|

井国庆. 铁路有砟道床[M]. 北京: 中国铁道出版社, 2013: 8-10.

|

|

曾树谷. 铁路散粒体道床[M]. 北京: 中国铁道出版社, 1997: 41.

|

|

RAYMOND G P. Research on railroad ballast specification and evaluation[J]. Transportation Research Record, 1985, 1006: 1-8.

|

|

ANOCHIE-BOATENG J K, KOMBA J J, MVELASE G M. Three-dimensional laser scanning technique to quantify aggregate and ballast shape properties[J]. Construction and Building Materials, 2013, 43: 389-398. doi: 10.1016/j.conbuildmat.2013.02.062

|

|

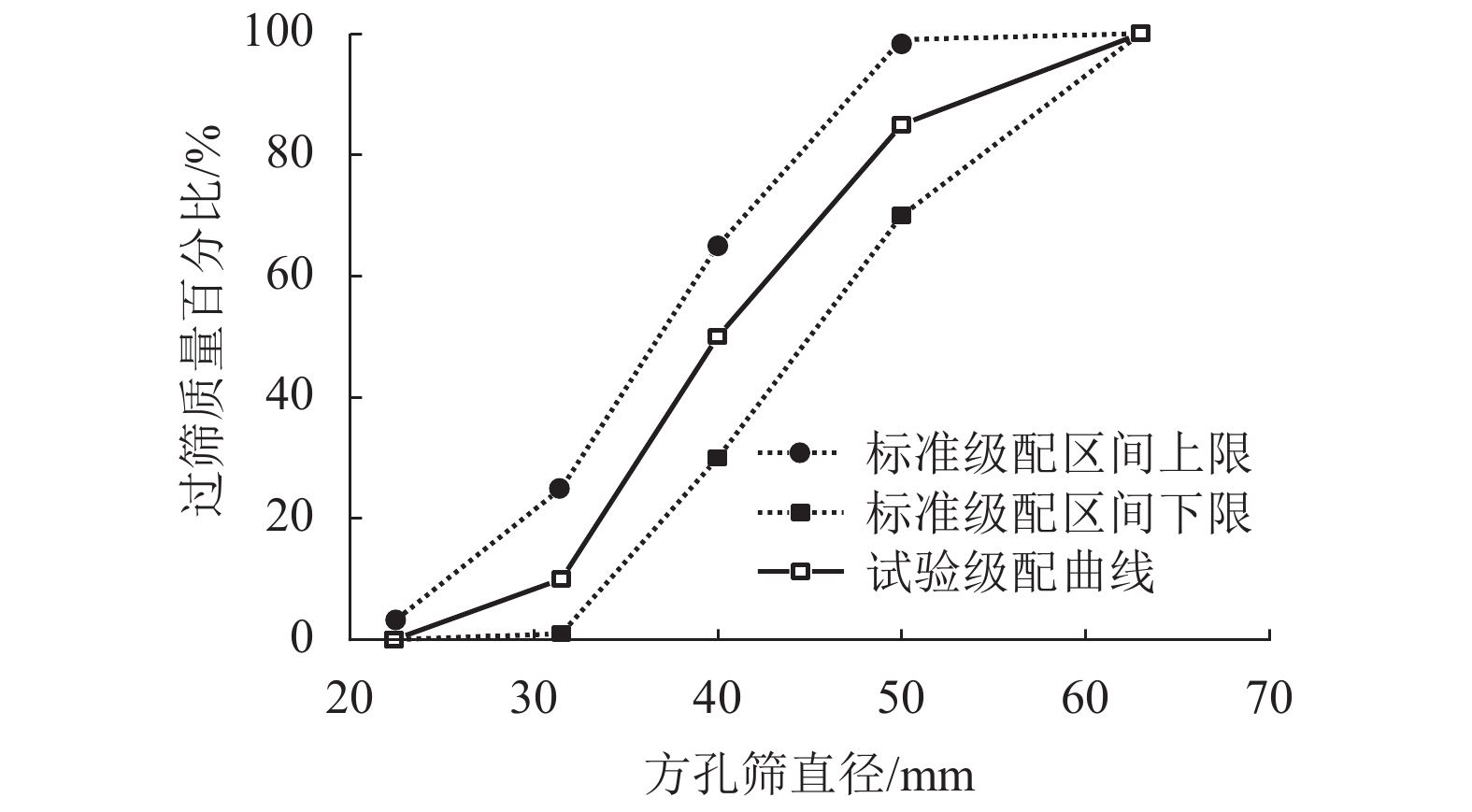

中华人民共和国铁道部. 铁路碎石道砟: TB/T 2140—2008[S]. 北京: 中国铁道出版社, 2008.

|

|

American Society of Testing and Materials. Standard test method for flat particles, elongated particles, or flat and elongated particles in coarse aggregate: D 4791—2010[S]. West Conshohocken: ASTM International, 2010.

|

|

SELIG E T, WATERS J M. Track geotechnology and substructure management[M]. London: Thomas Telford, 1994.

|

|

Australian Standard. Methods for sampling and testing aggregates-method 14: particle shape, by proportional caliper: AS 1141.14—2007[S]. Sydney: Standards Australia Ltd., 2007

|

|

Australian Standard Institution. Methods for sampling and testing aggregates-method 15: flakiness index: AS1141.15—1999[S]. Sydney: Standards Australia Ltd., 1999.

|

|

British Standards Institution. Tests for geometrical properties of aggregates—part 3: determination of particle shape—flakiness index: EN 933-3—2012[S]. London: BSI Standards Ltd., 2012.

|

|

British Standards Institution. Tests for geometrical properties of aggregates—part 4: determination of particle shape —shape index: EN 933-4 —2000[S]. London: BSI Standards Ltd., 2000.

|

|

American Railway Engineering and Maintenance-of-Way Association. Manual for railway engineering[M]. Lanham: American Railway Engineering Association, 2012: 5-10.

|

|

Australian Standard. Aggregates and rock for engineering purposes—part 7: railway ballast: AS 2758.7—2015[S]. Sydney: SAI Global Ltd., 2015

|

|

中华人民共和国铁道部. 铁路碎石道砟: TB/T 2140—1990[S]. 北京: 中国铁道出版社, 1990.

|

|

American Society of Testing and Materials. Standard test method for direct shear test of soils under consolidated drained conditions: D3080—2011[S]. West Conshohocken: ASTM International, 2011.

|

|

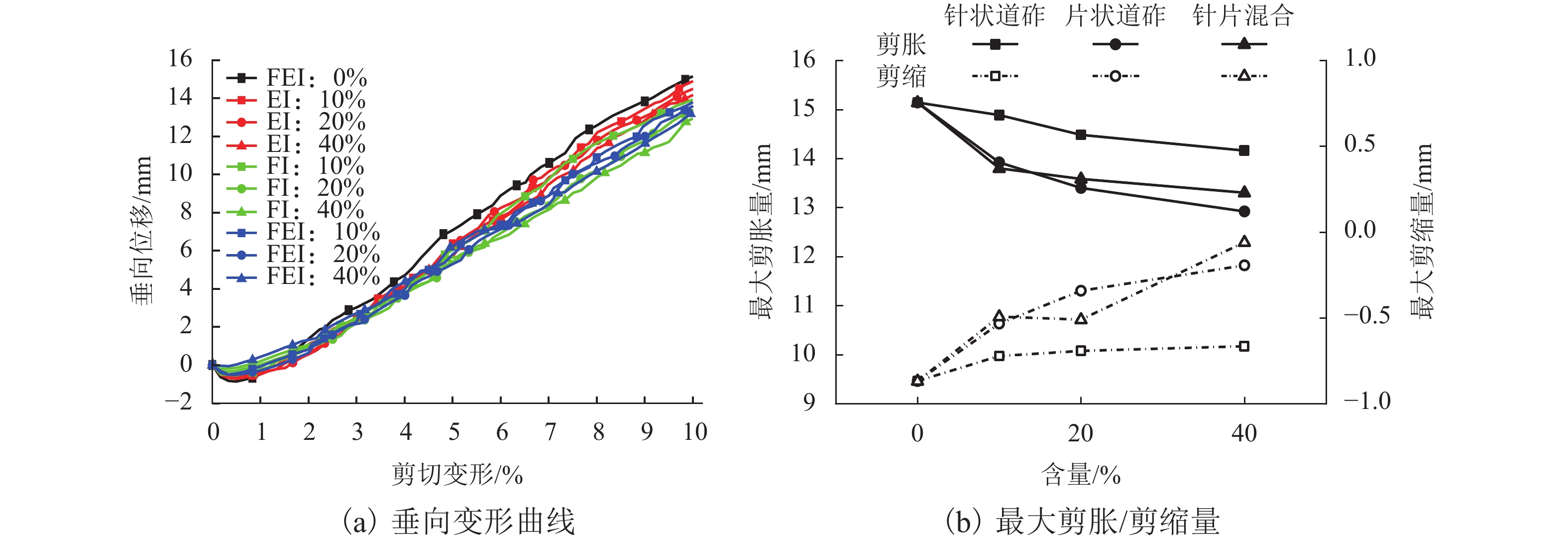

MISHRA D, MAHMUD S M N. Effect of particle size and shape characteristics on ballast shear strength: a numerical study using the direct shear test[C]//Proceeding of the 2017 Joint Rail Conference. Philadelphia: American Society of Mechanical Engineers, 2017: 1-10.

|

|

POTTICARY M, ZERVOS A, HARKNESS J. The effect of particle elongation on the strength of granular materials[C]//Proceedings of the 24th UK Conference of the Association for Computational Mechanics in Engineering. Cardiff: University of Southampton Institutional Repository, 2016: 239-242.

|

|

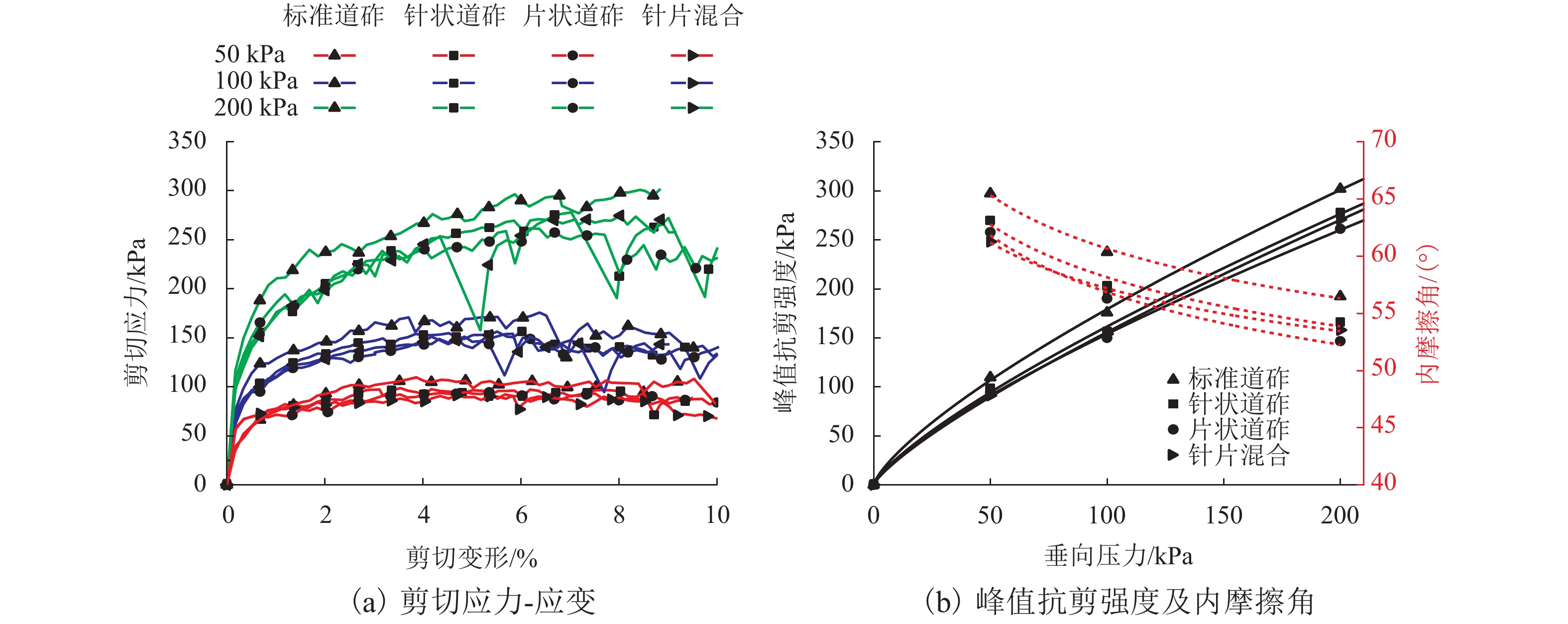

井国庆,黄红梅,常锦秀,等. 清洗后的劣化道砟直剪力学特性分析[J]. 西南交通大学学报,2017,52(5): 1055-1060.JING Guoqing, HUANG Hongmei, CHANG Jinxiu, et al. Analysis of mechanical characteristics of degradation railway ballast by direct shear test[J]. Journal of Southwest Jiaotong University, 2017, 52(5): 1055-1060.

|

|

INDRARATNA B, IONESCU D, CHRISTIE H D. Shear behavior of railway ballast based on large-scale triaxial tests[J]. Journal of Geotechnical & Geoenvironmental Engineering, 1998, 124(5): 439-449.

|

|

ASADZADEH M, SOROUSH A. Direct shear testing on a rockfill material[J]. Arabian Journal for Science and Engineering, 2009, 34(2): 379-396.

|

|

王鹏程,刘建坤,李旭,等. 直剪条件下碎石集料力学特性研究[J]. 铁道学报,2014(2): 103-108. doi: 10.3969/j.issn.1001-8360.2014.02.016WANG Pengcheng, LIU Jiankun, LI Xu, et al. Mechanical behavior of crushed stone aggregate subjected to direct shear conditions[J]. Journal of The China Railway Society, 2014(2): 103-108. doi: 10.3969/j.issn.1001-8360.2014.02.016

|

下载:

下载: