Test Study on True-Triaxial Loading and Unloading for Marble with Unloaded Single Face

-

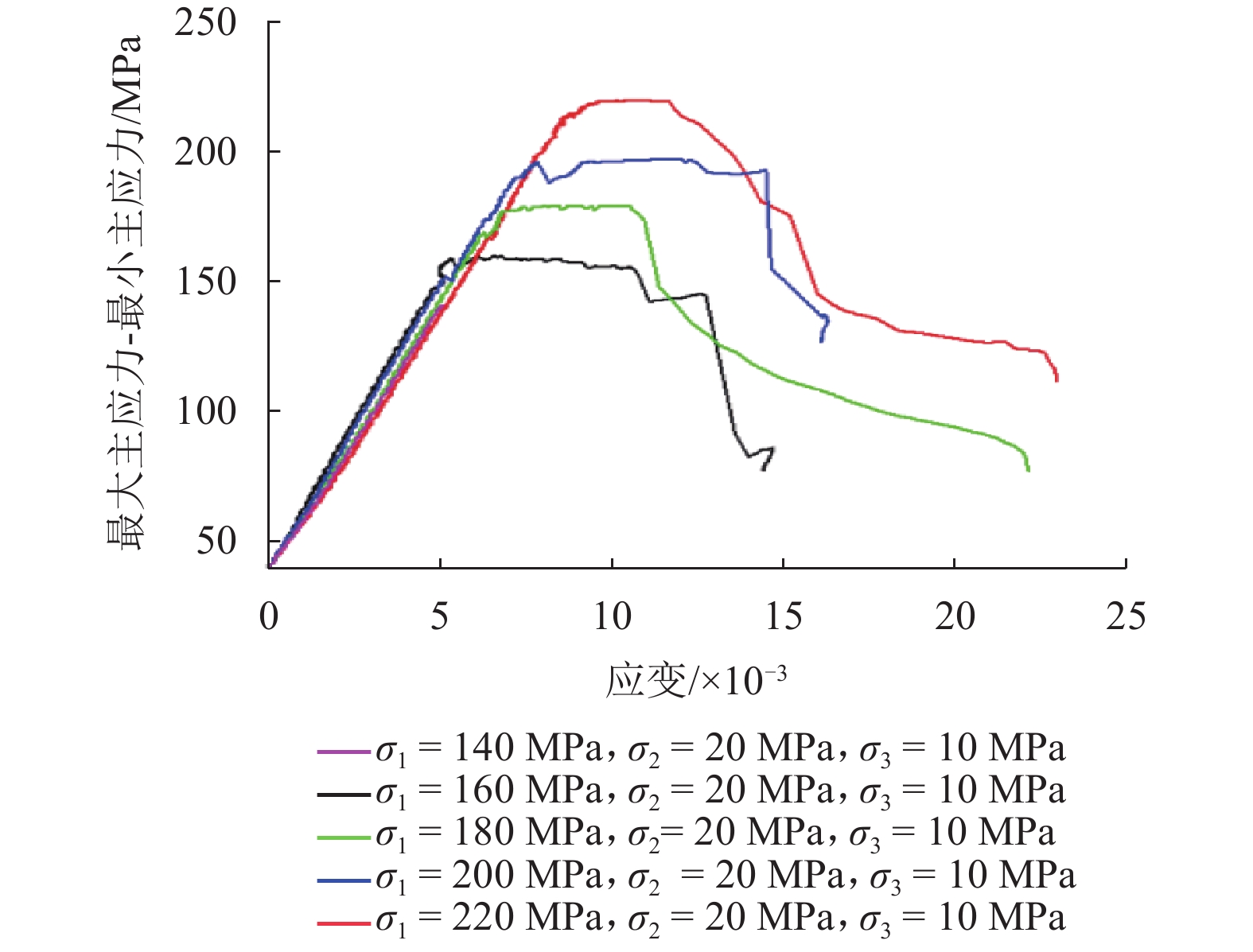

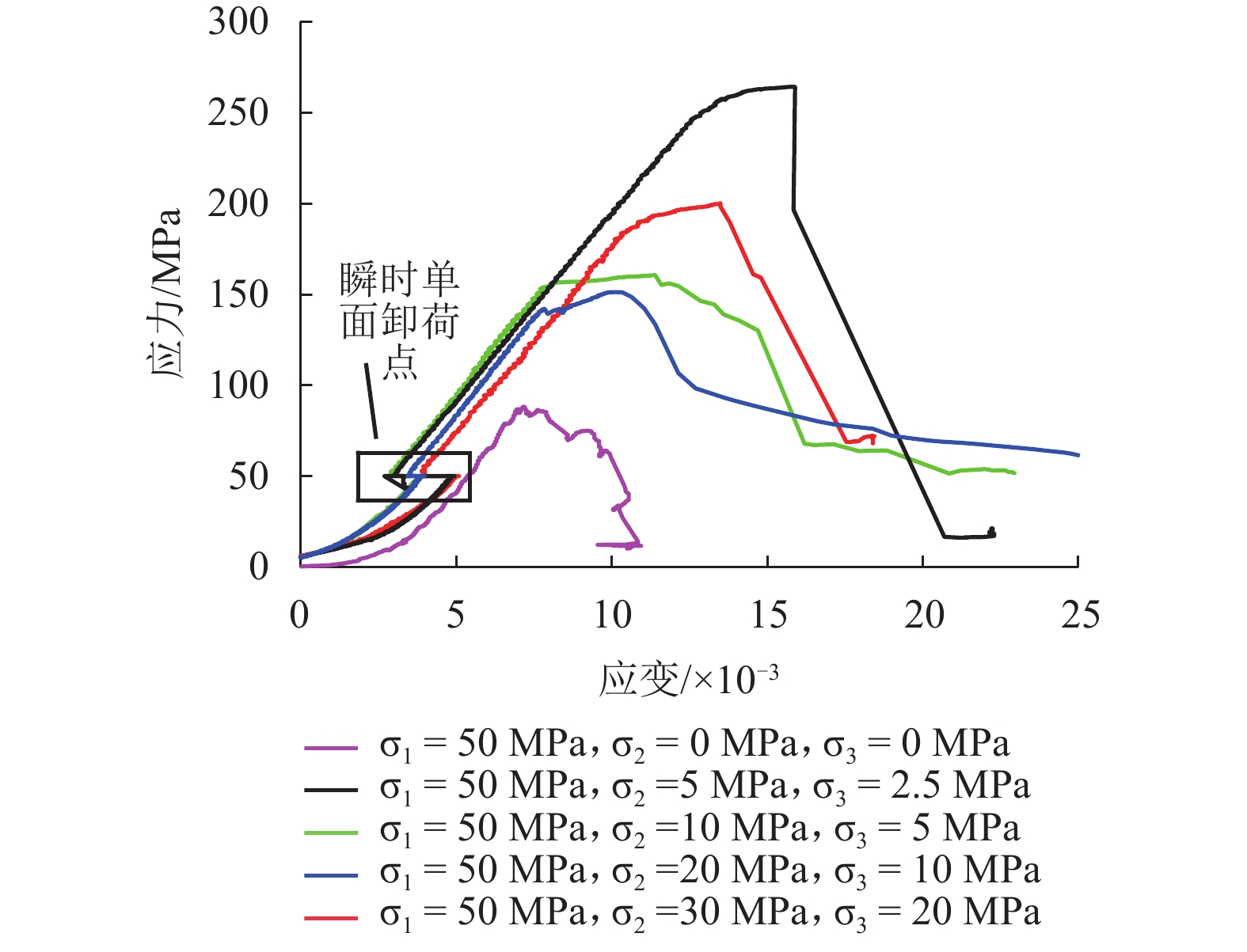

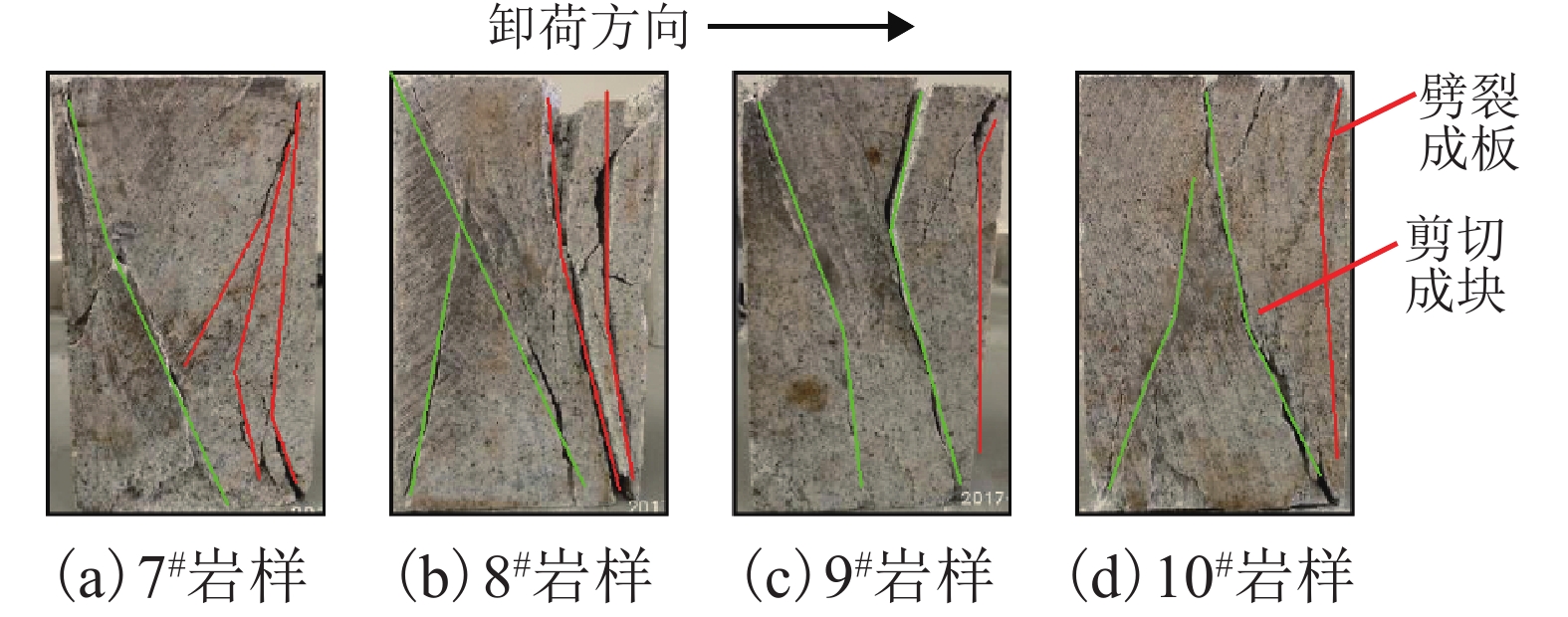

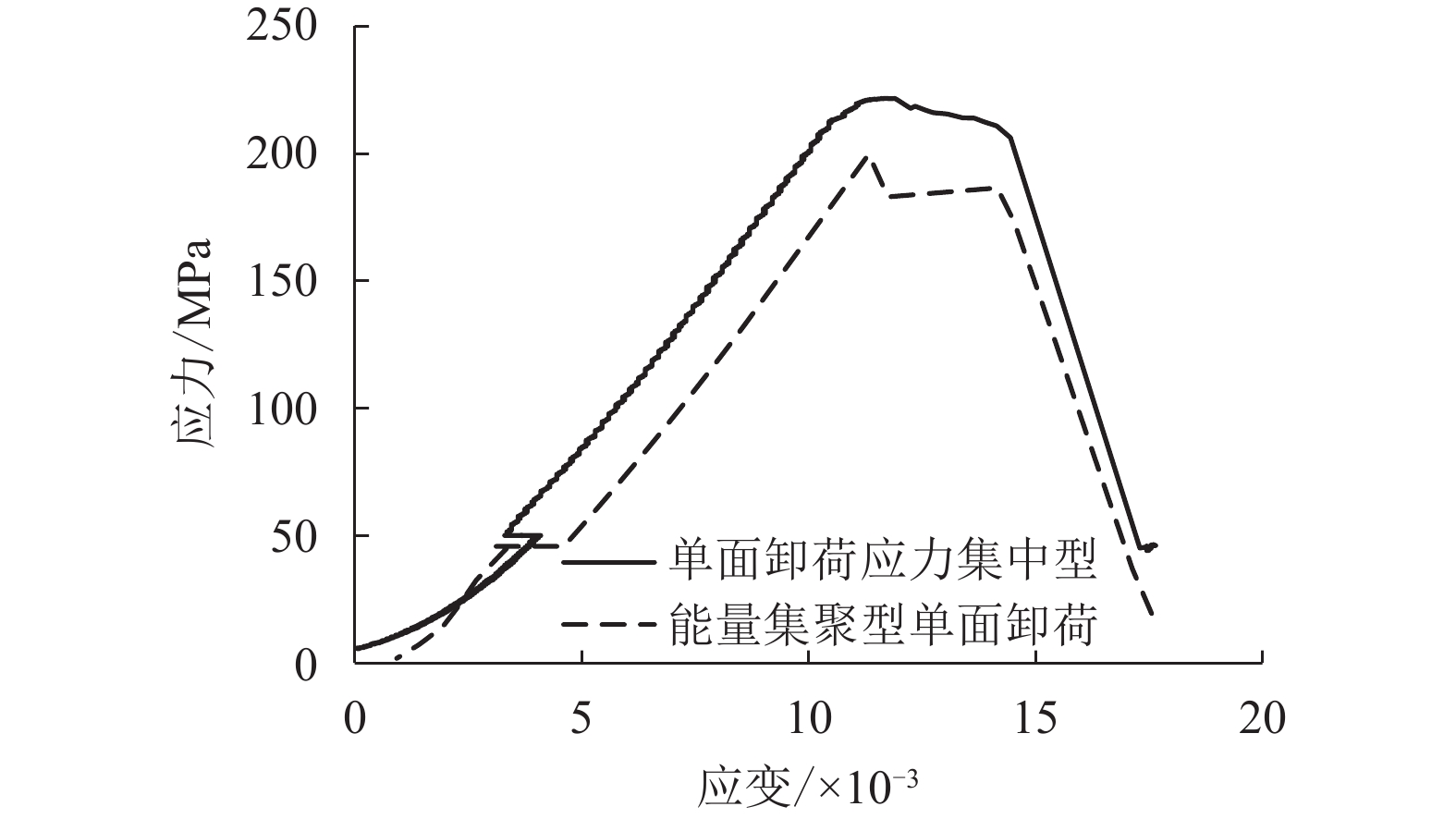

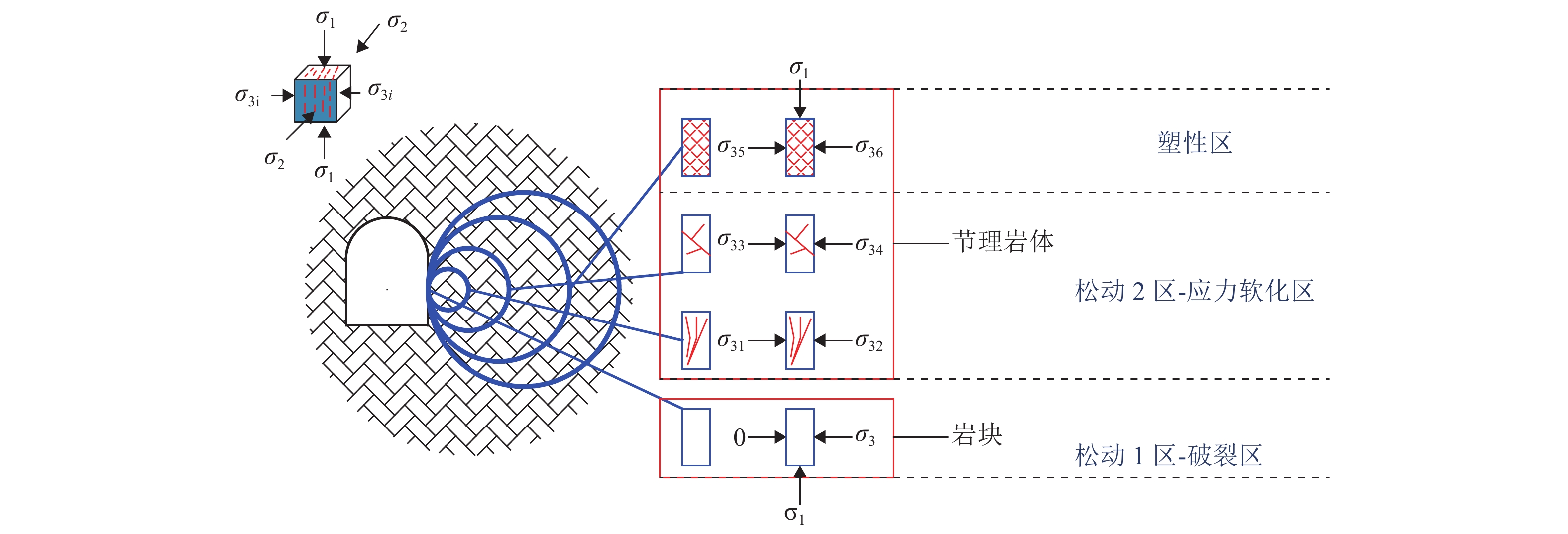

摘要: 为了准确地评价巷(隧)道开挖面附近围岩的稳定性,采用真三轴卸荷扰动岩石测试系统对大理岩岩样进行第三主应力单面卸荷加、卸载试验研究. 通过高应力巷(隧)道开挖围岩失稳机理分析,采用不同应力加卸路径模拟能量积聚型和应力集中型两种物理工程破坏模型,进一步分析两种破坏模型的应力-应变曲线规律、破坏特征和强度特征. 研究结果表明:随着卸荷面应力的减小出现扩容现象,主要破坏面在临空面附近,随着轴压的升高,劈裂破坏范围增大,卸荷临界值也增大;随着围压增高,屈服点和峰值点增大,并且屈服点和峰值之间的曲线斜率较为平缓,破坏由局部张拉-劈裂-剪切复合性破坏发展成整体劈裂破坏;同围压条件下卸荷破坏强度是加载破坏强度的80%,岩体卸荷比加载更容易破坏,进而修正了广义Hoek-Brown强度准则.

-

关键词:

- 真三轴试验 /

- 单面卸荷 /

- Hoek-Brown准则 /

- 破坏特征

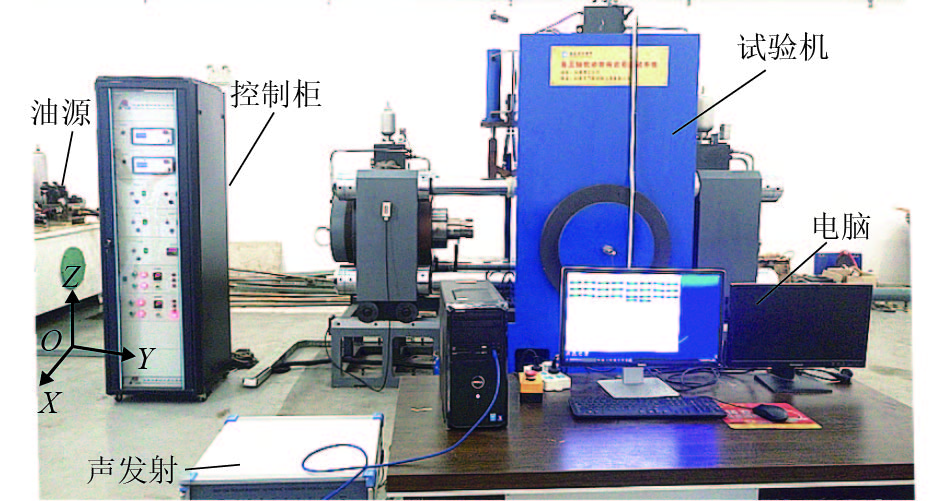

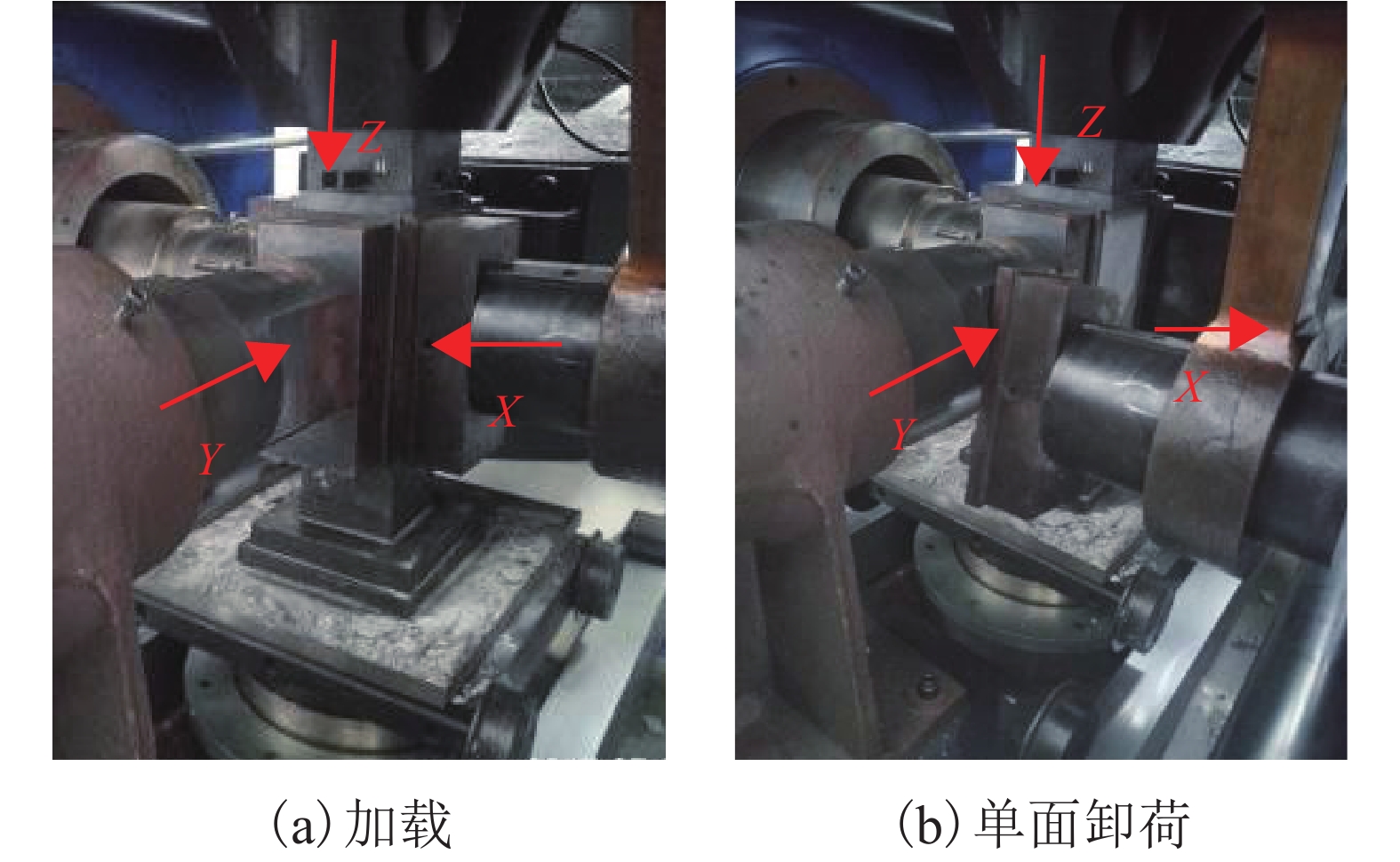

Abstract: To accurately evaluate rock stability around the excavation face of roadway(tunnel), a true-triaxial unloading disturbance testing system is applied in the loading and unloading tests of marble samples, where single-face was unloaded in the direction of the minimum principal stress. Through the analysis on instability mechanism of rock around roadway excavation face with high geostress, two kinds of failure modes, including energy accumulation failure and stress concentration failure, were simulated in different loading and unloading paths. Then, stress-strain curves, and failure and strength characteristics were further analyzed. The results indicate that there is dilatancy when the stress on unloading surface decreases; the main failure surface is near the free face; moreover, with the increase of the axial load, the splitting failure area extends and the critical unloading value increases. With the increase of the confining pressure, the stress peaks and yields increase, and the curve slope between the yield and peak is reduced. The composite failure mode with local tension-splitting-shear failures develops into the overall splitting failure. Under the same confining pressure, the unloading failure strength is 80% of the loading failure strength, and the marble sample in unloading is more likely to fail than in loading. The Hock-Brown criterion is modified using the calculated fracture strength value. -

表 1 初始应力值

Table 1. Initial stresses

岩样编号 $ {\sigma _1}$ $ {\sigma _2}$ $ {\sigma _3}$ 1# 0 0 0 2# 140.0 20.0 10.0 3# 160.0 20.0 10.0 4# 180.0 20.0 10.0 5# 200.0 20.0 10.0 6# 220.0 20.0 10.0 7# 50.0 5.0 2.5 8# 50.0 10.0 5.0 9# 50.0 20.0 10.0 10# 50.0 30.0 20.0 表 2 第三主应力单面卸荷临界值

Table 2. Critical values of minimum principal stress under single-face unloading condition

轴压 卸荷临界值 破坏程度 140 0 不破坏 160 0.38 破坏 180 0.74 破坏 200 1.62 剧烈破坏 220 2.99 剧烈破坏 -

齐庆新,陈尚本,王怀新,等. 冲击地压、岩爆、矿震的关系及其数值模拟研究[J]. 岩石力学与工程学报,2003,22(11): 1852-1858. doi: 10.3321/j.issn:1000-6915.2003.11.020QI Qingxin, CHAN Shangben, WANG Huaixin, et al. Study on the relations among coal bump,rockburst and mining tremor with numerical simulation[J]. Chinese Journal of Rock Mechanics and Engineering, 2003, 22(11): 1852-1858. doi: 10.3321/j.issn:1000-6915.2003.11.020 李忠,汪俊民. 重庆陆家岭隧道岩爆工程地质特征分析与防治措施研究[J]. 岩石力学与工程学报,2005,24(18): 3398-3402. doi: 10.3321/j.issn:1000-6915.2005.18.034LI Zhong, WANG Junmin. Geological characters of rockburst in Lujialing tunnel and its prevention methods[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(18): 3398-3402. doi: 10.3321/j.issn:1000-6915.2005.18.034 何川,汪波,吴德兴. 苍岭隧道岩爆特征与影响因素的相关性及防治措施研究[J]. 水文地质工程地质,2007(2): 25-28. doi: 10.3969/j.issn.1000-3665.2007.02.006HE Chuan, WANG Bo, WU Dexing. Research of relativity between rockburst character and influence factor and prevention measure in Cangling tunnel[J]. Hydrogeogy & Engineering Geology, 2007(2): 25-28. doi: 10.3969/j.issn.1000-3665.2007.02.006 曹强,贾海波,廖卓. 锦屏辅助洞岩爆特征及防治措施研究[J]. 隧道建设,2009,29(5): 510-512.CAO Qiang, JIA Haibo, LIAO Zhuo. Case study on characteristics and prevention and control measures of rockburst in Jinping auxiliary tunnel[J]. Tunnel Construction, 2009, 29(5): 510-512. LI Diyuan, CHARLIE C L, LI Xibing. Influence of sample height-to-width ratios on failure mode for rectangular prism samples of hard rock loaded in uniaxial compression[J]. Rock Mechanics and Rock Engineering, 2011, 44(3): 253-267. doi: 10.1007/s00603-010-0127-0 LEE M, HAIMSON B C. Laboratory study of borehole breakouts in Lac du Bonnet granite:a case of ex tensile fracture mechanism[J]. International Journal of Rock Mechanics and Mining Sciences and Geomechanics Abstracts, 1993, 30(7): 1039-1045. 黄达,黄润秋,张永兴. 三轴加卸载下花岗岩脆性破坏及应力跌落规律[J]. 土木建筑与环境工程,2011,33(2): 1-6.HUANG Da, HUANG Runqiu, ZHANG Yongxing. Character of brittle failure and stress drop under triaxial loading and unloading[J]. Journal of Civil,Architectural & Environmental Engineering, 2011, 33(2): 1-6. 李地元,孙志,李夕兵,等. 不同应力路径下花岗岩三轴加卸载力学相应及其破坏特征[J]. 岩石力学与工程学报,2016,35(2): 3449-3457.LI Diyuan, SUN Zhi, LI Xibing, et al. Mechanical response and failure characteristics of granite under different stress paths in triaxial loading and unloading conditions[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(2): 3449-3457. 何满潮,苗金丽,李德建,等. 深部花岗岩试样岩爆过程实验研究[J]. 岩石力学与工程学报,2007,26(5): 865-876. doi: 10.3321/j.issn:1000-6915.2007.05.001HE Manchao, MIAO Jinli, LI Dejian, et al. Experimental study on rockburst processes of granite specimen at great depth[J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(5): 865-876. doi: 10.3321/j.issn:1000-6915.2007.05.001 苏国韶,蒋剑青,冯夏庭,等. 岩爆弹射破坏过程的试验研究[J]. 岩石力学与工程学报,2016,35(10): 1990-1999.SU Guoshao, JIANG Jianqing, FENG Xiating, et al. Experimental study of ejection process in rockburst[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(10): 1990-1999. 冯夏庭, 陈炳瑞, 张传庆, 等. 岩爆孕育过程的机制、预警与动态调控[M]. 北京: 科学出版社, 2013: 15-32 史贵才,葛修润,卢允德. 大理岩应力脆性跌落系数的试验研究[J]. 岩石力学与工程学报,2006,25(8): 1625-1631. doi: 10.3321/j.issn:1000-6915.2006.08.016SHI Guicai, GE Xiurun, LU Yunde. Experimental study on coefficients of brittle stress drop of marble[J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(8): 1625-1631. doi: 10.3321/j.issn:1000-6915.2006.08.016 刘立鹏,汪小刚,贾志欣,等. 锦屏二级水电站施工排水洞岩爆机理及特征分析[J]. 中南大学学报(自然科学版),2011,42(10): 3150-3156.LIU Lipeng, WANG Xiaogang, JIA Zhixin, et al. Analysis of mechanism and characteristic of rockburst in drainage-hole of Jinping II hydropower station[J]. Journal of Central South University (Science and Technology Edition), 2011, 42(10): 3150-3156. 俞茂宏. 强度理论百年总结[J]. 力学进展,2004,34(4): 529-560. doi: 10.3321/j.issn:1000-0992.2004.04.009YU Maohong. Strength theory in the past century[J]. Advances in Mechanice, 2004, 34(4): 529-560. doi: 10.3321/j.issn:1000-0992.2004.04.009 李建贺,盛谦,朱泽奇,等. Mine-by试验洞开挖过程中围岩应力路径与破坏模式分析[J]. 岩石力学与工程学报,2017,36(4): 821-830.LI Jianhe, SHENG Qian, ZHU Zeqi, et al. Analysis of stress path and failure mode of surrounding rock during Mine-by test tunnel excavation[J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(4): 821-830. 葛修润, 任建喜, 蒲毅彬, 等著. 岩土损伤力学宏细观试验研究[M]. 北京: 科学出版社2004: 86-88 杨圣奇,苏承东,徐卫亚. 大理岩常规三轴压缩下强度和变形特性的试验研究[J]. 岩土力学,2005,26(3): 475-478. doi: 10.3969/j.issn.1000-7598.2005.03.028YANG Shengqi, SU Chengdong, XU Weiya. Experimental investigation on strength and deformation properties of marble under conventional triaxial compression[J]. Rock and Soil Mechanics, 2005, 26(3): 475-478. doi: 10.3969/j.issn.1000-7598.2005.03.028 徐松林,吴文,王广印,等. 大理岩等围压三轴压缩全过程研究:三轴压缩全过程峰前、峰后卸围压全过程实验[J]. 岩石力学与工程学报,2001,20(6): 763-767. doi: 10.3321/j.issn:1000-6915.2001.06.002XU Songlin, WU Wen, WANG Guangyin, et al. Study on complete procedures of marble under triaxial compression:testing study on complete procedure of triaxal compression and the processes of unloading confining at the pre-peak and post-peak[J]. Chinese Journal of Rock Mechanics and Engineering, 2001, 20(6): 763-767. doi: 10.3321/j.issn:1000-6915.2001.06.002 SINGH M, RAJ A, SINGH B. Modified Mohr-Coulomb criterion for non-linear triaxial and polyaxial strength on intact rocks[J]. International Journal of Rock Mechanics and Ming Sciences, 2011, 48(3): 546-555. HOEK E. Strength of jointed rock masses[J]. Geotechnique, 1980, 23(33): 187-223. SINGH B, GOEL R K, MEHROTA V K, et al. Effect of intermediate principal stress on strength of anisotropic rock mass[J]. Tunnelling and Under-ground Space Technology, 1998, 13(1): 71-79. doi: 10.1016/S0886-7798(98)00023-6 李斌,许梦国,刘艳章,等. 三轴条件下完整岩石Hoek-Brown强度准则的改进[J]. 采矿与安全学报,2015,32(6): 1010-1016.LI Bin, XU Mengguo, LI Yanzhang, et al . Modified Hoek-Brown strength criterion for intact rocks under the condition of triaxial stress test[J]. Journal of Mining & Safe Engineering, 2015, 32(6): 1010-1016. -

下载:

下载: