|

MORYS B. Enlargement of out-of-round wheel profiles on high speed trains[J]. Journal of Sound & Vibration, 1999, 227(5): 965-978.

|

|

BROMMUNDT E. A simple mechanism for the polygonalization of railway wheels by wear[J]. Mechanics Research Communications, 2012, 24(4): 435-442.

|

|

NIELSEN J. Out-of-round railway wheels[M/OL]//LEWIS R, OLOFSSON U. Wheel-rail interface handbook. [S.l.]: Woodhead Publishing, 2009: 245-279[2018-10-12]. https://doi.org/10.1533/9781845696788.1.245.

|

|

NIELSEN J C, JOHANSSON A. Out-of-round railway wheels-a literature survey[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 2000, 214(2): 79-91. doi: 10.1243/0954409001531351

|

|

NIELSEN J C O, JOHANSSON A. Out-of-round railway wheels-a literature survey[J]. Proceedings of the Institution of Mechanical Engineers Part F Journal of Rail & Rapid Transit, 2000, 214(2): 79-91.

|

|

KALOUSEK J, JOHNSON K L. An investigation of short pitch wheel and rail corrugations on the Vancouver mass transit system[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 1992, 206(2): 127-135. doi: 10.1243/PIME_PROC_1992_206_226_02

|

|

罗仁,曾京,邬平波,等. 高速列车车轮不圆顺磨耗仿真及分析[J]. 铁道学报,2010,32(5): 30-35.LUO Ren, ZENG Jing, WU Pingbo, et al. Simulation and analysis of wheel out-of-roundness wear of high-speed train[J]. Journal of the China Railway Society, 2010, 32(5): 30-35.

|

|

陈光雄,金学松,邬平波,等. 车轮多边形磨耗机理的有限元研究[J]. 铁道学报,2011,33(1): 14-18. doi: 10.3969/j.issn.1001-8360.2011.01.003CHEN Guangxiong, JIN Xuesong, WU Pingbo, et al. Finite element study on the generation mechanism of polygonal wear of railway wheels[J]. Journal of the China Railway Society, 2011, 33(1): 14-18. doi: 10.3969/j.issn.1001-8360.2011.01.003

|

|

陈光雄,崔晓璐,王科. 高速列车车轮踏面非圆磨耗机理[J]. 西南交通大学学报,2016,51(2): 244-250. doi: 10.3969/j.issn.0258-2724.2016.02.004CHEN Guangxiong, CUI Xiaolu, WANG Ke. Generation mechanism for plolygonalization of wheel treads of high-speed trains[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 244-250. doi: 10.3969/j.issn.0258-2724.2016.02.004

|

|

李伟,李言义,张雄飞,等. 地铁车辆车轮多边形的机理分析[J]. 机械工程学报,2013,49(18): 17-22.LI Wei, LI Yanyi, ZHANG Xiongfei, et al. Mechanism of the polygonal wear of metro train wheels[J]. Journal of Mechanical Engineering, 2013, 49(18): 17-22.

|

|

吴越,韩健,刘佳,等. 高速列车车轮多边形磨耗对轮轨力和转向架振动行为的影响[J]. 机械工程学报,2018,54(4): 37-46.WU Yue, HAN Jian, LIU Jia, et al. Effect of high-speed train polygonal wheels on wheel/rail contact force and bogie vibration[J]. Journal of Mechanical Engineering, 2018, 54(4): 37-46.

|

|

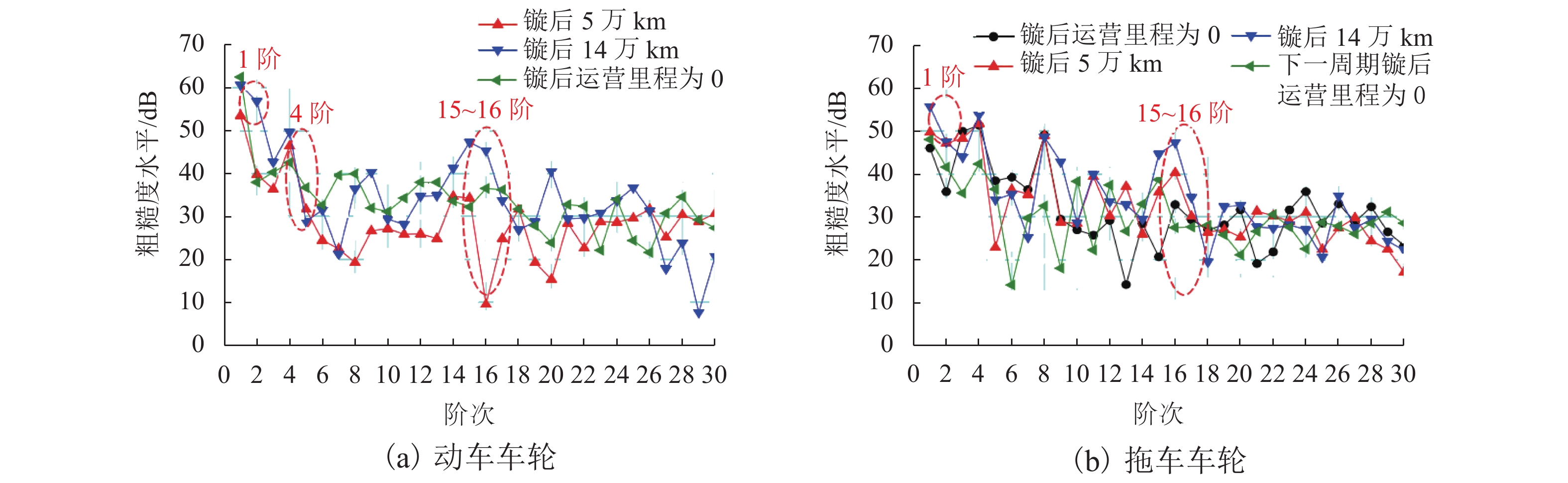

彭来先. 200 km/h动车组转向架振动噪声随运营里程变化规律[D]. 成都: 西南交通大学, 2018.

|

|

王争鸣. 兰新高铁穿越大风区线路选线及防风措施设计[J]. 铁道工程学报,2015,32(1): 1-6. doi: 10.3969/j.issn.1006-2106.2015.01.001WANG Zhengming. Design of route selection and windproof measures for strong wind-hit section of second double line of Lanzhou-Urumqi railway[J]. Journal of Railway Engineering Society, 2015, 32(1): 1-6. doi: 10.3969/j.issn.1006-2106.2015.01.001

|

|

尹鹏飞. 兰新铁路客运专线动车组运用维修研究[D]. 北京: 中国铁道科学研究院, 2015.

|

|

李凌翔. 兰新高铁双块式无砟轨道有限元仿真分析研究[D]. 兰州: 兰州交通大学, 2016.

|

|

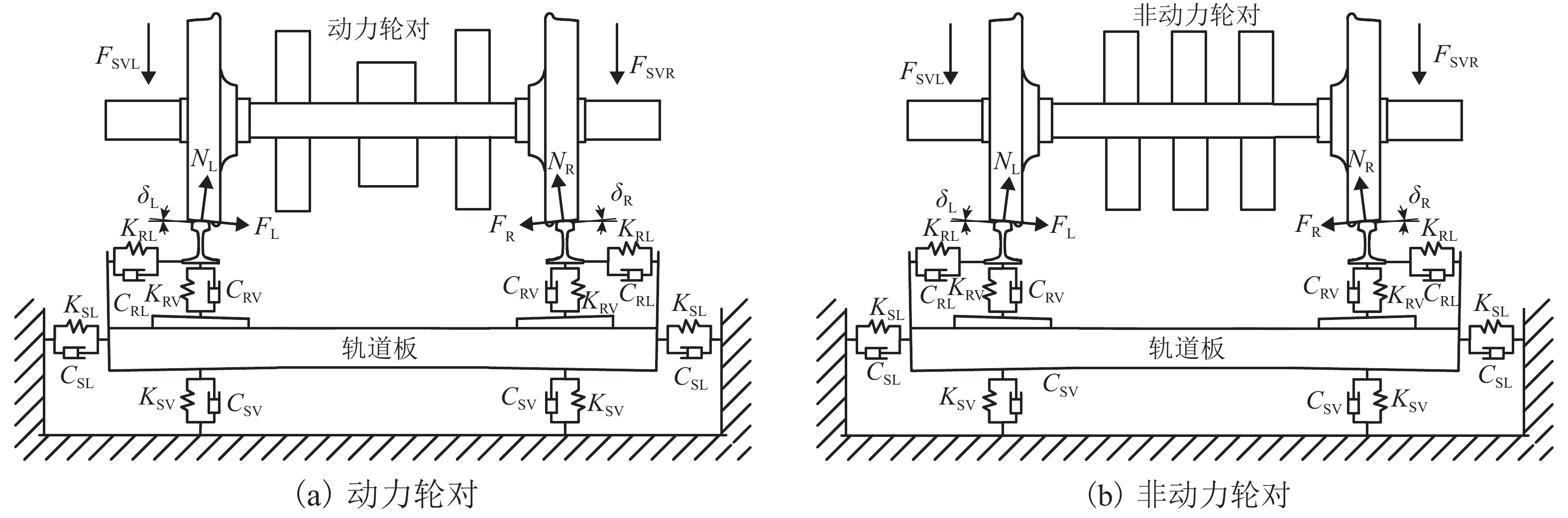

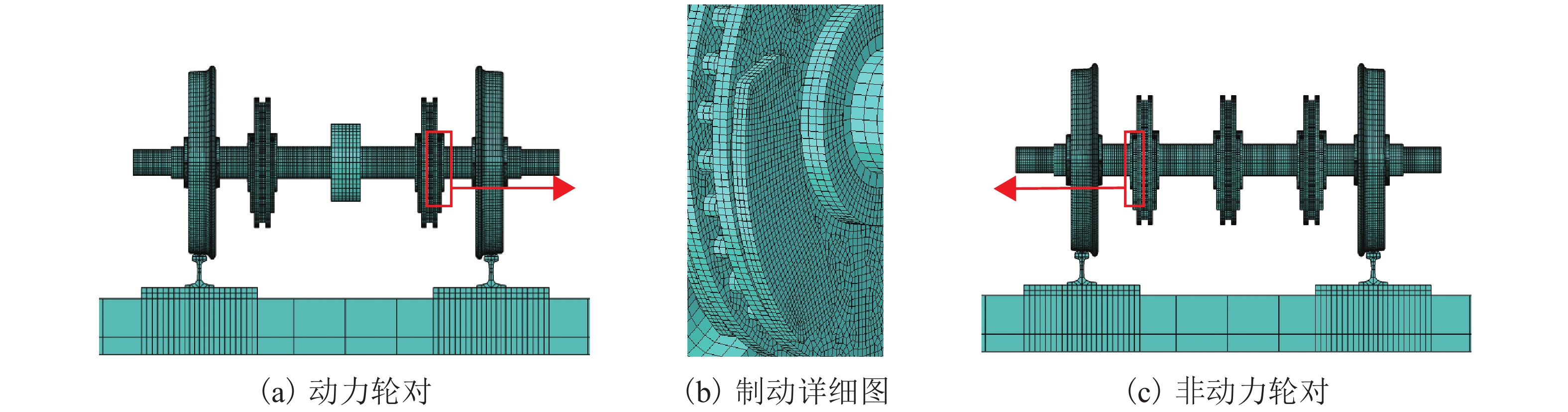

崔晓璐,陈光雄,杨宏光. 轮对结构和扣件刚度对钢轨波磨的影响[J]. 西南交通大学学报,2017,52(1): 112-117. doi: 10.3969/j.issn.0258-2724.2017.01.016CUI Xiaolu, CHEN Guangxiong, YANG Hongguang. Influence of wheelset structure and fastener stiffness on rail corrugation[J]. Journal of Southwest Jiaotong University, 2017, 52(1): 112-117. doi: 10.3969/j.issn.0258-2724.2017.01.016

|

|

陈光雄,钱韦吉,莫继良,等. 轮轨摩擦自激振动引起小半径曲线钢轨波磨的瞬态动力学[J]. 机械工程学报,2014,50(9): 71-76.CHEN Guangxiong, QIAN Weiji, MO Jiliang, et al. A transient dynamics study on wear-type rail corrugation on a tight curve due to the friction-induced self-excited vibration of a wheelset-track system[J]. Journal of Mechanical Engineering, 2014, 50(9): 71-76.

|

|

YUAN Y. An eigenvalue analysis approach to brake squeal problem[C]//Proceedings of the 29th ISATA Conference Automotive Braking Systems. Florence: [s. n.], 1996: 337-344.

|

|

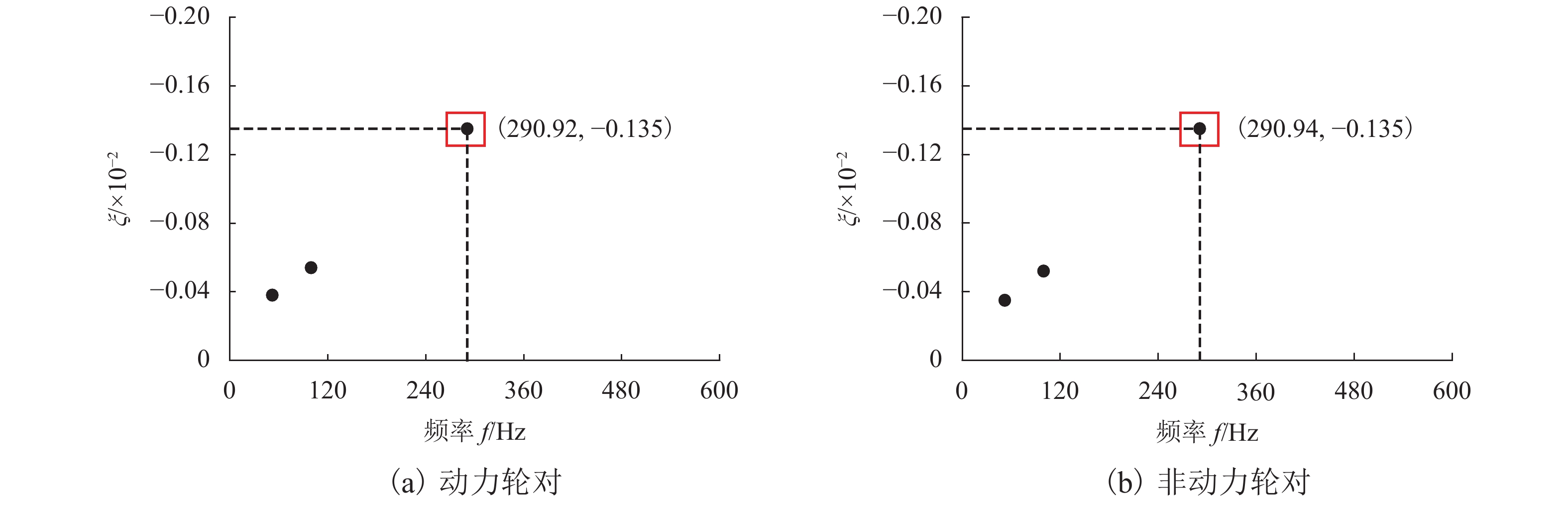

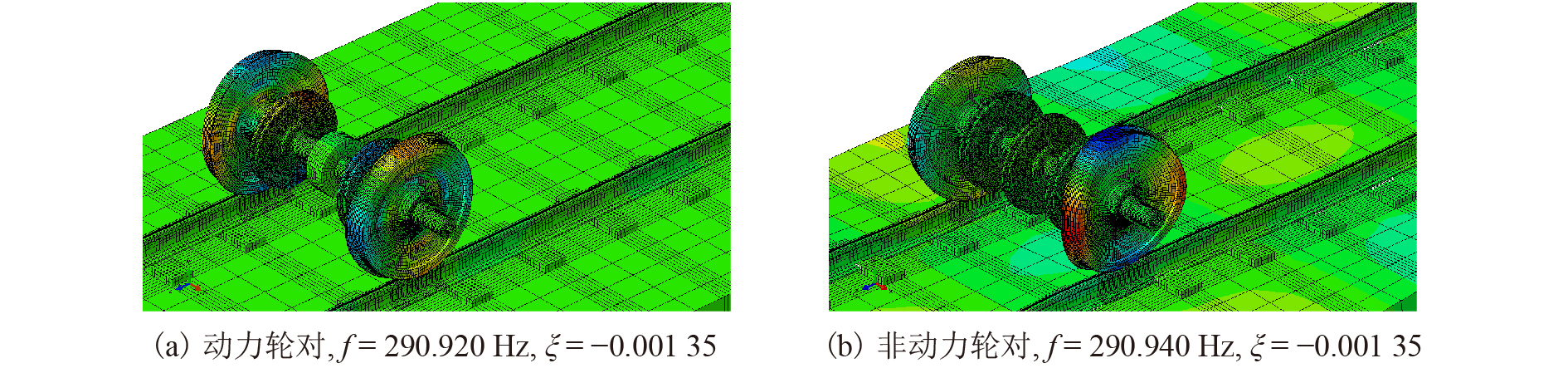

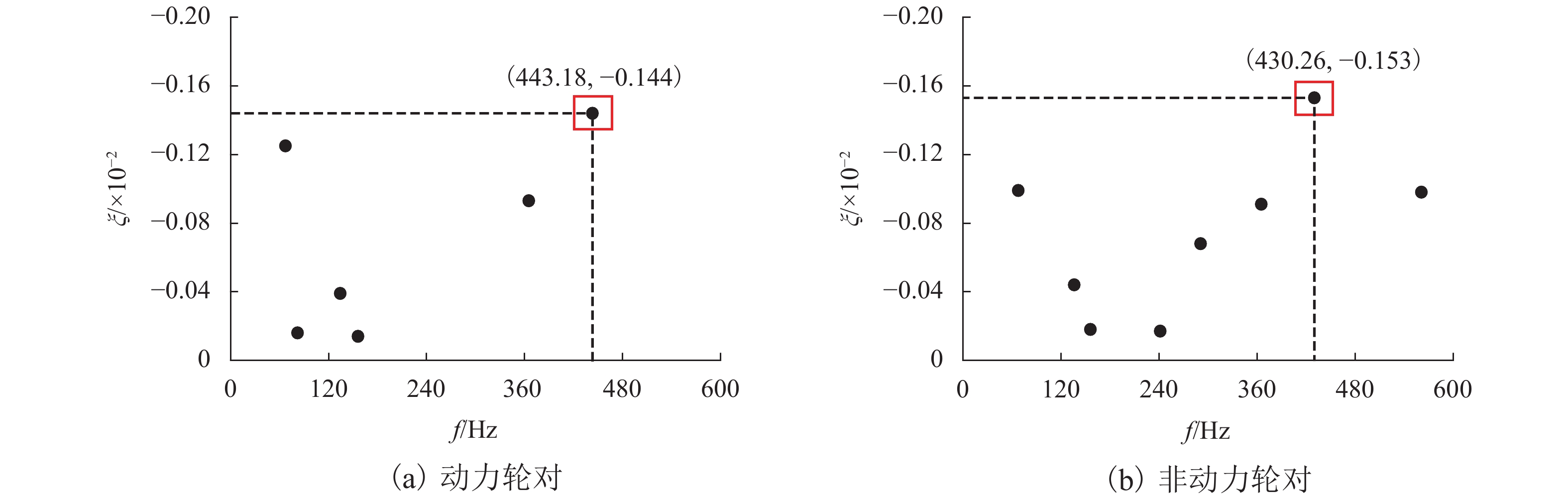

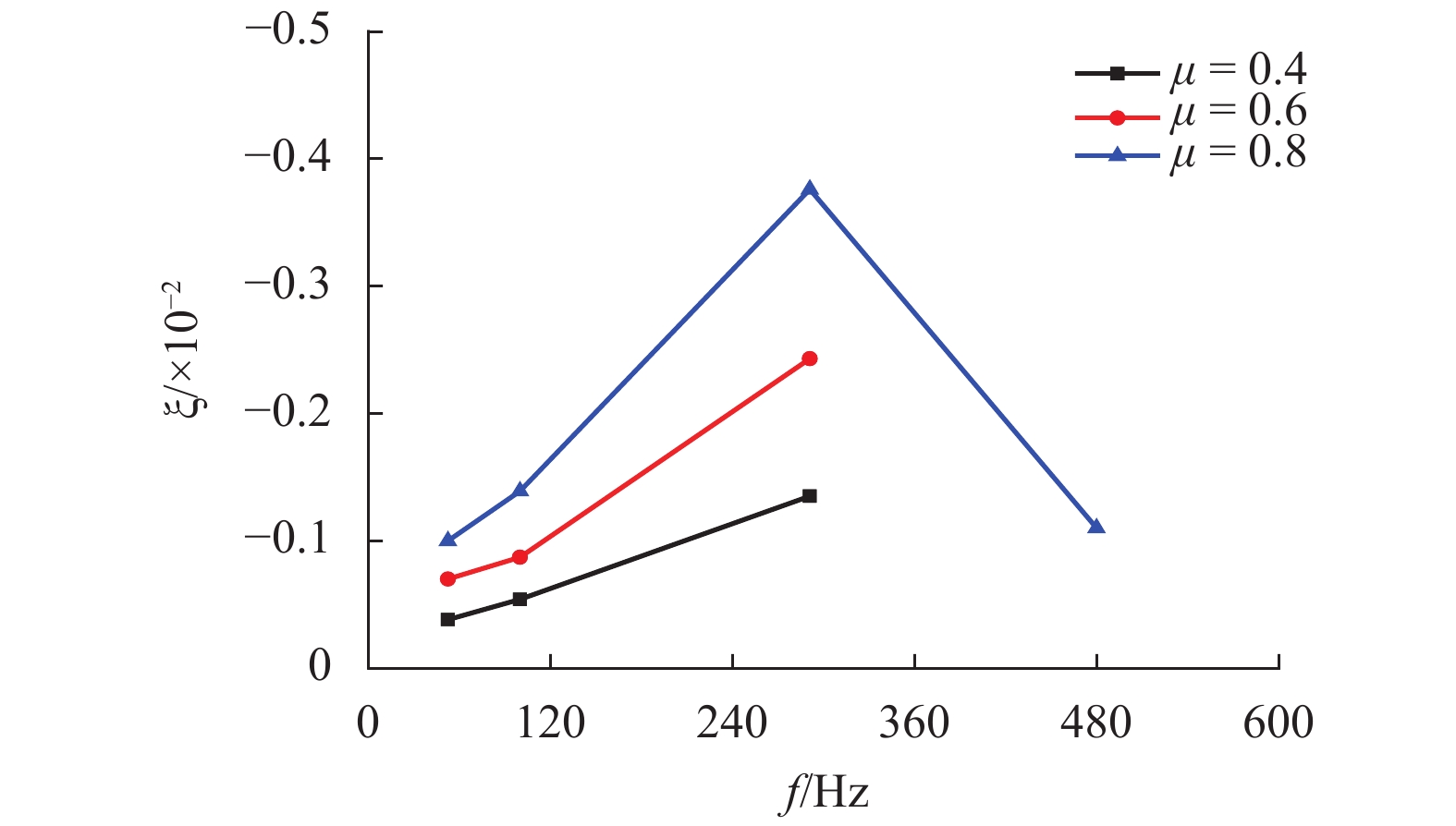

赵晓男,陈光雄,崔晓璐,等. 高速列车车轮多边形磨耗的形成机理及影响因素探究[J]. 表面技术,2018,47(8): 8-13.ZHAO Xiaonan, CHEN Guangxiong, CUI Xiaolu, et al. Study on the formation mechanism and influencing factors of the polygonal wear of high-speed train wheels[J]. Surface Technology, 2018, 47(8): 8-13.

|

|

黄问盈,杨宁清,黄民. 列车制动力的二次换算计算[J]. 中国铁道科学,1999(2): 69-80.HUANG Wenying, YANG Ningqing, HUANG Min. Second conversion calculation for train braking force[J]. China Academy of Railway Sciences, 1999(2): 69-80.

|

|

KUMAR S, KRISHNAMOORTHY P K, RAO D P. Wheel-rail wear and adhesion with and without sand for a North American locomotive[J]. Journal of Engineering for Industry, 1986, 108(2): 141-147. doi: 10.1115/1.3187049

|

下载:

下载: