Laser Visual Dynamic Measurement of Rail Wear on Complete Profile

-

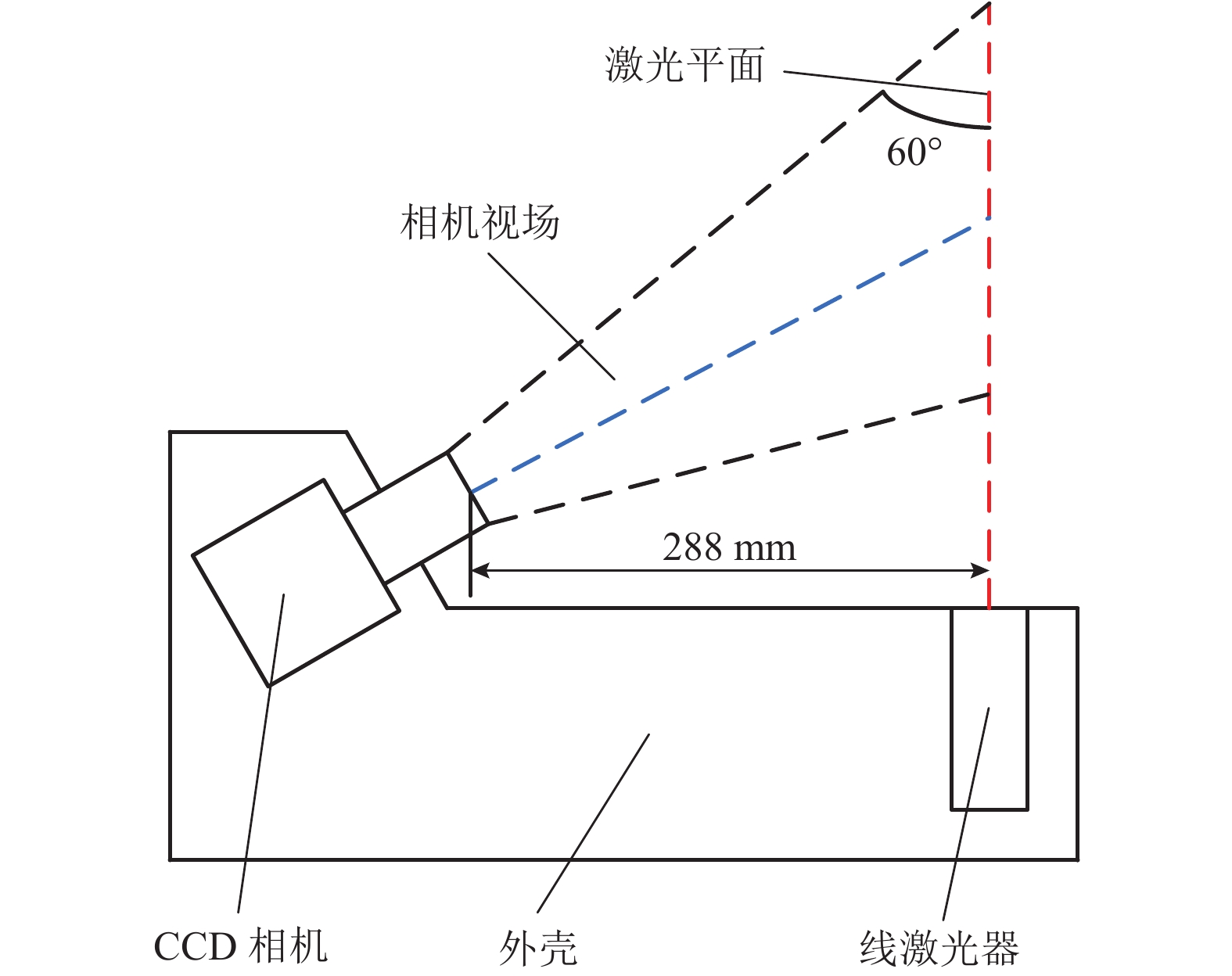

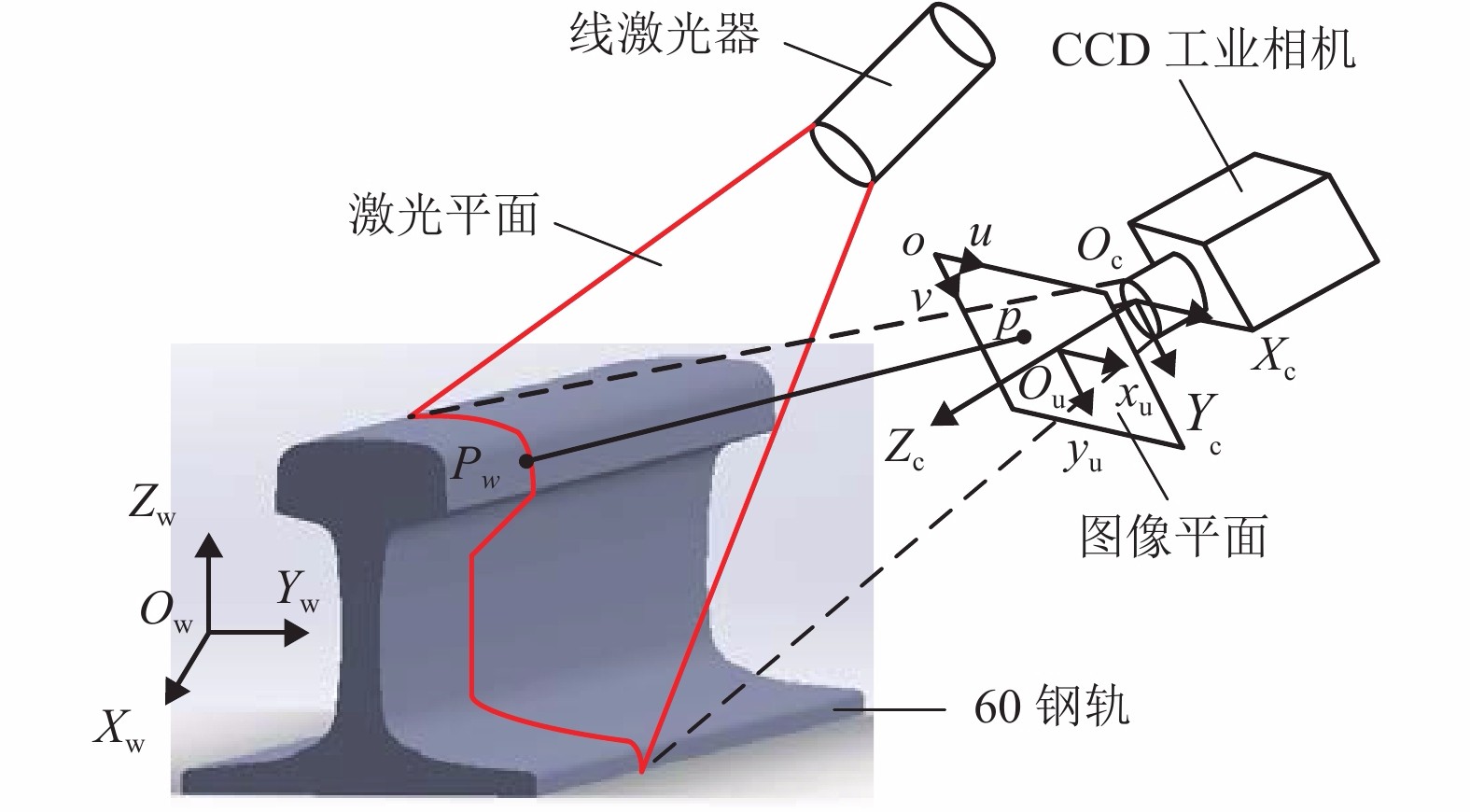

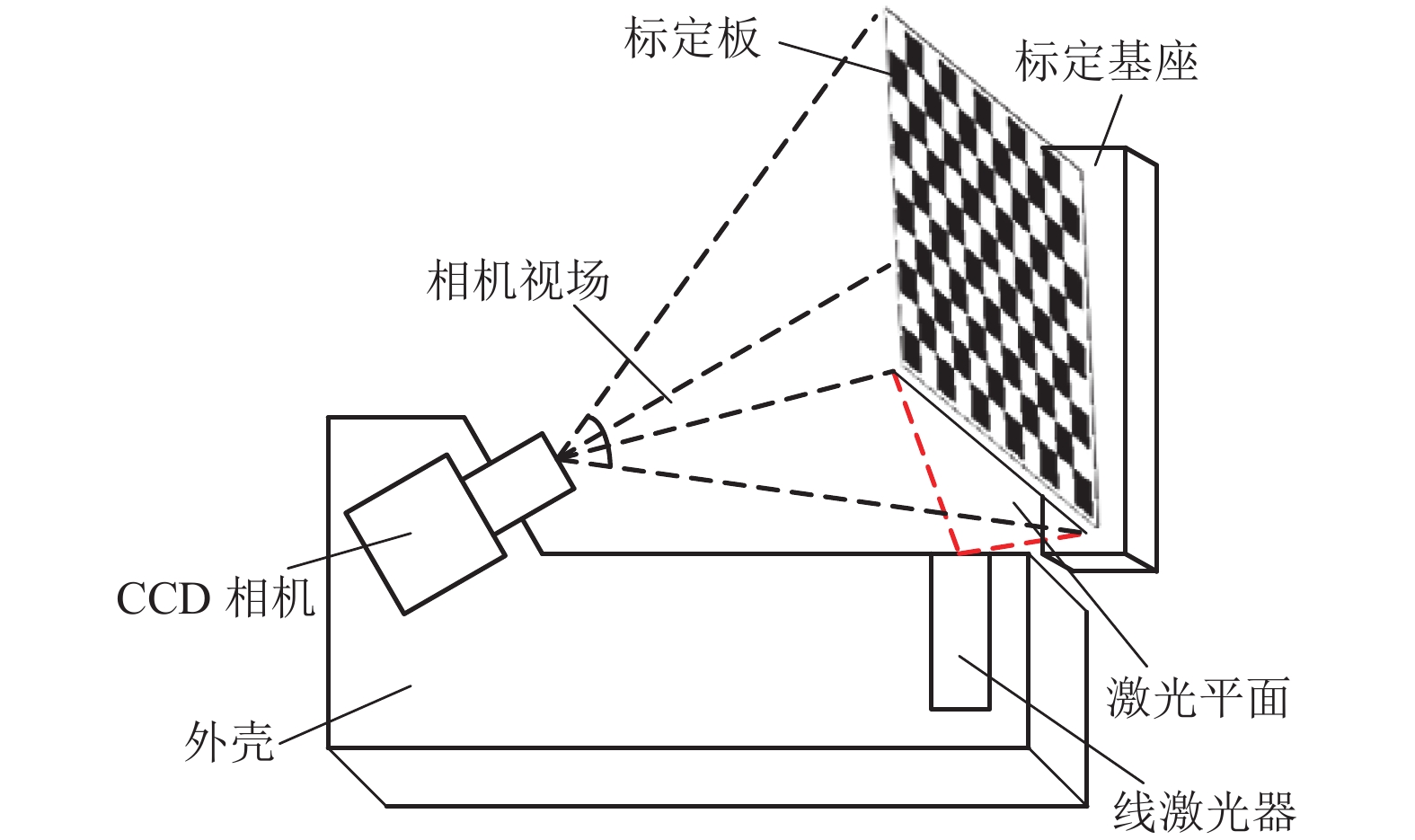

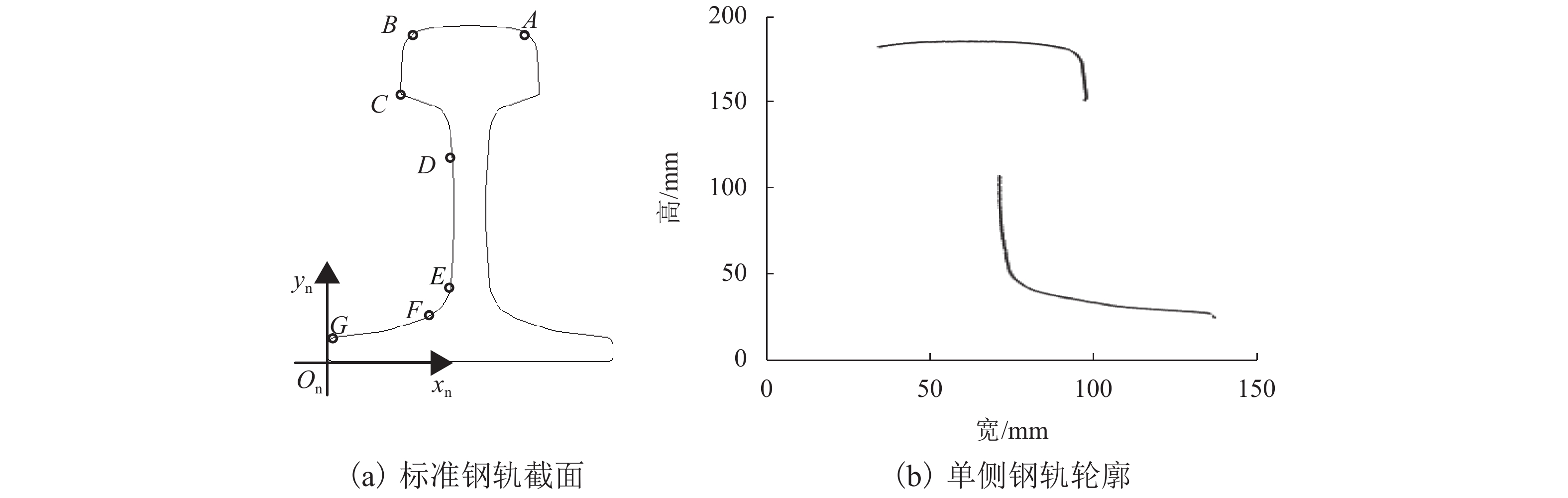

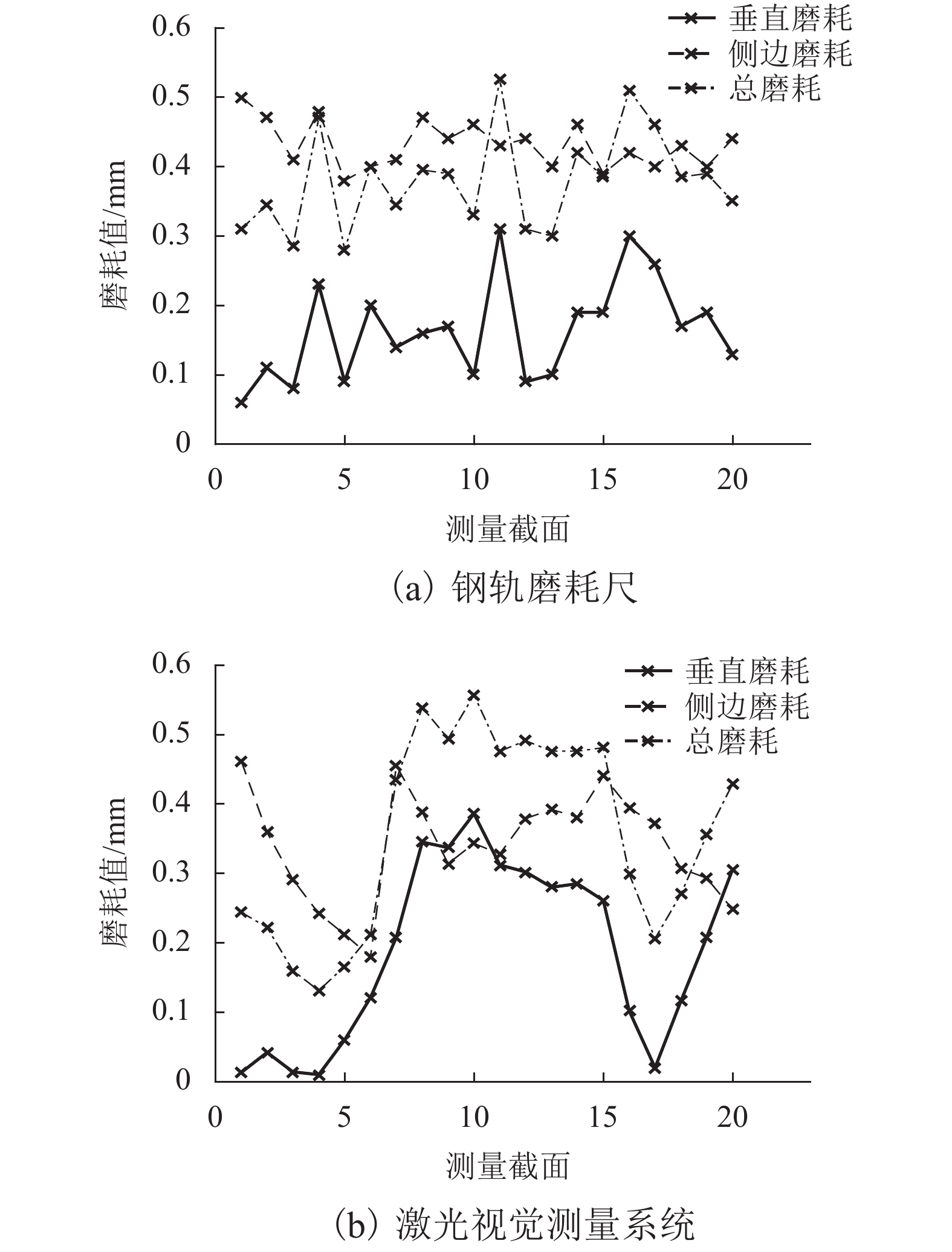

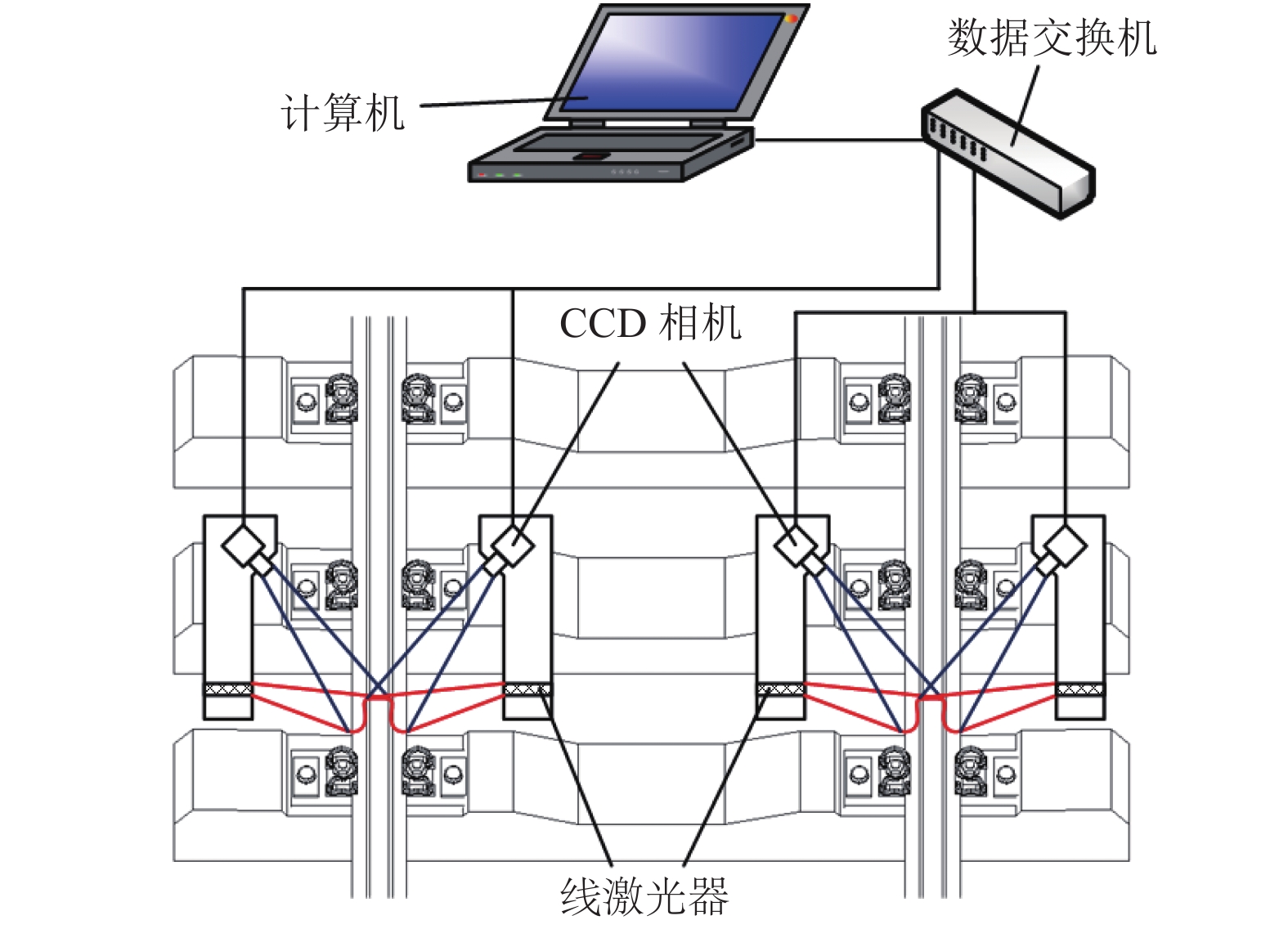

摘要: 钢轨磨耗直接影响铁路运行安全,为了替代目前手工测量方式,提高测量精度和效率,研究并设计了线激光钢轨断面全轮廓视觉测量系统来实现钢轨磨耗动态测量. 首先通过计算激光视觉测量模型完成激光测量单元的结构设计,然后采用平面标定法对测量头进行精确标定,获取激光平面与传感器成像平面之间的映射关系,将拍摄的钢轨轮廓光条图像还原为实际钢轨断面轮廓;利用钢轨同一截面两侧轮廓中轨头踏面轮廓相同的特征获取钢轨断面全轮廓数据,采用ICP精确配准将钢轨两侧测量轮廓合并,其中轨头踏面轮廓采用欧式聚类和距离分割方法提取;最后以双侧未磨损轨腰轮廓及其特征点为基准,将测量钢轨全轮廓与标准钢轨轮廓进行配准对比,获取钢轨磨耗值;将线激光钢轨磨耗测量单元装载于自行研制的轨道测量小车上进行现场测量试验. 研究结果表明:该测量系统标定精度可达4.922 × 10−3 mm,测量速度可达21.6 km/h,与钢轨磨耗尺测量值对比垂直磨耗、侧边磨耗平均偏差约为0.023 mm和0.093 mm,对同一对象多次重复测量最大偏差小于0.05 mm,该测量精度满足公务要求,提高了测量效率,便于铁路测量数字化管理.Abstract: Rail wear directly affects the safety of the railway transportation. To replace the current manual measurement methods and improve the measurement accuracy and efficiency, a laser rail full-profile visual measurement system was researched and designed to realize the dynamic measurement of rail wear. Firstly, the hardware structure of the laser measurement unit was designed by calculating laser vision measurement model. Then, the checkerboard plane calibration method was used to precisely calibrate the laser measurement unit to obtain the projection relationship between the laser plane and the camera plane, so the laser image of rail profile could be converted to the actual profile of rail. Based on the same characteristics of rail head profile on both sides at the same section which could be extracted by Euclidean clustering and distance segmentation, the full profile of rail section could be synthesized by ICP registration method. Finally, the waist contour and characteristic points of the unworn rail on both sides were taken as the datum, the full profile of the measured rail was compared with the standard rail profile, so rail wear was calculated from the difference between them. The laser measurement units were mounted on a self-developed rail measurement trolley for field measurement tests. The results show that the calibration accuracy of the measurement system can reach 4.922 × 10−3 mm and the measurement speed can reach 21.6 km/h. Compared with the rail wear gauge, the average deviation of vertical wear and horizontal wear of this system is 0.023 mm and 0.093 mm. The maximum deviation of the system for repeated measurement of the same object is less than 0.05 mm. The new system meets the demand of rail wear measurement, improves the measurement efficiency, and is convenient for the digital management of railway survey.

-

Key words:

- rail wear /

- rail full profile /

- visual measurement system /

- laser measurement unit /

- calibration /

- ICP registration

-

表 1 相机标定结果

Table 1. Cameras calibration results

相机 标定参数 标定结果 内侧相机 A ${{A}}$ $\left[ {\begin{array}{*{20}{c}} {2\;077.157\;23}&0\;\;\;\;\;\;\;&{486.549\;08} \\ 0\;\;\;\;\;\;\;&{2\;068.912\;80}&{599.250\;88} \\ 0\;\;\;\;\;\;\;&0\;\;\;\;\;\;\;&1\;\;\;\;\;\;\;\;\; \end{array}} \right]$ ${{D}}$ $\left[ {\begin{array}{*{20}{c}} {{\rm{ - 0}}{\rm{.165\;22}}}&{{\rm{2}}{\rm{.437\;94}}}&{{\rm{ - 0}}{\rm{.006\;33}}}&{{\rm{0}}{\rm{.002\;11}}} \end{array}} \right]$ $\left[ {\begin{array}{*{20}{c}} {{R}}&{{t}} \end{array}} \right]$ $\left[ {\begin{array}{*{20}{c}} {{\rm{0}}{\rm{.954\;73}}}&{{\rm{ - 0}}{\rm{.0038\;2}}}\;\;\;\;&{{\rm{0}}{\rm{.297\;45}}}&{{\rm{ - 60}}{\rm{.166\;30}}} \\ {{\rm{0}}{\rm{.126\;0}}}\;\;\;&{{\rm{0}}{\rm{.910\;99}}}&{{\rm{ - 0}}{\rm{.392\;72}}}\;\;\;\;&{{\rm{ - 58}}{\rm{.465\;27}}} \\ {{\rm{ - 0}}{\rm{.269\;47}}}\;\;\;\;&{{\rm{0}}{\rm{.412\;42}}}&{{\rm{0}}{\rm{.870\;23}}}&\;{{\rm{326}}{\rm{.175\;65}}} \end{array}} \right]$ 外侧相机 B ${{A}}$ $\left[ {\begin{array}{*{20}{c}} {2\;550.854\;0}&0\;\;\;\;\;\;\;&{707.001\;42} \\ 0\;\;\;\;&{2\;717.902\;20}&{608.549\;12} \\ 0\;\;\;\;&0\;\;\;\;\;\;\;&1\;\;\;\;\;\;\;\;\;\; \end{array}} \right]$ ${{D}}$ $\left[ {\begin{array}{*{20}{c}} {{\rm{ - 0}}{\rm{.171\;74}}}&{{\rm{1}}{\rm{.537\;84}}}&{{\rm{1}}{\rm{.537\;84}}}&{{\rm{ - 0}}{\rm{.021\;87}}} \end{array}} \right]$ $\left[ {\begin{array}{*{20}{c}} {{R}}&{{t}} \end{array}} \right]$ $\left[ {\begin{array}{*{20}{c}} {{\rm{0}}{\rm{.945\;86}}}&{{\rm{ - 0}}{\rm{.025\;59}}}\;\;\;\;&{{\rm{ - 0}}{\rm{.323\;56}}}&{{\rm{ - 84}}{\rm{.213\;45}}} \\ {{\rm{ - 0}}{\rm{.137\;83}}}\;\;\;\;&{{\rm{0}}{\rm{.870\;87}}}&{{\rm{ - 0}}{\rm{.471\;79}}}&{{\rm{ - 48}}{\rm{.262\;83}}} \\ {{\rm{0}}{\rm{.293\;86}}}&{{\rm{0}}{\rm{.490\;84}}}&\;\;\;{{\rm{0}}{\rm{.820\;20}}}&\;{{\rm{382}}{\rm{.732\;68}}} \end{array}} \right]$ 表 2 钢轨磨耗测量平均值

Table 2. Average results of rail wear measurement

mm 类别 垂直磨耗 侧边磨耗 总磨耗 钢轨磨耗尺 0.163 50 0.431 50 0.379 25 视觉测量系统 0.186 40 0.338 95 0.355 90 偏差 0.022 90 0.092 55 0.023 35 -

金学松,李霞,李伟,等. 铁路钢轨波浪形磨损研究进展[J]. 西南交通大学学报,2016,51(2): 264-273. doi: 10.3969/j.issn.0258-2724.2016.02.006JIN Xuesong, LI Xia, LI Wei, et al. Review of rail corrugation progress[J]. Journal of Southweat Jiaotong University, 2016, 51(2): 264-273. doi: 10.3969/j.issn.0258-2724.2016.02.006 成都铁路局. 轨道检测技术[M]. 北京: 中国铁道出版社, 2008: 92-95. WANG C, MA Z, LI Y, et al. Distortion calibrating method of measuring rail profile based on local affine invariant feature descriptor[J]. Measurement, 2017, 110(6): 11-21. LIU Z, LI F, HUANG B, et al. Real-time and accurate rail wear measurement method and experimental analysis[J]. Journal of the Optical Society of America A —Optics Image Science and Vision, 2014, 31(8): 1721-1729. doi: 10.1364/JOSAA.31.001721 YI B, YANG Y, YI Q, et al. Novel method for rail wear inspection based on the sparse iterative closest point method[J]. Measurement Science and Technology, 2017, 28(12): 1252-1258. 王培俊,吕东旭,陈鹏. 高速道岔尖轨点云的复合拼接及数据处理优化[J]. 西南交通大学学报,2018,53(4): 806-812. doi: 10.3969/j.issn.0258-2724.2018.04.019WANG Peijun, LU Dongxu, CHEN Peng. Complex point cloud registration and optimized data processing for high-speed railway turnout[J]. Journal of Southweat Jiaotong University, 2018, 53(4): 806-812. doi: 10.3969/j.issn.0258-2724.2018.04.019 MINBASHI N, BAGHERI M, GOLROO A, et al. Turnout degradation modelling using new inspection technologies: a literature review[C]//Current Trends in Reliability, Availability, Maintainability and Safety.[S.l.]: Springer International Publishing, 2016: 49-63. RUSU M, ROBERTS C, KENT S. The use of a laser based trolley for railway switch and crossing inspection[J]. International Journal of COMADEM, 2013, 16: 13-23. SUN J, LIU Z, ZHAO Y, et al. Motion deviation rectifying method of dynamically measuring rail wear based on multi-line structured-light vision[J]. Optics And Laser Technology, 2013, 50(2): 25-32. 伯特霍尔德•霍恩. 机器视觉[M]. 北京: 中国青年出版社, 2014: 19-29. 徐刚. 由2维影像建立3维模型[M]. 武汉: 武汉大学出版社, 2006: 6-14. ZHANG Z Y. A flexible new technique for camera calibration[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2000, 22(11): 1330-1334. doi: 10.1109/34.888718 MADSEN K, NIELSEN H B, TINGLEFF O. Methods for nonlinear least squares problems[J]. Society for Industrial & Applied Mathematics, 2004(1): 1409-1415. RAVISHANKAR S, DUTT H N V, GURUMOORTHY B. Automated inspection of aircraft parts using a modified ICP algorithm[J]. International Journal of Advanced Manufacturing Technology, 2010, 46(1/2/3/4): 227-236. EGGERT D W, LORUSSO A, FISCHER R B. Estimating 3-D rigid body transformations:a comparison of four major algorithms[J]. Machine Vision And Applications, 1997, 9(5/6): 272-290. 孙丰荣,刘积仁. 快速霍夫变换算法[J]. 计算机学报,2001,24(10): 1102-1109. doi: 10.3321/j.issn:0254-4164.2001.10.013SUN Fengrong, LIU Jiren. Fast hough transform algorithm[J]. Chinese Journal Computer, 2001, 24(10): 1102-1109. doi: 10.3321/j.issn:0254-4164.2001.10.013 中华人民共和国铁道部. 高速铁路无砟轨道线路维修规则(试行)[M]. 北京: 中国铁道出版社, 2013: 20-23. STEGER C. An unbiased detector of curvilinear structures[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 1998, 20(2): 113-125. doi: 10.1109/34.659930 -

下载:

下载: