Optimization and Tensile Properties of Composite Insulator at High and Low Temperature

-

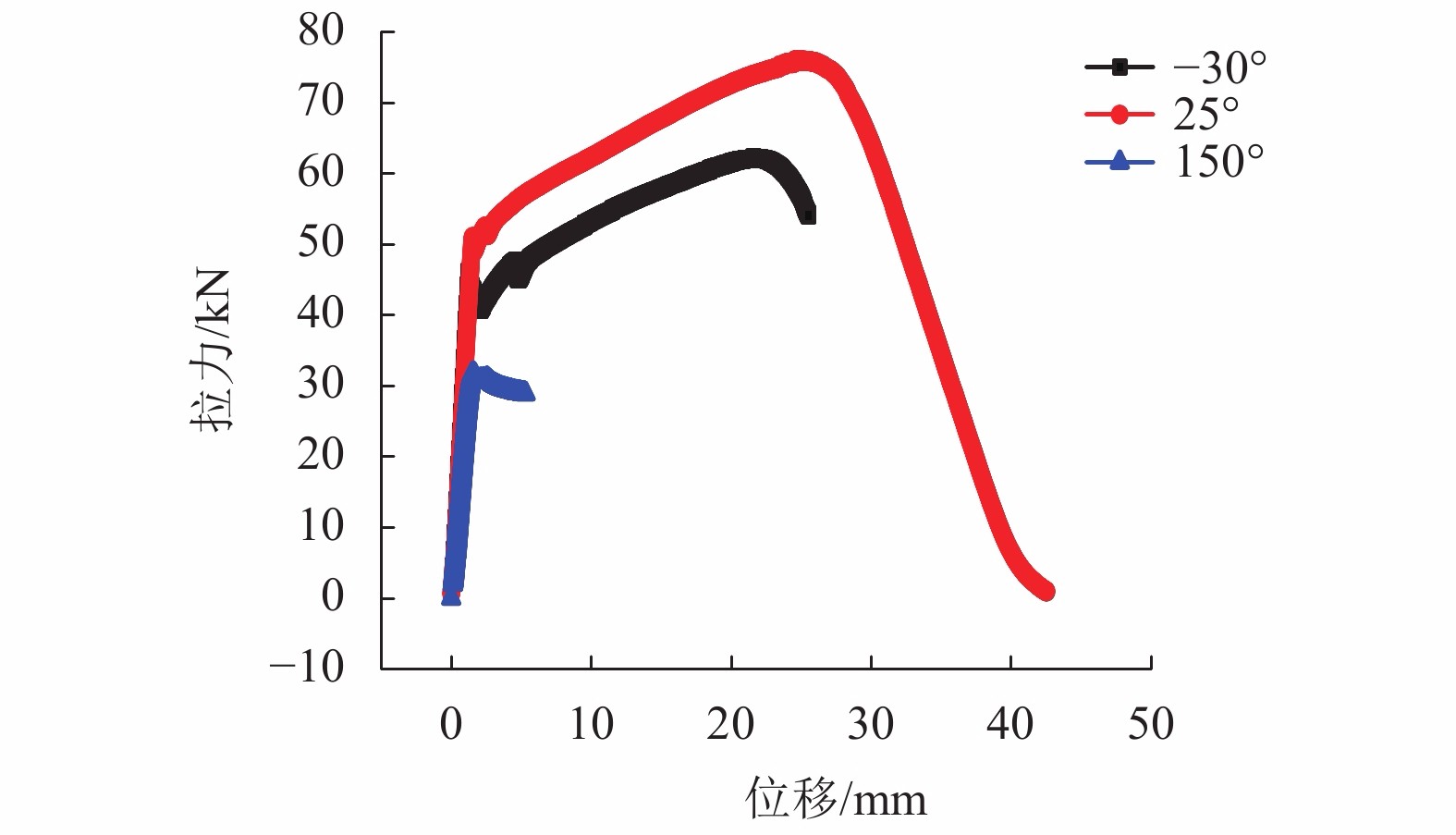

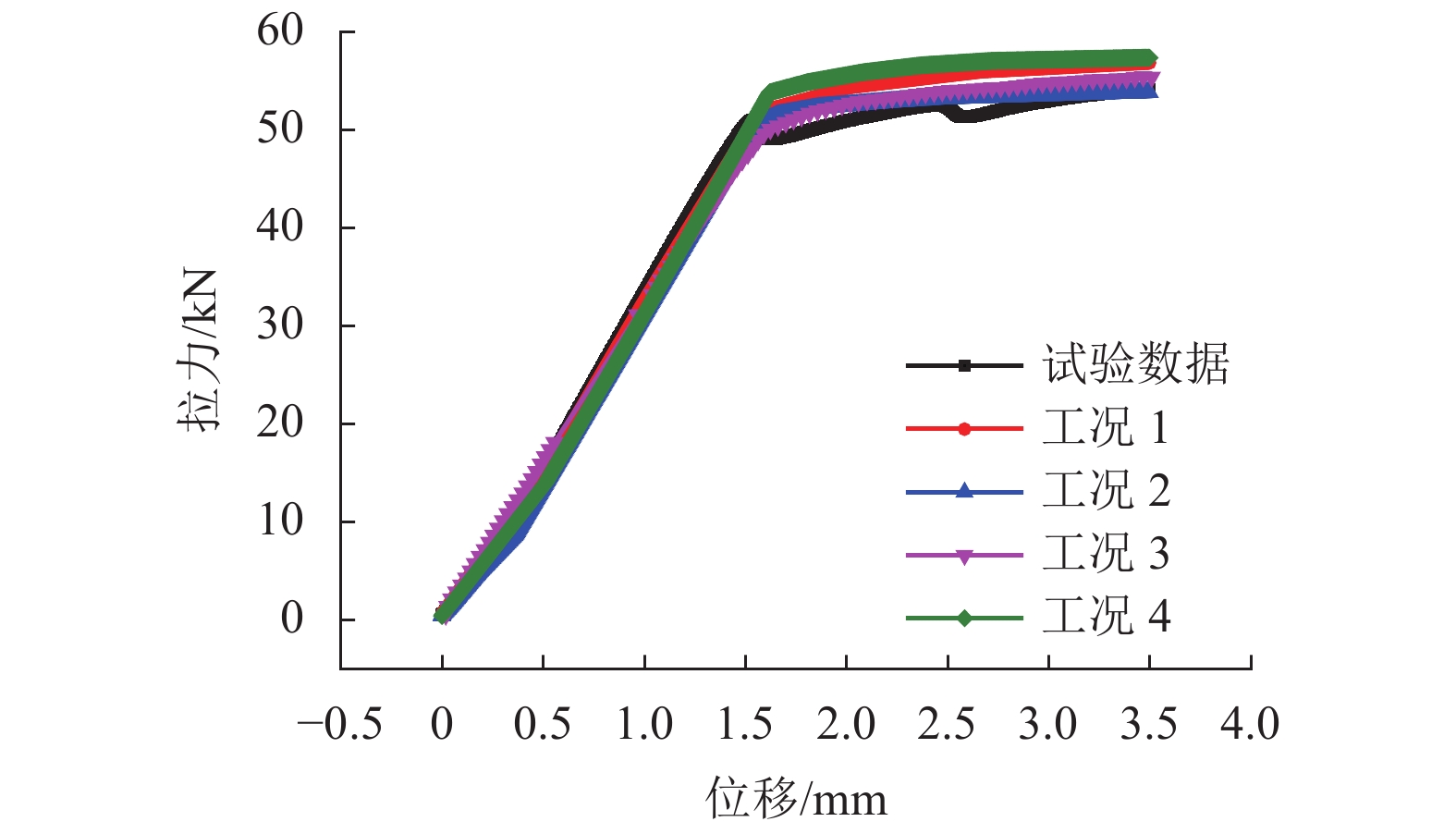

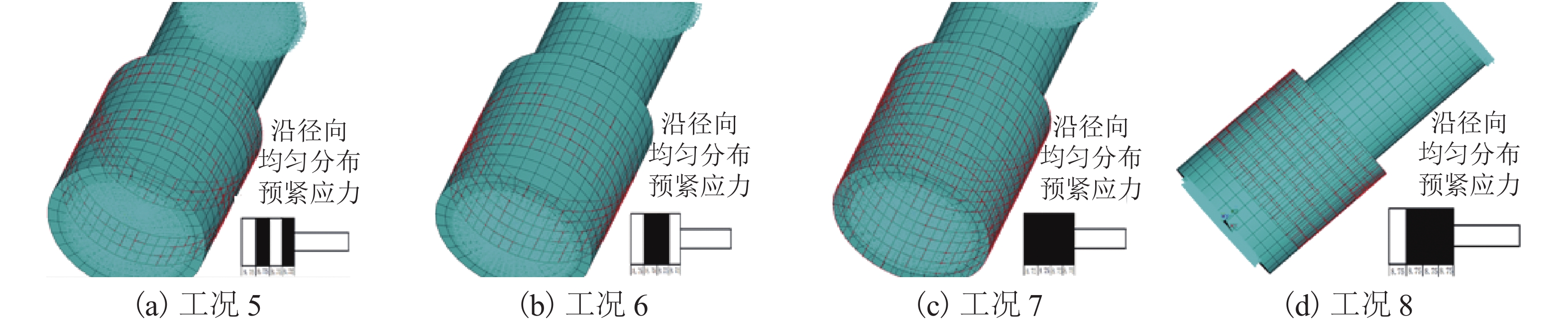

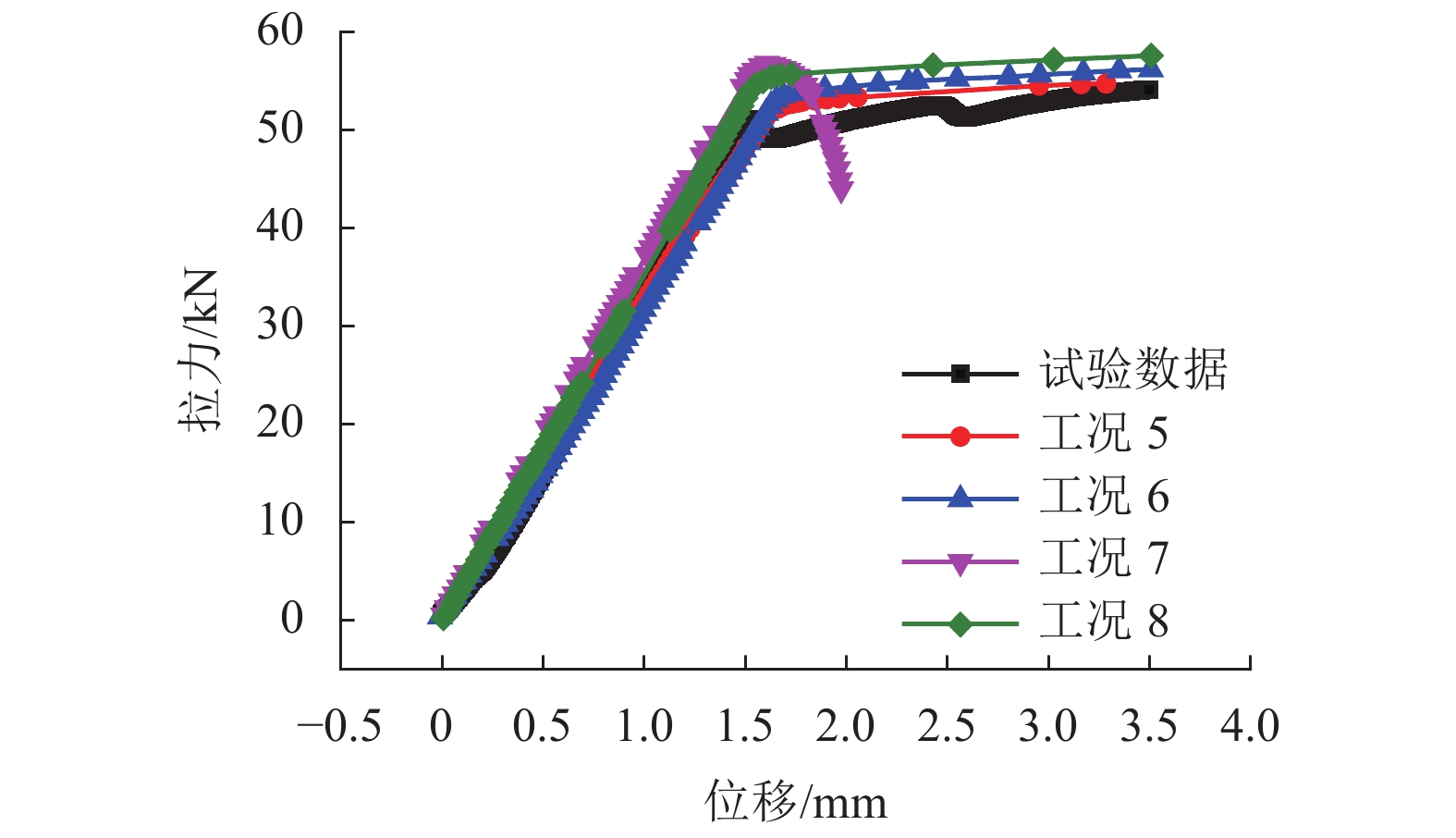

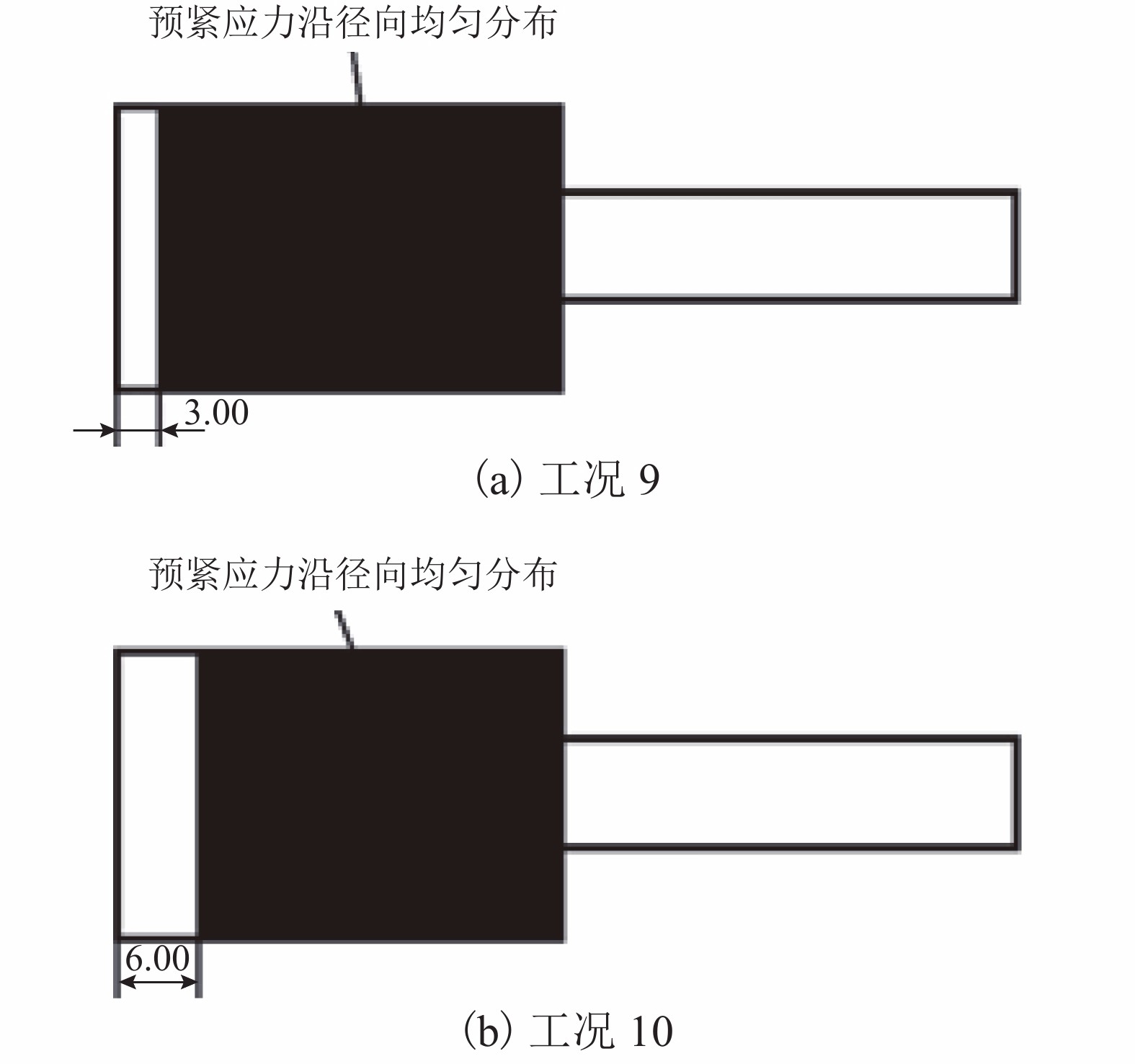

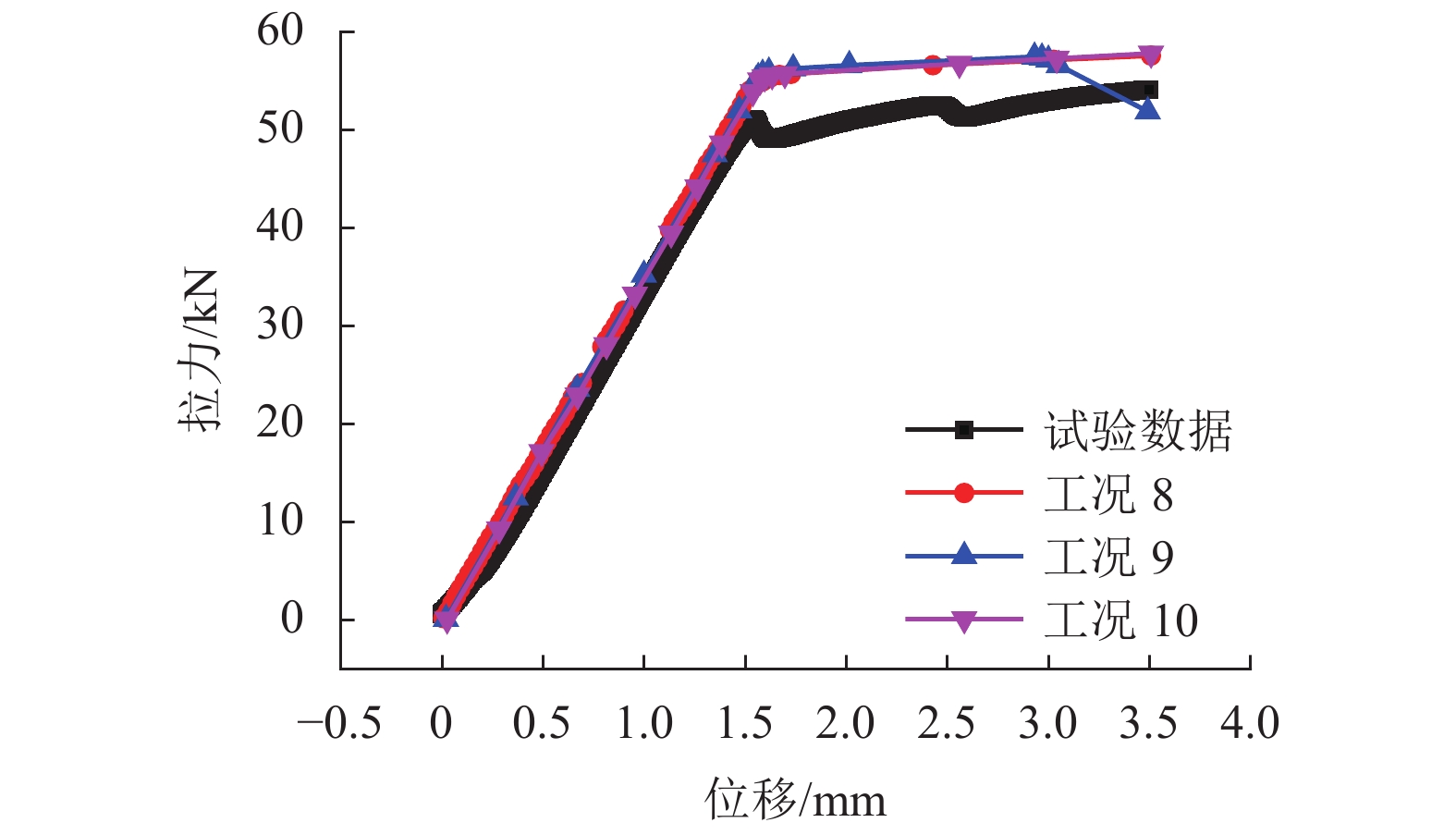

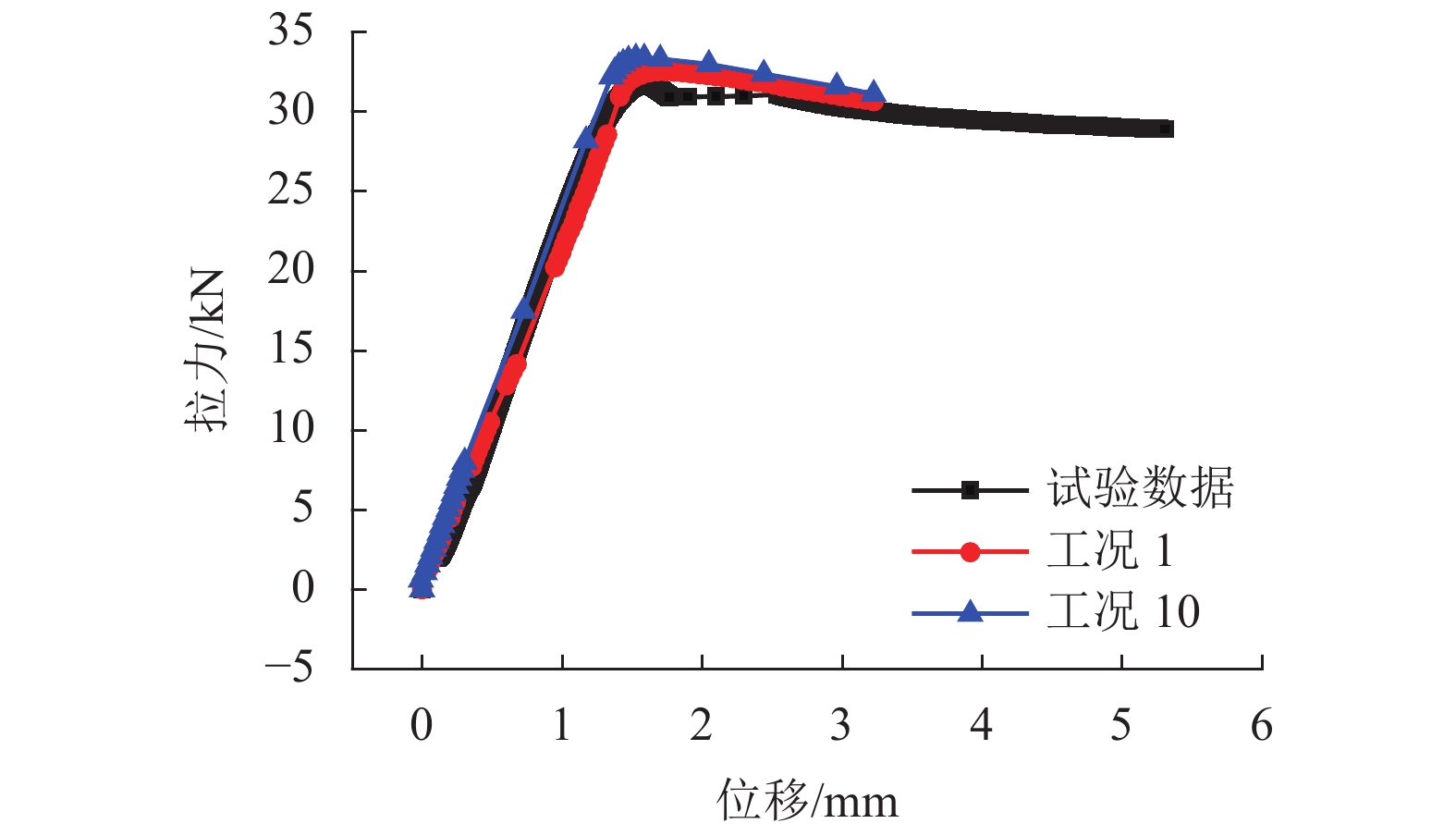

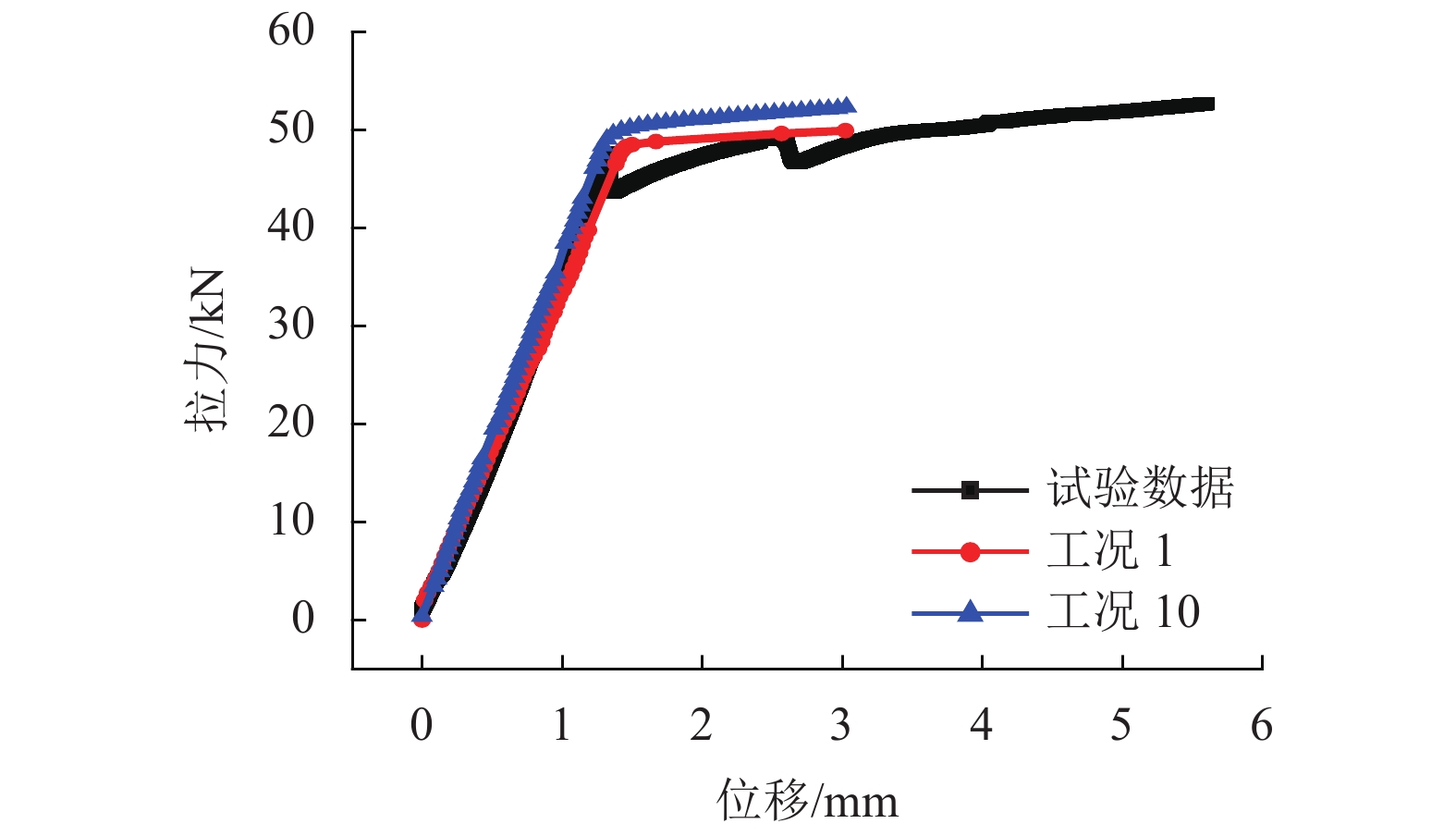

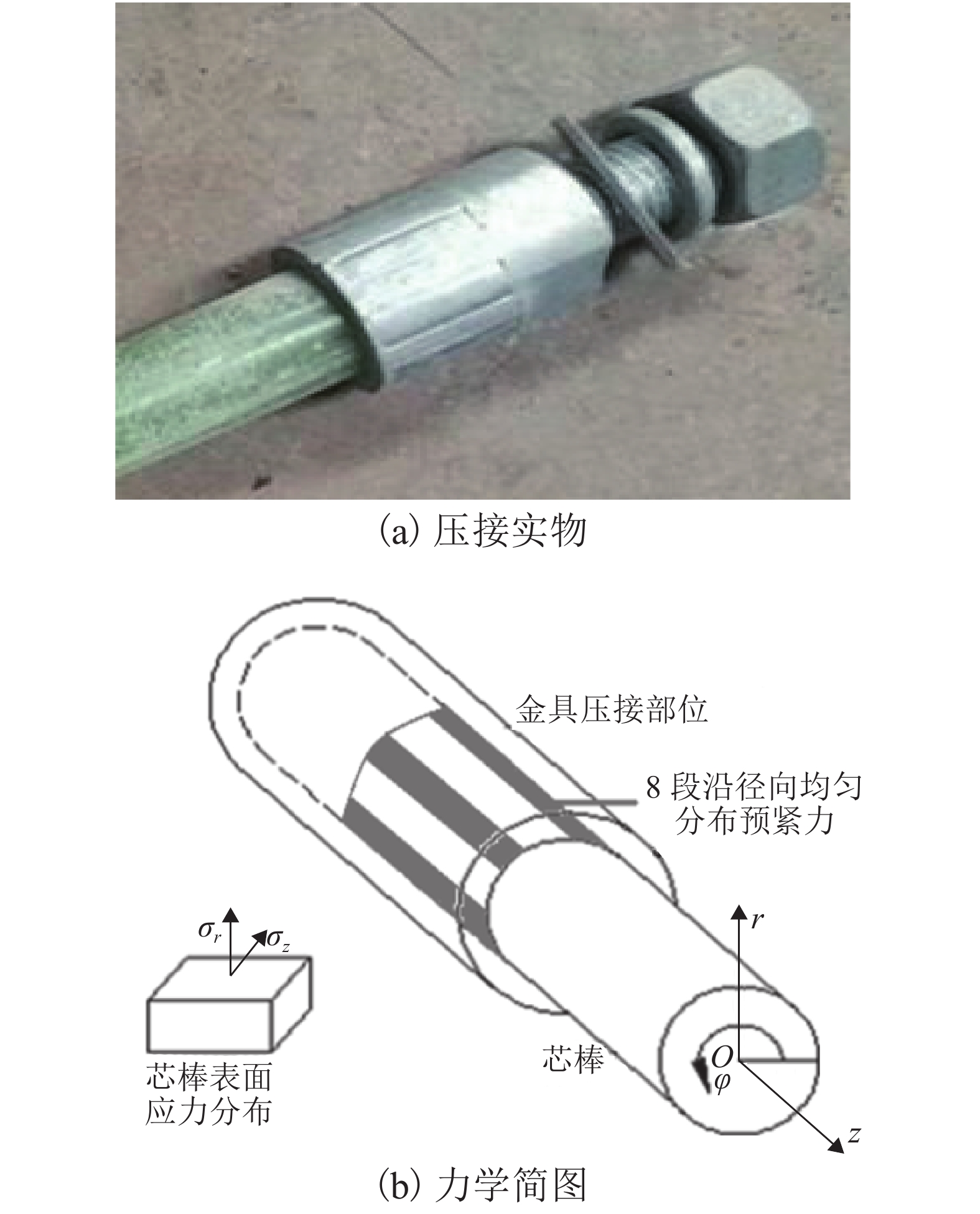

摘要: 为了探究复合绝缘子的承载力受高低温以及芯棒与端部金具压接工艺的影响规律,得出最后优化的压接方式,对绝缘子芯棒和端部金具的高低温拉伸试验结果进行了有限元模拟分析. 在常温状态对金具与芯棒的受力进行了模拟,结果与实验数据吻合较好;设计出10种压接工况,评估最优的复合绝缘子端部金具的预紧应力工况;进一步对高低温下的绝缘子承载能力进行了仿真. 研究结果表明:当预紧应力沿金具径向均匀分布并预留金具长度的18%~25%无预紧力的工况下,复合绝缘子链接的承载能力最优,最优模型的弹性极限荷载较现有厂家工艺增大8.23%;本文模拟方法能较好地模拟高低温状态下的绝缘子力学性能,但压接优化对其承载能力提升不明显.Abstract: In order to find out the influence of high and low temperature and the crimping process between the core rod and the end fittings on the bearing capacity of composite insulator, and to get the final optimized crimping mode, the finite element simulation analysis was carried out on the high and low temperature tensile test results of the core rod and the end fittings.Firstly, the stress of the fittings and mandrels was simulated at normal temperature, and the results were in good agreement with the experimental data. Then, 10 kinds of crimping conditions were designed to evaluate the optimal preloading conditions of the end fittings of composite insulator. The results show that when the preloading stress is evenly distributed along the radial direction of the fittings and 18% − 25% of the length of the fittings is reserved, the bearing capacity of the composite insulator link is the best, and the elastic limit load of the optimal model is 8.23% higher than that of the existing manufacturers. The simulation method can also be used to simulate the mechanical properties of insulators at high and low temperature, but the compression optimization cannot improve the bearing capacity significantly.

-

Key words:

- composite insulators /

- fitting /

- preload /

- tensile properties /

- optimization

-

表 1 Q235碳素结构钢金具力学性能

Table 1. Mechanical properties of Q235 carbon steel fittings

屈服强

度/MPa极限强

度/MPa泊松比 弹性模

量/GPa热膨胀系数/K−1 235 400 0.28 210 12.2 × 10−6 表 2 单向玻璃纤维增强环氧树脂力学性能

Table 2. Mechanical properties of unidirectional glass fiber reinforced epoxy resin

屈服强

度/MPa泊松比 径向弹性模量/GPa 轴向弹性模量/GPa 热膨胀系数/K−1 452 0.294 13 72 3.29 × 10−6 -

徐如恬. 瓷绝缘子强度及瓷材料种类强度水平的探讨[J]. 电瓷避雷器,1988(1): 1-8.XU Rutian. Discussion on porcelain insulator strength and porcelain material type strength level[J]. Electric Porcelain Arrester, 1988(1): 1-8. 郭晨鋆,王科,颜冰,等. 线弹性断裂力学的支柱瓷绝缘子断裂特性及断裂机理研究[J]. 云南电力技术,2018,46(2): 12-18.GUO Chenyun, WANG Ke, YAN Bing, et al. Fracture characteristics and fracture mechanism of pillar porcelain insulators based on linear elastic fracture mechanics[J]. Yunnan Electric Power Technology, 2018, 46(2): 12-18. DHANESWARA D, SUHARNO B, NUGRAHA N D, et al. Effects of ceramic fibre insulation thickness on skin formation and nodule characteristics of thin wall ductile iron casting[C]//IOP Conference Series: Materials Science and Engineering, International Conference on Advanced Materials for Better Future. Surakarta: IOP Publishing Ltd., 2017, 176: 12-32 张硕,姚宁,吴继平,等. 玻璃纤维增强环氧树脂复合材料的力学性能[J]. 电工材料,2016(1): 11-14.ZHANG Shuo, YAO Ning, WU Jiping, et al. Mechanical properties of glass fiber reinforced epoxy composites[J]. electrical materials, 2016(1): 11-14. 贾红,张鹏. 玻璃纤维增强塑料低温收缩率的测量[J]. 上海交通大学学报,2016,50(4): 502-505.JIA Hong, ZHANG Peng. Measurement of low temperature shrinkage of glass fiber reinforced plastics[J]. Journal of Shanghai Jiaotong University, 2016, 50(4): 502-505. PARIS L, PARGAMIN L, DUMORORA D, et al. Rating of composite suspension insulators related to the long term mechanical strength of rods[J]. IEEE Transactions on Power Delivery, 1994, 9(4): 2055-2063. doi: 10.1109/61.329538 DEMIDOV A N, KARIMBEKOV M A, MARCHENKOV A Y. Heating and cooling impact on mechanical properties of rip electric insulator for high voltage inputs[J]. Solid State Phenomena, 2017, 265: 496-500. doi: 10.4028/www.scientific.net/SSP.265.496 DE TOURREIL C, ROBERGE R, BOURDON P. Long-term mechanical properties of high voltage composite insulators[J]. Power Apparatus & Systems IEEE Transactions on, 1985, 104(10): 2918-2921. 余涛,杨新华. 压接式复合绝缘子接头处的破坏分析[J]. 水电能源科学,2010,28(10): 139-141.YU Tao, YANG Xinhua. Failure analysis of joints of compression type composite insulators[J]. Hydropower and Energy Science, 2010, 28(10): 139-141. 袁骏. 特高压线路用复合绝缘子的机械性能[J]. 电网技术,2006(12): 29-32.YUAN Jun. Mechanical properties of composite insulators for UHV transmission lines[J]. Power Grid Technology, 2006(12): 29-32. 钟万才. 超高压输电线路架空地线复合绝缘子断裂分析[J]. 广西电力,2014,37(5): 48-50.ZHONG Wancai. Fracture analysis of composite insulators for overhead ground wires of EHV transmission lines[J]. Guangxi Electric Power, 2014, 37(5): 48-50. 杨祉豪. 一种通用型绝缘子卡具夹头力学及有限元分析[J]. 内燃机与配件,2019(3): 46-47.YANG Weihao. Mechanical and finite element analysis of a universal insulator clamp[J]. Internal Combustion Engines and Accessories, 2019(3): 46-47. 陈显贻,刘志强. 棒形悬式复合绝缘子金具对芯棒不同连接结构与机械拉伸强度的关系[J]. 电瓷避雷器,2002(5): 9-13.CHEN Xianyi, LIU Zhiqiang. The relationship between the different connecting structures of mandrel and the mechanical tensile strength of the rod suspension composite insulator fittings[J]. Electric Porcelain Arrester, 2002(5): 9-13. 谢占山. 500 kV“V”串复合绝缘子机械疲劳试验研究[D]. 北京: 华北电力大学, 2012. MANE J V, CHANDRA S, SHARMA S, et al. Mechanical property evaluation of polyurethane foam under quasi-static and dynamic strain rates-an experimental study[J]. Procedia Engineering, 2017, 173: 726-731. doi: 10.1016/j.proeng.2016.12.160 KUMOSA M, HAN Y, KUMOSA L. Analyses of composite insulators with crimped end-fittings:part I—nonlinear finite element computations[J]. Composites Science & Technology, 2002, 62(9): 1191-1207. -

下载:

下载: