Force Transfer and Deformation Mechanism of Single Ring Structure of Prefabricated Subway Station

-

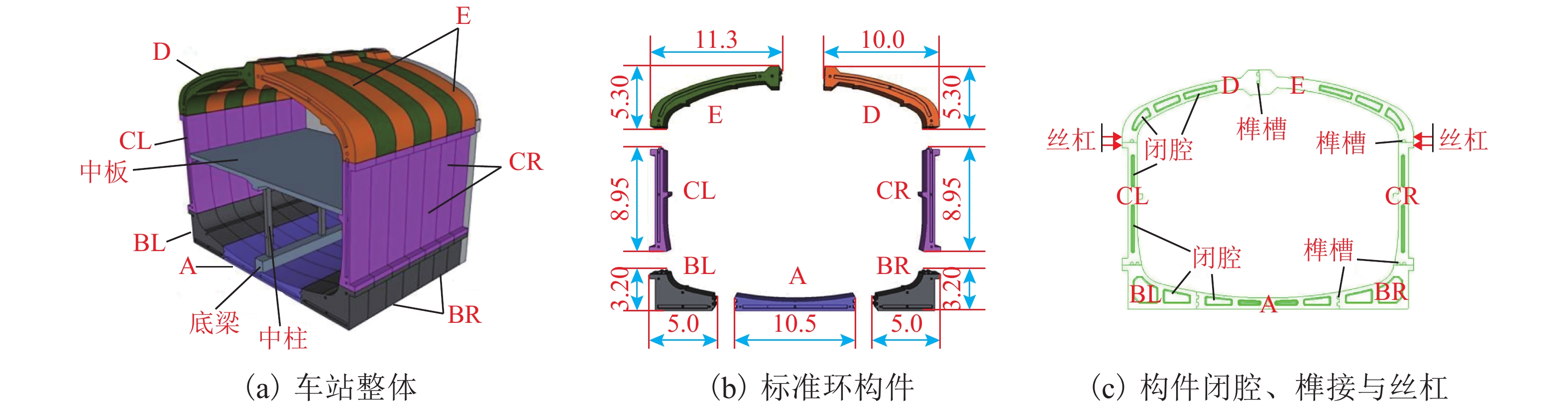

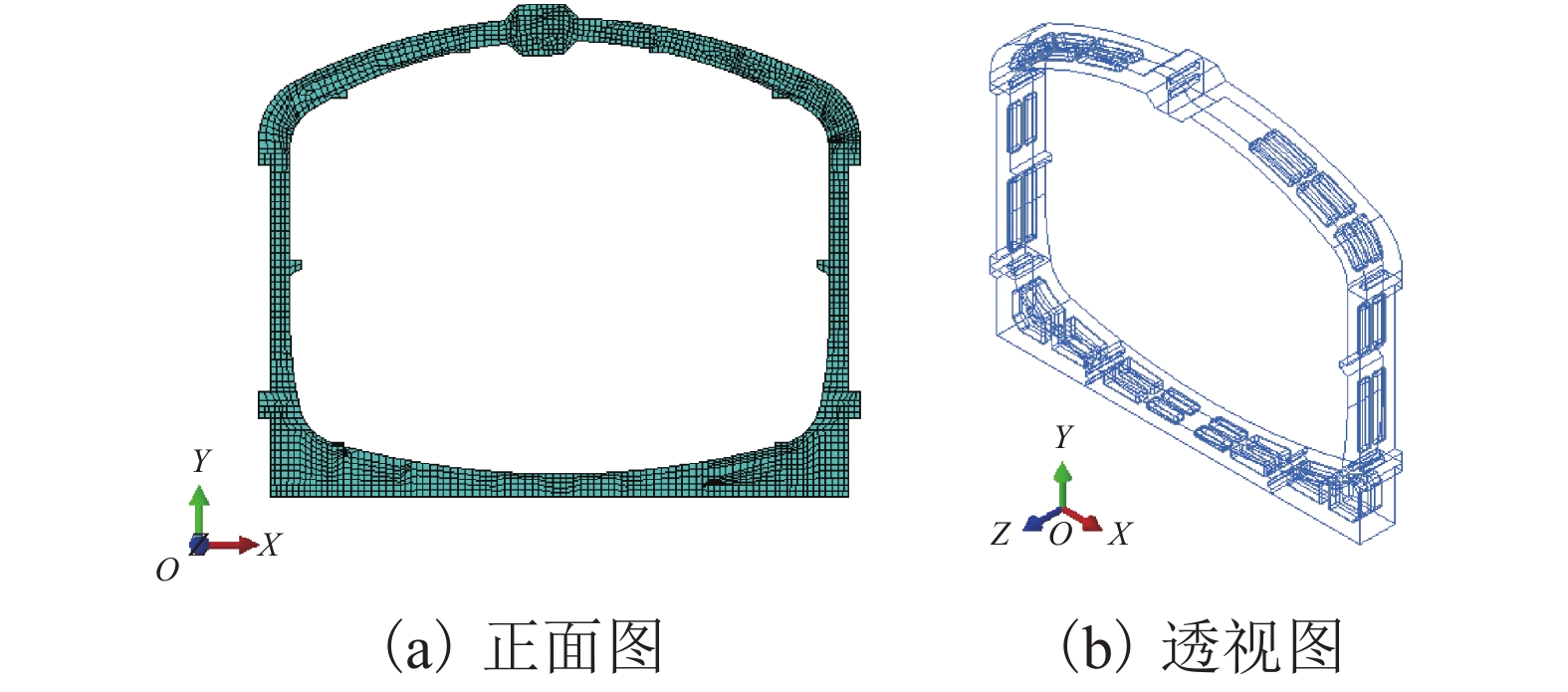

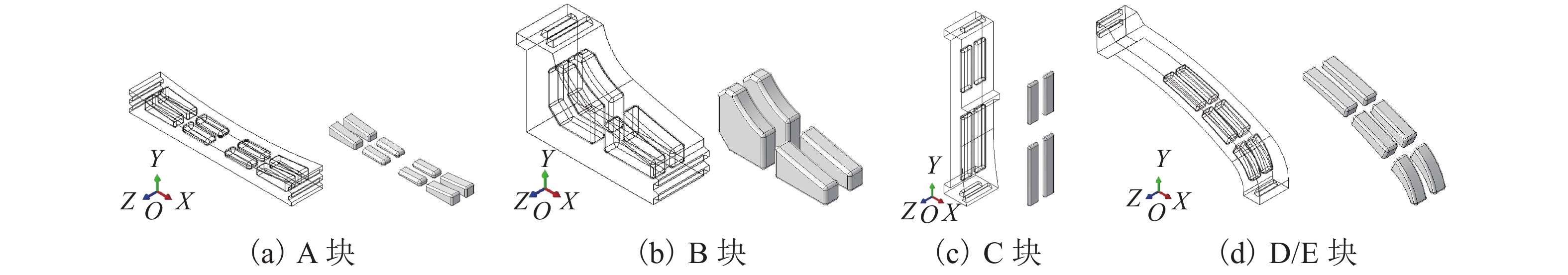

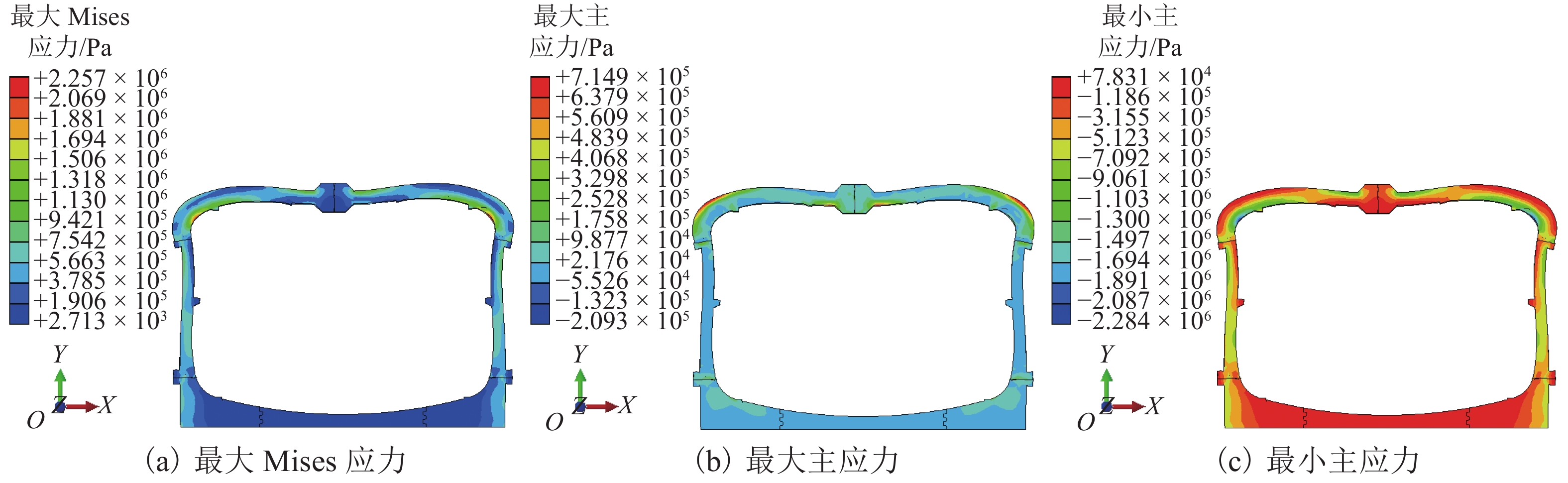

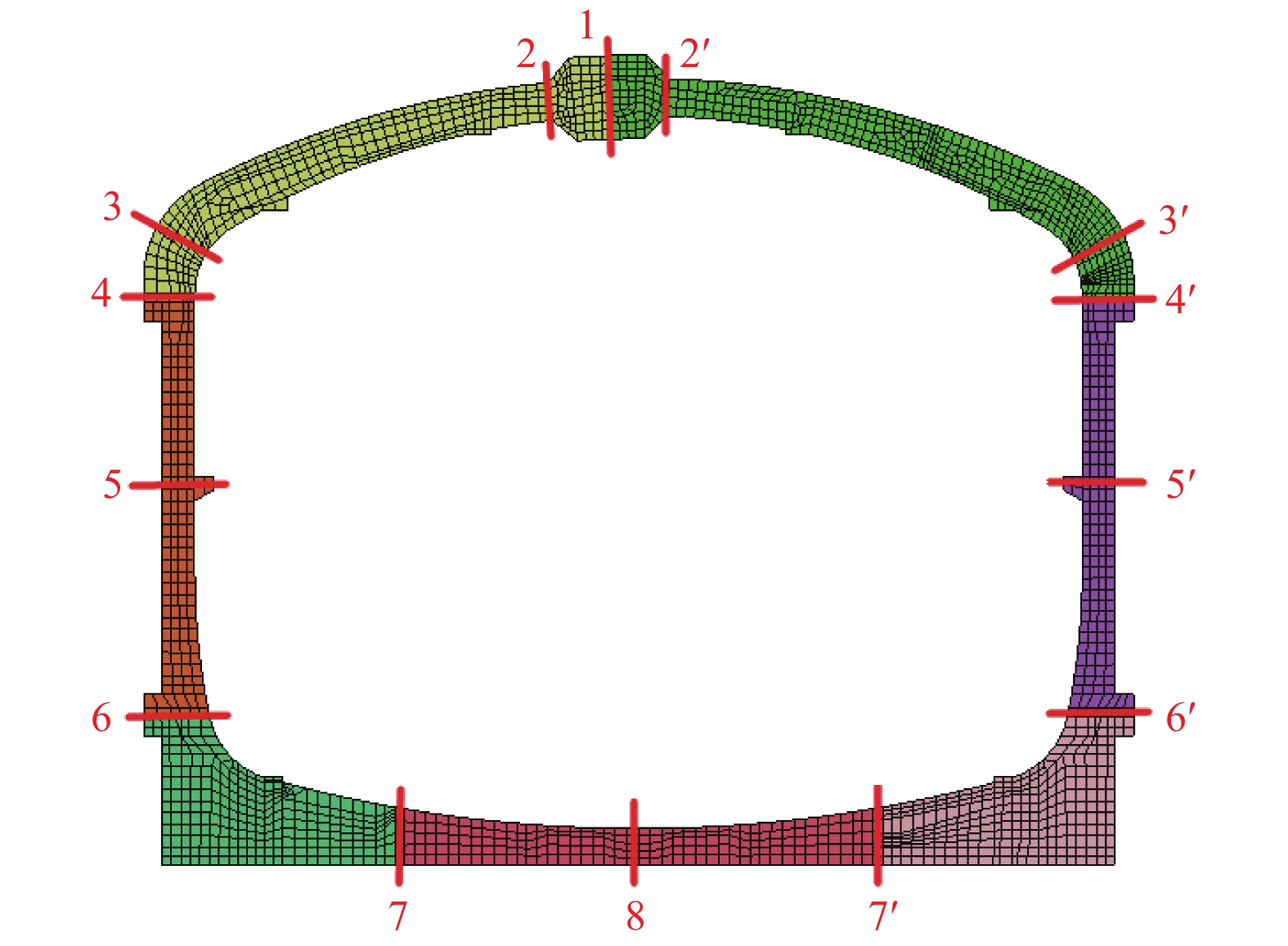

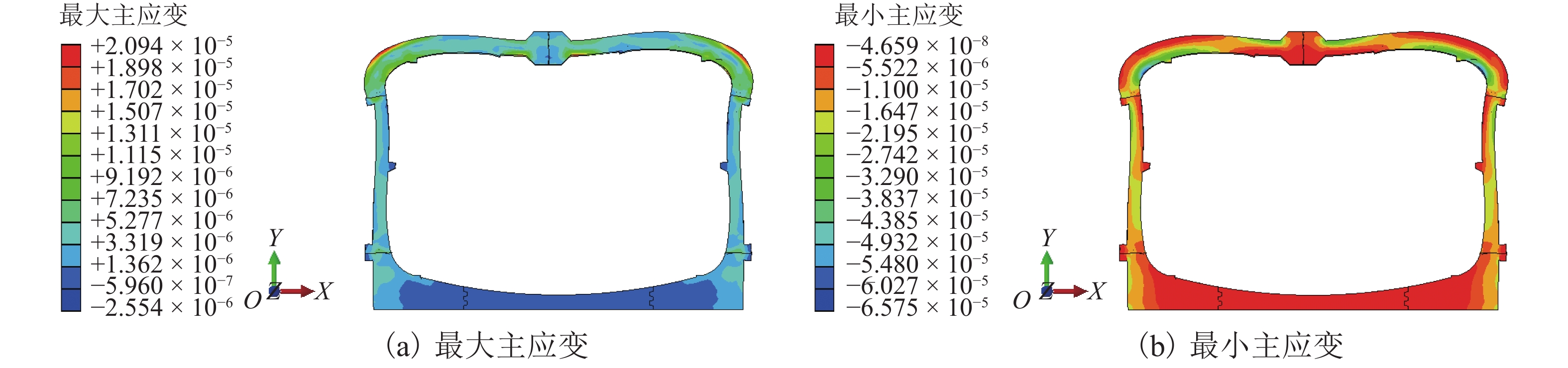

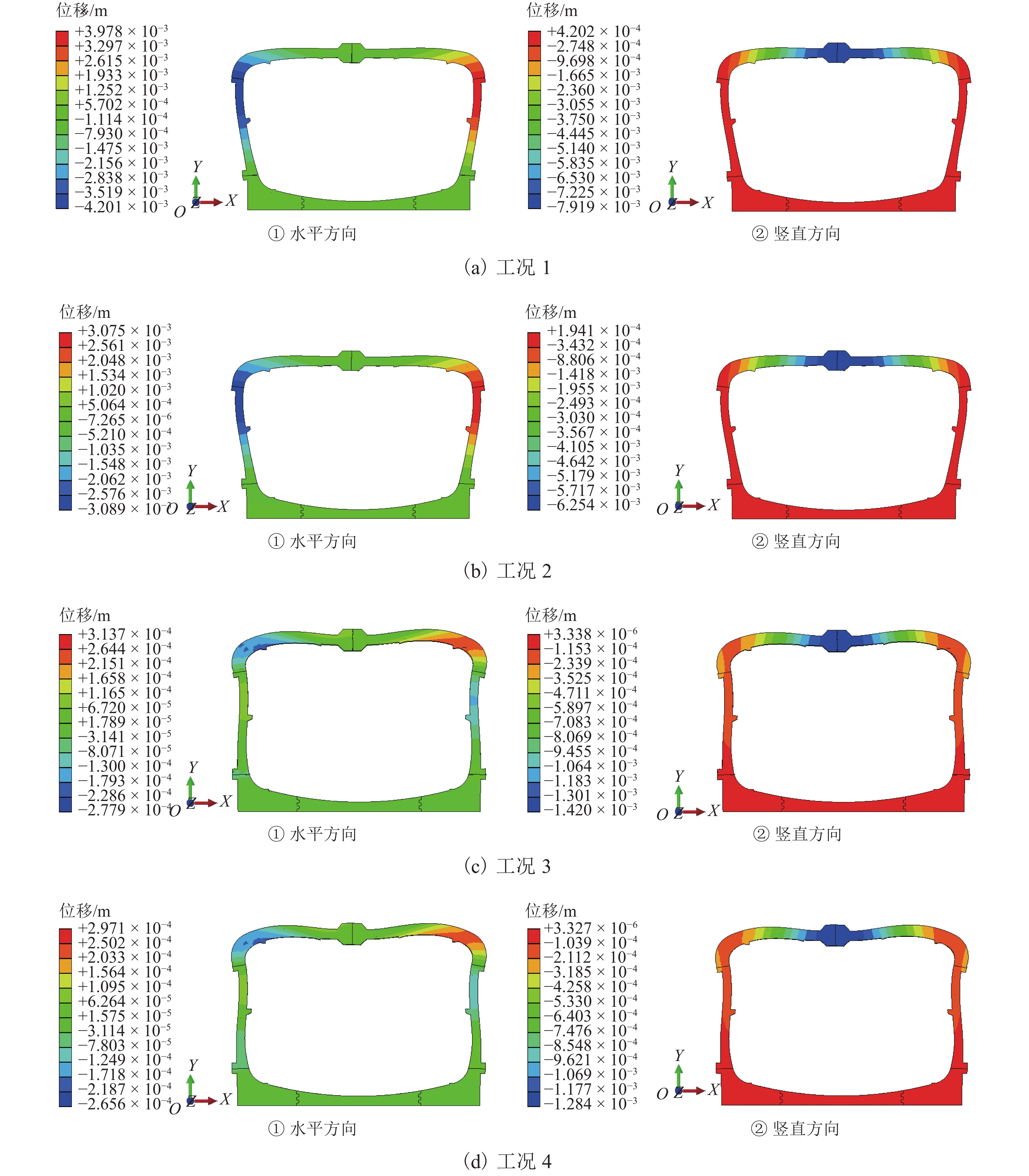

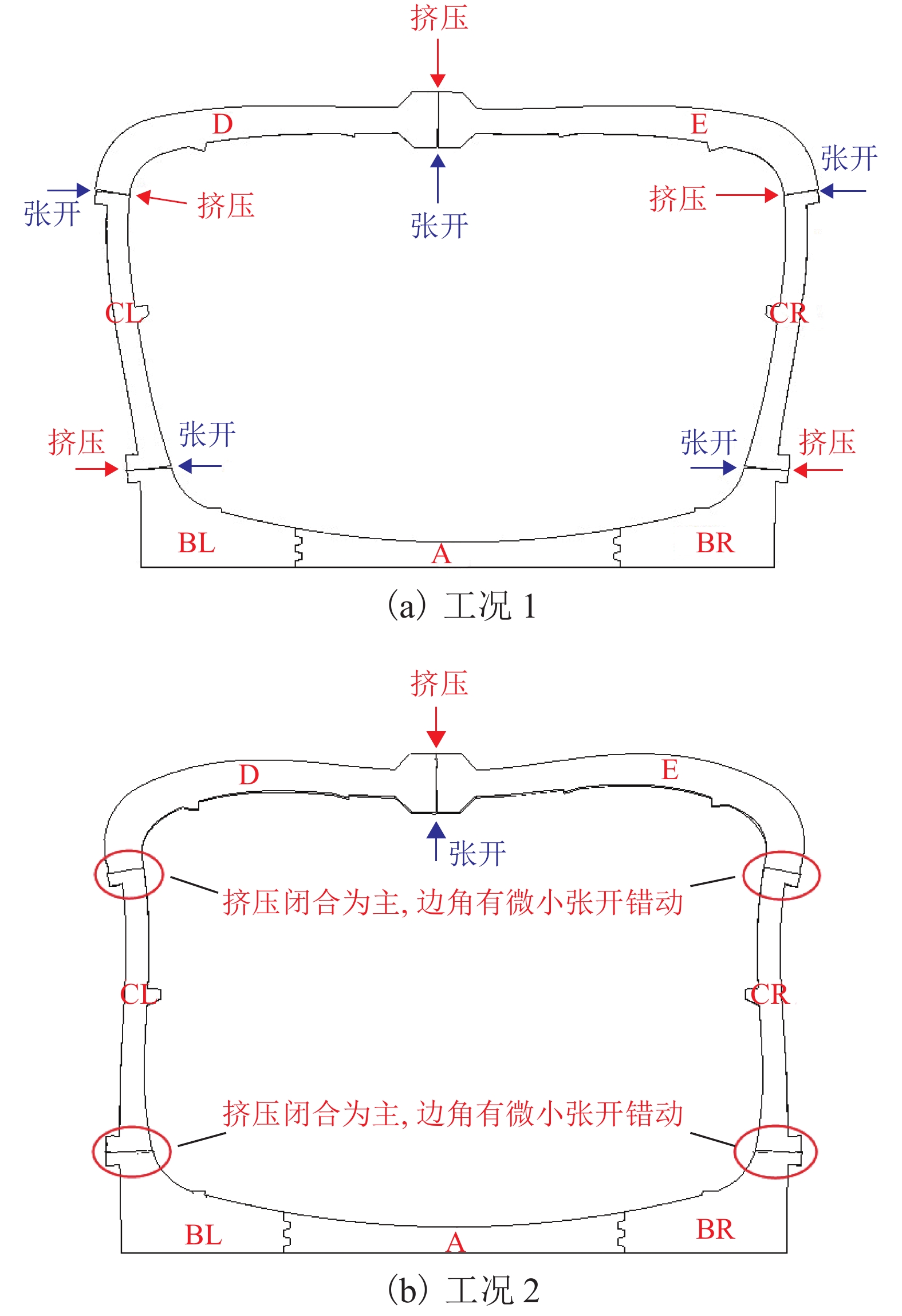

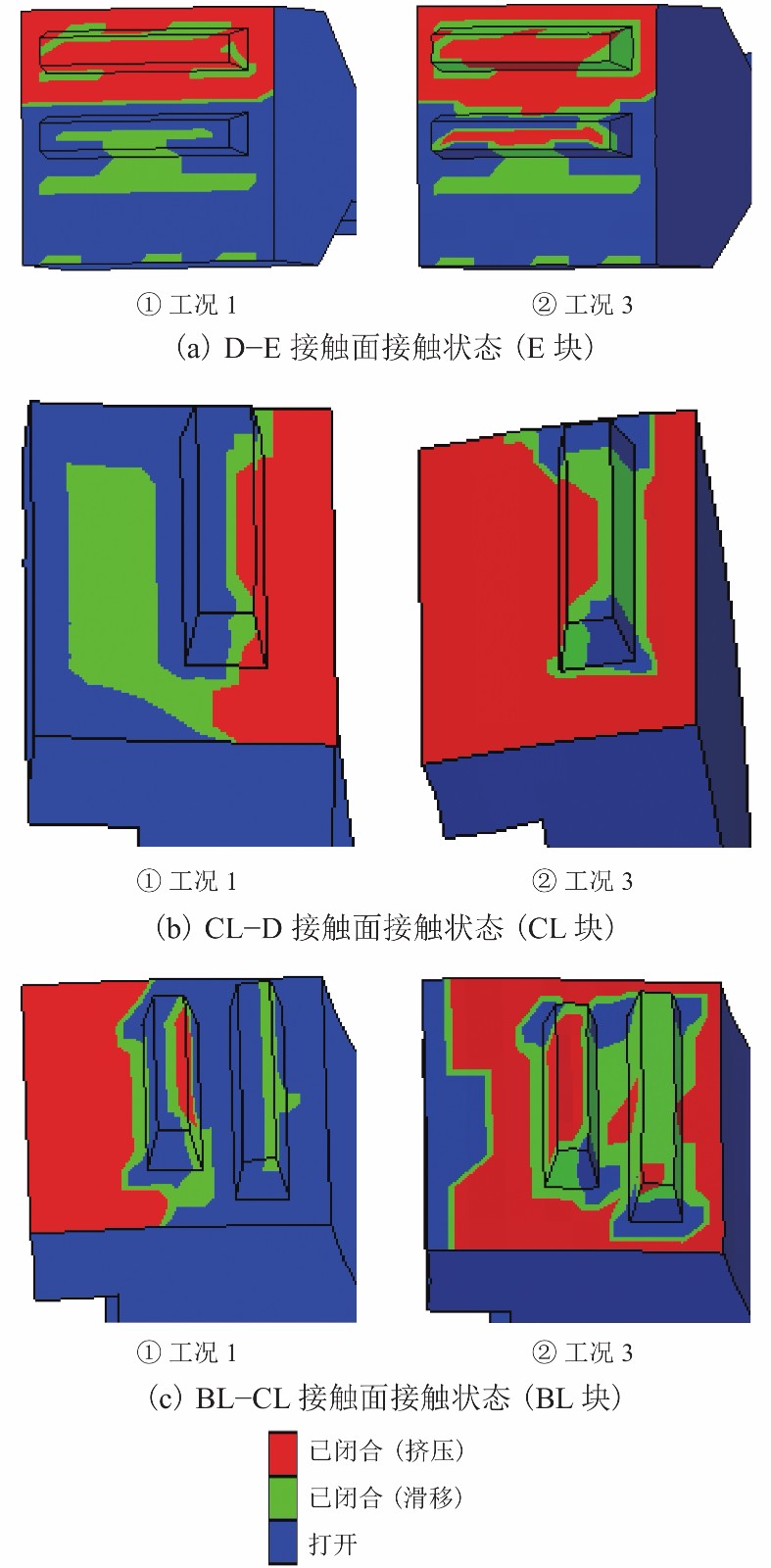

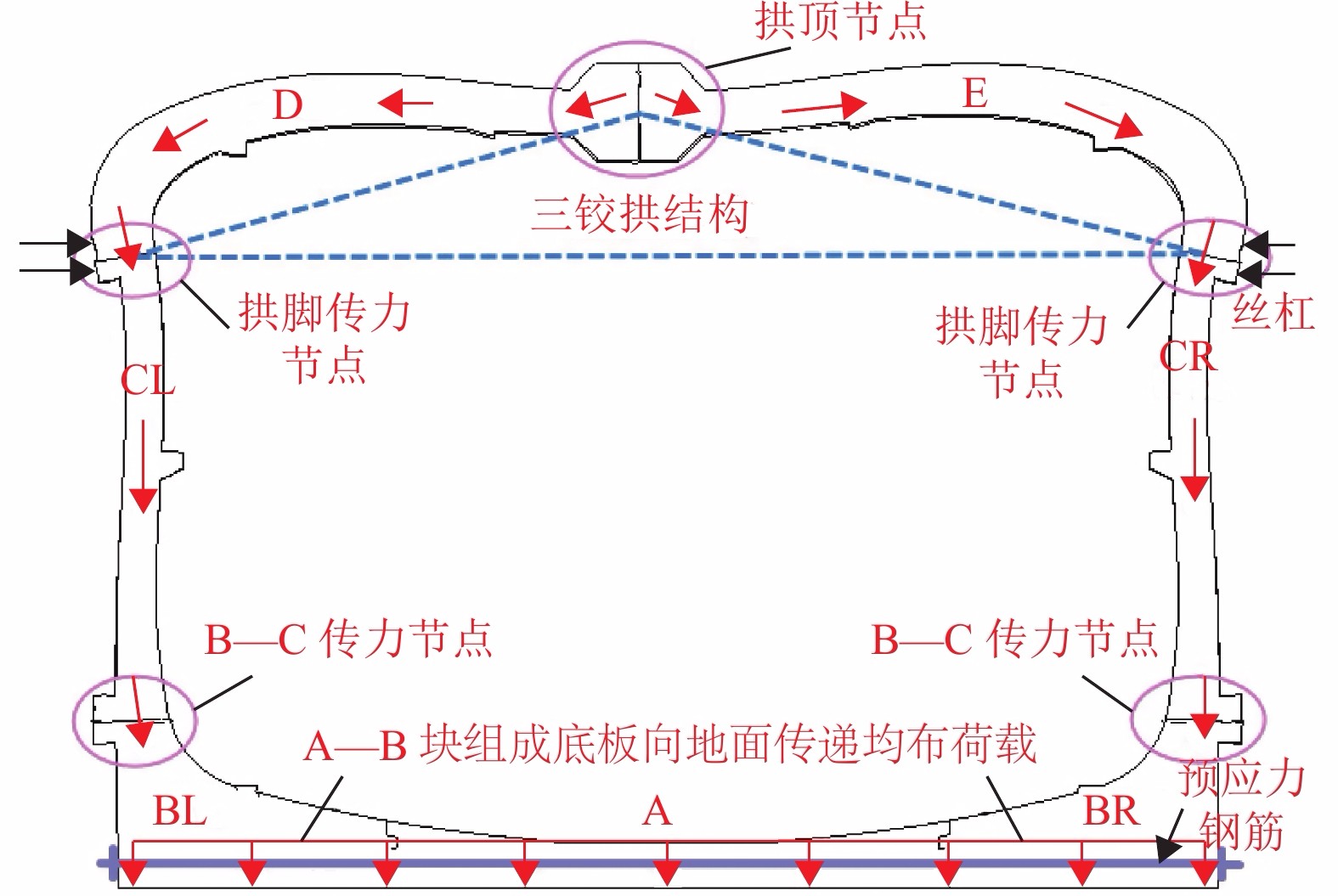

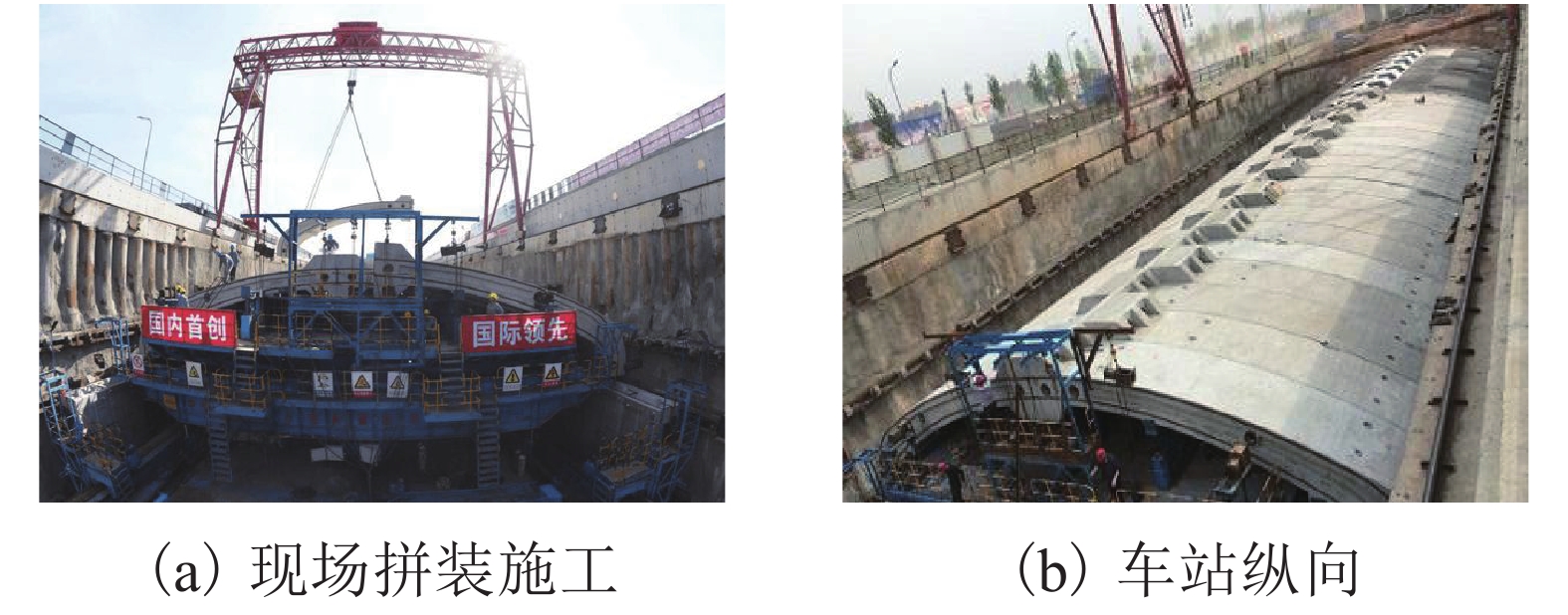

摘要: 为了研究新型装配式车站结构的力学与变形性能,以长春某国内首例预制装配式地铁车站为背景,基于有限元软件ABAQUS对装配式地铁车站单环结构拼装成环后传力与变形机理进行研究. 首先,建立了不同结构形式与钢丝杠支撑组合的4种工况数值模型;其次,对结构在自重作用下的力学、变形和接头接触性能进行了对比分析;最后,揭示了该类型预制装配式地铁车站单环结构的传力与变形机理. 研究结果表明:钢丝杠的支撑作用不容忽视,在拱脚外侧增设水平钢丝杠后,结构最大Mises应力降低约40%,最大主应力降低约80%,最大水平位移降低约90%,拱顶挠度降低约80%,结构内部降剪、降弯效果明显;接头接触状态发生明显变化,除拱顶D-E接头外其余接头接触面挤压面积比例显著增大,拼装结构基本达到了传力稳定可靠、变形安全可控的设计要求,整体自稳能力显著提升. 钢丝杠与拼装结构协同工作优化了单环结构的传力路径,有效限制了结构的水平与竖直变形,该类型装配式结构的力学与变形性能优于未设置钢丝杠的现浇结构的对应指标.Abstract: In order to study the mechanical and deformation properties of the new prefabricated subway station, took the first prefabricated subway station in Changchun as the background, based on the large-scale general finite element software ABAQUS, the force transfer and deformation mechanism of the single-ring structure of the prefabricated subway station after assembling into a ring were studied.Four numerical models of different structure types and steel bars bracing combination were established. The mechanical, deformation and joint contact surfaces performances of the structure under the action of self-weight were compared and analyzed. The force transfer and deformation mechanism of the type of prefabricated subway station single ring structure were revealed. The results show that the supporting function of steel bars could not be ignored. After added horizontal steel bars to the outside of arch foot, the maximum Mises stress of the structure was reduced by about 40%, the maximum principal stress was reduced by about 80%, the maximum horizontal displacement was reduced by about 90%, and the deflection of the vault was reduced by about 80%, the shear force and bending moment of the structure decreased obviously. The contact state of the joints changed obviously, and the extrusion area ratio of the other joints increased significantly except the D-E joint of the vault, the assembled structure basically met the design requirements of stable and reliable force transmission, safe and controllable deformation, and the overall self-stabilization ability was significantly improved. The cooperative work of steel bars and assembled structure optimized the transmission path of single-ring structure, limited the horizontal and vertical deformation of the structure effectively, the mechanical and deformation performance of this type of fabricated structure was better than the corresponding index of the cast-in-place structure without the steel bar.

-

表 1 工况设置

Table 1. Working conditions setting

工况 说明 接头形式 钢丝杠 荷载 1 装配式结构 接触面 无 自重 2 现浇结构 绑定 无 3 装配式结构 + 丝杠 接触面 有 4 现浇结构 + 丝杠 绑定 有 表 2 结构应力极值及位置统计

Table 2. Statistics of extreme value and location of structural stress

MPa 工况 最大 Mises 应力 最大主应力(受拉) 最小主应力(受压) 应力 位置 应力 位置 应力 位置 1 3.80 C 块上部内侧和

拱顶变截面处3.54 C 块上部外侧和

D—E 接头下侧变截面处−3.91 C 块上部内侧和 D—E

接头上侧变截面处2 3.81 3.41 −3.91 3 2.25 拱脚内侧 0.71 D—E 接头下侧变截面处和

拱腰外侧−2.28 拱脚内侧 4 2.18 0.83 −2.20 表 3 结构主应变及位置

Table 3. Structure main strain values and positions

×10−6 工况 最大主应变(受拉) 最小主应变(受压) 应变 位置 应变 位置 1 100 C 块上部外侧和 D—E 接头下侧变截面处 −112 C 块上部内侧和 D—E接头上侧变截面处 2 94 −112 3 22 D—E 接头下侧变截面处和拱腰外侧 −63 拱脚内侧 4 20 −65 表 4 结构位移最大值及位置统计

Table 4. Maximum and position statistics of structural displacements

mm 工况 构件块

名称水平挠度 竖直(拱顶挠度) 位移

最大值位置 位移

最大值位置 1 D −4.20 拱脚 7.91 D—E

接头

(拱顶)E 3.97 2 D −3.08 6.25 E 2.07 3 D −0.28 拱腰 1.42 E 0.31 4 D 0.26 1.28 E 0.29 表 5 各接触面变形与最大法向接触应力

Table 5. Deformation and maximum normal contact stress at each contact surface

接头

位置工况 1(无钢丝杠) 工况 3(有钢丝杠) 最大张开

距离/mm最大转角/(°) 最大法向接触应力/MPa 最大张开

距离/mm最大转角/(°) 最大法向接触应力/MPa 压 拉 压 拉 D—E 1.13 0.072 1.70 −0.90 1.03 0.067 0.68 0.33 CL—D 1.25 0.130 3.25 −1.78 1.01 − 0.39 0 CR—E 1.15 0.120 3.10 −2.40 1.01 − 0.41 0 BL—CL 1.30 0.105 0.98 −0.46 1.01 − 0.68 −0.01 BR—CR 1.29 0.104 0.91 −0.49 1.01 − 0.64 −0.01 -

DING Peng, TAO Lianjin, YANG Xiuren, et al. Three-dimensional dynamic response analysis of a single-ring structure in a prefabricated subway station[J]. Sustainable Cities and Society, 2019, 45: 271-286. doi: 10.1016/j.scs.2018.11.010 MARTH V. Achieving sustainability with precast concrete[J]. PCI Journal, 2006, 51(1): 42-61. doi: 10.15554/pcij.01012006.42.61 TAO Lianjin, DING Peng, SHI Cheng, et al. Shaking table test on seismic response characteristics of prefabricated subway station structure[J]. Tunnelling and Underground Space Technology, 2019, 91: 102994.1-102994.25. AKIN A, SEZER R. A study on strengthening of reinforced concrete frames using precast concrete panels[J]. KSCE Journal of Civil Engineering, 2016, 20(6): 1-8. HA S K, YU S Y, KIM J S. Experimental study on existing reinforced concrete frames strengthened by L-type precast concrete wall panels to earthquake-proof buildings[J]. KSCE Journal of Civil Engineering, 2018, 22(9): 1-13. KESNER K, BILLINGTON S L. Investigation of infill panels made from engineered cementitious composites for seismic strengthening and retrofit[J]. Journal of Structural Engineering, 2005, 131(11): 1712-1720. doi: 10.1061/(ASCE)0733-9445(2005)131:11(1712) 丁鹏,陶连金,杨秀仁,等. 预制装配式地铁车站闭腔构造优化设计[J]. 北京工业大学学报,2019,45(10): 946-955.DING Peng, TAO Lianjin, YANG Xiuren, et al. Optimum design of closed cavity structure for prefabricated metro station[J]. Journal of Beijing University of Technology, 2019, 45(10): 946-955. 丁鹏,杨秀仁,高向宇,等. 单拱大跨预制装配式地铁车站水平与竖直的地震响应[J]. 黑龙江科技大学学报,2018,28(6): 630-637. doi: 10.3969/j.issn.2095-7262.2018.06.006DING Peng, YANG Xiuren, GAO Xiangyu, et al. Horizontal and vertical seismic response of single-arch and large-span prefabricated subway stations[J]. Journal of Heilongjiang University of Science and Technology, 2018, 28(6): 630-637. doi: 10.3969/j.issn.2095-7262.2018.06.006 杨秀仁,黄美群. 地铁车站预制装配新技术研究策略[J]. 都市快轨交通,2018,31(1): 78-85. doi: 10.3969/j.issn.1672-6073.2018.01.012YANG Xiuren, HUANG Meiqun. Study on seismic performance of sidewall joints in assembled monolithic subway station[J]. China Civil Engineering Journal, 2018, 31(1): 78-85. doi: 10.3969/j.issn.1672-6073.2018.01.012 赖永标,王梦恕,油新华,等. 隧道与地下工程支护预制技术综述与展望[J]. 建筑技术开发,2015,42(1): 24-28. doi: 10.3969/j.issn.1001-523X.2015.01.006LAI Yongbiao, WANG Mengshu, YOU Xinhua, et al. Overview and outlook for protection and prefabrication techniques of tunnel and underground projects[J]. Building Technique Development, 2015, 42(1): 24-28. doi: 10.3969/j.issn.1001-523X.2015.01.006 张弛. 法国大跨度隧道预制管片装配法施工技术[J]. 现代世界隧道,1997(2): 10-18. 王德超,王国富,乔南,等. 预制装配式结构在地下工程中的应用及前景分析[J]. 中国科技论文,2018,13(1): 115-120. doi: 10.3969/j.issn.2095-2783.2018.01.023WANG Dechao, WANG Guofu, QIAO Nan, et al. The application and prospect analysis of prefabricated construction in underground engineering[J]. China Science paper, 2018, 13(1): 115-120. doi: 10.3969/j.issn.2095-2783.2018.01.023 李兆平, 王臣, 苏会峰, 等. 装配式地铁车站结构接头混凝土裂缝及接缝变形规律试验研究[J]. 土木工程学报, 2015, 48(增刊1): 409-413.LI Zhaoping, WANG Chen, SU Huifeng, et al. An experiment study on the evolution law of concrete structure crack and joint seam deformation for tenon groove joints in the prefabricated metro station[J]. China Civil Engineering Journal, 2015, 48(S1): 409-413. 李兆平,王臣,苏会峰,等. 预制装配式地铁车站结构榫槽式接头力学性能研究[J]. 中国铁道科学,2015,36(5): 7-11. doi: 10.3969/j.issn.1001-4632.2015.05.02LI Zhaoping, WANG Chen, SU Huifeng, et al. Mechanical property of tenon-groove joints for metro station constructed by prefabricated structure[J]. China Railway Science, 2015, 36(5): 7-11. doi: 10.3969/j.issn.1001-4632.2015.05.02 LIU Hongtao, YAN Qiushi, DU Xiuli. Seismic performance comparison between precast beam joints and cast-in-place beam joints[J]. Advances in Structural Engineering, 2017, 20(9): 1299-1314. doi: 10.1177/1369433216674952 路林海,王国富,王婉婷,等. 地铁车站基坑预制桩-墙结构设计与受力分析[J]. 铁道工程学报,2017,34(10): 93-98. doi: 10.3969/j.issn.1006-2106.2017.10.018LU Linhai, WANG Guofu, WANG Wanting, et al. Research on the structure design and mechanics analysis of the precast pile-retaining wall for metro station[J]. Journal of Railway Engineering Society, 2017, 34(10): 93-98. doi: 10.3969/j.issn.1006-2106.2017.10.018 路林海,韩帅,陈振兴,等. 采用承插式桩接头的预制方桩受弯承载性能研究[J]. 建筑结构学报,2018,39(2): 153-161.LU Linhai, HAN Shuai, CHEN Zhenxing, et al. Study on bending performance of prefabricated square pile with socket and spigot joint[J]. Journal of Building Structures, 2018, 39(2): 153-161. 中华人民共和国住房和城乡建设部. 混凝土结构设计规范: GB 50010—2010 [S]. 北京: 中国建筑工业出版社, 2011. -

下载:

下载: