Research on Multi-Parameter Fitting of Fastener Structures to Suppress Wheel-Rail Friction Self-Excited Vibration

-

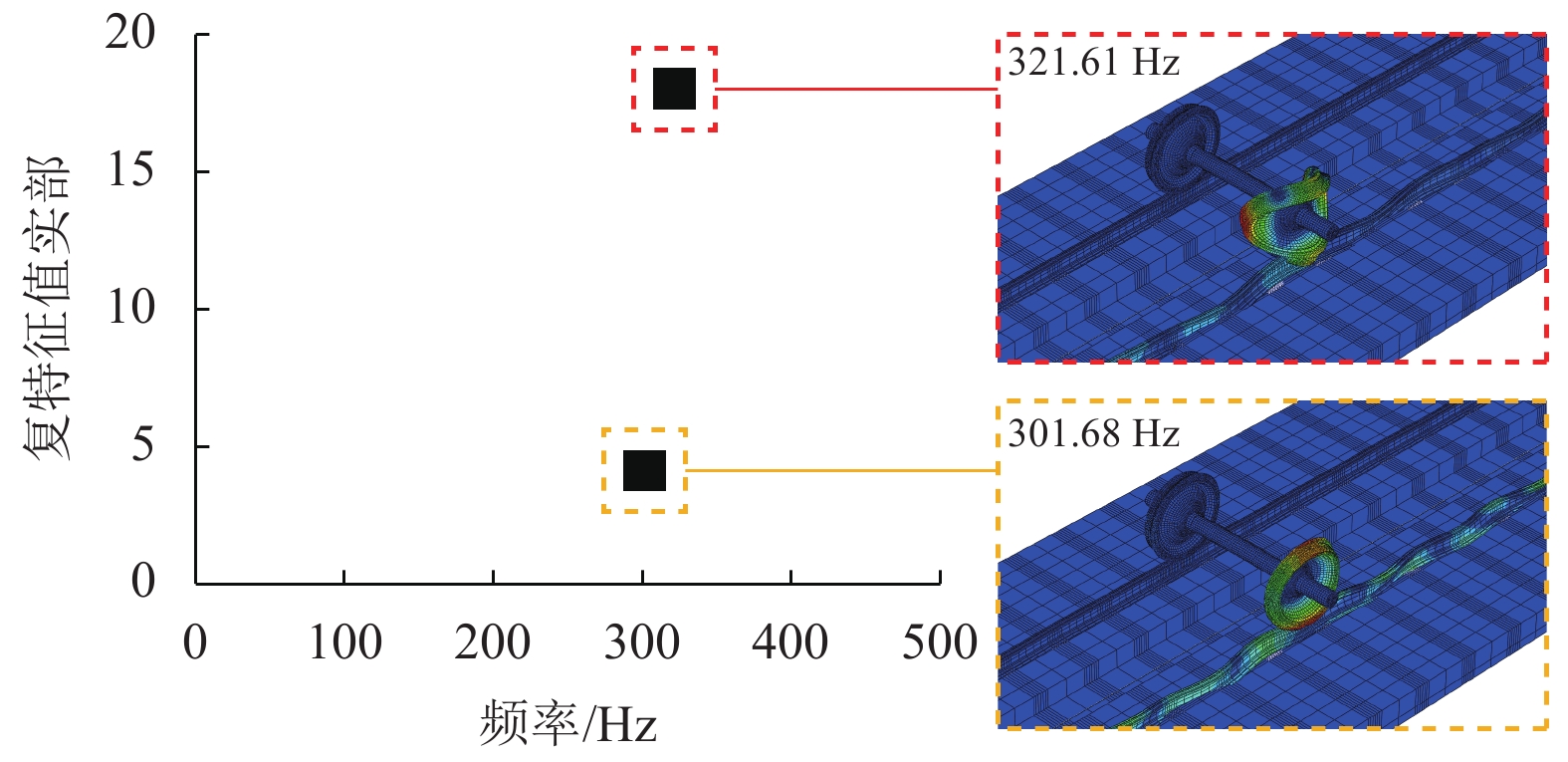

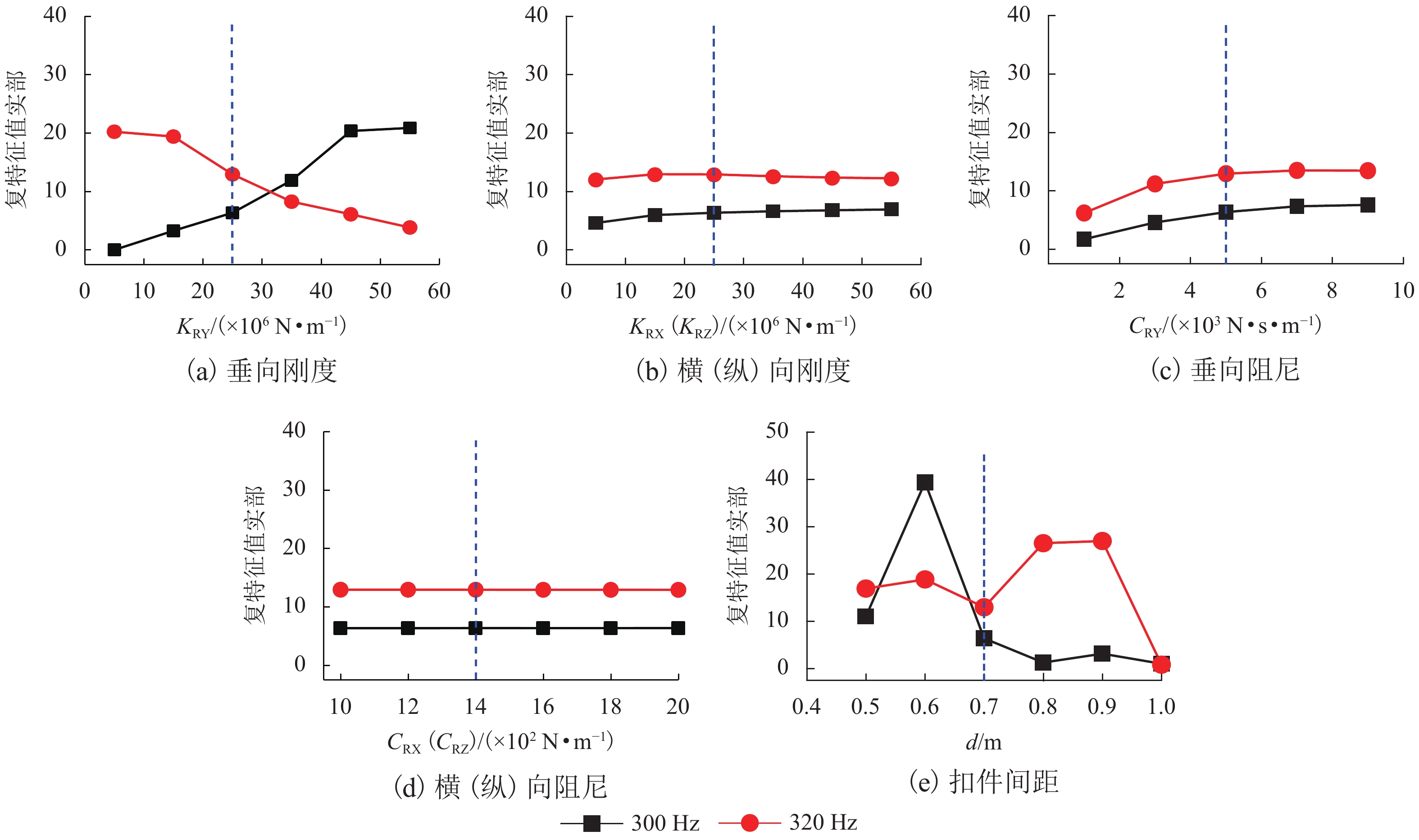

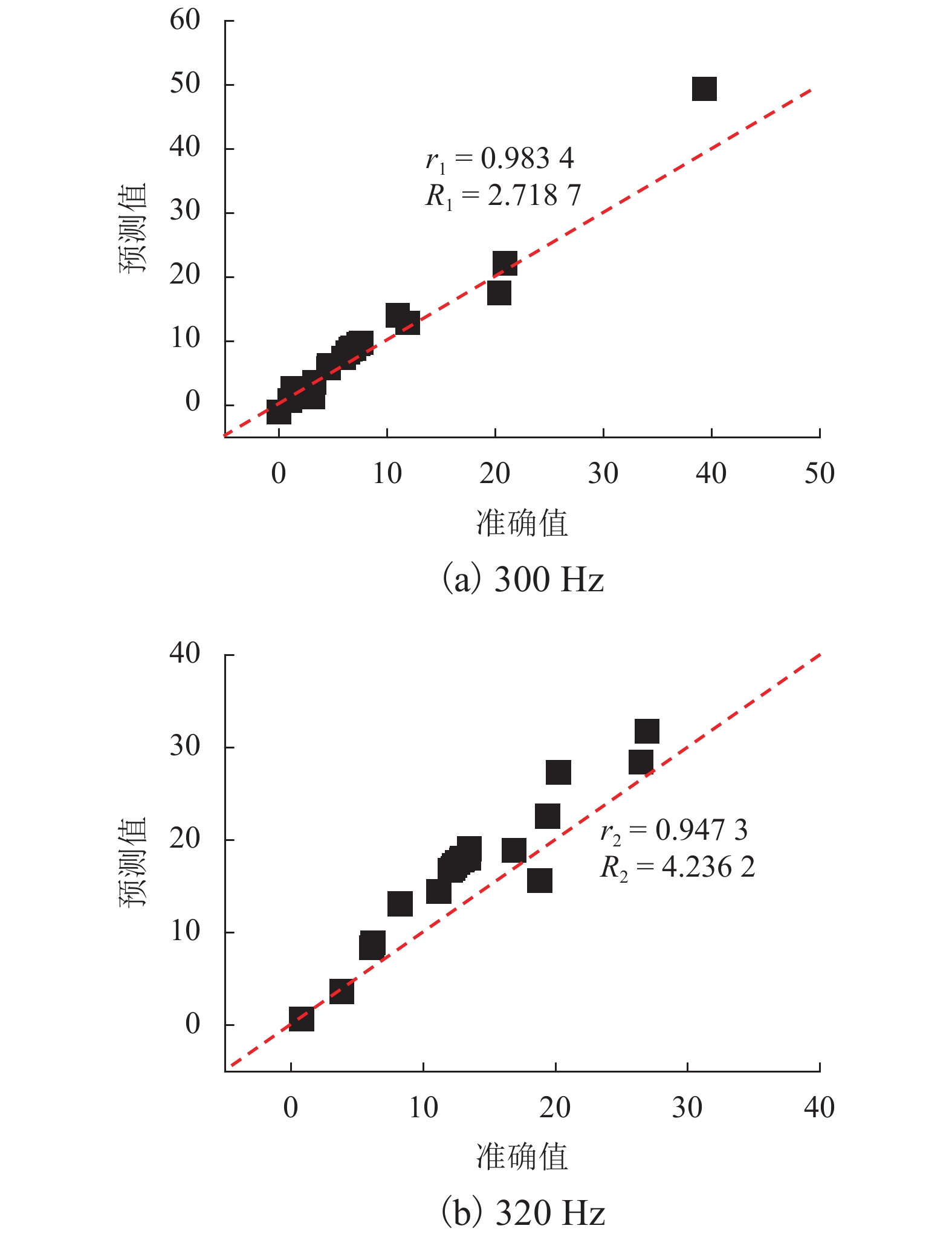

摘要: 为研究扣件结构参数对轮轨摩擦自激振动的影响,基于轮轨摩擦耦合自激振动的观点建立了小半径曲线轨道整体道床支承的轮轨系统有限元模型;通过现场测试和数值仿真验证了轮轨摩擦自激振动模型,进而基于该模型研究了扣件结构中各参数对轮轨摩擦自激振动的影响;综合考虑多因素之间的相互影响,采用最小二乘法得到了预测轮轨摩擦自激振动发生可能性的扣件结构多参数拟合方程. 研究结果表明:在整体道床支承的小半径曲线轨道上,轮轨间饱和蠕滑力引起的轮轨摩擦自激振动是诱导该区间钢轨波磨的关键因素,轮轨系统的摩擦自激振动主要发生在300 Hz和320 Hz;根据扣件结构的多参数拟合方程,在适当范围内,扣件的垂向阻尼为1000 N•s/m,扣件间距为1.0 m组合时,可以降低小半径曲线轨道上轮轨系统摩擦自激振动发生的可能性,从而降低钢轨波磨发生的可能性.Abstract: To study the effect of fastener structure parameters on wheel-rail frictional self-excited oscillation, based on the viewpoint of frictional self-excited vibration of the wheel-rail, a finite element model of the wheelset-track system on a small-radius curve track supporting by the monolithic roadbed was established. Then, the wheel-rail frictional self-excited vibration model was verified by the field test and numerical simulation. Furthermore, the influence of fastener parameters on the wheel-rail frictional self-excited oscillation was studied. Considering the interaction between multiple factors, the occurrence possibility of wheel-rail frictional self-excited oscillation was obtained by the least squares method. The results show that the wheel-rail frictional self-excited oscillation caused by the saturated creep force between the wheel and rail is a key reason that causes rail corrugation on a small-radius curve track supporting by the monolithic roadbed. The frictional self-excited oscillation mainly occurs at 300 Hz and 320 Hz. According to the multi-parameter fitting equation of fastener structure, when the vertical damping of fastener is 1000 N•s/m and the fastener distance is 1.0 m in the appropriate range, the possibility of wheel-rail frictional self-excited oscillation is reduced, thereby the possibility of rail corrugation is reduced.

-

表 1 轮轨系统有限元模型的材料参数

Table 1. Material parameters of finite element model of wheelset-track system

部件 弹性模量/(×1011 Pa) 泊松比 密度/(kg•m−3) 轮对 2.100 0.30 7800 钢轨 2.059 0.30 7790 轨道板 0.325 0.24 2500 表 2 科隆蛋扣件轨道支承结构参数

Table 2. Parameters of track support structure of Cologne-egg fastener

轨道支承结构参数 符号 数值 轨枕间距/m d 0.625 扣件垂向刚度/(N•m−1) KRY 1.21 × 107 扣件横向刚度/(N•m−1) KRX 7.58 × 106 扣件纵向刚度/(N•m−1) KRZ 7.58 × 106 扣件垂向阻尼/(N•s•m−1) CRY 1361.12 扣件横向阻尼/(N•s•m−1) CRX 974.27 扣件纵向阻尼/(N•s•m−1) CRZ 974.27 地基支承刚度/(N•m−1) KF 1.7 × 108 地基支承阻尼/(N•s•m−1) CF 3.1 × 108 表 3 轨道支承结构的参数变化范围

Table 3. Parameter variation range of track support structure

轨道支承结构参数 变化范围下限 变化范围上限 间隔 d/m 0.5 1.0 0.1 KRY/(N•m−1) 5.0 × 106 5.5 × 107 10.0 KRX/(N•m−1) 5.0 × 106 5.5 × 107 10.0 KRZ/(N•m−1) 5.0 × 106 5.5 × 107 10.0 CRY/(N•s•m−1) 1 000 9 000 2 000 CRX/(N•s•m−1) 1 000 2 000 200 CRZ/(N•s•m−1) 1 000 2 000 200 -

GRASSIE S L, KALOUSEK J. Rail corrugation:characteristics,causes,and treatments[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 2009, 207(16): 57-68. OOSTERMEIJER K H. Review on short pitch rail corrugation studies[J]. Wear, 2008, 265(9): 1231-1237. 金学松,李霞,李伟,等. 铁路钢轨波浪形磨损研究进展[J]. 西南交通大学学报,2016,51(2): 264-273. doi: 10.3969/j.issn.0258-2724.2016.02.006JIN Xuesong, LI Xia, LI Wei, et al. Review of rail corrugation process[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 264-273. doi: 10.3969/j.issn.0258-2724.2016.02.006 EGANA J I, VINOLAS J, SECO M. Investigation of the influence of rail pad stiffness on rail corrugation on a transit system[J]. Wear, 2006, 261(2): 216-224. doi: 10.1016/j.wear.2005.10.004 ZHANG H, LIU W, LIU W, et al. Study on the cause and treatment of rail corrugation for Beijing metro[J]. Wear, 2014, 317(1/2): 120-128. doi: 10.1016/j.wear.2014.05.011 CUI X L, CHEN G X, YANG H G, et al. Study on rail corrugation of a metro tangential track with Cologne-egg type fasteners[J]. Vehicle System Dynamics, 2016, 54(3): 353-369. doi: 10.1080/00423114.2015.1137955 LIU W, ZHANG H, LIU W, et al. Experimental study of the treatment measures for rail corrugation on tracks with Egg fasteners in the Beijing metro[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 2017, 232(5): 1360-1374. ZHAO C, WANG P, SHENG X, et al. Theoretical simulation and experimental investigation of a rail damper to minimize short-pitch rail corrugation[J]. Mathematical Problems in Engineering, 2017, 1(1): 1-14. WU T X. Effects on short pitch rail corrugation growth of a rail vibration absorber/damper[J]. Wear, 2011, 271(1): 339-348. YAN Z, MARKINE V, GU A, et al. Optimisation of the dynamic properties of ladder track to minimize the chance of rail corrugation[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 2014, 228(1): 292-298. OYARZABAL O, G MEZ J, SANTAMAR A J, et al. Dynamic optimization of track components to minimize rail corrugation[J]. Journal of Sound and Vibration, 2009, 319(3): 904-917. CHEN G X, ZHOU Z R, OUYANG H, et al. A finite element study on rail corrugation based on saturated creep force-induced self-excited vibration of a wheelset-track system[J]. Journal of Sound and Vibration, 2010, 329(22): 4643-4655. doi: 10.1016/j.jsv.2010.05.011 KURZECK B. Combined friction induced oscillations of wheelset and track during the curving of metros and their influence on corrugation[J]. Wear, 2011, 271(1): 299-310. SUN Y Q, SIMSON S. Wagon-track modelling and parametric study on rail corrugation initiation due to wheel stick-slip process on curved track[J]. Wear, 2008, 265(1): 1193-1201. 崔晓璐,闫硕,陈光雄. 短轨枕区间钢轨波磨的现场测试和数值研究[J]. 振动与冲击,2018,37(12): 171-176.CUI Xiaolu, YAN Shuo, CHEN Guangxiong. Field measurement and numerical simulation for rail corrugation in sector of fixed dual short sleeper[J]. Journal of Vibration and Shock, 2018, 37(12): 171-176. LI W, WANG H, WEN Z, et al. An investigation into the mechanism of metro rail corrugation using experimental and theoretical methods[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 2016, 230(4): 1025-1039. doi: 10.1177/0954409715596182 李霞. 地铁钢轨波磨形成机理研究[D]. 成都: 西南交通大学, 2012. QIAN W, HUANG Z, OUYANG H, et al. Numerical investigation of the effects of rail vibration absorbers on wear behaviour of rail surface[J]. Proceedings of the Institution of Mechanical Engineers,Part J:Journal of Engineering Tribology, 2019, 233(3): 424-438. doi: 10.1177/1350650118785061 BROCKLEY C A, KO P L. An investigation of rail corrugation using friction-induced vibration theory[J]. Wear, 1988, 128(1): 99-106. doi: 10.1016/0043-1648(88)90256-6 ABUBAKAR A R, OUYANG H. Complex eigenvalue analysis and dynamic transient analysis in predicting disc brake squeal[J]. International Journal of Vehicle Noise and Vibration, 2006, 2(2): 143-155. doi: 10.1504/IJVNV.2006.011051 李伟. 地铁钢轨波磨成因及其对车辆/轨道行为的影响研究[D]. 成都: 西南交通大学, 2015. ZHAO H Y, JENG D S. Accumulated pore pressures around submarine pipeline buried in trench layer with partial backfills[J]. Journal of Engineering Mechanics, 2016, 142(7): 1-15. HUANG B, ZHU B, CUI S A, et al. Influence of current velocity on wave-current forces on coastal bridge decks with box girders[J]. Journal of Bridge Engineering, 2018, 23(12): 1-21. -

下载:

下载: