Adaptive Detection Algorithm for High-Speed Railway Fasteners by Vision

-

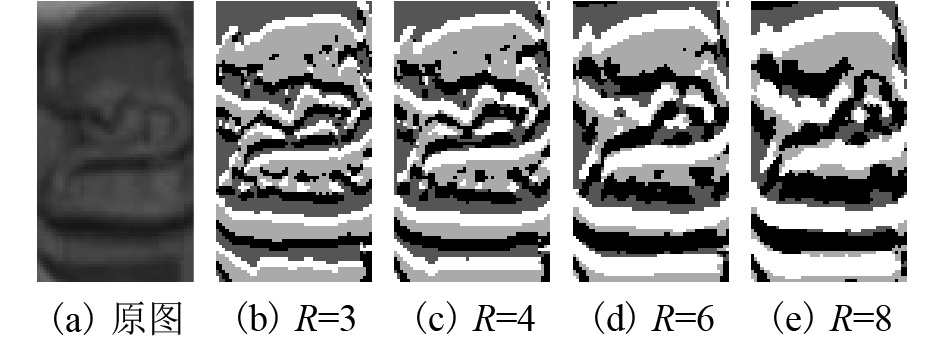

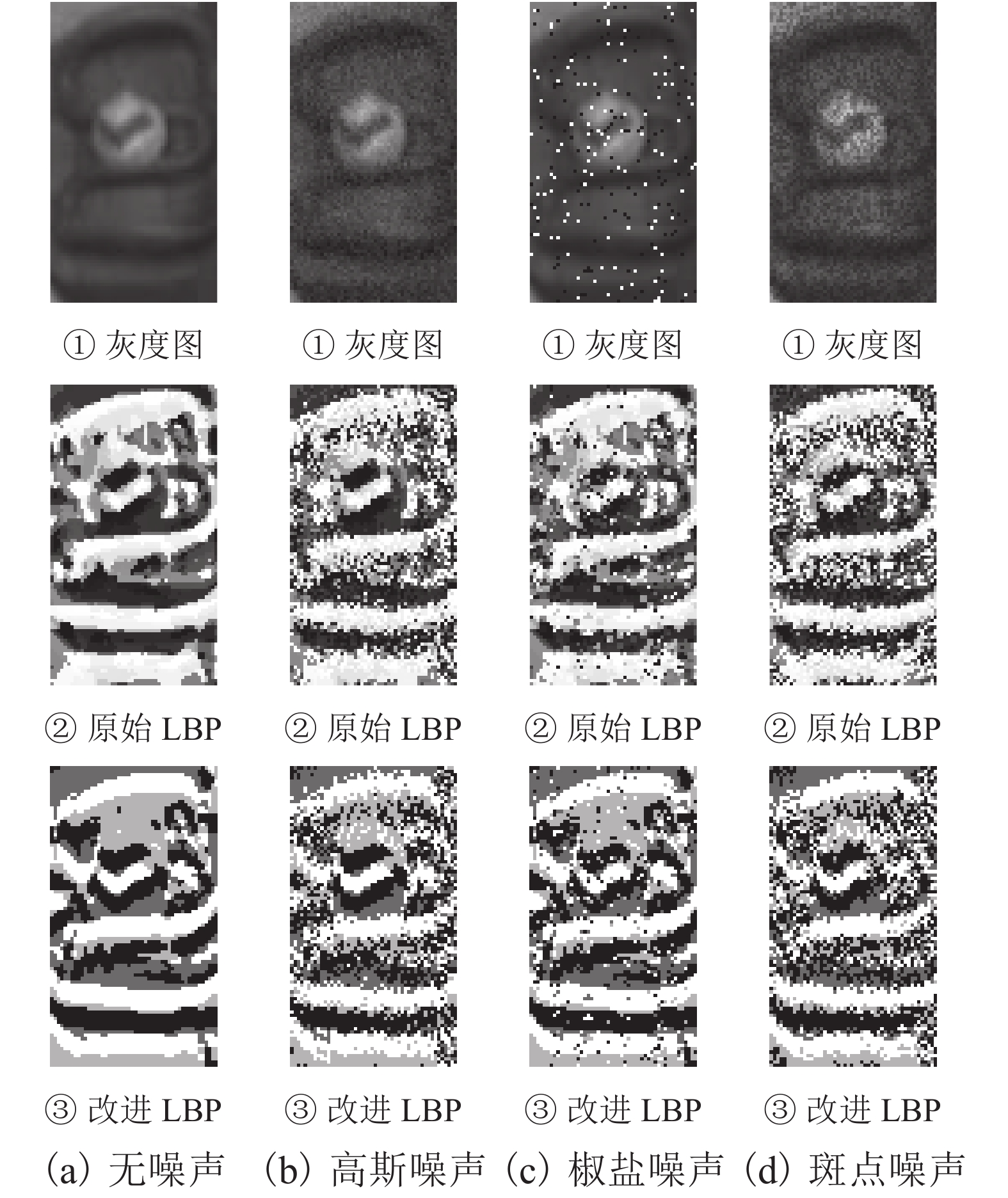

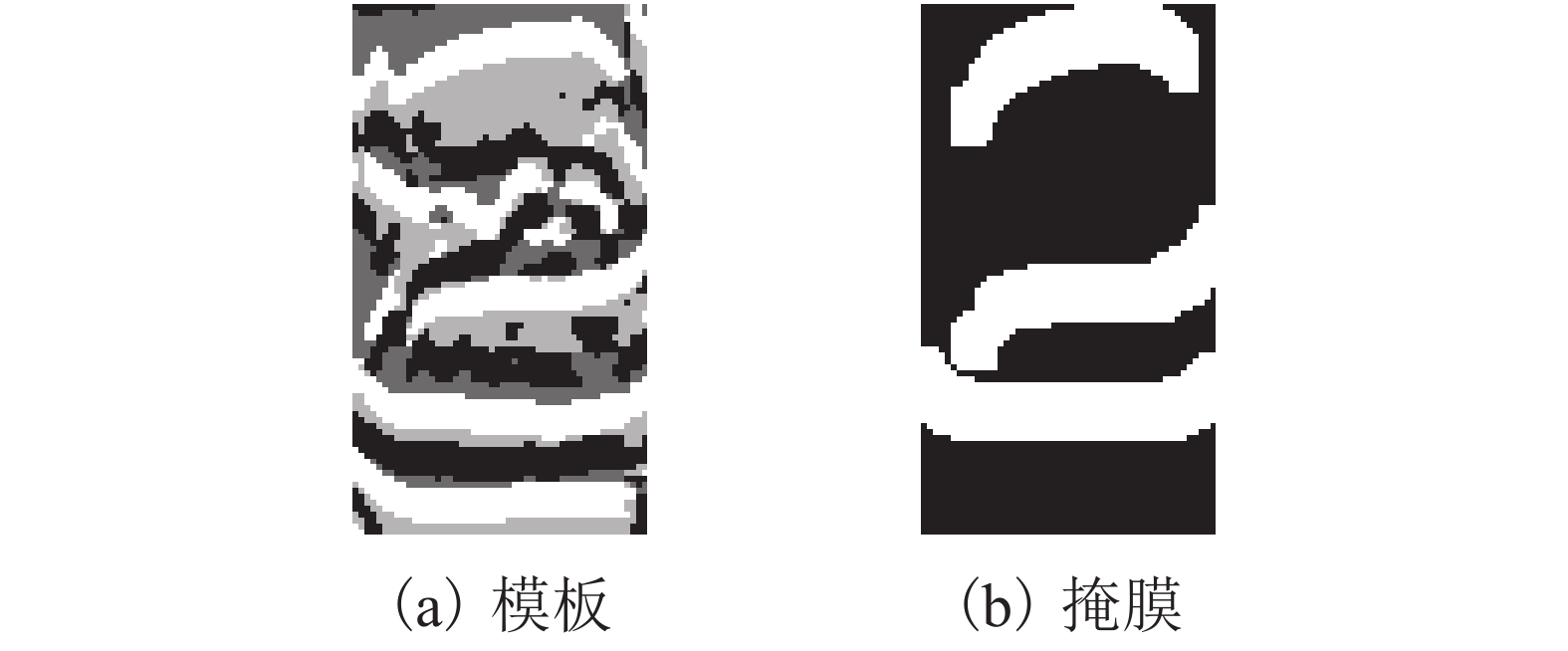

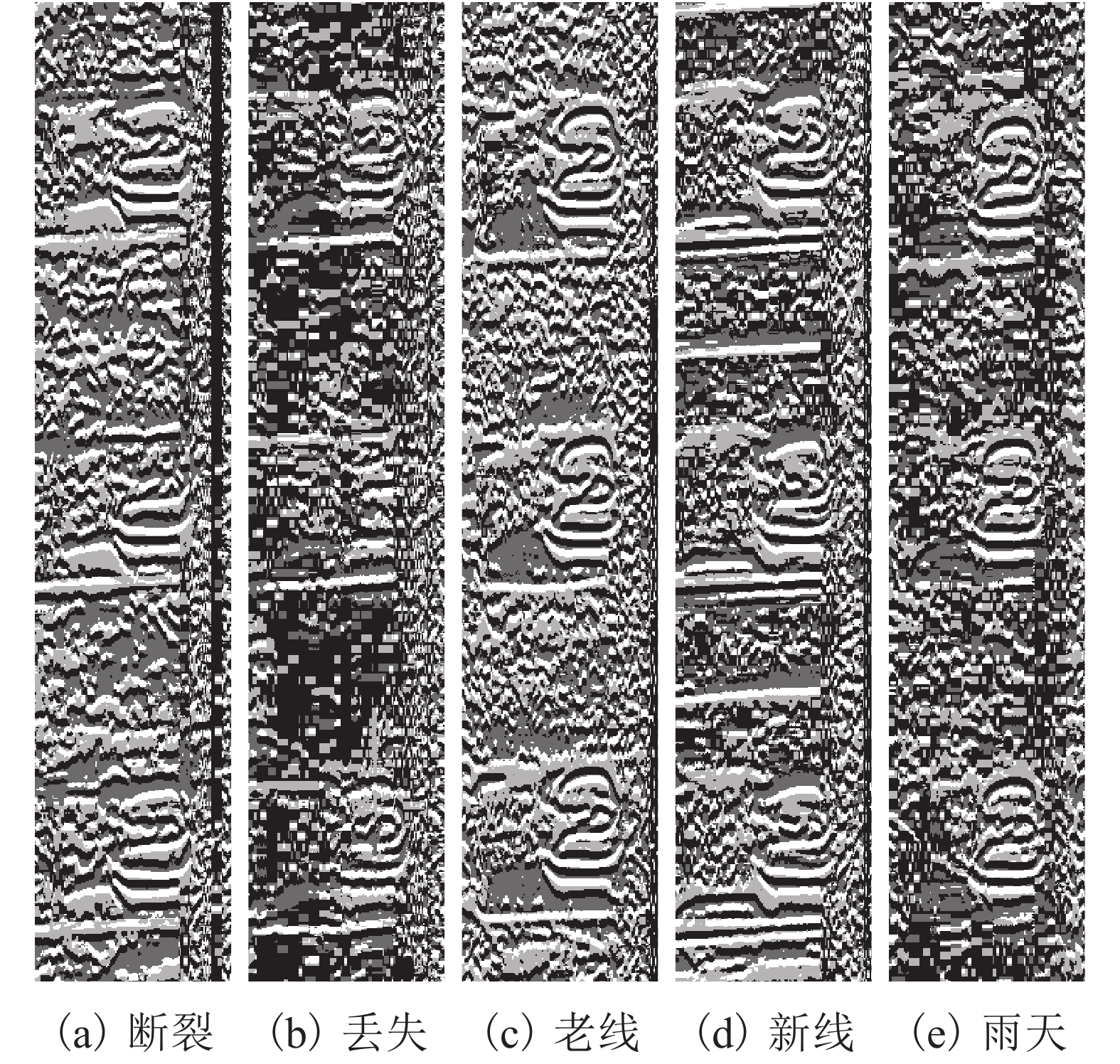

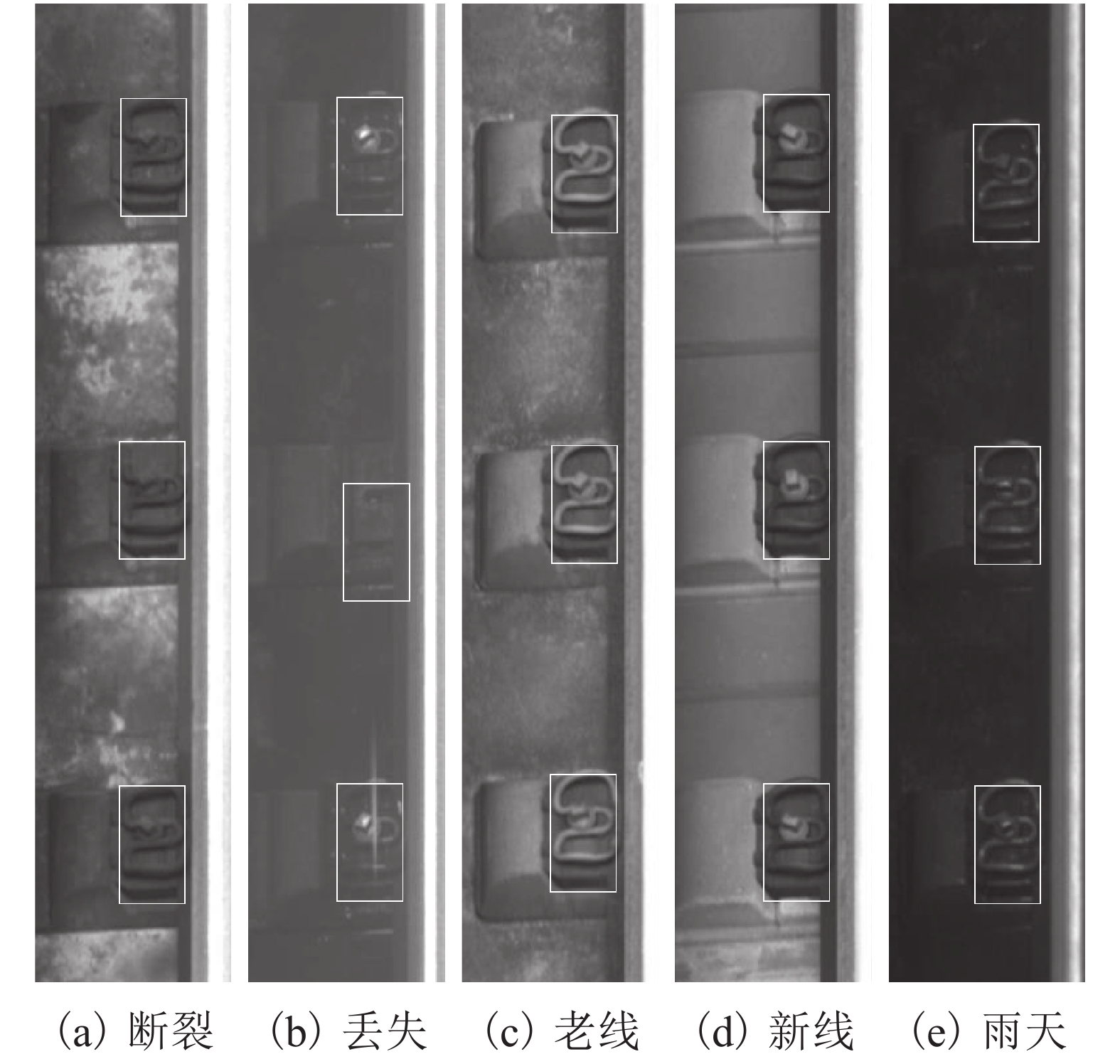

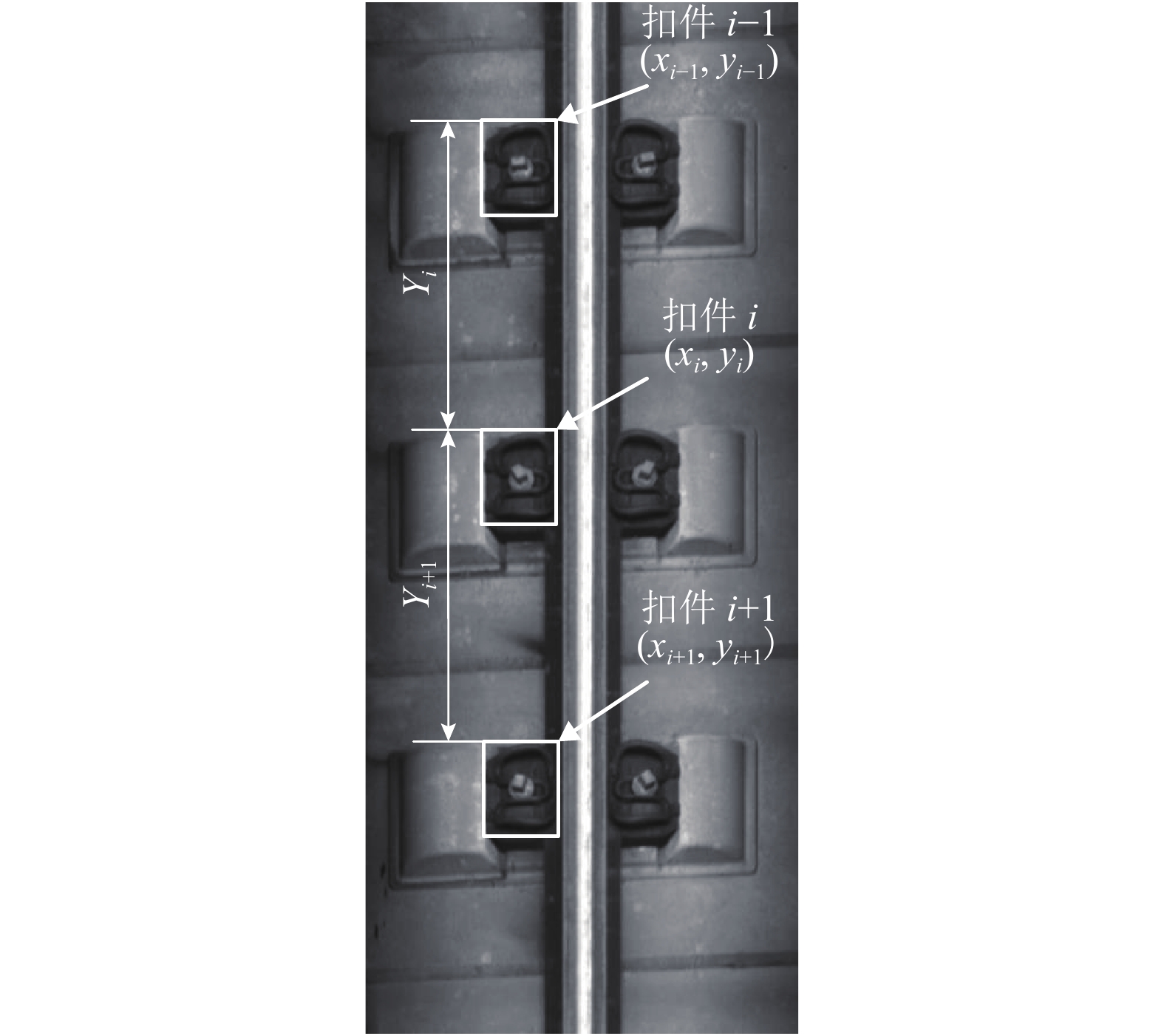

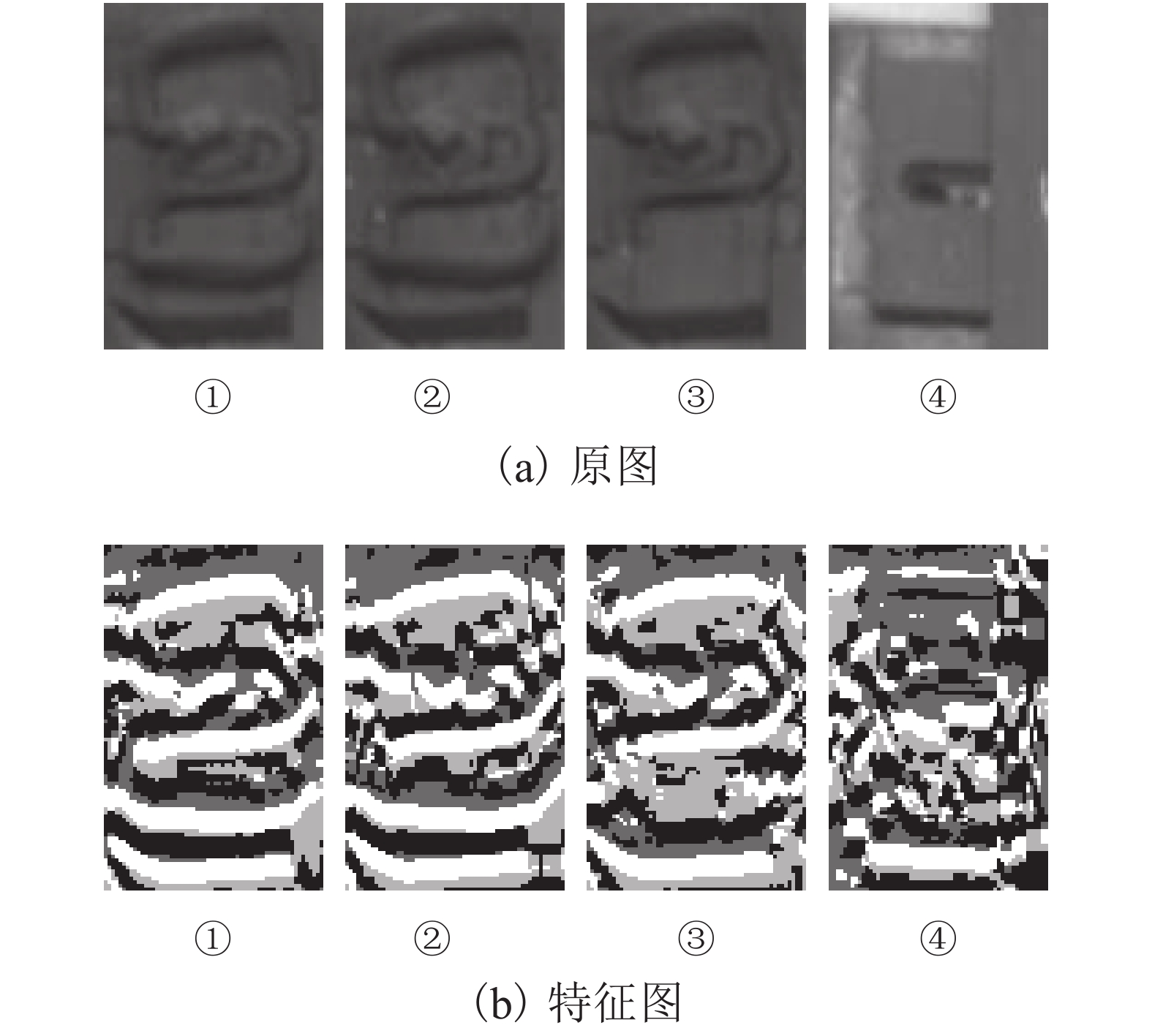

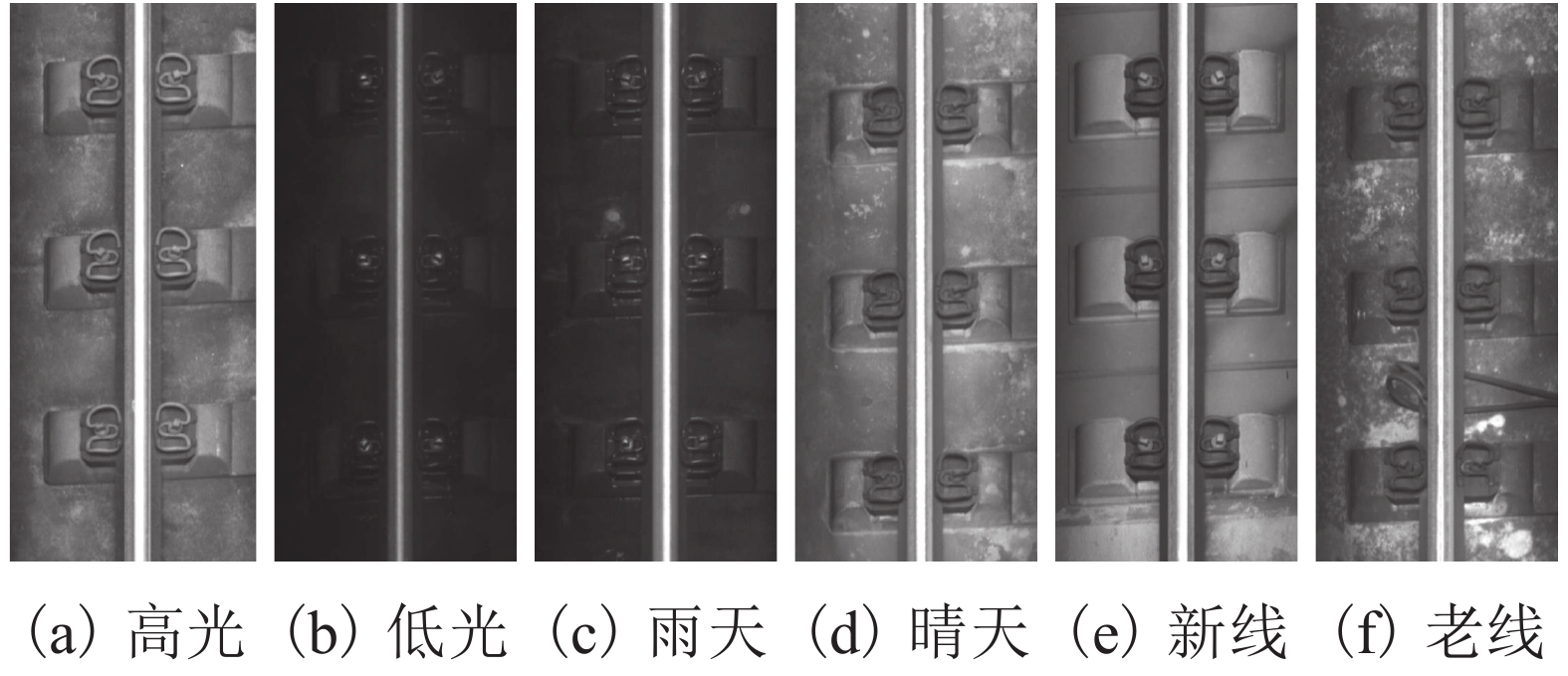

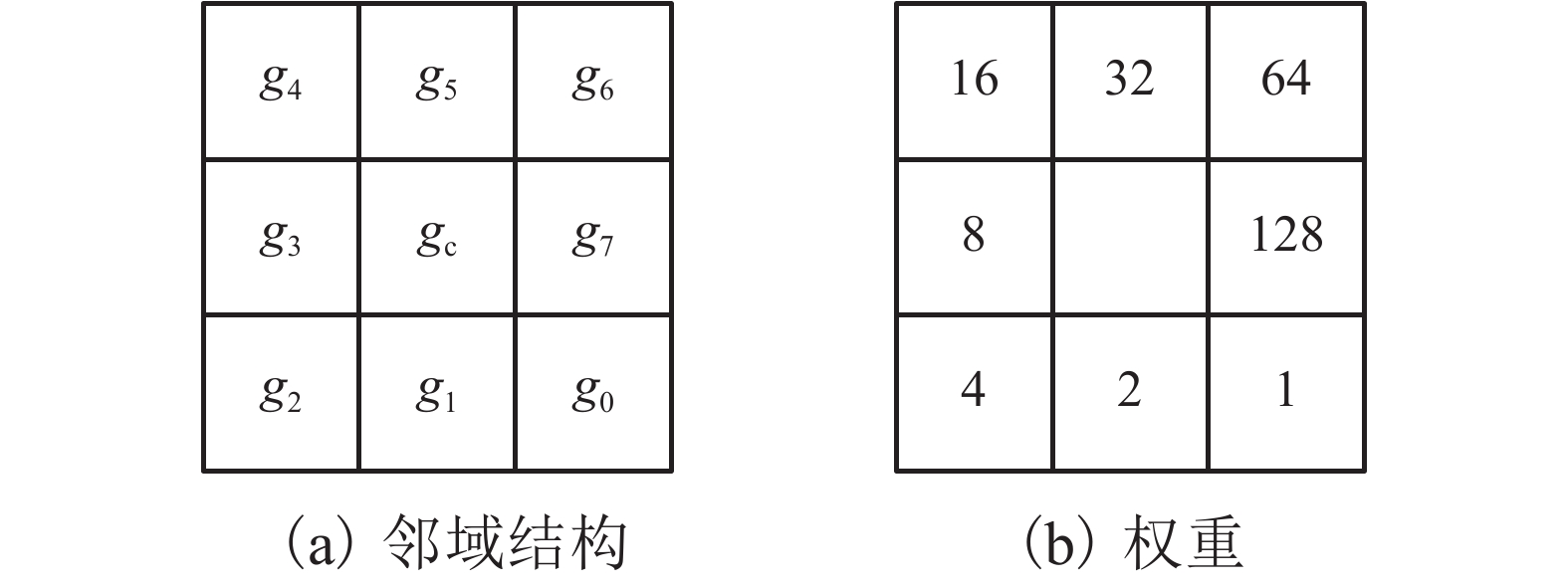

摘要: 为了实现高铁缺陷扣件的准确、快速和自动化检测,提出一种基于图像处理技术的高铁扣件自适应视觉检测算法. 针对高铁扣件图像的特性,使用改进的LBP (local binary pattern)算子提取扣件的显著特征;在扣件特征图的基础上,采用模板匹配算法得到扣件区域在原始图中的精确位置,进而得到扣件子图并用扣件的位置信息校验定位结果;以相邻两个扣件子图的差值作为判断依据,如果差值大于预设的阈值,相应的扣件则被判断为缺陷扣件. 将该检测算法应用于高铁工务部门提供的真实扣件图. 研究结果表明:本文提出的自适应扣件检测算法在雨天的表现最差,检出率为96%,误检率为0.50%;在晴天的表现最好,检出率为100%,误检率为0.22%;在不同天气、光照、环境下的综合检出率为99%,综合误检率为0.33%.Abstract: In order to achieve accurate, rapid and automatic detection of high-speed railway defective fasteners, an adaptive vision detection algorithm for high-speed railway fastener was proposed based on image processing technology. Aiming at the particularity of high-speed railway fastener images, the improved LBP (local binary pattern) operator was used to extract the salient features of fastener. Based on the prominent feature maps of fastener, the template matching algorithm was used to obtain the precise position of fastener region in the original image, and then get the sub-map of fastener and use the position information of fastener to verify the localization result; The difference between two adjacent sub-maps was used as the judgment basis, if the difference was greater than the preset threshold, the corresponding fasteners were judged as defective fasteners. The detection algorithm was applied to the real fastener image provided by the track maintenance division. The results show that the adaptive fastener detection algorithm proposed in this paper performs worst on rainy days, with a correct detection rate of 96% and a false detection rate of 0.50%; It performs best on sunny days, with a correct detection rate of 100% and a false detection rate of 0.22%; It achieves a comprehensive correct detection rate of 99% and a comprehensive false detection rate of 0.33% under different weather, lighting and environment.

-

Key words:

- high-speed railway /

- fastener detection /

- machine vision /

- image processing /

- pattern recognition

-

表 1 扣件定位结果

Table 1. Results of fastener localization

表 2 扣件识别结果(Td = 0.3)

Table 2. Results of fastener recognition algorithm (Td = 0.3)

图像类别 输入图像总数/(× 103 幅) 正常图像数/幅 缺陷图像数/幅 正确检出/幅 错误检出/幅 检出率/% 误检率/% 高光照 5 4 968 32 32 16 100.00 0.32 低光照 5 4 964 36 35 21 97.22 0.42 雨天 5 4 975 25 24 25 96.00 0.50 晴天 5 4 966 34 34 11 100.00 0.22 新线路 5 4 972 28 28 12 100.00 0.24 老线路 5 4 955 45 45 14 100.00 0.28 综合 30 29 800 200 198 99 99.00 0.33 -

肖新标,金学松,温泽峰. 钢轨扣件失效对列车动态脱轨的影响[J]. 交通运输工程学报,2006,6(1): 10-15. doi: 10.3321/j.issn:1671-1637.2006.01.002XIAO Xinbiao, JIN Xuesong, WEN Zefeng. Influence of rail fastener failure on vehicle dynamic derailment[J]. Journal of Traffic and Transportation Engineering, 2006, 6(1): 10-15. doi: 10.3321/j.issn:1671-1637.2006.01.002 翟婉明,赵春发. 现代轨道交通工程科技前沿与挑战[J]. 西南交通大学学报,2016,51(2): 209-226. doi: 10.3969/j.issn.0258-2724.2016.02.001ZHAI Wanming, ZHAO Chunfa. Frontiers and challenges of sciences and technologies in modern railway engineering[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 209-226. doi: 10.3969/j.issn.0258-2724.2016.02.001 LI Q, REN S. A real-time visual inspection system for discrete surface defects of rail heads[J]. IEEE Transaction on Instrumentation and Measurement, 2012, 61(8): 2189-2199. doi: 10.1109/TIM.2012.2184959 WU X, YUAN P, PENG Q, et al. Detection of bird nests in overhead catenary system images for high-speed rail[J]. Pattern Recognition, 2016, 51: 242-254. doi: 10.1016/j.patcog.2015.09.010 SUN J, XIAO Z, XIE Y. Automatic multi-fault recognition in TFDS based on convolutional neural network[J]. Neurocomputing, 2017, 222: 127-136. doi: 10.1016/j.neucom.2016.10.018 QIAO Y, CAPPELLE C, RUICHEK Y. Visual localization across seasons using sequence matching based on multi-feature combination[J]. Sensors, 2017, 17: 24-42. SINGH M, SINGH S, JAISWAL J, et al. Autonomous rail track inspection using vision based system[C]//Proceedings of IEEE Int. Conf. Comput. Intell. Homeland Security Personal Safety. Piscataway: IEEE, 2006: 56-59. MARINO F, DISTANTE A, MAZZEO P, et al. A real-time visual inspection system for railway maintenance:automatic hexagonal-headed bolts detection[J]. IEEE Transactions on Systems,Man and Cybernetics,Part C (Applications and Reviews), 2007, 37(3): 418-428. doi: 10.1109/TSMCC.2007.893278 STELLA E, MAZZEO P, NITTI M, et al. Visual recognition of missing fastening elements for railroad maintenance[C]// Proceedings of IEEE Int. Conf. Intell. Transp. Syst. Piscataway: IEEE, 2002: 94-99. YANG J, TAO W, LIU M, et al. An efficient direction field-based method for the detection of fasteners on high-speed railways[J]. Sensors, 2011, 11: 7364-7381 XIA Y, XIE F, JIANG Z. Broken railway fastener detection based on adaboost algorithm[C]//Proceedings of International Conference on Optoelectronics and Image Processing. Washington D. C.: IEEE, 2010: 313-316. 刘甲甲,李柏林,罗建桥,等. 融合PHOG和MSLBP特征的铁路扣件检测算法[J]. 西南交通大学学报,2015,50(2): 256-263. doi: 10.3969/j.issn.0258-2724.2015.02.008LIU Jiajia, LI Bailin, LUO Jianqiao, et al. Railway fastener detection algorithm integrating PHOG and MSLBP features[J]. Journal of Southwest Jiaotong University, 2015, 50(2): 256-263. doi: 10.3969/j.issn.0258-2724.2015.02.008 LI Y, OTTO C, HAAS N, et al. Component-based track inspection using machine-vision technology[C]// Proceedings of the 1st ACM International Conference on Multimedia Retrieval. New York: ACM, 2011: 60-61. FENG H, JIANG Z, XIE F, et al. Automatic fastener classification and defect detection in vision-based railway inspection systems[J]. IEEE Trans. Instrumentation and Measurement, 2014, 63(4): 877-888. doi: 10.1109/TIM.2013.2283741 OJALA T, PIETIKAINEN M, MAENPAA T. Multi-resolution gray-scale and rotation invariant texture classification with local binary patterns[J]. IEEE Trans. Pattern Analysis and Machine Intelligence, 2002, 24(7): 971-987. doi: 10.1109/TPAMI.2002.1017623 -

下载:

下载: