Heat Dissipation Characteristics Analysis of Surface Air-Oil Heat Exchanger Applied in Aircraft Engine

-

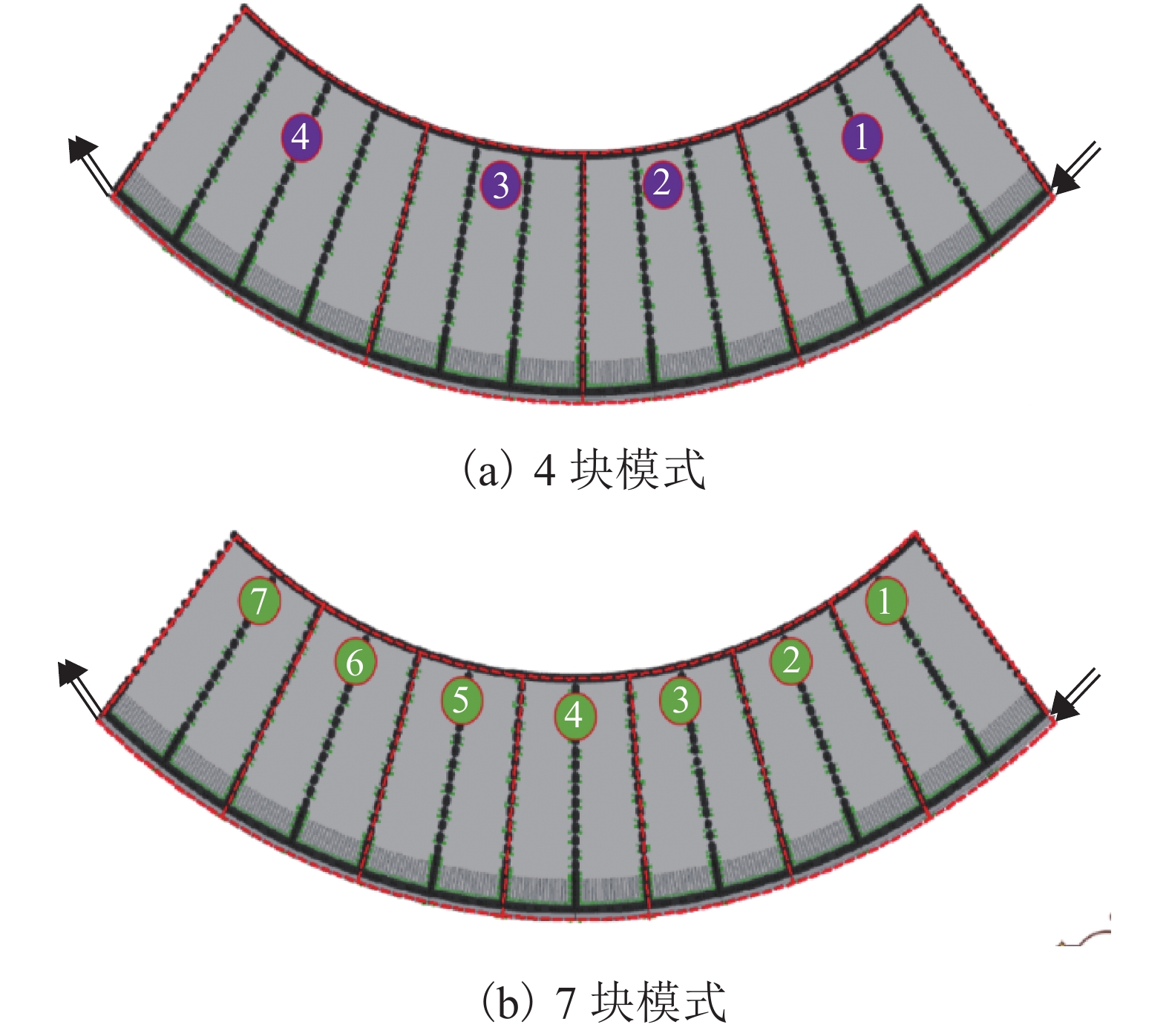

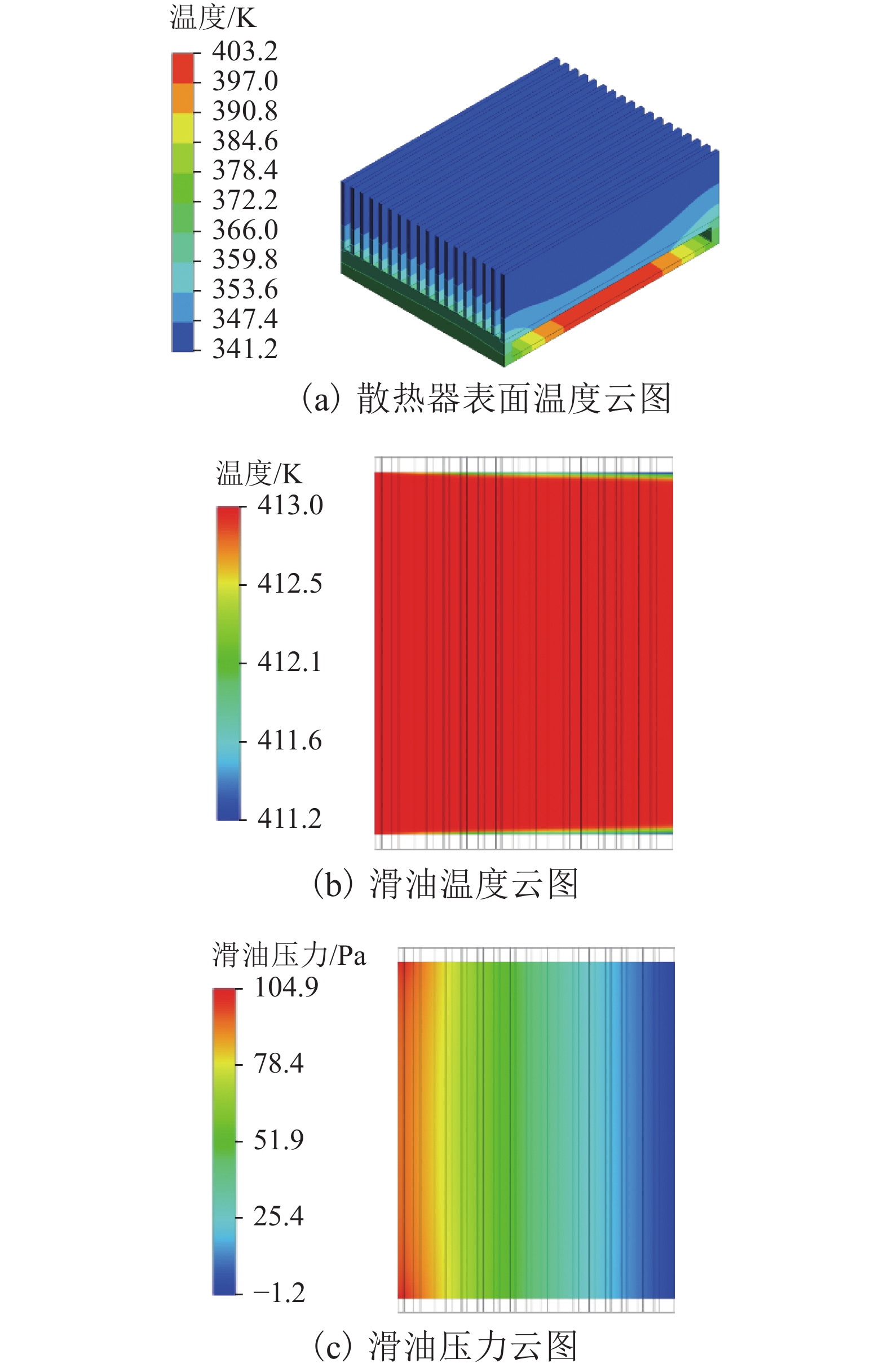

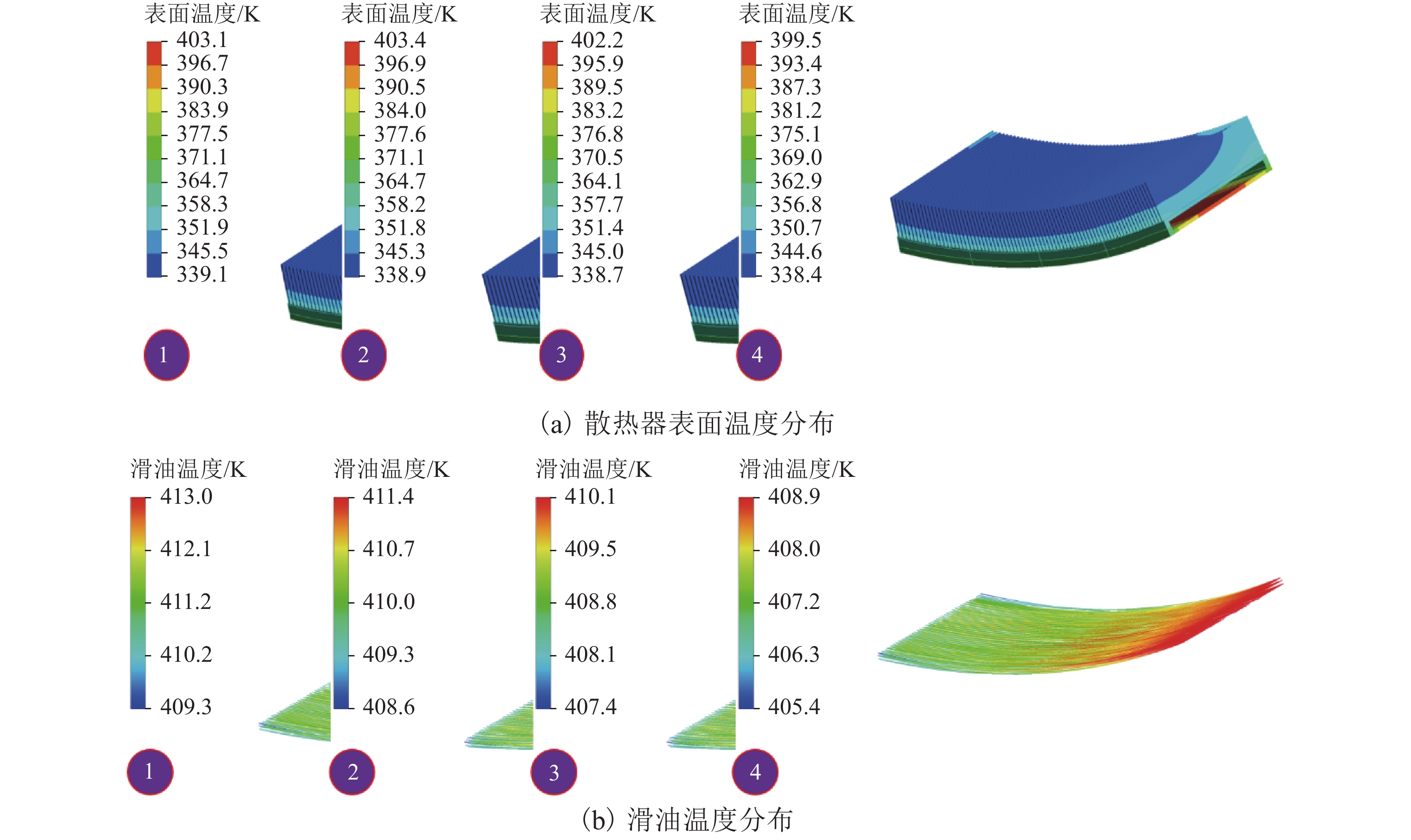

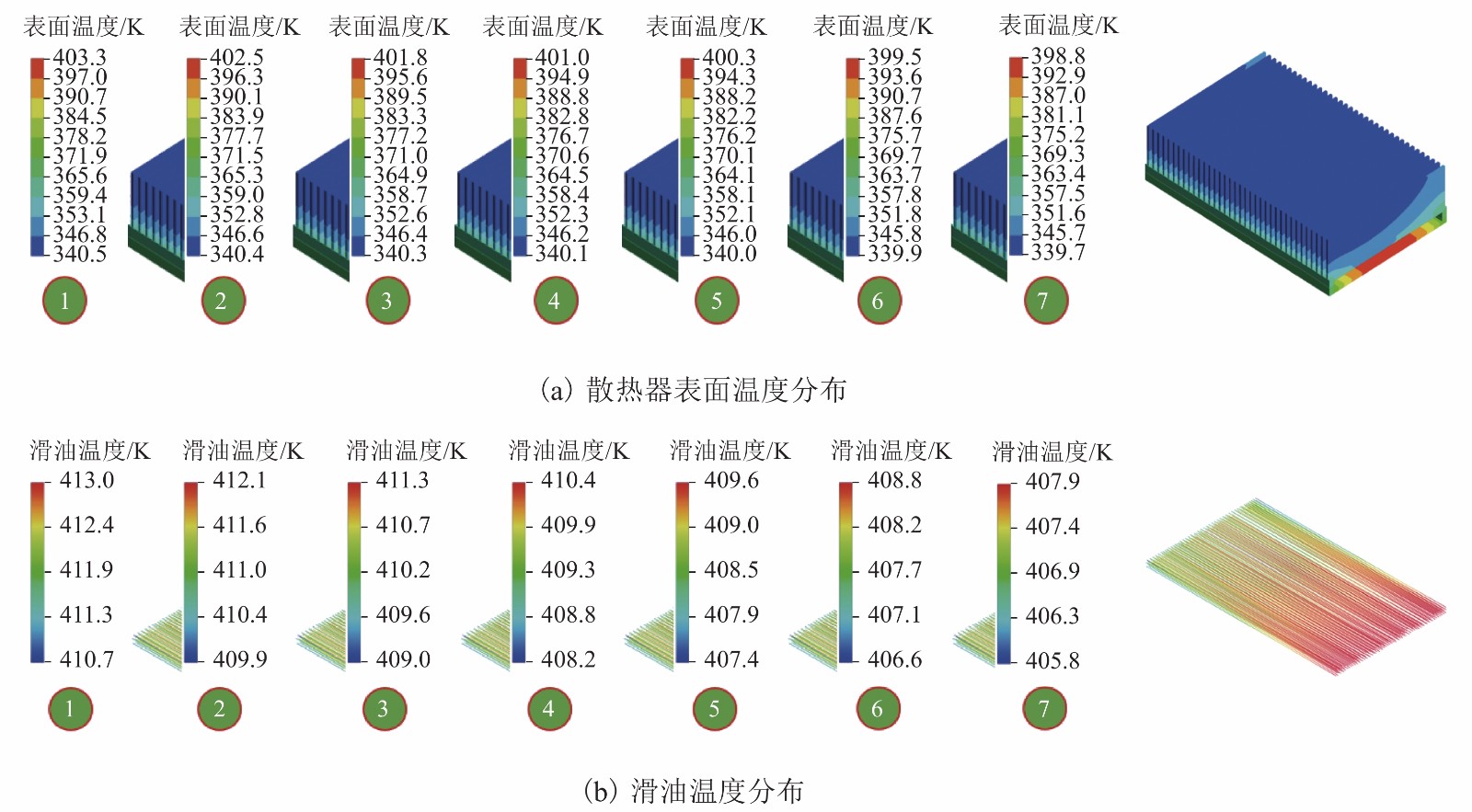

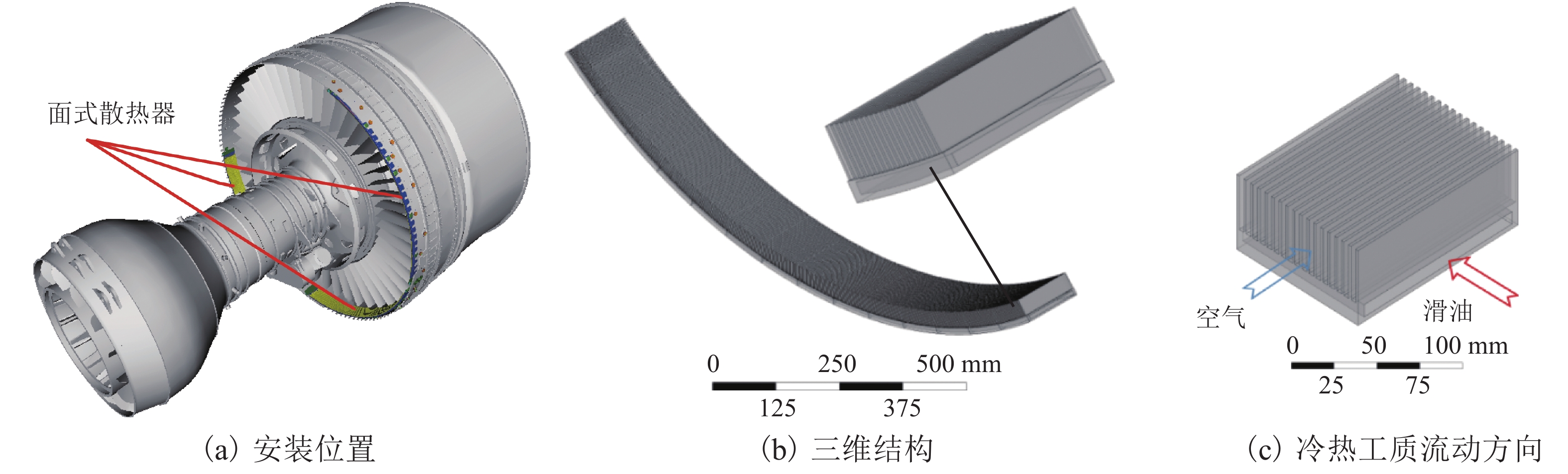

摘要: 为了改进航空发动机在地面停机、起飞滑跑等工况下散热能力差的问题,利用发动机进气道作为传热表面设计了一款面式空气-滑油散热器,并基于4分块、7分块、直平面代替弧面等分区模拟的方法开展了其传热特性研究及分块模拟的等效性分析. 研究结果表明:采用4分块、7分块以及直平面代替弧面等条件下散热器和滑油温度分布及变化趋势都基本相似,且温度差都在1 K以内,通过滑油侧与空气侧计算出的单元散热器散热量偏差也都在5%以内;采用分区模拟进行大型面式散热器的散热特性分析以及采用“以直代曲”等方法模拟弧长与直径比在0.203以下的弧面具有可行性和可靠性.

-

关键词:

- 航空发动机 /

- 面式空气-滑油散热器 /

- 散热 /

- 分区模拟

Abstract: In order to enhance aircraft engine heat transfer performance in the conditions of ground idle speed or low flying speed, a surface air-oil exchanger was presented using air inlet passage as its dissipation area. Its heat dissipation characteristics, as well as districted simulation equivalence, were investigated through the studies of 4 districted mode, 7 districted mode and the mode of using flat surface to replace arc surface. The numerical results demonstrate that temperature distributions in air side are almost the same in the cases of 4 districted mode, 7 districted mode and the mode used flat surface to replace arc surface in the simulations. All of their temperature differences are smaller than 1 K, and the discrepancies of calculated heat dissipation power are below 5%. The phenomena of heat transfer in oil side are also the same in the three cases. The research validates the feasibility and reliability of the methods of using districted simulation and using flat surface instead of arc surface where the ratio of arc length to diameter is below 0.203, when analyzing thermal characteristics of a large surface heat exchanger.-

Key words:

- aircraft engine /

- surface air-oil heat exchanger /

- heat transfer /

- districted simulation

-

表 1 散热器尺寸大小及其工作条件

Table 1. Dimensions and working conditions of surface heat exchanger

参数 数值或说明 散热器外径/mm 2 000 扇形角度/(°) 81.5 散热器宽度/mm 132(沿空气流动方向为宽度) 散热器高度/mm 49 散热器处于流场部分的高度/mm 35(翅片高度) 散热器材质 铝合金 6061 外部工质(冷流体) 空气 内部工质(热流体) 滑油 滑油流量/(L•min−1) 50 滑油进口压力/MPa 0.6 滑油进口温度/K 413 空气流速/(m•s−1) 50 空气进口温度/K 327 表 2 材料物理参数

Table 2. Physical properties of heat exchanger

参数 空气

(327 K)滑油

(413 K)铝合金

6061密度/(kg•m−3) 1.11 −968.00 −2690.00 比热容/(J•kg−1•K−1) 1005 2194 896 导热系数/

(W•m−1•K−1)0.028 0.104 180.100 动力黏度/

(kg•m−1•s−1)1.896 × 10−5 2.065 × 10−3 − -

HUANG H, SPADACCINI L J, SOBEL D R. Fuel-cooled thermal management for advanced aeroengines[J]. Journal of Engineering for Gas Turbines and Power, 2004, 126: 284-293. doi: 10.1115/1.1689361 寿荣中, 何慧姗. 飞行器环境控制[M]. 北京: 北京航空航天大学出版社, 2004: 35-38. 朱春玲,宁献文. 用于机载大功率电子设备的新型液冷环控系统的研究[J]. 南京航空航天大学学报,2005,37(2): 203-207.ZHU Chunling, NING Xianwen. Liquid cooling system for high-powered avionics[J]. Journal of Nanjing University of Aeronautics & Astronautics, 2005, 37(2): 203-207. 陈德雄, 李敏. 飞机座舱制冷附件[M]. 北京: 国防工业出版社, 1981: 22-24. 丁顺利. 飞机环形散热器的性能研究[D]. 南京: 南京航空航天大学, 2012. 帕坦卡. 传热与流体流动的数值计算[M]. 张郑译. 北京: 科学出版社, 1984: 1-5. 陶文铨. 数值传热学[M]. 西安: 西安交通大学出版社, 1995: 1-10. WU H H, HSIAO Y Y, HUANG H S, et al. A practical plate-fin heat sink model[J]. Applied Thermal Engineering, 2011, 31(5): 984-992. doi: 10.1016/j.applthermaleng.2010.10.014 PATANKAR S V, SPALDING D B. A calculation procedure for transient and steady state behavior of shell and tube heat exchanger[M]. Washington D. C.: Scripta Book Company, 1974: 77-79. LI H Y, CHAO S M. Measurement of performance of plate-fin heat sinks with cross flow cooling[J]. International Journal of Heat & Mass Transfer, 2009, 52(13/14): 2949-2955. 蔡惠坤,张银亮,廖亦戴,等. 多海拔下不同散热器翅片的性能分析[J]. 华南理工大学学报(自然科学版),2017,45(2): 91-98.CAI Huikun, ZHANG Yinliang, LIAO Yidai, et al. Performance analysis of different radiator fins at various altitudes[J]. Journal of South China University of Technology (Natural Science Edition), 2017, 45(2): 91-98. LI H Y, CHAO S M, CHEN J W, et al. Thermal performance of plate-fin heat sinks with piezoelectric cooling fan[J]. International Journal of Heat & Mass Transfer, 2013, 57(2): 722-732. 李学康. 串联通道水冷散热器的建模与优化[D]. 成都: 电子科技大学, 2013. YUAN W, ZHAO J, TSO CP, et al. Numerical simulation of the thermal hydraulic performance of a plate pin fin heat sink[J]. Applied Thermal Engineering, 2012, 48: 81-88. CHEN C T, CHEN H I. Multi-objective optimization design of plate-fin heat sinks using a direction-based genetic algorithm[J]. Journal of the Taiwan Institute of Chemical Engineers, 2013, 44: 257-265. doi: 10.1016/j.jtice.2012.11.012 FENG S S, KUANG J J, WEN T, et al. An experimental and numerical study of finned metal foam heat sinks under impinging air jet cooling[J]. International Journal of Heat & Mass Transfer, 2014, 77: 1063-1074. CHEN H T, TSENG H C, JHU S W. Numerical andexperimental study of mixed convection heat transferand fluid flow characteristics of plate-fin heat sinks[J]. International Journal of Heat & Mass Transfer, 2017, 111: 1050-1062. 廖亦戴. 面式空气-滑油散热器设计及性能研究[D]. 厦门: 厦门大学, 2018. -

下载:

下载: