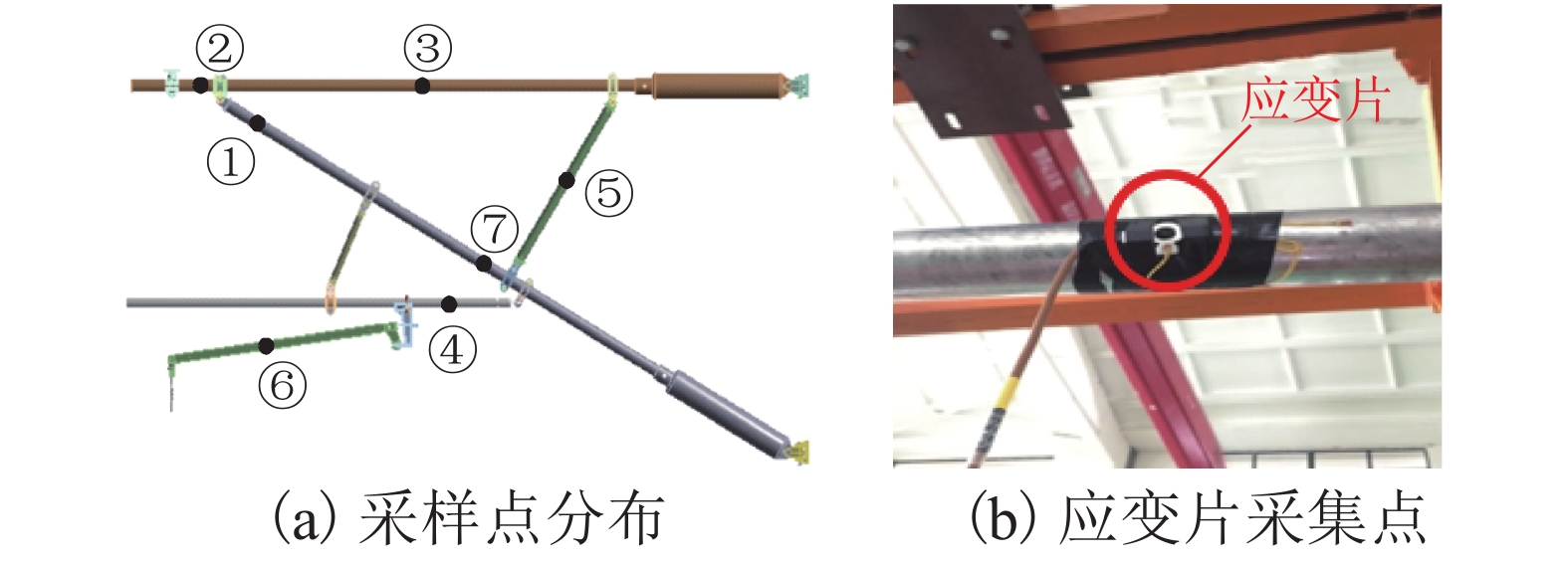

摘要: 为了解决高速铁路接触网腕臂疲劳裂纹及零部件脱落的难题进行了腕臂系统的力学特性研究. 建立了腕臂的实体有限元模型,研究了腕臂系统在风环境和覆冰影响下的静力学特性;采用模态分析,获得腕臂的固有频率和振型;基于变形方程,推导出腕臂系统载荷的传递函数,获得了腕臂上载荷的分布规律;通过台架试验验证了腕臂实体有限元模型的正确性. 研究结果表明:腕臂系统的最大位移均在定位线夹处;当覆冰载荷作用时,腕臂系统的最大应力点在斜腕臂和套管双耳连接的螺栓处;当静风荷载作用时,腕臂系统的最大应力点在定位线夹处.Abstract: In order to solve problems of parts’ fatigue cracks and falling off in the cantilever system for high-speed railway catenary, a study was conducted to investigate mechanical characteristics of the cantilever system. First, a finite element model of the cantilever system was established, whereby the static mechanical properties of the cantilever system were studied under different conditions of static wind load and icing load. Then, the modal analysis was performed to analyze the natural frequencies and mode shapes of the cantilever system. Based on the deformation equation, the transfer function of the load acting on the cantilever was derived, and the distribution rule of the force acting on cantilever brackets was obtained. Finally, the validity of the finite element model of the cantilever system was verified by a bench test. The result shows that the maximum displacement of the cantilever system occurs to the locating clamp. When the static wind load is applied, the maximum stress point of the cantilever system is at the joint-bolt of the inclined cantilever and the binaural casing. When the icing load is applied, however, the maximum stress point of the cantilever system is at the locating clamp.

-

Key words:

- cantilever system /

- finite element method /

- modal analysis /

- transfer function /

- bench test

-

表 1 腕臂载荷

Table 1. Cantilever load

N 条件 承力索座

水平负载承力索座

垂直负载定位线夹

水平负载定位线夹

垂直负载无环境荷载下 555 1082 640 120 30 m/s 风速下 1047 1082 1154 120 10 mm 覆冰厚度下 555 1809 640 120 综合覆冰和风载下 1515 1809 1576 120 表 2 腕臂前10阶固有频率

Table 2. First ten order natural frequencies of cantilever

Hz 阶数 频率 阶数 频率 1 4.230 6 20.912 2 6.110 7 21.097 3 9.503 8 26.182 4 12.494 9 36.978 5 17.178 10 43.694 表 3 腕臂装置静态强度试验与仿真结果对比

Table 3. Comparison of static strength test and simulation results of cantilever

测试点 测试值/×10−6 计算值/×10−6 相对误差/% ① −10.98 −9.34 14.94 ② −0.23 −0.22 4.35 ③ 17.99 13.78 23.40 ④ 27.51 25.51 7.27 ⑤ 13.88 12.70 8.50 ⑥ 709.28 780.01 9.97 ⑦ −27.07 −24.80 8.39 -

杨佳. 既有铁路三腕臂支柱悬挂的设计和检修[J]. 铁道工程学报,2012,136(4): 72-75. doi: 10.3969/j.issn.1006-2106.2012.04.013YANG Jia. The Design and overhaul for mast with there-cantilever suspension in built railway[J]. Journal of Railway Engineering Society, 2012, 136(4): 72-75. doi: 10.3969/j.issn.1006-2106.2012.04.013 宋洋,刘志刚,汪宏睿,等. 脉动风下高速铁路接触网抖振对弓网受流性能的影响[J]. 铁道学报,2014,36(6): 27-34. doi: 10.3969/j.issn.1001-8360.2014.06.005SONG Yang, LIU Zhigang, WANG Hongrui, et al. Influence of high-speed railway catenary buffeting on current collection under the fluctuating wind[J]. Journal of The China Railway Society, 2014, 36(6): 27-34. doi: 10.3969/j.issn.1001-8360.2014.06.005 张静,郭宏伟,刘荣强,等. 铰链对含铰结构非线性动力学特性影响分析[J]. 航空学报,2014,35(5): 1433-1445.ZHANG Jing, GUO Hongwei, LIU Rongqiang, et al. Influence analysis of joints on nonlinear dynamic characteristics of articulated structures[J]. Acta Aeronautica et Astronautica Sinica, 2014, 35(5): 1433-1445. 宋洋,刘志刚,汪宏睿,等. 接触网三维模型的建立与风偏的非线性求解[J]. 铁道学报,2015,37(4): 30-38. doi: 10.3969/j.issn.1001-8360.2015.04.005SONG Yang, LIU Zhigang, WANG Hongrui, et al. Establishment of 3D model catenary and nonlinear solution for its wind deflection[J]. Journal of the China Railway Society, 2015, 37(4): 30-38. doi: 10.3969/j.issn.1001-8360.2015.04.005 SONG Y, LIU Z, WANG H, et al. Nonlinear modelling of high-speed catenary based on analytical expressions of cable and truss elements[J]. Vehicle System Dynamics, 2015, 53(10): 1-25. 宋洋,刘志刚,汪宏睿,等. 高速铁路覆冰接触线气动系数研究与风振响应分析[J]. 铁道学报,2014,36(9): 20-27. doi: 10.3969/j.issn.1001-8360.2014.09.04SONG Yang, LIU Zhigang, WANG Hongrui, et al. A study on aerodynamic parameters of high-speed railway iced contact wire and analysis of its wind vibration response[J]. Journal of the China Railway Society, 2014, 36(9): 20-27. doi: 10.3969/j.issn.1001-8360.2014.09.04 宋洋. 环境风下高速铁路弓网动态受流特性研究[D]. 成都: 西南交通大学, 2018. 吴亚飞. 高速铁路接触网非工作支平腕臂变性原因分析及措施[J]. 铁道标准设计,2015,59(4): 141-144.WU Yafei. Analysis of distortion of non-running cantilever for high-speed railway OCS and its solution[J]. Railway Standard Design, 2015, 59(4): 141-144. 林德福,古晓东,韩凌青. 日式钢腕臂结构性能研究分析[J]. 铁道工程学报,2013,173(2): 86-89. doi: 10.3969/j.issn.1006-2106.2013.02.018LIN Defu, GU Xiaodong, HAN Lingqing. Research and analysis of Japanese steel cantilever support structure property[J]. Journal of Railway Engineering Society, 2013, 173(2): 86-89. doi: 10.3969/j.issn.1006-2106.2013.02.018 刘峰涛. 接触网腕臂支持结构的仿真分析[J]. 电气化铁道,2004(6): 19-25.LIU Fengtao. The simulation analysis of catenary cantilever structure[J]. Journal of Electrified Railway, 2004(6): 19-25. 李少鹏,邓洪,古晓东. 接触网腕臂结构系统动力学分析[J]. 铁道标准设计,2015,59(11): 135-137.LI Shaopeng, Deng Hong, GU Xiaodong. Dynamic analysis of cantilever structure of OCS[J]. Railway Standard Design, 2015, 59(11): 135-137. 周宁,张卫华. 基于互推的接触网腕臂系统动应力问题研究的新方法[J]. 铁道学报,2008,30(4): 16-21. doi: 10.3321/j.issn:1001-8360.2008.04.004ZHOU Ning, ZHANG Weihua. A new inference-based method to investigate dynamic stresses of cantilever structures of the catenary system[J]. Journal of The China Railway Society, 2008, 30(4): 16-21. doi: 10.3321/j.issn:1001-8360.2008.04.004 -

下载:

下载: