Simulation Analysis and Verification on Three-Dimensional Temperature Field of Strain Clamps for Overhead Lines

-

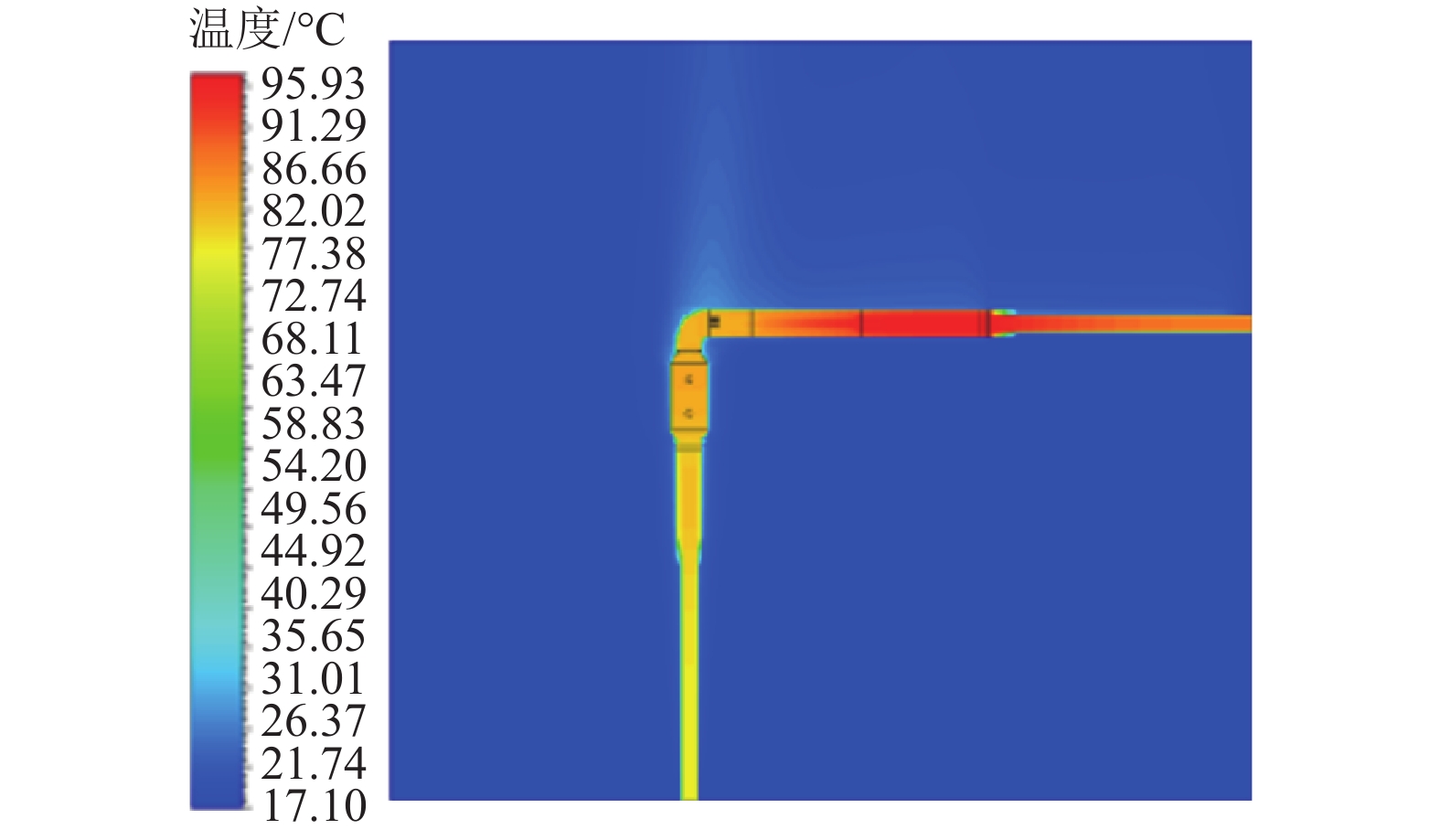

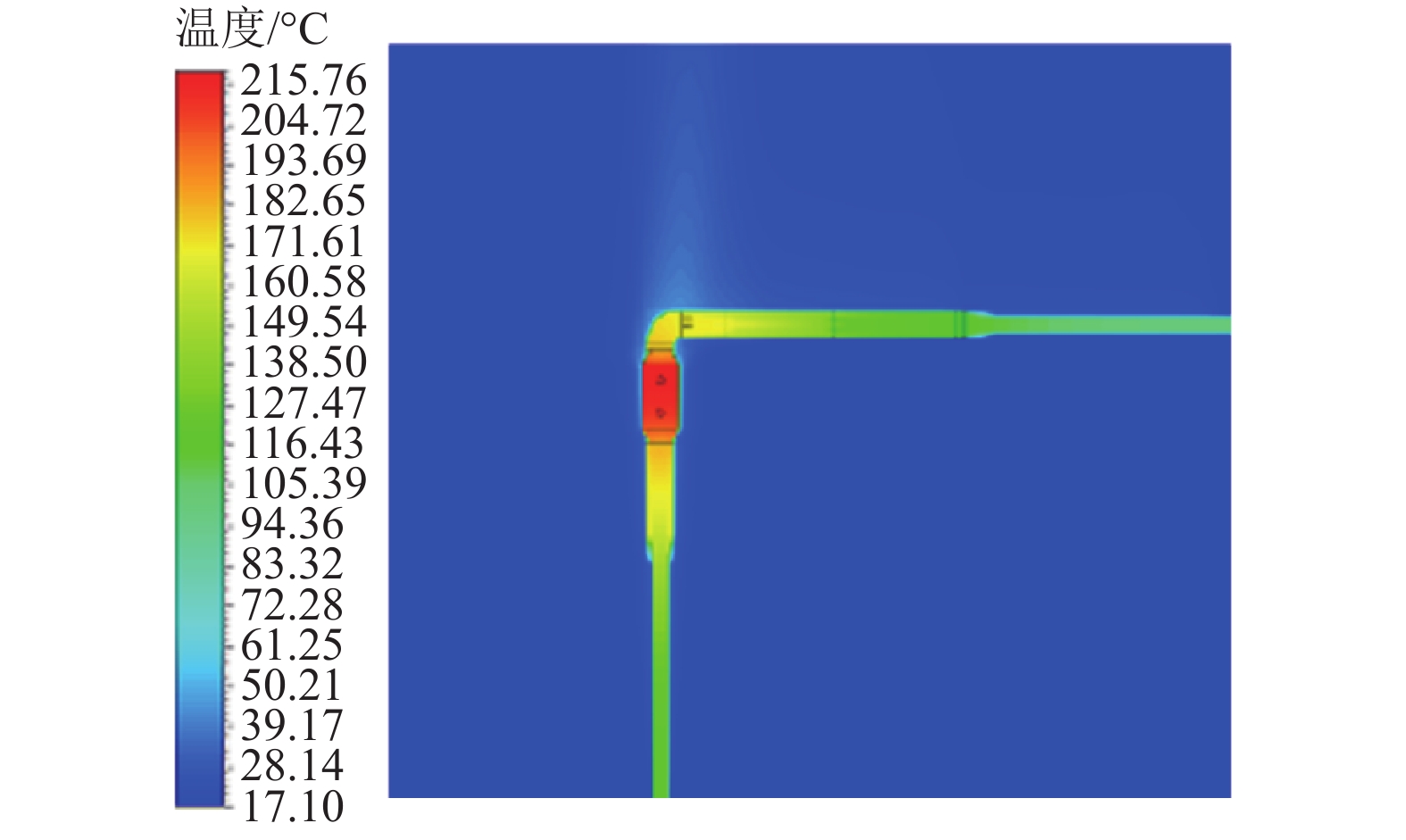

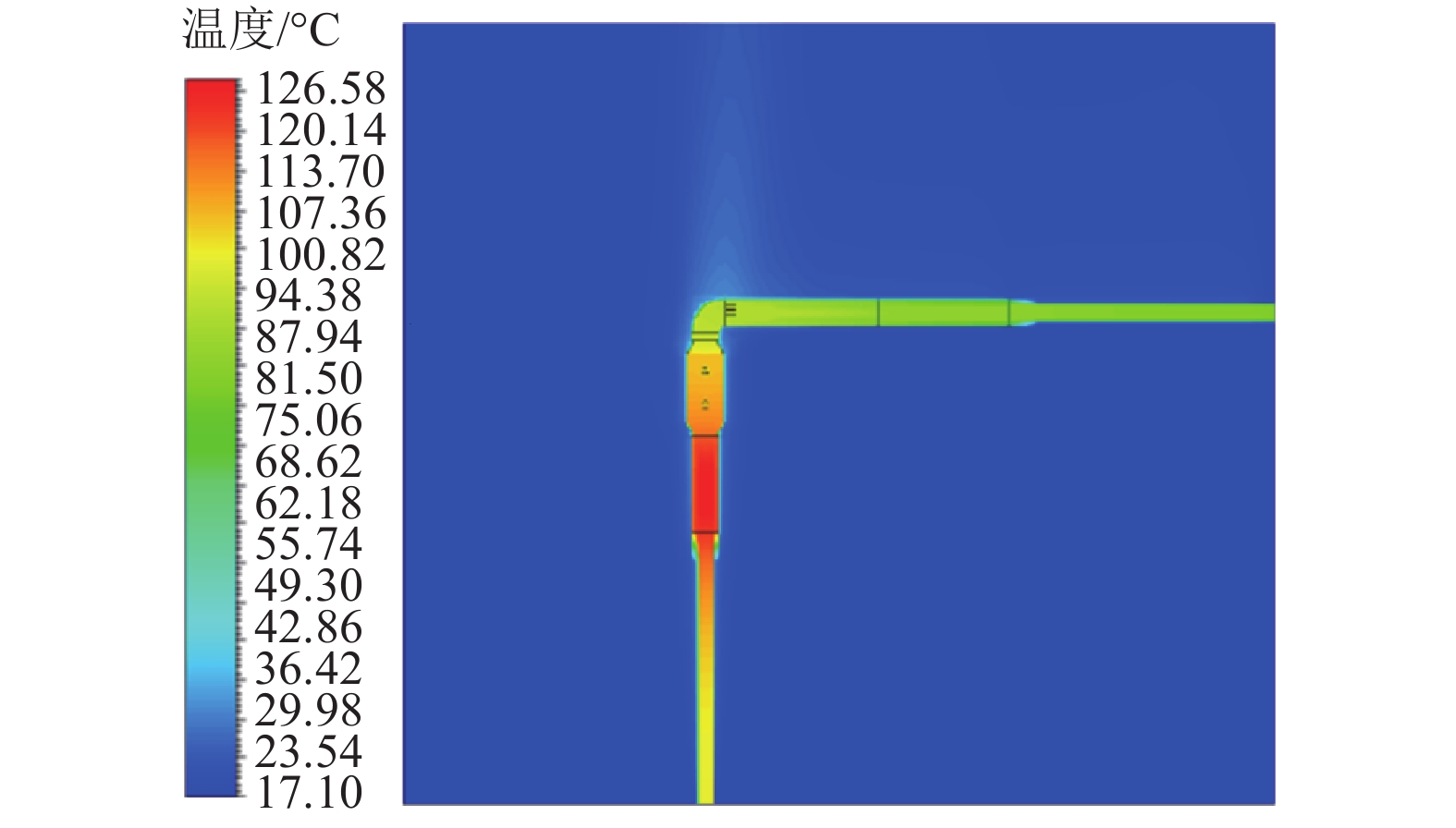

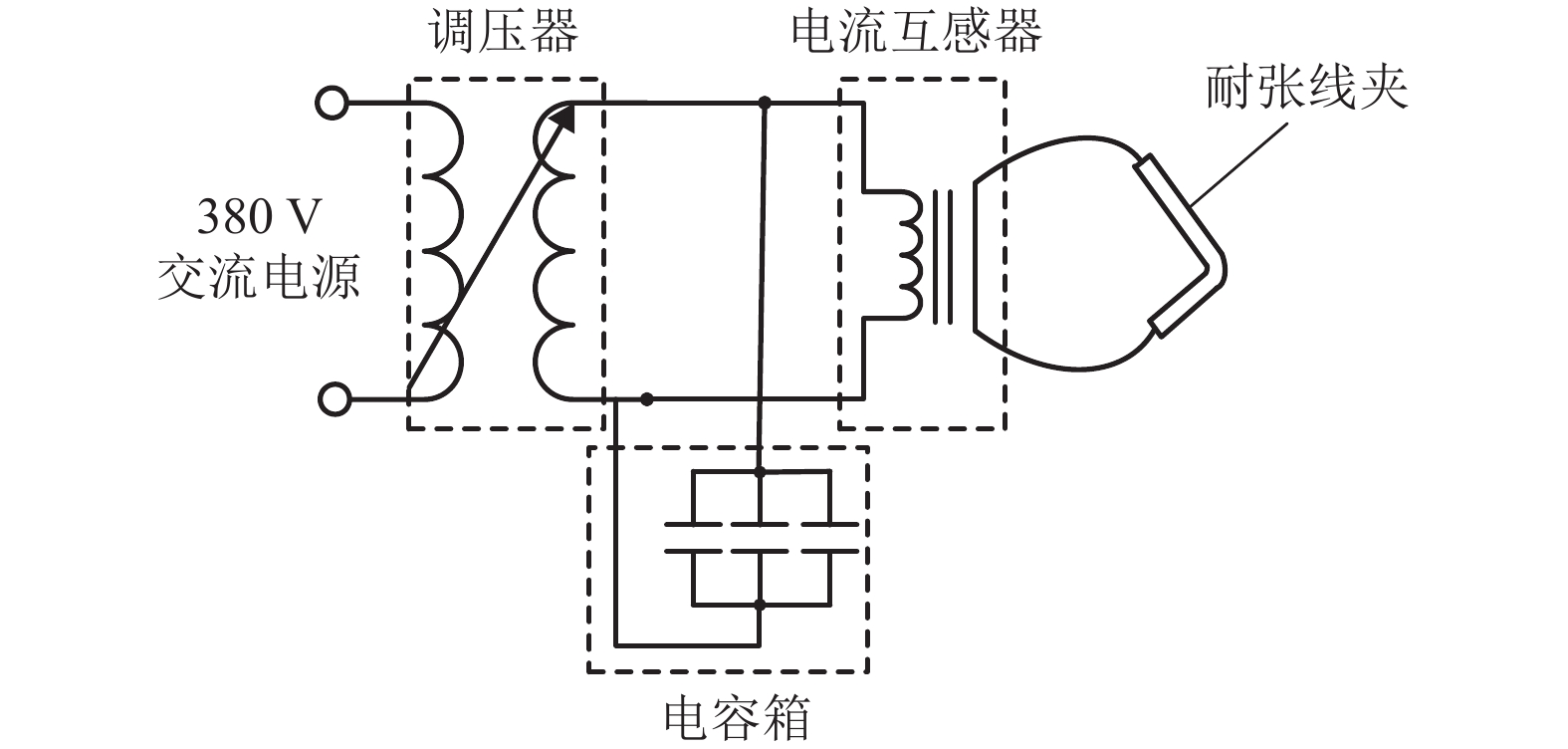

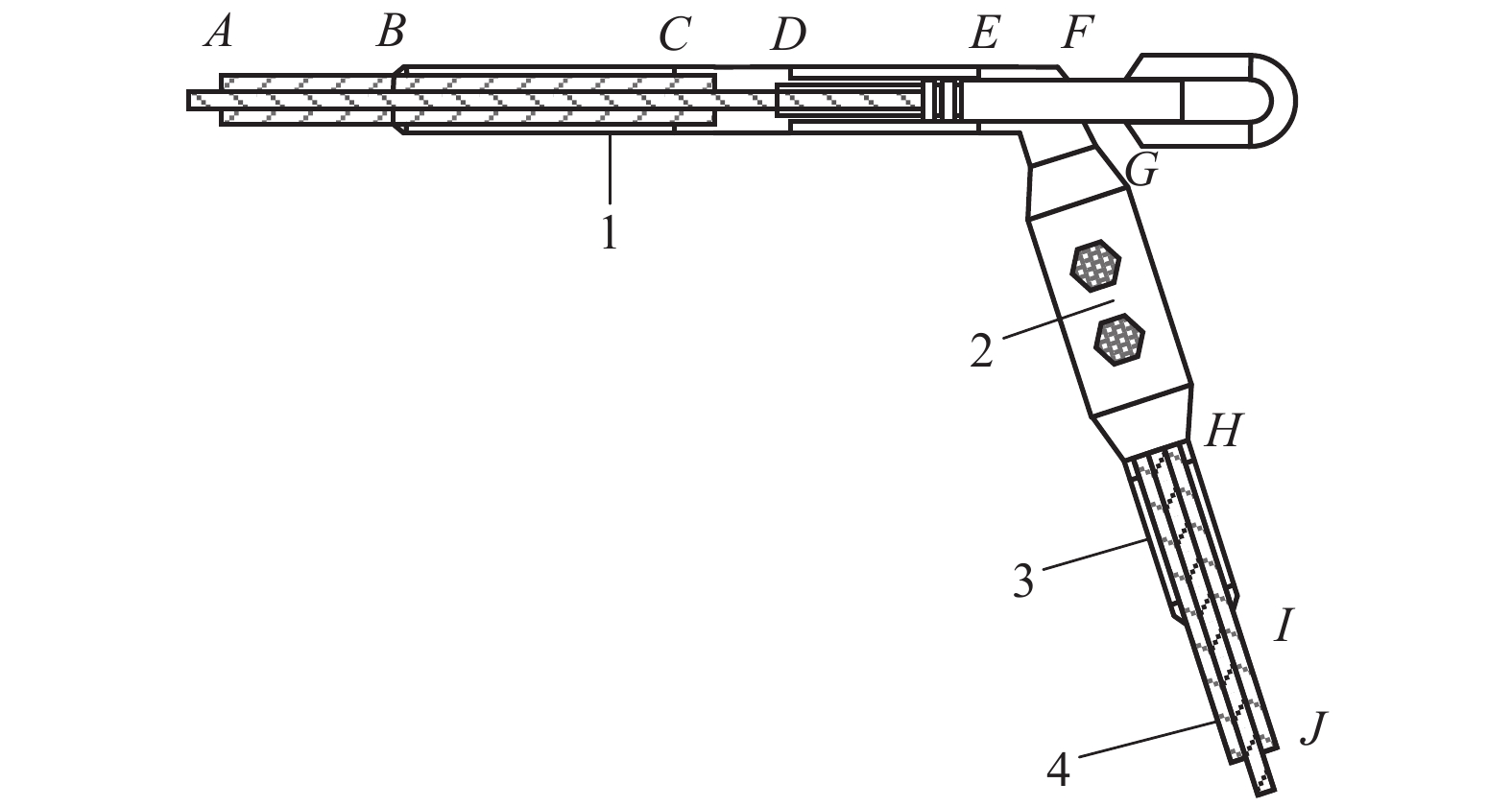

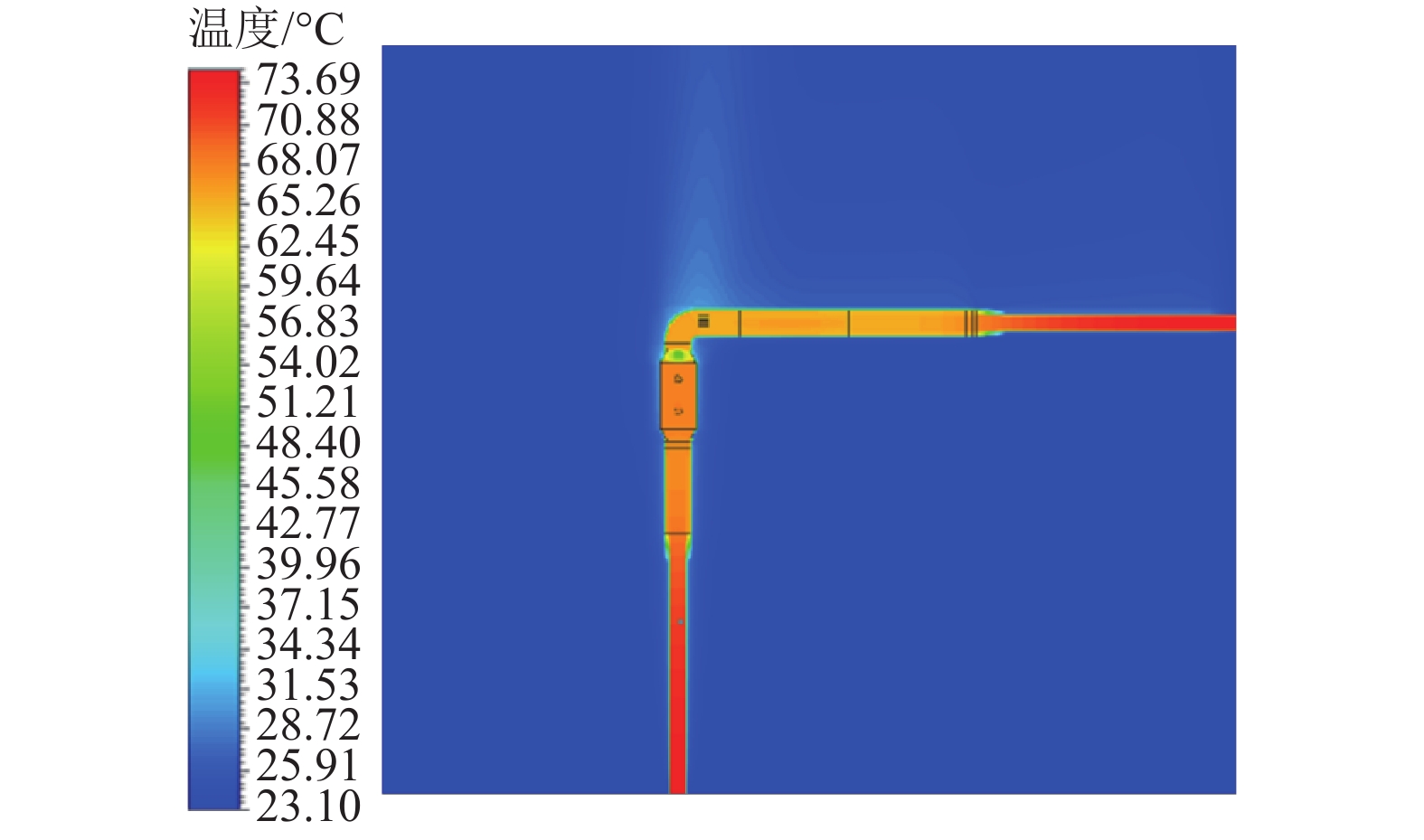

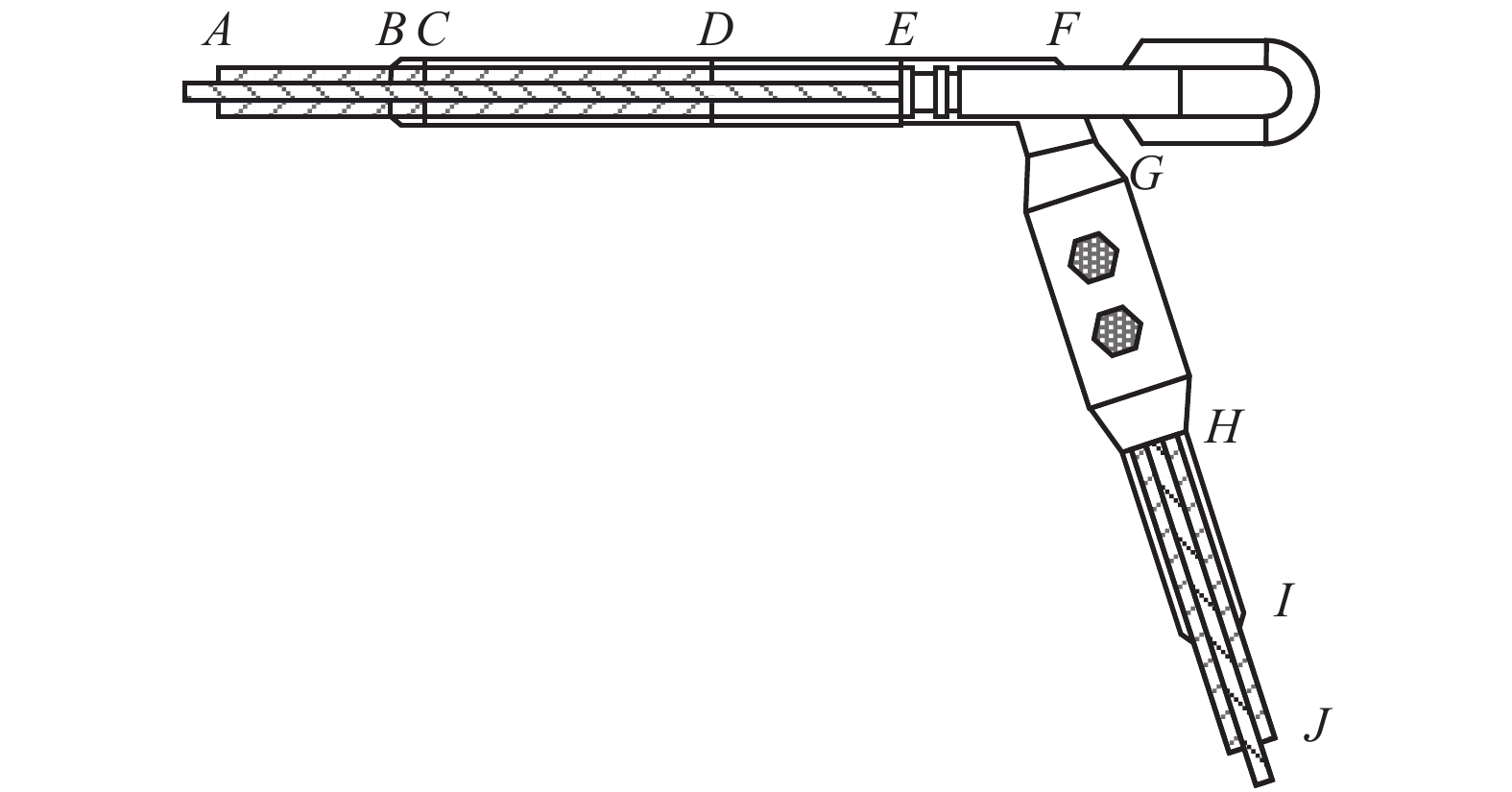

摘要: 为研究不同条件下架空线路耐张线夹温度分布情况,构建了基于耐张线夹简化结构的有限元模型,并在600 A工频交流电流和不同接触电阻比的条件下,进行了耐张线夹电磁-热耦合有限元仿真,最终得到耐张线夹的三维温度场分布. 仿真结果显示:在正常情况下,耐张线夹引流板处的温度最低;在线夹不同部位接触电阻增大的情况下,引流板处接触电阻的增大对线夹整体温度升高的影响最大,而线夹本体压接处接触电阻的增大对线夹温升影响最小,同时线夹温度升高也会制约架空线路导线载流量. 最后通过线夹电阻测量试验和温升试验验证仿真的准确性,误差约为2.3%.Abstract: In order to study the temperature distribution of the strain clamps of overhead lines under different conditions, the finite element model based on the simplified structure of the strain clamp was build, and under the conditions of 600 A power frequency alternating current and different contact resistance ratios, the electromagnetic-thermal coupling finite element simulation analysis of the strain clamp was carried out, and the three-dimensional temperature field distribution of the strain clamp was finally obtained. The simulation results show that under normal conditions, the temperature of the conductive plate of the strain clamp is the lowest. When the contact resistance at different parts of the clamp increases, the increase of contact resistance at the conductive plate has the greatest effect on the overall temperature rise of the clamp, whereas the increase of the contact resistance at the crimp connection of the clamp body has the least effect. Meanwhile the temperature of the clamp will also limit the current carrying capacity of overhead lines. Finally the accuracy of the simulation was verified through the clamp resistance test and temperature rise test, and the error is about 2.3%.

-

表 1 不同部位接触情况恶化下耐张线夹的最高温度

Table 1. Highest temperature of strain clamp underdifferent contact resistances for different parts

接触

面积比引流板

压接处线夹本体

压接处引流板

接触面所有

接触面10 000 74.07 74.07 74.07 74.07 20 000 82.02 75.11 94.52 98.27 40 000 94.53 81.03 130.96 138.84 100 000 128.35 97.21 218.88 239.91 表 2 实验测量电阻与仿真设置电阻对比

Table 2. Comparison of experimental resistance andsimulation resistance

项目 螺栓力矩

(N•m)接触面

积比总电阻/

μΩ引流板

电阻/μΩ实验 20 68.9 36.1 仿真 5 000 66.4 35.5 误差/% 3.7 1.6 实验 40 61.7 28.9 仿真 4 200 60.1 29.3 误差/% 2.6 1.5 实验 60 58.3 25.5 仿真 3 000 56.0 25.2 误差/% 4.0 1.2 表 3 仿真结果与试验各点温度对比

Table 3. Comparison between simulation results and experimental temperatures

力矩 结果 测温点 测温点 测温点 测温点 20 试验 64.3 71.3 70.5 69.4 仿真 65.1 68.9 69.8 70.7 误差/% 1.2 3.4 1.0 1.9 40 试验/% 65.1 66.6 66.3 66.9 仿真 63.9 66.2 65.2 68.2 误差/% 1.9 0.6 1.7 1.9 60 试验 64.5 63.5 61.3 64.4 仿真 62.4 62.9 62.8 67.2 误差/% 3.3 0.9 2.4 4.3 -

王中. 耐张管内钢芯铝绞线断线原因分析[J]. 电力建设,2005,26(4): 35-38. doi: 10.3969/j.issn.1000-7229.2005.04.012WANG Zhong. Analysis on breakage causes of steel-cored aluminum strands in strained tube[J]. Electric Power Construction, 2005, 26(4): 35-38. doi: 10.3969/j.issn.1000-7229.2005.04.012 杜毅,敬兴东,包健康,等. 500 kV输电线路引流板过热研究[J]. 四川电力技术,2015,38(1): 19-21. doi: 10.3969/j.issn.1003-6954.2015.01.005DU Yi, JING Xingdong, BAO Jiankang, et al. Study on overheat of 500 kV transmission line conductive plate[J]. Sichuan Electric Power Technology, 2015, 38(1): 19-21. doi: 10.3969/j.issn.1003-6954.2015.01.005 国家经济贸易委员会. 架空送电线路运行规程: DL/T 741—2001[S]. 北京: 中国电力出版社, 2005 郭晓飞,李拥春,赵元林. 耐张引流发热的分析与处理[J]. 电气技术,2010(8): 136-139. doi: 10.3969/j.issn.1673-3800.2010.08.036GUO Xiaofei, LI Yongchun, ZHAO Yuanlin. The analysis and process about high temperature of elementary streams[J]. Electrical Technology, 2010(8): 136-139. doi: 10.3969/j.issn.1673-3800.2010.08.036 刘毅刚,刘刚,王振华,等. 电缆中间接头连接管压接电阻实验及分析[J]. 广东电力,2016,29(5): 108-112. doi: 10.3969/j.issn.1007-290X.2016.05.020LIU Yigang, LIU Gang, Wang Zhenhua, et al. Experimental analysis on crimping resistance of connecting pipe of cable intermediate joint[J]. Guangdong Electric Power, 2016, 29(5): 108-112. doi: 10.3969/j.issn.1007-290X.2016.05.020 崔明,贾晨,王朔,等. 导线与线夹接触不良发热的热像特征[J]. 吉林电力,2013,41(6): 36-38.CUI Ming, JIA Chen, WANG Shuo, et al. Thermal image characteristic based on poor contact between conductor and clap[J]. Jilin Electric Power, 2013, 41(6): 36-38. WANG Pengyu, LIU Gang, MA Hui, Liu, et al. Investigation of the ampacity of a prefabricated straight-through joint of high voltage cable[J]. Energies, 2017, 10: 2050-2058. doi: 10.3390/en10122050 LIU Gang, GUO Deming, WANG Pengyu, et al. Calculation of equivalent resistance for ground wires twined with armor rods in contact terminals[J]. Energies, 2018, 11(4): 737-741. doi: 10.3390/en11040737 曾 嵘,周佩朋,王 森,等. 接地系统中接触电阻的仿真模型及其影响因素分析[J]. 高电压技术,2010,36(10): 2393-2397.ZENG Rong, ZHOU Peipeng, WANG Sen, et al. Modeling of contact resistance in ground system and analysis on its influencing factors[J]. High Voltage Engineering, 2010, 36(10): 2393-2397. DHOTRE M T, KORBEL J, YE X, et al. CFD simulation of temperature rise in high-voltage circuit breakers[J]. IEEE Trans. Power Deliv, 2017, 32: 2530-2536. 蔡向晖. 500 kV紧凑型线路耐张线夹断裂事故分析[J]. 华北电力技术,2003(3): 36-38. doi: 10.3969/j.issn.1003-9171.2003.03.012CAI Xianghui. Analysis on 500 kV compact transmissionLine strain clamps fracturing accident[J]. North China Electric Power, 2003(3): 36-38. doi: 10.3969/j.issn.1003-9171.2003.03.012 程礼椿. 电接触理论及应用[M]. 北京: 机械工业出版社, 1988: 10-48. HOLM R. Electric contacts: theory and application[M]. 4th ed. [S.l.]: Springer, 1979: 5-35. 冯慈璋, 马西奎. 工程电磁场导论[M]. 北京: 高等教育出版社, 2010: 183-186. 孙国霞,关向雨,金向朝,等. 基于多场耦合计算的气体绝缘开关设备母线接头过热性能分析[J]. 高电压技术,2014,40(11): 3445-3451.SUN Guoxia, GUAN Xiangyu, JIN Xiangchao, et al. Temperature rise calculation and overheating fault analysis of gas insulated switchgear bus connector based on coupled field theory[J]. High Voltage Engineering, 2014, 40(11): 3445-3451. 马冰然. 电磁场与电磁波[M]. 广州: 华南理工大学出版社, 2007: 148-152. 冯长根, 王新泉, 吴超, 等. 传热学[M]. 北京: 机械工业出版社, 2009: 13-21. 林建忠. 流体力学[M]. 北京: 清华大学出版社, 2005: 210-214. 孙纪宁. ANSYS CFX对流传热数值模拟基础应用教程[M]. 北京: 国防工业出版社, 2010: 365-377. 李雪. 耐热导线耐张线夹发热问题解决方案研究[D]. 北京: 华北电力大学, 2010 毛先胤,盛戈皞,刘亚东,等. 架空输电线路暂态载流能力的计算和评估[J]. 高压电器,2011,47(1): 70-74.MAO Xianyin, SHENG Gehao, LIU Yadong, et al. Calculation and evaluation of overhead transmission line transient ampacity[J]. High Voltage Apparatus, 2011, 47(1): 70-74. -

下载:

下载: