Low Temperature Rheological Performance Analysis of Rubber Modified Asphalt under Heat Aging Process

-

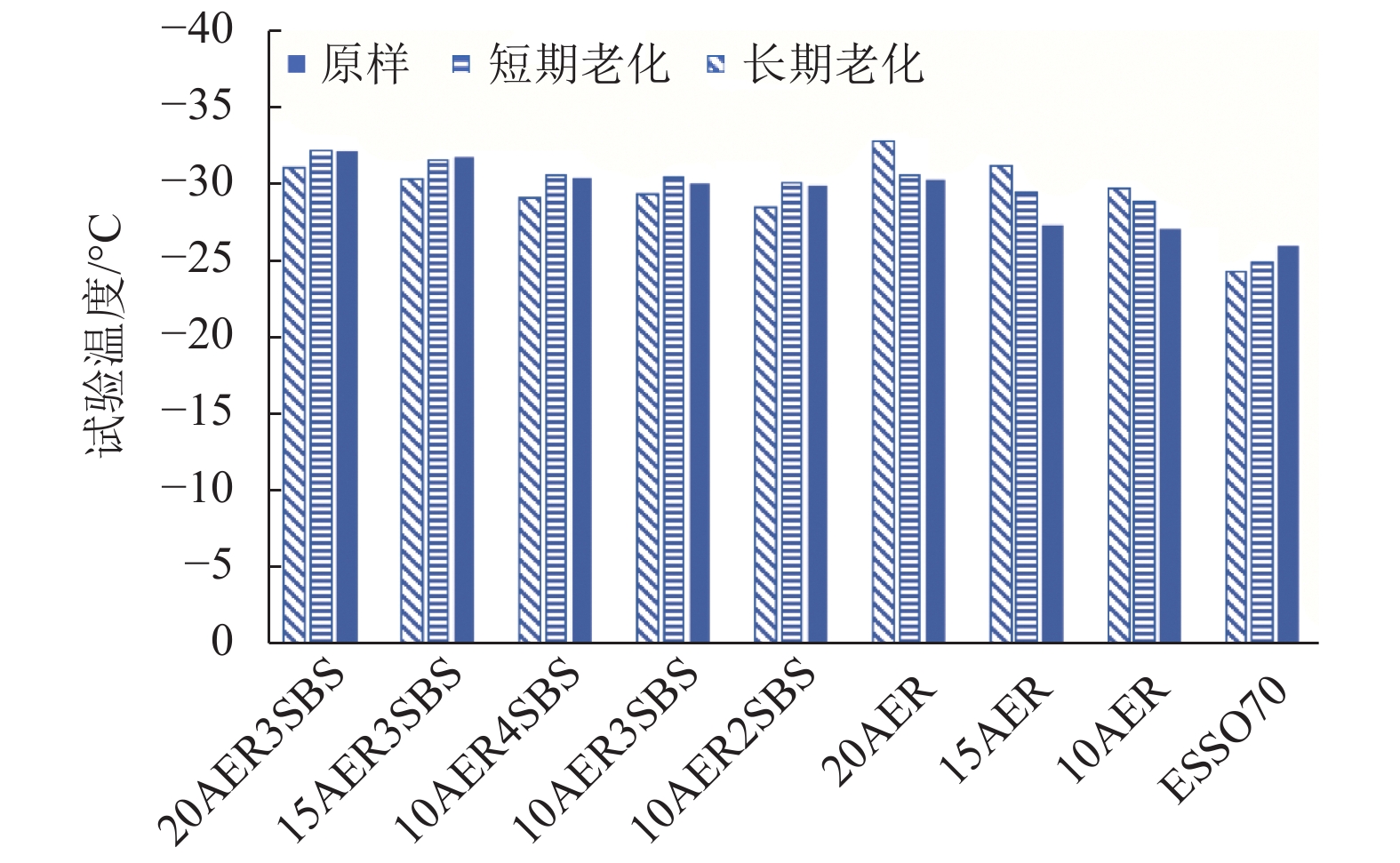

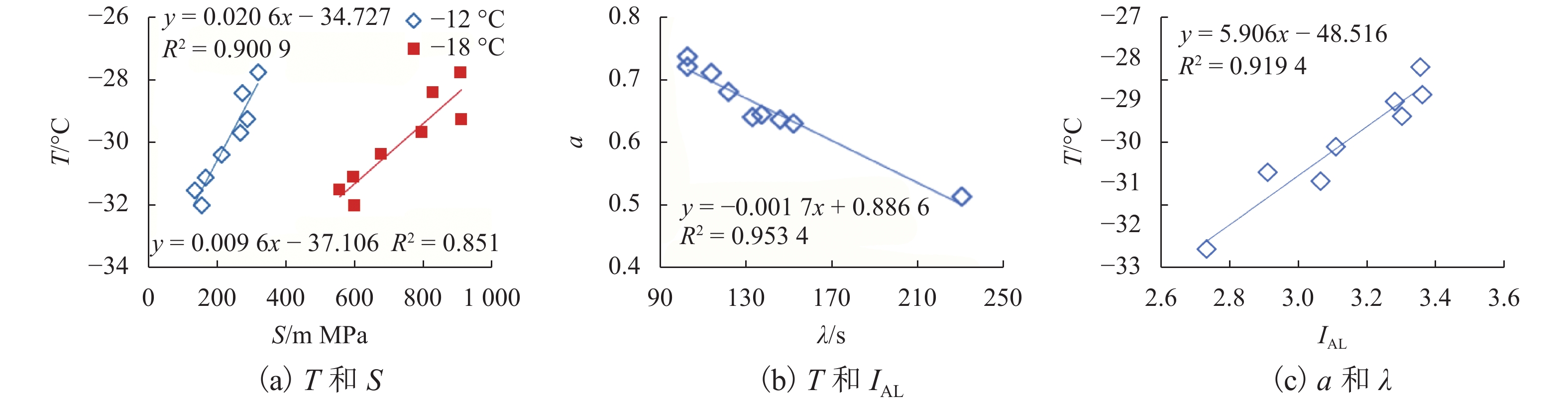

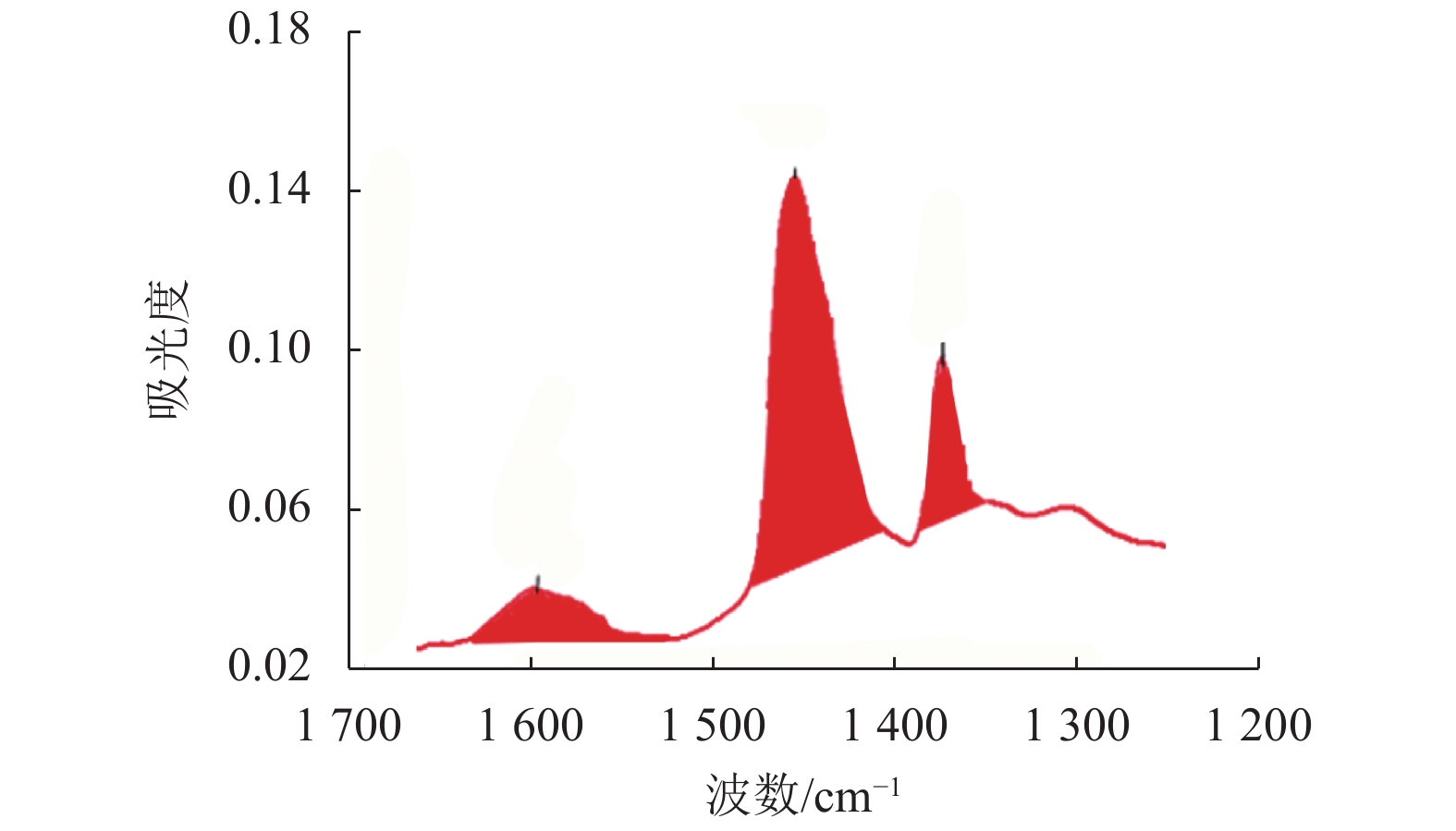

摘要: 为探究老化作用下橡胶改性沥青(AER)及其复合改性沥青(AER/SBS)的低温流变性能,借助常规性能、低温弯曲试验和Burgers模型,研究了在不同老化状态、不同橡胶粉掺量下AER改性沥青及其复合改性沥青的低温流变特性,同时借助红外光谱(FTIR)方法定量分析老化对AER改性沥青官能团的影响,并将其官能团指数和低温指标进行相关性分析. 研究结果表明:在不同老化状态下AER、SBS均可提高沥青低温性能,且短期老化下AER/SBS复合改性沥青的低温性能优于AER改性沥青,长期老化则反之;AER、SBS改性剂均可改善沥青的劲度模量,且AER对沥青劲度模量的影响程度更显著,同时低温指标(劲度模量S、蠕变速率m、劲度模量与蠕变速率之比S/m)与黏弹性指标(松弛时间λ、耗散能比a具有紧密的联系;AER改性沥青的低温性能与脂肪指数IA和脂肪长链指数IAL有较高的相关性,且IA越大其低温性能越好,IAL则反之.

-

关键词:

- 橡胶改性沥青(AER) /

- 沥青老化 /

- 低温弯曲试验 /

- Burgers模型 /

- 红外光谱 (FTIR) /

- 低温性能

Abstract: In order to explore the low temperature rheological properties of rubber modified asphalt (namely the activated twin-screw extruded rubber (AER) powder modified asphalt) and AER/SBS (styrene-butadiene styrene) composite modified asphalt under aging. The low temperature rheological properties of AER modified asphalt and its composite modified asphalt under different aging conditions and different rubber powder content were studied using conventional performance, low temperature bending test and Burgers model. At the same time, the influence of aging on the functional group of AER rubber modified asphalt was quantitatively analyzed by infrared FTIR method, and the correlation between its functional group index and various low temperature indicators was analyzed. The results show that AER and SBS can improve the low temperature performance of asphalt under different aging conditions; the low temperature performance of AER/SBS composite modified asphalt is better than AER modified asphalt under short-term aging, while the opposite is true under long-term aging. Both AER and SBS modifiers can improve the stiffness modulus of asphalt and AER has a greater impact on asphalt stiffness modulus, while low temperature grading indexes (i.e., stiffness modulus S, creep rate m, and the ratio S/m) and viscoelasticity indexes (i.e., relaxation time λ and dissipation-storage energy ratio a has a strong correlation. The low temperature performance of AER modified asphalt has a high correlation with the fat index IA and the fat long chain index IAL: the greater the aliphatic index, the better the low temperature performance, while the aliphatic fat long chain index is the opposite. -

表 1 ESSO70沥青技术指标

Table 1. Properties of ESSO70 asphalt

检测项 技术要求 检测结果 针入度(25 ℃,5 s)/mm 6.00~8.00 6.61 延度(15 ℃)/cm ≥ 100 > 150 软化点/℃ ≥ 46.0 49.6 黏度(135 ℃)/(Pa•s) 0.412 密度/(g•cm−3) 1.023 闪点/℃ ≥ 230 272 表 2 AER改性沥青的物理性能指标

Table 2. Properties of AER modified asphalt

沥青类型 针入度

(25 ℃)/

mm软化

点/℃延度

(5 ℃)/cm黏度

(135 ℃)/

(Pa•s)ESSO70 6.61 49.6 0 0.412 10AER 10.30 50.9 12.3 0.731 15AER 11.50 50.7 27.0 1.243 20AER 12.00 50.5 30.0 2.101 10AER2SBS 7.00 51.7 53.0 1.251 10AER3SBS 6.80 56.2 53.0 2.021 10AER4SBS 6.50 59.7 54.0 3.013 15AER3SBS 7.30 55.3 52.0 2.496 20AER3SBS 7.00 61.5 58.0 3.765 表 3 峰位置与谱峰归属

Table 3. Peak position and belongingness

峰位/cm−1 谱峰归属 对应沥青成分 700 聚苯乙烯 C = H

的伸缩振动聚苯乙烯 724 亚甲基链(CH2)n(n ≥ 4)协同振动 脂肪的长链 743 芳香族支链的弯曲振动 芳香分 814、864 苯环的伸缩振动 芳香分 965 丁二烯 C = H 的伸缩振动 聚丁二烯 1 030 亚砜基(S = O)的

伸缩振动沥青中硫氧氧化 1 310、2 953 烷烃(CH3) 脂肪的支链 1 376 甲基(−CH3)伞式振动 脂肪的支链 1 460 亚甲基(−CH2)剪式振动 脂肪的长链 1 600 非对称苯环的呼吸振动 苯环、羧基 1 700 羰基(C = O)伸缩振动 碳氧氧化 2 850、2 920 亚甲基C−H对称振动 脂肪的长链 表 4 不同老化状态下的BBR结果

Table 4. Low temperature bending bean rheology (BBR) test results under different aging conditions

状态 温度/℃ 名称 ESSO70 10AER 15AER 20AER 10AER2SBS 10AER3SBS 10AER4SBS 15AER3SBS 20AER3SBS O −12 S/MPa 139 183 116 83 194 129 97 55 m 0.401 0.435 0.415 0.423 0.4 0.434 0.416 0.418 −18 S/MPa 403 403 329 242 278 258 243 211 181 m 0.283 0.224 0.263 0.297 0.365 0.349 0.341 0.352 0.368 −24 S/MPa 872 776 463 426 456 420 338 367 m 0.168 0.162 0.201 0.297 0.263 0.253 0.271 0.285 R −12 S/MPa 180 173 108 67 123 102 103 74 m 0.37 0.372 0.362 0.459 0.365 0.392 0.413 0.435 −18 S/MPa 445 486 265 256 260 245 221 198 181 m 0.258 0.259 0.342 0.339 0.346 0.310 0.305 0.331 0.343 −24 S/MPa 904 512 373 386 493 444 386 368 m 0.156 0.193 0.238 0.244 0.241 0.256 0.251 0.254 P −12 S/MPa 206 105 88 74 122 105 85 74 63 m 0.322 0.380 0.405 0.411 0.391 0.393 0.395 0.426 0.451 −18 S/MPa 481 253 224 205 290 261 272 207 195 m 0.241 0.32 0.334 0.342 0.322 0.310 0.291 0.337 0.343 −24 S/MPa 855 453 379 332 511 484 452 431 427 m 0.167 0.246 0.251 0.278 0.221 0.224 0.213 0.260 0.271 注:O—未老化;R—短期老化;P—长期老化. 表 5 Burgers模型的黏弹性指标(−18 ℃)

Table 5. Burgers model of viscoelastic index (−18 ℃)

沥青类型 E1/MPa η1/(MPa•s) E2/MPa η2/(MPa•s) λ/s τ/s a/% ESSO70 910 225334 1158 35 847 247.6 31.0 46.1 10AER 536 74 563 459 14 876 139.1 32.4 61.3 15AER 426 48 768 341 11 406 114.5 33.4 67.5 20AER 351 37 541 269 8567 107.0 31.8 73.1 10AER2SBS 638 87 568 554 17856 137.3 32.2 62.4 10AER3SBS 532 76 751 467 16 025 144.3 34.3 63.5 10AER4SBS 541 66 879 449 15 891 123.6 35.4 66.9 15AER3SBS 483 58 457 421 14 265 121.0 33.9 67.4 20AER3SBS 472 51 025 384 13 178 108.1 34.3 72.5 表 6 沥青各官能团指数结果

Table 6. Results of various functional groups of asphalt

沥青类型 状态 IS IB IS=O IC=O IA IAR IAL ESSO70# O 0.00 0.06 0.69 0.01 30.32 15.21 3.98 R 0.00 0.07 0.65 0.08 30.78 15.11 3.67 P 0.00 0.11 0.78 1.06 30.56 14.89 3.41 10AER O 0.00 0.53 0.91 0.31 32.21 15.02 3.15 R 0.00 0.27 0.56 0.17 32.34 14.76 3.16 P 0.00 0.43 0.45 1.12 32.33 14.55 3.26 15AER O 0.00 0.48 0.62 0.00 33.17 14.91 3.11 R 0.00 0.39 0.54 0.03 32.68 14.45 3.13 P 0.00 0.51 0.53 0.71 32.72 14.68 3.11 20AER O 0.00 0.49 0.53 0.00 33.63 14.83 2.81 R 0.00 0.52 0.48 0.00 33.59 14.79 2.82 P 0.00 0.55 0.55 0.71 33.13 14.73 2.73 10AER2SBS O 0.53 1.05 0.59 0.09 32.09 14.43 3.30 R 0.57 1.09 0.61 0.25 32.13 14.31 3.27 P 0.60 1.02 0.53 1.01 31.27 14.39 3.35 10AER3SBS O 0.71 1.21 0.68 0.11 32.24 14.37 3.24 R 0.80 1.47 0.69 0.21 32.05 14.32 3.26 P 0.93 1.41 0.63 0.94 31.31 14.34 3.28 10AER4SBS O 0.71 1.19 0.67 0.19 32.14 14.33 3.29 R 1.13 2.04 0.64 0.06 32.06 14.11 3.20 P 1.19 1.69 0.51 0.92 31.08 14.34 3.36 15AER3SBS O 0.91 1.54 0.58 0.01 32.35 14.31 3.12 R 0.95 1.56 0.56 0.13 32.38 14.29 3.11 P 0.97 1.42 0.54 0.91 31.63 14.25 3.11 20AER3SBS O 0.93 1.51 0.56 0.00 33.07 14.30 2.91 R 0.94 1.76 0.64 0.00 33.71 13.94 2.80 P 1.01 1.47 0.51 1.00 31.96 14.11 2.91 注:IB 为丁二烯指数;IS=O 为亚砜指数;IC=O 为羰基指数. 表 7 黏弹性指标的相关性结果(−18 ℃)

Table 7. Correlation results of viscoelasticity index (−18 ° C)

指数 S/MPa m S/m/MPa T/℃ E1/MPa η1/(MPa•s) E2/MPa η2/(MPa•s) λ/s τ/s a/% 低温温度 −0.968 −0.961 −0.933 1 0.987 0.933 0.935 0.956 0.912 −0.615 0.598 IS −0.118 −0.055 0.212 −0.078 0.307 −0.156 −0.112 −0.056 −0.257 0.464 0.287 IB 0.154 0.205 0.478 −0.323 −0.254 −0.421 −0.410 −0.364 −0.519 0.612 0.364 IS=O −0.541 −0.536 −0.697 0.621 0.508 0.701 0.678 0.679 0.732 −0.532 0.301 IC=O −0.846 −0.834 −0.848 0.836 0.768 0.856 0.848 0.856 0.848 −0.533 0.515 IA 0.961 0.846 −0.879 −0.902 −0.913 −0.821 −0.842 −0.875 −0.812 0.425 −0.578 IAR 0.269 −0.016 −0.176 −0.484 −0.251 −0.117 −0.136 −0.126 −0.014 −0.225 −0.515 IAL −0.878 −0.938 0.881 0.811 0.838 0.843 0.897 0.909 0.927 −0.616 0.554 -

PETERSEN J C, ROBERTSON R E, BRANTHAVER J F, et al. Binder characterization and evaluation[J]. Distress, 1994, 1: 208-210. PRESTI D L. Recycled tyre rubber modified bitumens for road asphalt mixtures:a literature review[J]. Construction and Building Materials, 2013, 49: 863-881. doi: 10.1016/j.conbuildmat.2013.09.007 陈文青,黄承亚. 国外挤出法再生废旧橡胶的研究进展[J]. 合成橡胶工业,2008,31(5): 406-408.CHEN Wenqing, HUANG Chengya. Foreign research progress in reclaiming ground rubber by extrusion[J]. China Synthetic Rubber Industry, 2008, 31(5): 406-408. 刘志军,李翔,许晓飞,等. 超临界二氧化碳中废旧轮胎橡胶脱硫再生[J]. 高分子材料科学与工程,2015,31(12): 92-97.LIU Zhijun, LI Xiang, XU Xiaofei, et al. Devulcanization of waste tire rubber in supercritical carbon dioxide[J]. Polymer Materials Science & Engineering, 2015, 31(12): 92-97. 张广泰,李悦,陈柳灼,等. 废机油活化废旧轿车轮胎胶粉改性沥青的流变性能[J]. 建筑材料学报,2018,21(2): 320-326.ZHANG Guangtai, LI Yue, CHEN Liuzhuo, et al. Rheological properties of the asphalt modified by the activated rubber in the presense of waste engine oil[J]. Journal of Building Materials, 2018, 21(2): 320-326. 蔡键. 助剂活化胶粉/SBS复合改性沥青路用性能研究计划[D]. 武汉: 武汉工程大学, 2016. 朱月风,姜鹏. 掺加国产TOR的橡胶沥青黏温特性及路用性能研究[J]. 材料导报,2016,30(12): 134-139.ZHU Yuefeng, JIANG Peng. Viscosity temperature characteristics and pavement performance rubber modified asphalt added with domestic tor[J]. Materials review, 2016, 30(12): 134-139. 谭忆秋,符永康,纪伦,等. 橡胶沥青低温评价指标[J]. 哈尔滨工业大学学报,2016,48(3): 66-70.TAN Yiqiu, FU Yongkang, JI Lun, et al. Low-temperature evaluation index of rubber asphalt[J]. Journal of Harbin Institute of Technology, 2016, 48(3): 66-70. KÖK B V,YILMAZ M,GEÇKIL A. Evaluation of low-temperature and elastic properties of crumb rubber– and SBS-modified bitumen and mixtures[J]. Journal of Materials in Civil Engineering,2013,25(2): 257-265. ROOJ S, BASAK G C, MAJI P K, et al. New route for devulcanization of natural rubber and the properties of devulcanized rubber[J]. Journal of Polymers & the Environment, 2011, 19(2): 382-390. 赵安东. 双螺杆挤出机制备脱硫橡胶及脱硫橡胶改性沥青的性能和机理研究[D]. 北京: 北京化工大学, 2015 黄卫东,吕泉,柴冲冲. Terminal Blend胶粉改性沥青的复合改性研究[J]. 建筑材料学报,2016,19(1): 111-118.HUANG Weidong, LÜ Quan, CHAI Chongchong. Research on composite modification by Terminal Blend asphalt[J]. Journal of Building Materials, 2016, 19(1): 111-118. 董瑞琨,戚昌鹏,郑凯军,等. 高温裂解胶粉改性沥青的低温性能试验[J]. 中国公路学报,2017,30(10): 32-38.DONG Ruikun, QI Changpeng, ZHENG Kaijun, et al. Test on low tempeiature performance for high temperature pyrolytic rubber modified asphalt[J]. China Journal of Highway and Transport, 2017, 30(10): 32-38. 吕泉,黄卫东,柴冲冲. Terminal Blending橡胶沥青的特性与应用前景[J]. 重庆交通大学学报 (自然科学版),2014,33(4): 51-55.LÜ Quan, HUANG Weidong, CAI Chongchong. Properties and application of Terminal Blending rubber asphalt[J]. Journal of Chongqing Jiaotong University (Natural Science), 2014, 33(4): 51-55. 陈华鑫,陈拴发,王秉纲. 基质沥青老化行为与老化机理[J]. 合成材料老化与应用,2009,38(1): 13-19.CHEN Huaxin, CHEN Shunfa, WANG Binggang. The aging behavior and mechanism of base asphalts[J]. Synthetic Materials Aging and Application, 2009, 38(1): 13-19. 李萍,念腾飞,魏定邦,等. FTIR定量分析方法与老化沥青流变参数新探[J]. 华中科技大学学报(自然科学版),2018,46(2): 34-39.LI Ping, NIAN Tengfei, WEI Dingbang, et al. Quantitative analysis method for FTIR and exploration on rheological parameters of aging asphalt binders[J]. Journal of Huazhong University of Science and Technology (Natural science edition), 2018, 46(2): 34-39. 赵永利,顾凡,黄晓明. 基于FTIR的SBS改性沥青老化特性分析[J]. 建筑材料学报,2011,14(5): 620-623.ZHAO Yongli, GU Fan, HUANG Xiaoming. Analsys on SBS modified zsphalt aging characterization based on Fourier transform infrared spectroscppy[J]. Journal of Building Materials, 2011, 14(5): 620-623. 中华人民共和国交通运输部. 公路工程沥青及沥青混合料试验规程[M]. 北京: 人民交通出版社, 2011: 42-45. LIU S, CAO W, SHANG S, et al. Analysis and application of relationships between low-temperature rheological performance parameters of asphalt binders[J]. Construction & Building Materials, 2010, 24(4): 471-478. 黄明奎. 公路工程材料流变学[M]. 成都: 西南交通大学出版社, 2010: 68-70. -

下载:

下载: