Static Bearing Capacity Analysis of CFRP-Reinforced Short CHS Steel Tubular Columns under Axial Compression

-

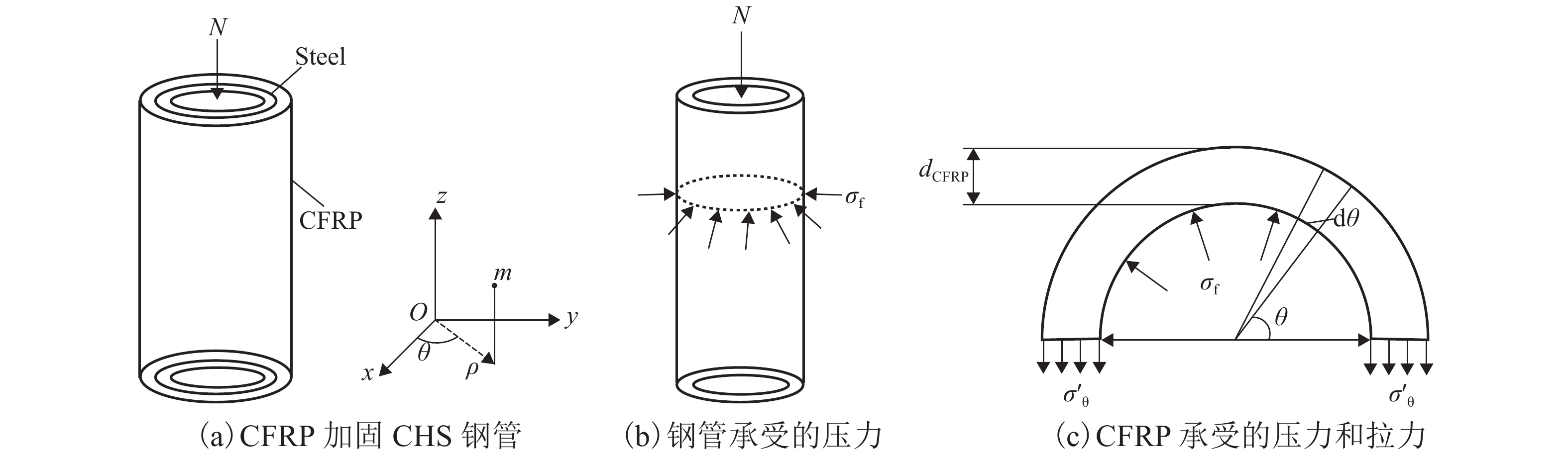

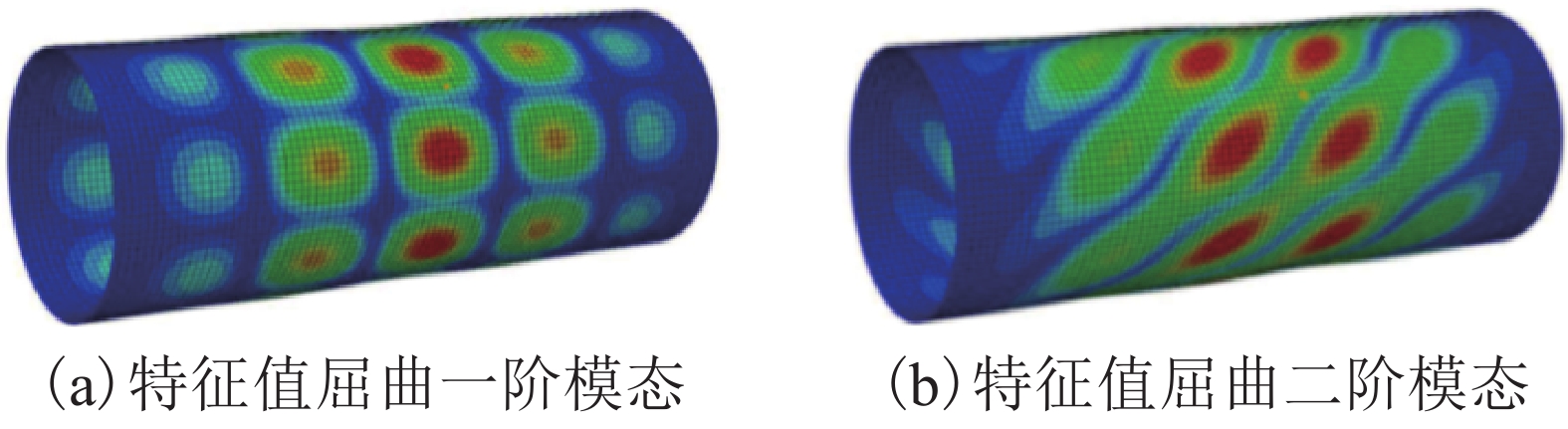

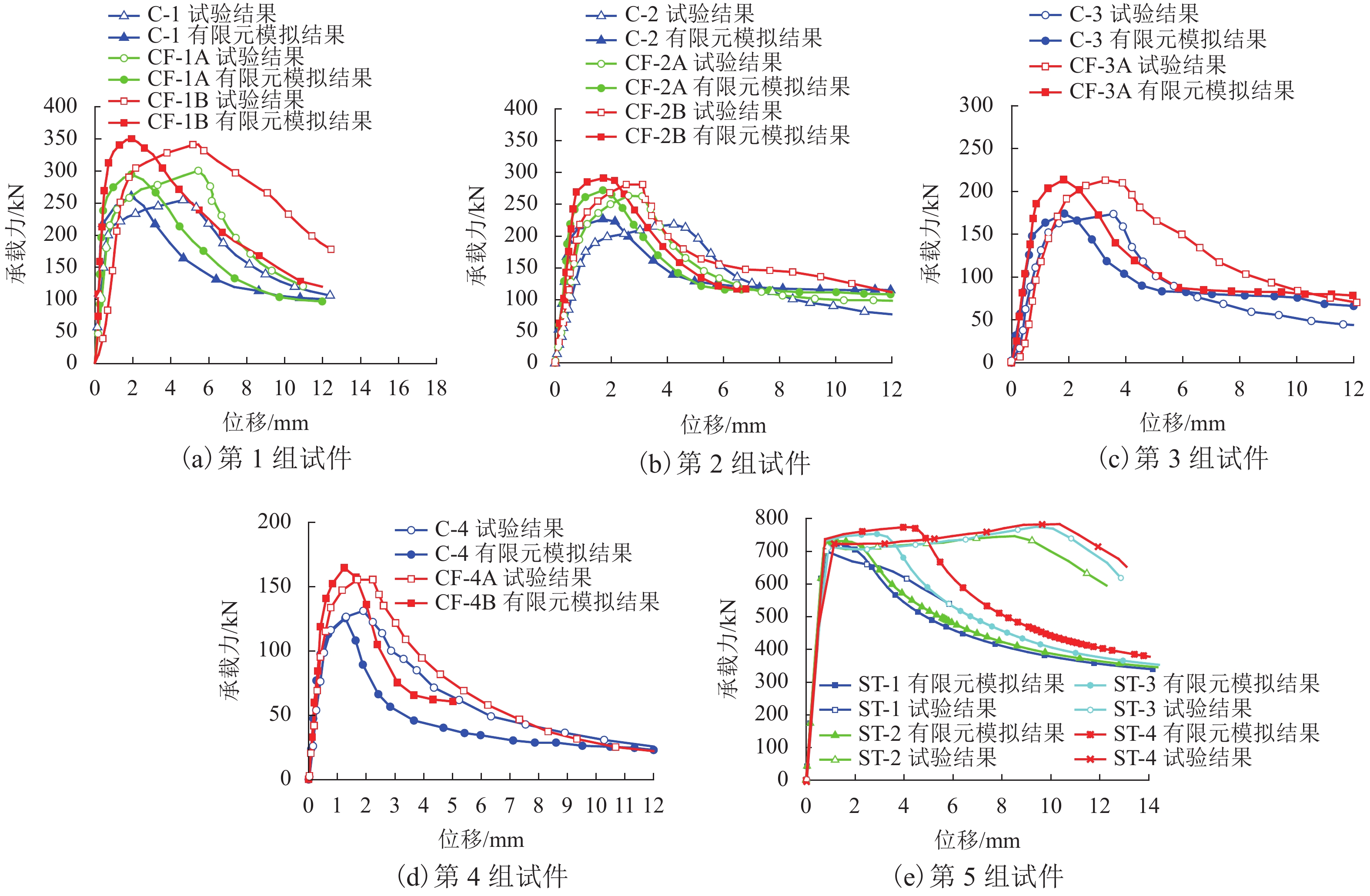

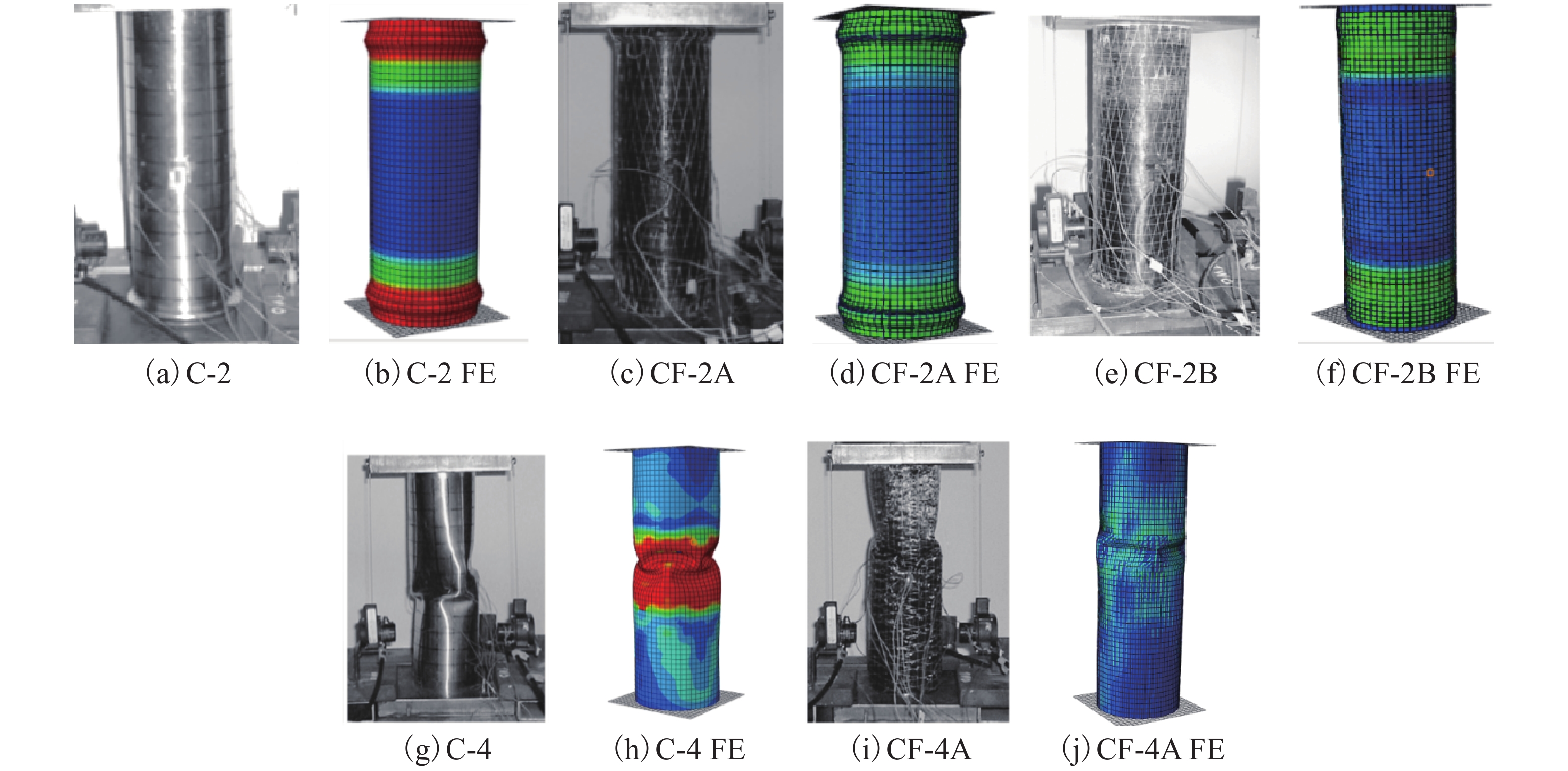

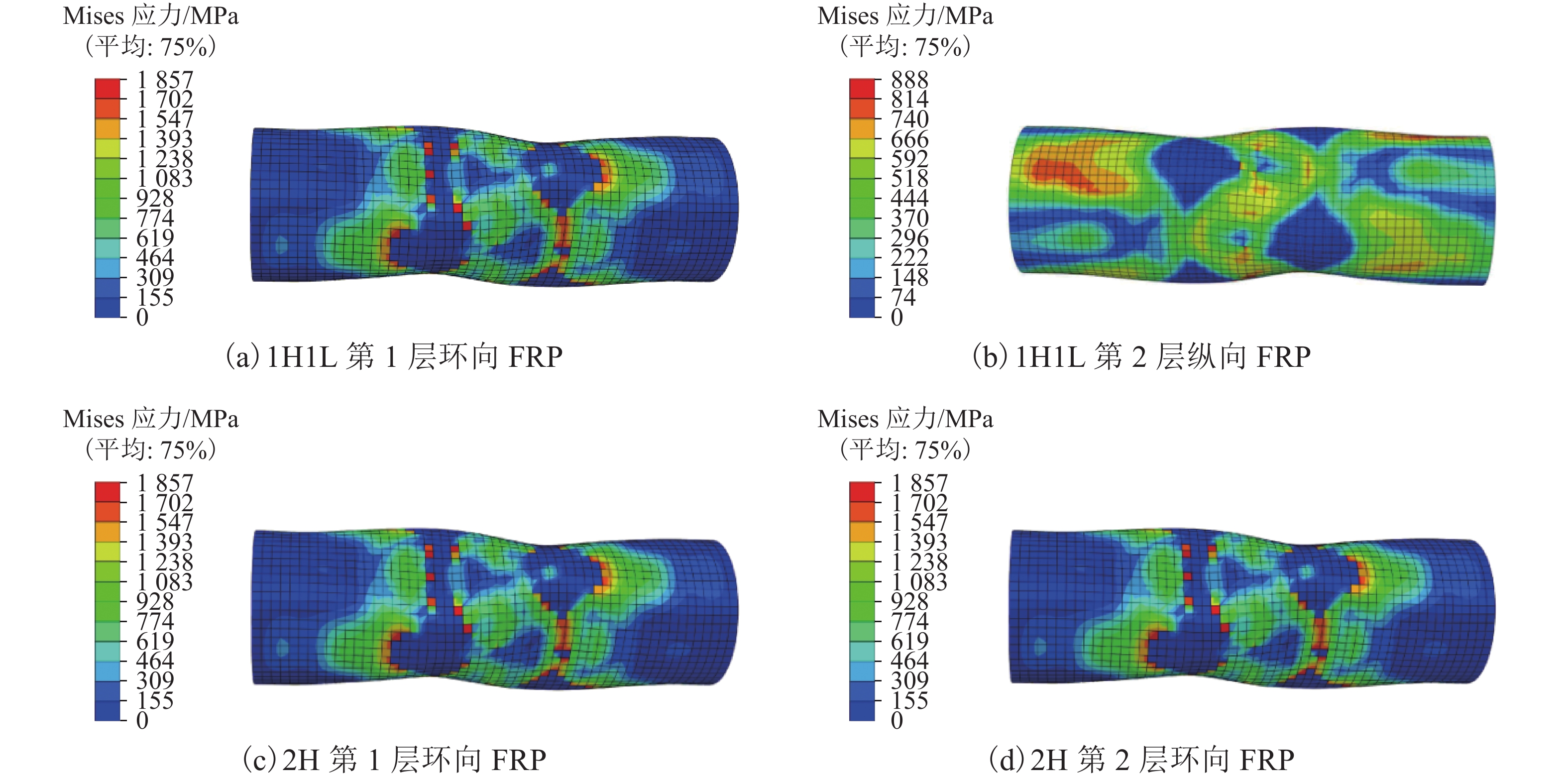

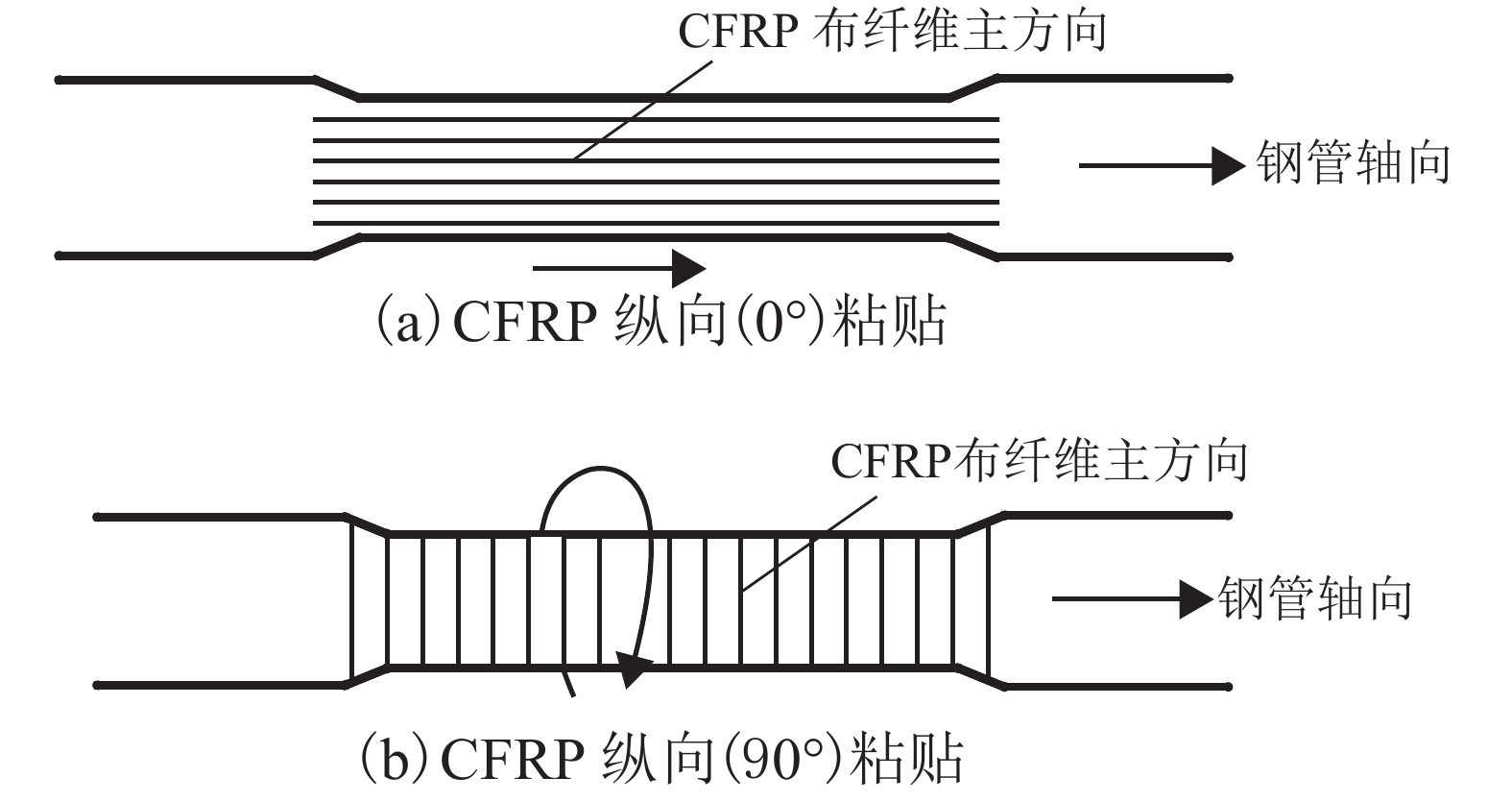

摘要: 为了研究轴压作用下碳纤维增强复合材料(carbon fibre-reinforced polymer,CFRP)加固圆形空心截面(circular hollow section,CHS)钢管短柱的极限承载力,对轴压作用下CFRP加固CHS钢管短柱进行了理论和数值分析. 理论分析中,利用等效截面法推导了两种不同粘贴方式(全环向粘贴以及环向和纵向交替粘贴)的CFRP加固圆钢管短柱在轴压作用下静力承载力的理论计算公式;数值分析中,将特征值屈曲与Riks法相结合建立了轴压作用下CFRP加固圆钢管短柱的非线性有限元分析模型. 对该模型中的环向和纵向CFRP进行应力分析后发现,环向CFRP处于拉伸状态,约束钢管的径向变形;纵向CFRP会承担轴压荷载中的部分压力,限制钢管的变形. 最后,将所建立的有限元分析模型结果和所推导的理论公式结果与已有文献的试验结果进行对比,发现三者之间的最大误差不超过2%,验证了建立的有限元模型和所推导的理论公式分析结果的准确性.

-

关键词:

- CFRP加固圆钢管短柱 /

- 轴压作用 /

- 静力承载力 /

- 等效截面法 /

- 有限元分析

Abstract: To predict the ultimate strength of a short circular hollow section (CHS) steel tubular columns reinforced with carbon fibre-reinforced polymer (CFRP), both theoretical and numerical analyses were carried out. In the theoretical analysis, based on equivalent section method, the equations for calculating the load bearing capacities of CHS steel tubular columns under axial compression are deduced, which correspond to two different reinforcing methods, in which CFRPs are arranged in circumferential placement and in longitudinal-circumferential placement. In the numerical analysis, both eigenvalue buckling method and Riks method are combined to build a nonlinear finite element model of the tubular columns under axial compression. The finite element analysis for the stress distribution of the longitudinal and circumferential CFRPs shows that the circumferential CFRPs are under tension and restrain the radial deformation of the tubular columns, while the longitudinal CFRPs share the axial compression and restrain the deformation of the tubular columns. The comparison of the numerical results, theoretical results and reported experimental results show that the maximum deviation among them is no more than 2%, which verifies the finite element model and deduced equations. -

表 1 CHS参数

Table 1. CHS parameters

组号 试件编号 ${D_{\rm{s}}}$/mm ${t_{\rm{s}}}$/mm ${E_{\rm{s}}}$/(N•mm−2) $\sigma _{\rm{y}}$/(N•mm−2) ${E_{\rm{p,CFRP}}}$/(N•mm−2) ${D_{\rm{s}}}/{t_{\rm{s}}}$ $L/{D_{\rm{s}}}$ FRP 层数和方向 1 C-1 87.25 2.36 209 571 455 — 37 3.2 — CF-1A 87.23 2.32 209 571 455 230 000 38 3.2 1H1L CF-1B 87.21 2.32 209 571 455 230 000 38 3.2 2H2L 2 C-2 86.31 2.00 209 571 455 — 43 3.2 — CF-2A 86.38 1.91 209 571 455 230 000 45 3.2 1L1H CF-2B 86.39 1.96 209 571 455 230 000 44 3.2 2L2H 3 C-3 85.75 1.57 209 571 455 — 55 3.2 — CF-3A 85.68 1.57 209 571 455 230 000 54 3.2 1H1L 4 C-4 85.11 1.13 209 571 455 — 75 3.2 — CF-4A 85.21 1.10 209 571 455 230 000 78 3.2 1H1L 5 ST1 165 4.2 206 000 339 — 39 2.7 — ST2 166 4.2 206 000 339 76 000 40 2.7 1H ST3 165 4.2 206 000 339 76 000 39 2.7 2H ST4 165 4.2 206 000 339 76 000 39 2.7 2H 表 2 CFRP材料属性

Table 2. CFRP material properties

${E_1}$/MPa ${E_2}$/MPa ${N_{\rm{u}}}$ ${G_{12}}$/MPa ${G_{13}}$/MPa ${G_{23}}$/MPa $t_{\rm{CFRP}}$/mm 230 000 1 900 0.3 3 387 3 387 3 387 0.176 注:当采用 文献[12 ]的模型建模时 $t_{\rm{CFRP}} = 0.17\;{\rm{mm}}$;E1 为纤维方向的弹性模量;E2 为垂直于纤维方向的弹性模量;

Nu 为泊松比;G12、G13、G23 为材料各平面内剪切模量.表 3 Hashin失效参数

Table 3. Hashin’s failure parameters

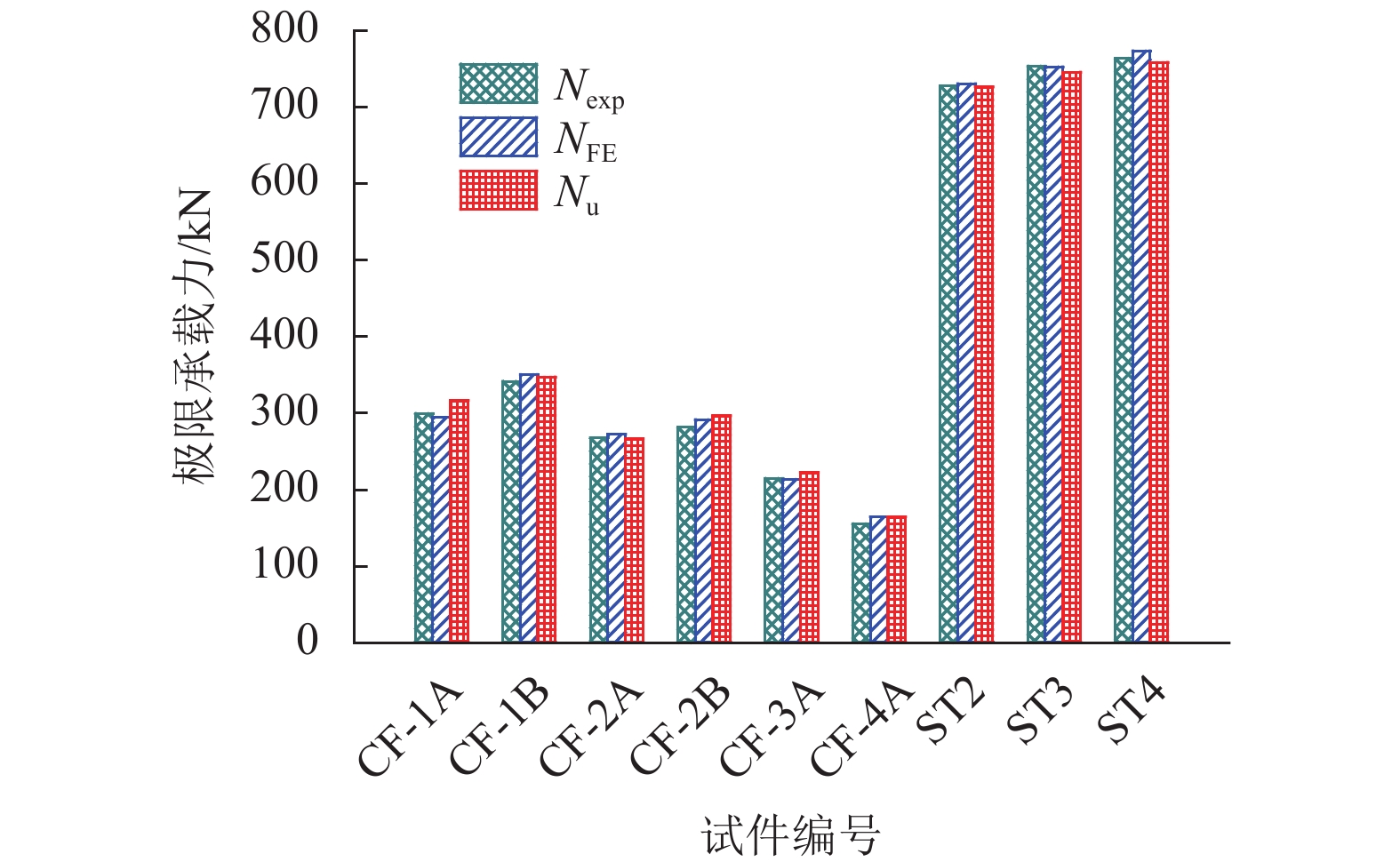

MPa 方向 参数 值 方向 参数 值 X 拉伸强度 XT 1 830 Y 拉伸强度 YT 31.3 压缩强度 XC 895 压缩强度 YC 124.5 剪切强度 SL 72 剪切强度 ST 62.3 表 4 极限承载力对比分析

Table 4. Comparison and analysis of load carrying capacity

组 试件编号 Nexp/kN NFE/kN Nu/kN 提高率/% NFE/Nexp Nu/Nexp Nu/NFE 1 C-1 253 260 280 — 1.03 1.10 1.08 CF-1A 299 294 316 13 0.98 1.06 1.07 CF-1B 341 350 347 24 1.03 1.02 0.99 2 C-2 220 226 241 — 1.03 1.10 1.07 CF-2A 267 272 266 10.4 1.02 1.00 0.98 CF-2B 281 291 296 23 1.04 1.05 1.02 3 C-3 170 174 188 — 1.02 1.10 1.08 CF-3A 214 213 222 22.4 1.00 1.04 1.04 4 C-4 120 125 137 — 1.04 1.14 1.10 CF-4A 155 164 164 31.2 1.06 1.06 1.00 5 ST1 719 722 719 — 1.00 1.00 1.00 ST2 727 730 726 1.4 1.00 1.00 0.99 ST3 753 752 745 4.7 1.00 0.99 0.99 ST4 763 763 758 6.2 1.00 0.99 0.99 -

季园园,韩庆华,芦燕,等. CFRP在土木工程中的应用研究[J]. 结构工程师,2014(5): 210-219. doi: 10.3969/j.issn.1005-0159.2014.05.032JI Yuanyuan, HAN Qinghua, LU Yan, et al. Application research of CFRP in civil engineering[J]. Structural Engineers, 2014(5): 210-219. doi: 10.3969/j.issn.1005-0159.2014.05.032 SEICA M V, PACKER J A. FRP materials for the rehabilitation of tubular steel structures for underwater applications[J]. Composite Structures, 2007, 80(3): 440-450. doi: 10.1016/j.compstruct.2006.05.029 完海鹰,江勇. 碳纤维复材布加固轴压圆管柱静力试验和数值分析[J]. 工业建筑,2017,47(2): 33-37.WAN Haiying, JIANG Yong. A static test and numerical analysis of circular hollow section (CHS) columns reinforced by CFRP sheets under axial compression[J]. Industrial Construction, 2017, 47(2): 33-37. 朱佳,完海鹰. 碳纤维增强复合材料加固轴压足尺圆管柱的试验研究[J]. 工业建筑,2016,46(4): 104-109.ZHU Jia, WAN Haiying. Experimental study of full scale circular hollow section (CHS) columns reinforced by CFRP under axial compression[J]. Industrial Construction, 2016, 46(4): 104-109. 周乐,王晓初,王军伟,等. 负载条件下CFRP加固轴心受压钢管短柱受力性能研究[J]. 工程力学,2015,32(11): 201-209. doi: 10.6052/j.issn.1000-4750.2014.04.0357ZHOU Le, WANG Xiaochu, WANG Junwei, et al. Research on mechanical properties of axially loaded tubular steel stub columns reinforced by CFRP[J]. Engineering Mechanics, 2015, 32(11): 201-209. doi: 10.6052/j.issn.1000-4750.2014.04.0357 李兆阳,高小育,陈沿辰. 碳纤维布加固钢管轴压短柱有限元分析[J]. 四川理工学院学报(自然科学版),2015,28(5): 74-80. doi: 10.11863/j.suse.2015.05.14LI Zhaoyang, GAO Xiaoyu, CHEN Yanchen. Finite element analysis of CFRP strengthened steel tubular short columns under axial compression[J]. Journal of Sichuan University of Science & Engineering (Natural Science Edition), 2015, 28(5): 74-80. doi: 10.11863/j.suse.2015.05.14 南波, 武岳,孙浩田. 缠绕型CFRP圆管轴压力学性能[J]. 工程力学,2017,34(1): 92-100.NAN Bo, WU Yue, SUN Haotian. Mechanical properties of filament-wound CFRP tube under axially compressive load[J]. Engineering Mechanics, 2017, 34(1): 92-100. 南波,武岳,孙浩田. 拉挤型CFRP管轴压性能[J]. 哈尔滨工程大学学报,2015,36(6): 779-783.NAN Bo, WU Yue, SUN Haotian. Buckling behavior of pultruded carbon fiber reinforced polymer under axially compressive load[J]. Journal of Harbin Engineering University, 2015, 36(6): 779-783. 张贵文,李俊杰,王秀丽. 碳纤维布加固薄壁圆钢管轴心抗拉承载力有限元分析[J]. 甘肃科学学报,2012,24(1): 32-36. doi: 10.3969/j.issn.1004-0366.2012.01.009ZHANG Guiwen, LI Junjie, WANG Xiuli. Finite element analysis on axial tensile bearing capacity of round thin-walled steel-tubes strengthened with CFRP sheets[J]. Journal of Gansu Sciences, 2012, 24(1): 32-36. doi: 10.3969/j.issn.1004-0366.2012.01.009 HAEDIR J, ZHAO X L, BANBACH M R, et al. Analysis of CFRP externally-reinforced steel CHS tubular beams[J]. Composite Structures, 2010, 92(12): 2992-3001. doi: 10.1016/j.compstruct.2010.05.012 HAEDIR J, ZHAO X L. Design of short CFRP-reinforced steel tubular columns[J]. Journal of Constructional Steel Research, 2011, 67(3): 497-509. doi: 10.1016/j.jcsr.2010.09.005 TENG J G, HU Y M. Behavior of FRP-jacketed circular steel tubes and cylindrical shells under axial compression[J]. Construction & Building Materials, 2007, 21(4): 827-838. 刘勇,陈世健,高鑫,等. 基于Hashin准则的单层板渐进失效分析[J]. 装备环境工程,2010,7(1): 34-39. doi: 10.3969/j.issn.1672-9242.2010.01.009LIU Yong, CHEN Shijian, GAO Xin, et al. Progressive failure analysis of monolayer composite based on Hashin criterion[J]. Equipment Environmental Engineering, 2010, 7(1): 34-39. doi: 10.3969/j.issn.1672-9242.2010.01.009 庄茁. ABAQUS非线性有限元分析与实例[M]. 北京: 科学出版社, 2005: 55-90. 廖云龙,吴剑. 基于Riks方法的复合材料贮箱稳定性分析[J]. 火箭推进,2013,39(5): 65-69. doi: 10.3969/j.issn.1672-9374.2013.05.012LIAO Yunlong, WU Jian. Stability analysis based on Riks method for composite material vessel[J]. Journal of Rocket Propulsion, 2013, 39(5): 65-69. doi: 10.3969/j.issn.1672-9374.2013.05.012 -

下载:

下载: