Similarity of Small-Scale Wheelset-Track Model for Investigation of Rail Corrugation

-

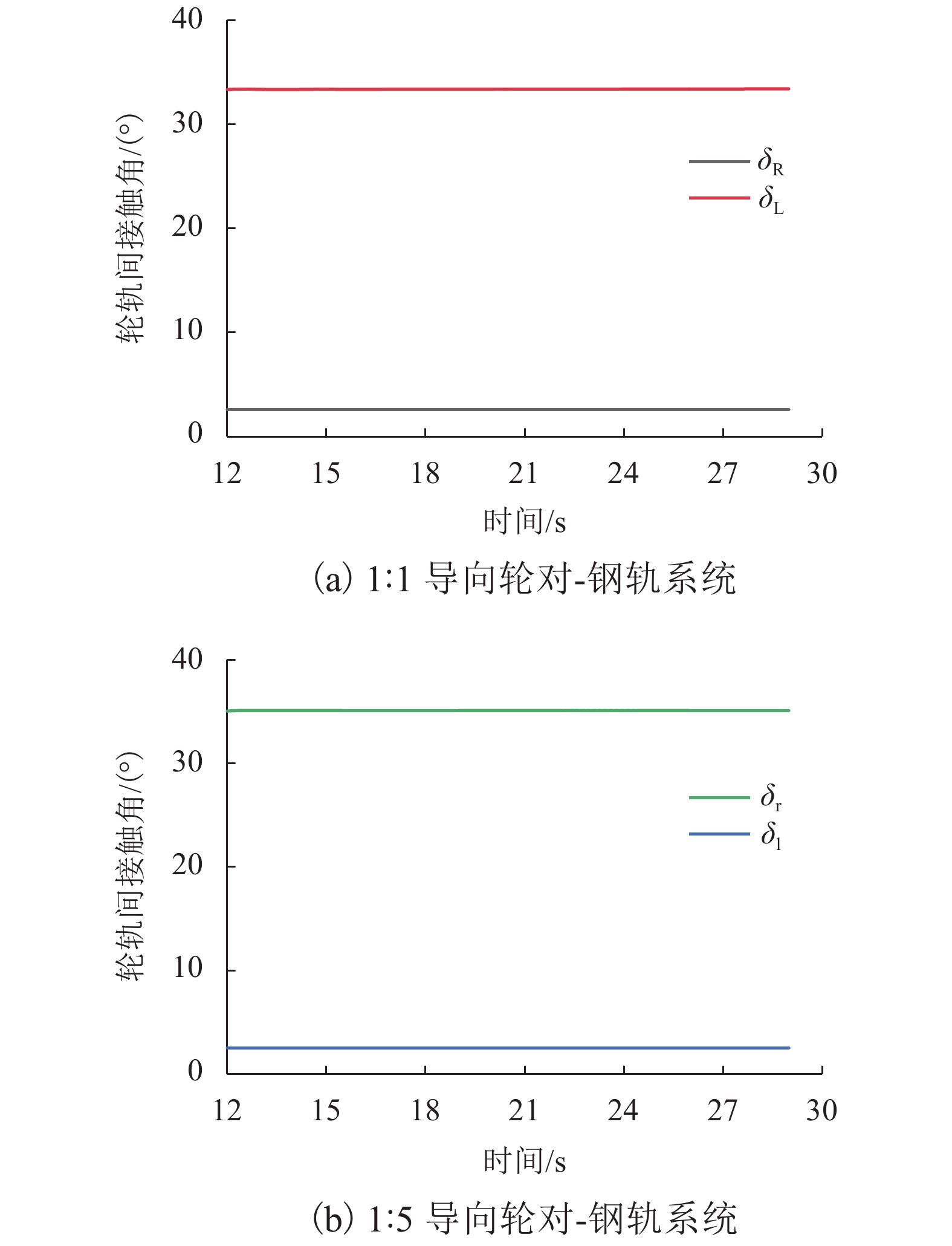

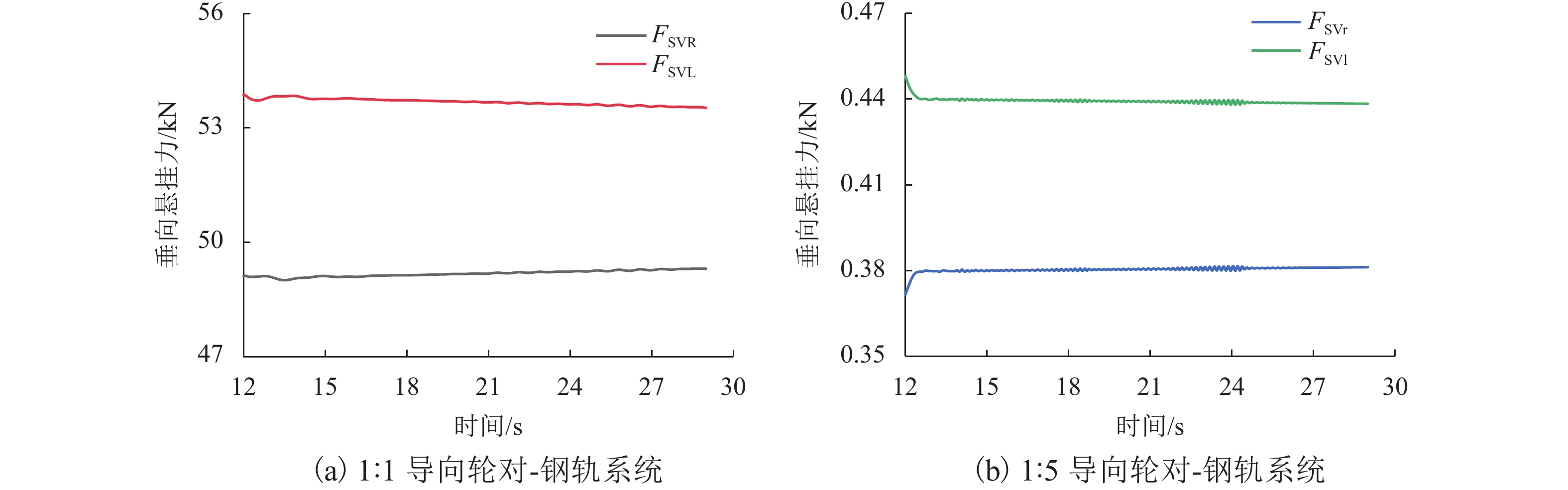

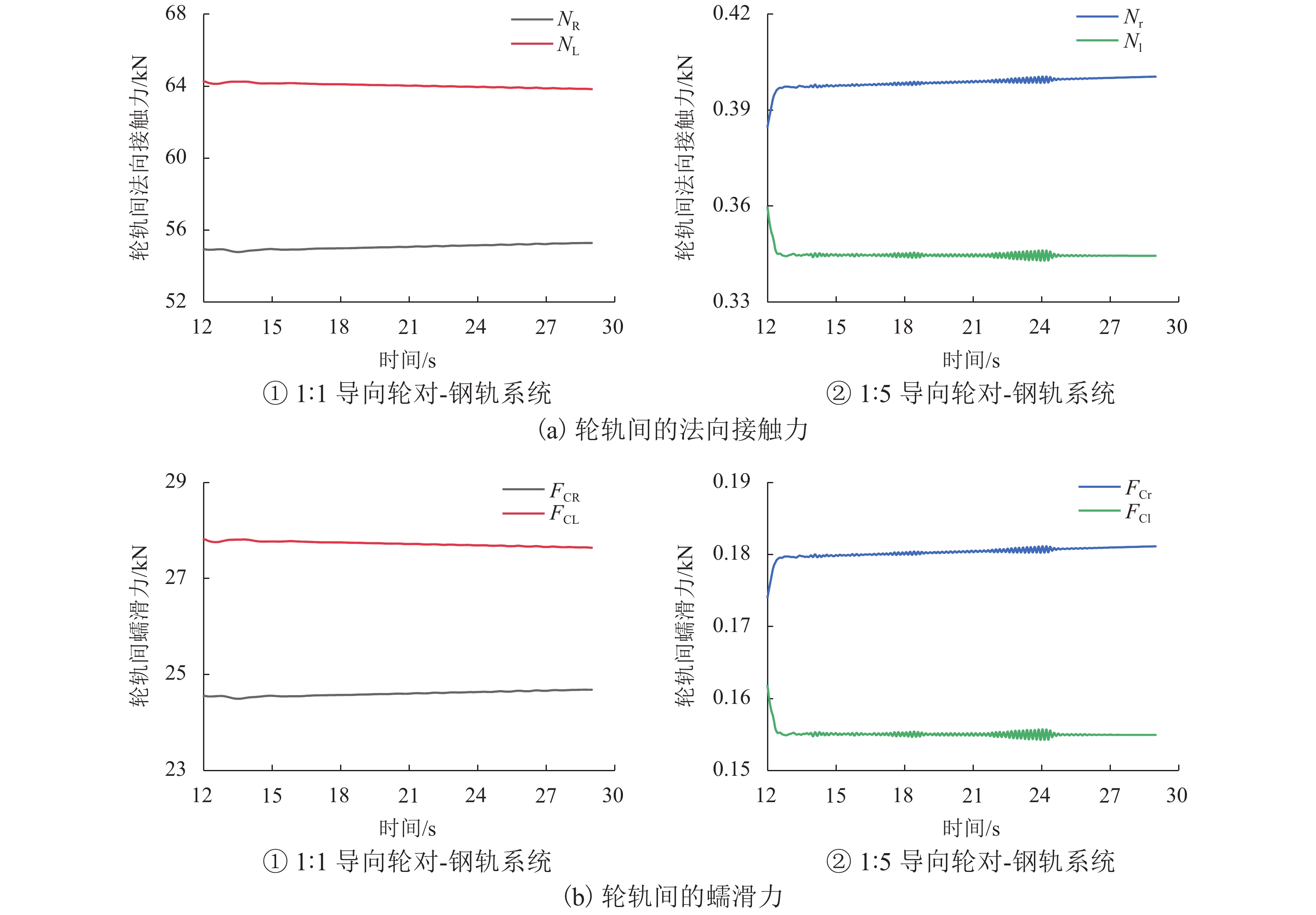

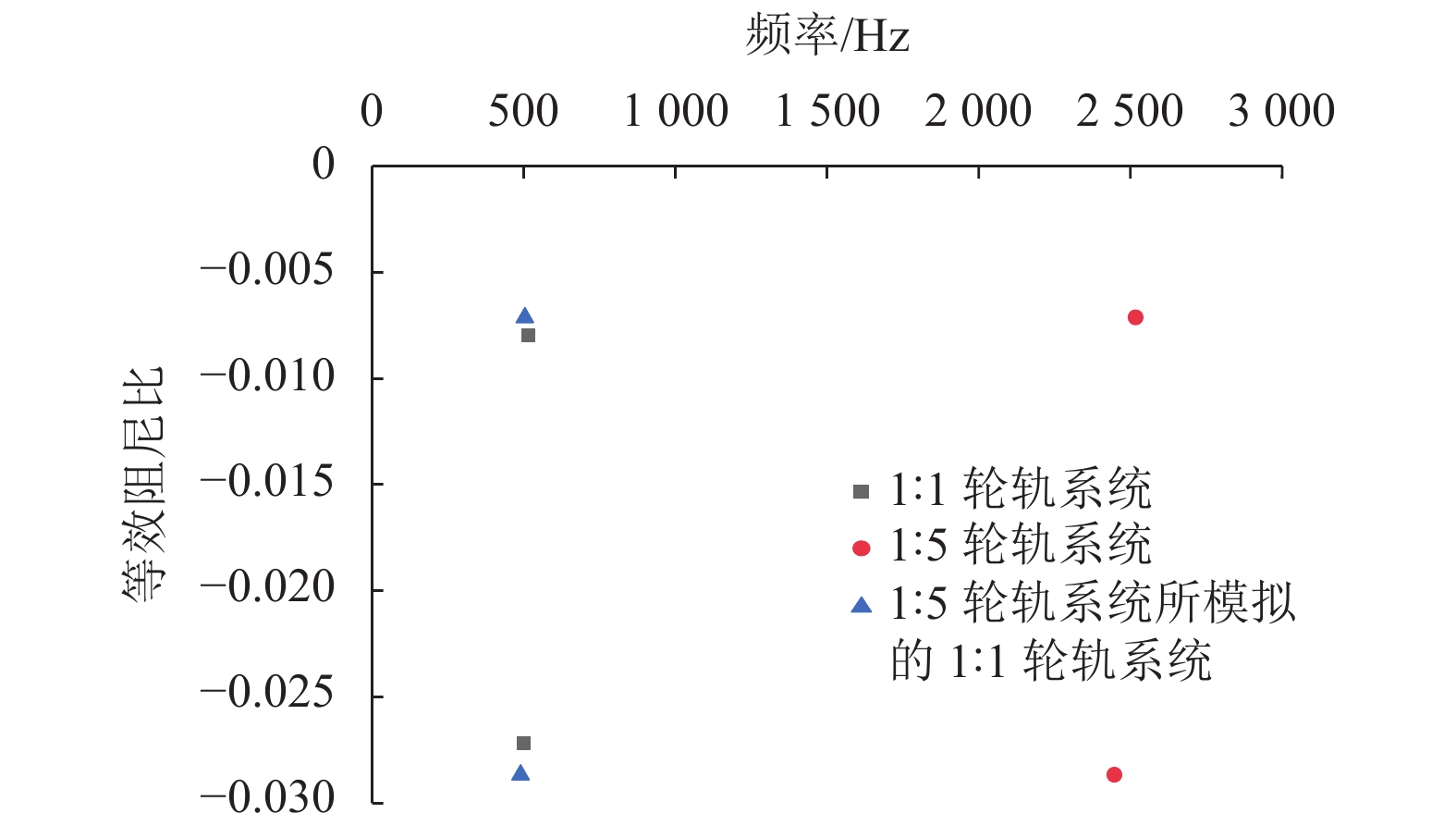

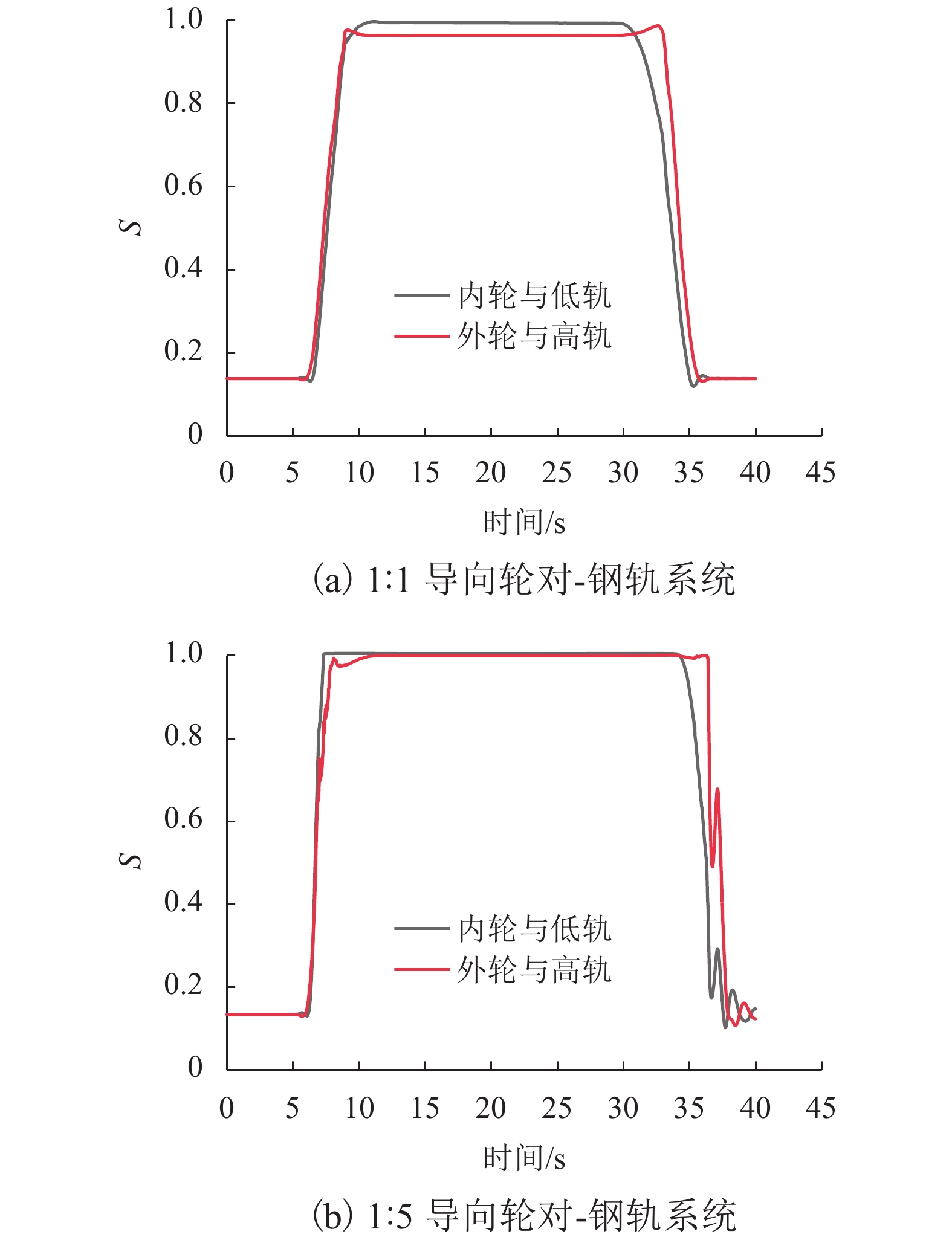

摘要: 为了研究地铁小半径曲线线路的钢轨波磨现象,基于轮轨间饱和蠕滑力引起摩擦自激振动导致钢轨波磨的理论,对全尺寸和缩尺轮轨模型的相似性进行了研究. 分别建立1∶1和1∶5车辆-轨道系统的动力学模型,确定每个车辆模型在通过小半径曲线线路时前转向架导向轮对与轨道间的蠕滑力饱和情况;根据动力学仿真所得轮轨接触参数,建立轮对-轨道-轨枕有限元模型;采用复特征值分析研究各个轮轨系统的稳定性. 研究结果表明:全尺寸和缩尺车辆模型分别通过小半径曲线线路时,导向轮对内外车轮上的蠕滑力均接近饱和;轮对两端垂向悬挂力的偏差小于3%,轮轨接触角的偏差小于5%;相似不稳定振动模态对应的频率偏差均小于3%;缩尺轮轨模型在动力学表现及稳定性方面与全尺寸模型具有良好的相似性,故可用缩尺模型对钢轨波磨的形成机理进行理论与试验研究.Abstract: In order to study rail corrugation on sharp metro curved tracks, based on the theory that the friction-induced vibration causes rail corrugation, the similarity between a full-scale and a small-scale wheelset-track models was studied. Firstly, to determine if the wheel-rail creep force was saturated, 1∶1 and 1∶5 dynamics models of vehicle-track system were established, respectively. Curve negotiations of these two models were simulated. Secondly, two finite element models were established whose wheel-rail contact parameters were from the dynamic simulation. Finally, using the complex eigenvalue analysis studied the stability of each wheelset-track system.The results show that when 1∶1 and 1∶5 vehicle models negotiate the sharp curved line respectively, creep forces on the inner and outer wheels of leading wheelsets are approximately saturated. Deviations of the vertical suspension force on two axle-ends of the wheelset and the wheel-rail contact angle are less than 3% and 5%, respectively. Frequency deviations of all similar unstable vibration modes are lower than 3%. The small-scale wheelset-track model has good similarity with full-scale model in the dynamic performance and the stability; therefore, the small-scale model can be used to study the formation mechanism of rail corrugation, both theoretically and experimentally.

-

Key words:

- rail corrugation /

- friction /

- small-scale wheelset-track model /

- similarity study /

- numerical simulation

-

表 1 车辆-轨道系统动力学模型的基本参数

Table 1. Basic parameters of dynamic model of the vehicle-track system

参数名称 原数值 缩尺系数 缩尺后数值 质量 m/kg m 53 m/125 转动惯量 I/(kg•m2) I 54 I/625 刚度 K1/(kN•m−1) K1 5 K1/5 阻尼 C1/(kN•m−1) C1 52 C1/25 杨氏模量 E/GPa 210 1 210 泊松比 V 0.3 1 0.3 摩擦系数 μ 0.45 1 0.45 运行速度 v/(km•h−1) 60 5 12 曲线区段超高 H/m 0.1 5 0.02 曲线区段半径 R/m 350 5 70 轨道总长度 L/m 700 5 140 表 2 轮对-钢轨系统的有限元模型参数

Table 2. Parameters of finite element models of the wheelset-track system

参数名称 1:1 1:5 左侧横向悬挂力/kN 0.233 0.046 左侧垂向悬挂力/kN 53.681 0.439 右侧横向悬挂力/kN 0.204 0.046 右侧垂向悬挂力 /kN 49.164 0.382 轨枕间距 LS/mm 625 125 摩擦系数 0.45 0.45 轮轨材料密度/(kg•m−3) 7800 7800 轮轨材料杨氏模量/GPa 210 210 轮轨材料泊松比 0.3 0.3 轨枕材料密度/(kg•m−3) 2500 2500 轨枕材料杨氏模量/GPa 35 35 轨枕材料泊松比 0.2 0.2 -

GRASSIE S L. Rail corrugation:characteristics,causes,and treatments[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 2009, 223(6): 581-596. doi: 10.1243/09544097JRRT264 金学松,李霞,李伟,等. 铁路钢轨波浪形磨损研究进展[J]. 西南交通大学学报,2016,51(2): 264-273. doi: 10.3969/j.issn.0258-2724.2016.02.006JIN Xuesong, LI Xia, LI Wei, et al. Review of rail corrugation progress[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 264-273. doi: 10.3969/j.issn.0258-2724.2016.02.006 金学松,温泽峰,肖新标. 曲线钢轨初始波磨形成的机理分析[J]. 机械工程学报,2008,44(3): 1-8. doi: 10.3321/j.issn:0577-6686.2008.03.001JIN Xuesong, WEN Zefeng, XIAO Xinbiao. Investigation into mechanism of initial rail corrugation formation at a curved track[J]. Chinese Journal of Mechanical Engineering, 2008, 44(3): 1-8. doi: 10.3321/j.issn:0577-6686.2008.03.001 BAEZA L, VILA P, XIE G, et al. Prediction of rail corrugation using a rotating flexible wheelset coupled with a flexible track model and a non-Hertzian/non-steady contact model[J]. Journal of Sound and Vibration, 2011, 330(18/19): 4493-4507. 李霞,李伟,温泽峰,等. 普通短轨枕轨道结构钢轨波磨初步研究[J]. 机械工程学报,2013,49(2): 109-115. doi: 10.3901/JME.2013.02.109LI Xia, LI Wei, WEN Zefeng, et al. Preliminary study on the rail corrugation of the fixed-dual short sleepers track[J]. Journal of Mechanical Engineering, 2013, 49(2): 109-115. doi: 10.3901/JME.2013.02.109 TORSTENSSON P T, PIERINGER A, NIELSN J C O. Simulation of rail roughness growth on small radius curves using a non-Hertzian and non-steady wheel–rail contact model[J]. Wear, 2014, 314(1/2): 241-253. WU T X, THOMPSON D J. An investigation into rail corrugation due to micro-slip under multiple wheel/rail interactions[J]. Wear, 2004, 258(7): 1115-1125. SUN Y Q, SIMSON S. Wagon–track modelling and parametric study on rail corrugation initiation due to wheel stick-slip process on curved track[J]. Wear, 2008, 265(9/10): 1193-1201. doi: 10.1016/j.wear.2008.02.043 CHEN G X, ZHOU Z R, OUYANG H, et al. A finite element study on rail corrugation based on saturated creep force-induced self-excited vibration of a wheelset–track system[J]. Journal of Sound and Vibration, 2010, 329(22): 4643-4655. doi: 10.1016/j.jsv.2010.05.011 陈光雄,钱韦吉,莫继良,等. 轮轨摩擦自激振动引起小半径曲线钢轨波磨的瞬态动力学[J]. 机械工程学报,2014,50(9): 71-76. doi: 10.3901/JME.2014.09.071CHEN Guangxiong, QIAN Weiji, MO Jiliang, et al. A transient dynamics study on wear-type rail corrugation on a tight curve due to the friction-induced self-excited vibration of a wheelset-track system[J]. Journal of Mechanical Engineering, 2014, 50(9): 71-76. doi: 10.3901/JME.2014.09.071 JIN X, WEN Z. Rail corrugation formation studied with a full-scale test facility and numerical analysis[J]. Proceedings of the Institution of Mechanical Engineers,Part J:Journal of Engineering Tribology, 2007, 221(6): 675-698. doi: 10.1243/13506501JET269 温泽峰,金学松. 非稳态载荷下轮轨滚动接触及其钢轨波磨研究[J]. 摩擦学学报,2007,27(3): 252-258. doi: 10.3321/j.issn:1004-0595.2007.03.012WEN Zefeng, JIN Xuesong. Analysis of rolling contact and rail corrugation under non-steady state loading[J]. Tribology, 2007, 27(3): 252-258. doi: 10.3321/j.issn:1004-0595.2007.03.012 ZHANG W, CHEN J, WU X, et al. Wheel/rail adhesion and analysis by using full scale roller rig[J]. Wear, 2002, 253(1): 82-88. 张立民,张卫华. 轮轨波磨形成机理与再现试验[J]. 西南交通大学学报,2005,40(4): 435-439. doi: 10.3969/j.issn.0258-2724.2005.04.001ZHANG Limin, ZHANG Weihua. Mechanism and experimental formation of wheel/rail corrugation[J]. Journal of Southwest Jiaotong University, 2005, 40(4): 435-439. doi: 10.3969/j.issn.0258-2724.2005.04.001 刘启跃,王夏秋,周仲荣. 钢轨表面波浪形磨损研究[J]. 摩擦学学报,1998,18(4): 50-53.LIU Qiyue, WANG Xiaqiu, ZHOU Zhongrong. An investigation of rail corrugation[J]. Tribology, 1998, 18(4): 50-53. 刘启跃,张波,周仲荣,等. 滚动轮波形磨损实验研究[J]. 摩擦学学报,2003,23(2): 132-135. doi: 10.3321/j.issn:1004-0595.2003.02.013LIU Qiyue, ZHANG Bo, ZHOU Zhongrong, et al. Experimental study on rolling wheel corrugation[J]. Tribology, 2003, 23(2): 132-135. doi: 10.3321/j.issn:1004-0595.2003.02.013 刘启跃,何成刚,黄育斌,等. 轮轨疲劳损伤模拟实验研究及展望[J]. 西南交通大学学报,2016,51(2): 282-290. doi: 10.3969/j.issn.0258-2724.2016.02.008LIU Qiyue, HE Chenggang, HUANG Yubin, et al. Research and prospects of simulation experiment on wheel/rail fatigue damage[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 282-290. doi: 10.3969/j.issn.0258-2724.2016.02.008 NAEIMI M, LI Z, PETROV R H, et al. Development of a new downscale setup for wheel-rail contact experiments under impact loading conditions[J]. Experimental Techniques, 2018, 42(1): 1-17. doi: 10.1007/s40799-017-0216-z SUDA Y. Effects of vibration system and rolling conditions on the development of corrugations[J]. Wear, 1991, 144(1/2): 227-242. SUDA Y, KOMINE H, IWASA T, et al. Experimental study on mechanism of rail corrugation using corrugation simulator[J]. Wear, 2002, 253(1): 162-171. LEWIS R, OLOFSSON U. Mapping rail wear regimes and transitions[J]. Wear, 2004, 257(7/8): 721-729. LEWIS R, DWYER-JOYCE R S. Wear at the wheel/rail interface when sanding is used to increase adhesion[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 2006, 220(1): 29-41. doi: 10.1243/095440905X33260 LEWIS R, GALLARDO-HERNANDEZ E A, HILTON T, et al. Effect of oil and water mixtures on adhesion in the wheel/rail contact[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 2009, 223(3): 275-283. doi: 10.1243/09544097JRRT248 LI Z, ARIAS-CUEVAS O, LEWIS R, et al. Rolling–sliding laboratory tests of friction modifiers in leaf contaminated wheel–rail contacts[J]. Tribology Letters, 2009, 33(2): 97-109. doi: 10.1007/s11249-008-9393-3 ARIAS-CUEVAS O, LI Z, LEWIS R, et al. Rolling–sliding laboratory tests of friction modifiers in dry and wet wheel-rail contacts[J]. Wear, 2010, 268(3/4): 543-551. ARIAS-CUEVAS O, LI Z, LEWIS R. A laboratory investigation on the influence of the particle size and slip during sanding on the adhesion and wear in the wheel–rail contact[J]. Wear, 2011, 271(1/2): 14-24. JASCHINSKI A. On the application of similarity laws to a scaled railway bogie model[D]. Holland: Delft University of Technology, 1990. 张卫华,林建辉,IWNICK S. 1∶5 比例车辆模型滚动试验台试验研究[J]. 机械工程学报,1998,34(4): 28-34. doi: 10.3321/j.issn:0577-6686.1998.04.005ZHANG Weihua, LIN Jianhui, IWNICK S. Study on 1∶ 5 scale railway roller rig[J]. Chinese Journal of Mechanical Engineering, 1998, 34(4): 28-34. doi: 10.3321/j.issn:0577-6686.1998.04.005 JASCHINSKI A, CHOLLET H, IWNICK S, et al. The application of roller rigs to railway vehicle dynamics[J]. Vehicle System Dynamics, 1999, 31(5/6): 345-392. IWNICK S. Handbook of railway vehicle dynamics[M]. CRC: Taylor & Francis, 2006: 507-526. 邹锦华,王荣辉,魏德敏. 车辆-轨道系统缩尺模型振动试验研究[J]. 铁道建筑,2011,51(8): 112-116. doi: 10.3969/j.issn.1003-1995.2011.08.036 EOM B G, KANG B B, LEE H S. Design of small-scaled derailment simulator for investigating bogie dynamics[J]. International Journal of Railway, 2011, 4(2): 50-55. doi: 10.7782/IJR.2011.4.2.050 崔晓璐. 地铁线路钢轨波磨现象发生机理研究[D]. 成都: 西南交通大学, 2017. CUI X L, CHEN G X, YANG H G, et al. Effect of the wheel/rail contact angle and the direction of the saturated creep force on rail corrugation[J]. Wear, 2015, 330/331(3): 554-562. LI W, WANG H, WEN Z, et al. An investigation into the mechanism of metro rail corrugation using experimental and theoretical methods[J]. Proceedings of the Institution of Mechanical Engineers, 2016, 230(4): 1025-1039. doi: 10.1177/0954409715596182 YUAN Y. An eigenvalue analysis approach to brake squeal problem[C]//Proc. of the 29th ISATA Conf. on Automotive Braking Systems. Florence: [s.n.], 1996: 3-9. OUYANG H, NACK W, YUAN Y, et al. Numerical analysis of automotive disc brake squeal:a review[J]. International Journal of Vehicle Noise & Vibration, 2005, 1(3/4): 207-230. -

下载:

下载: