Biotransformation of Bioethanol from Lignocellulose by High Yield Cellulase-Producing Aspergillus

-

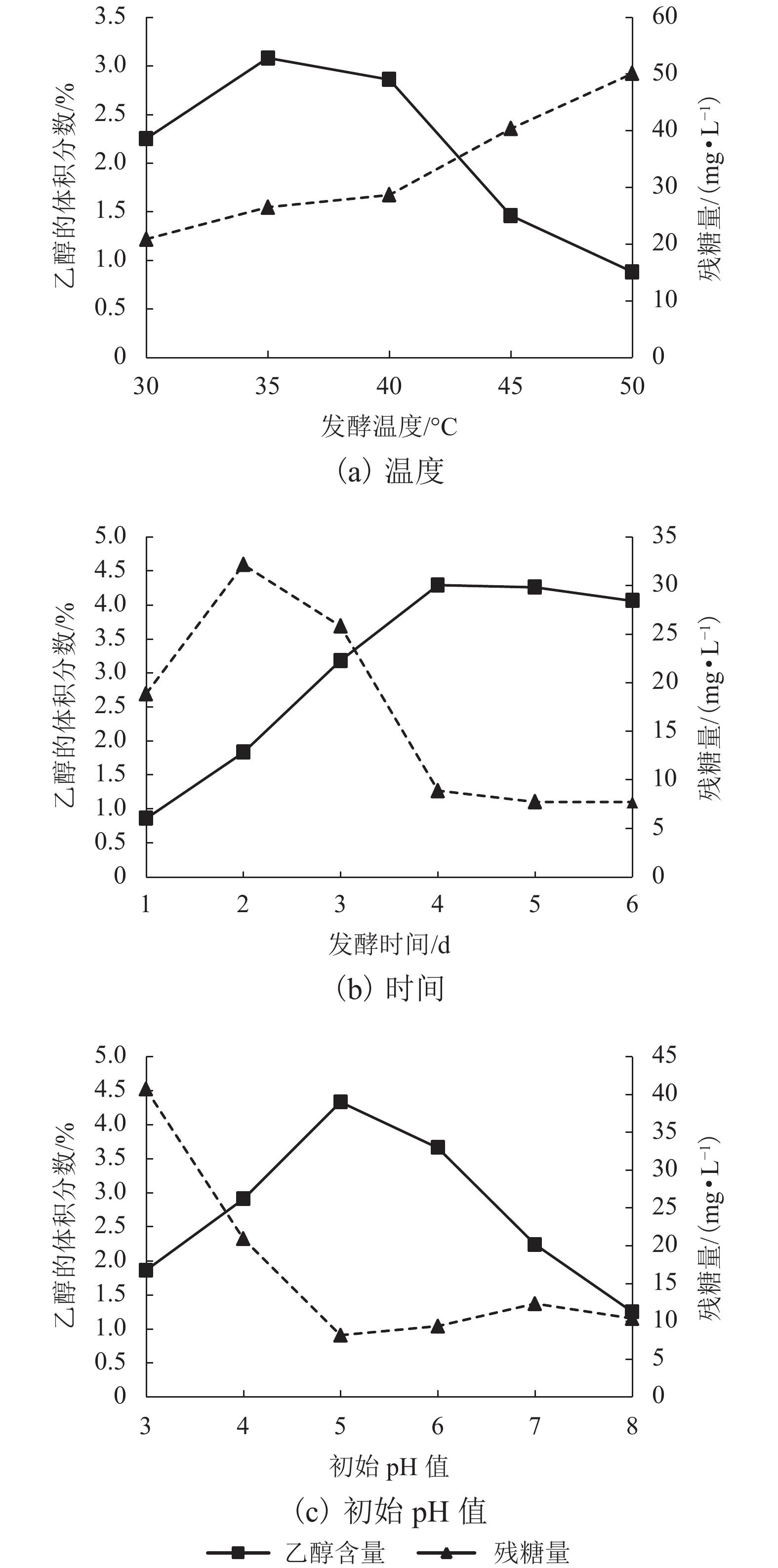

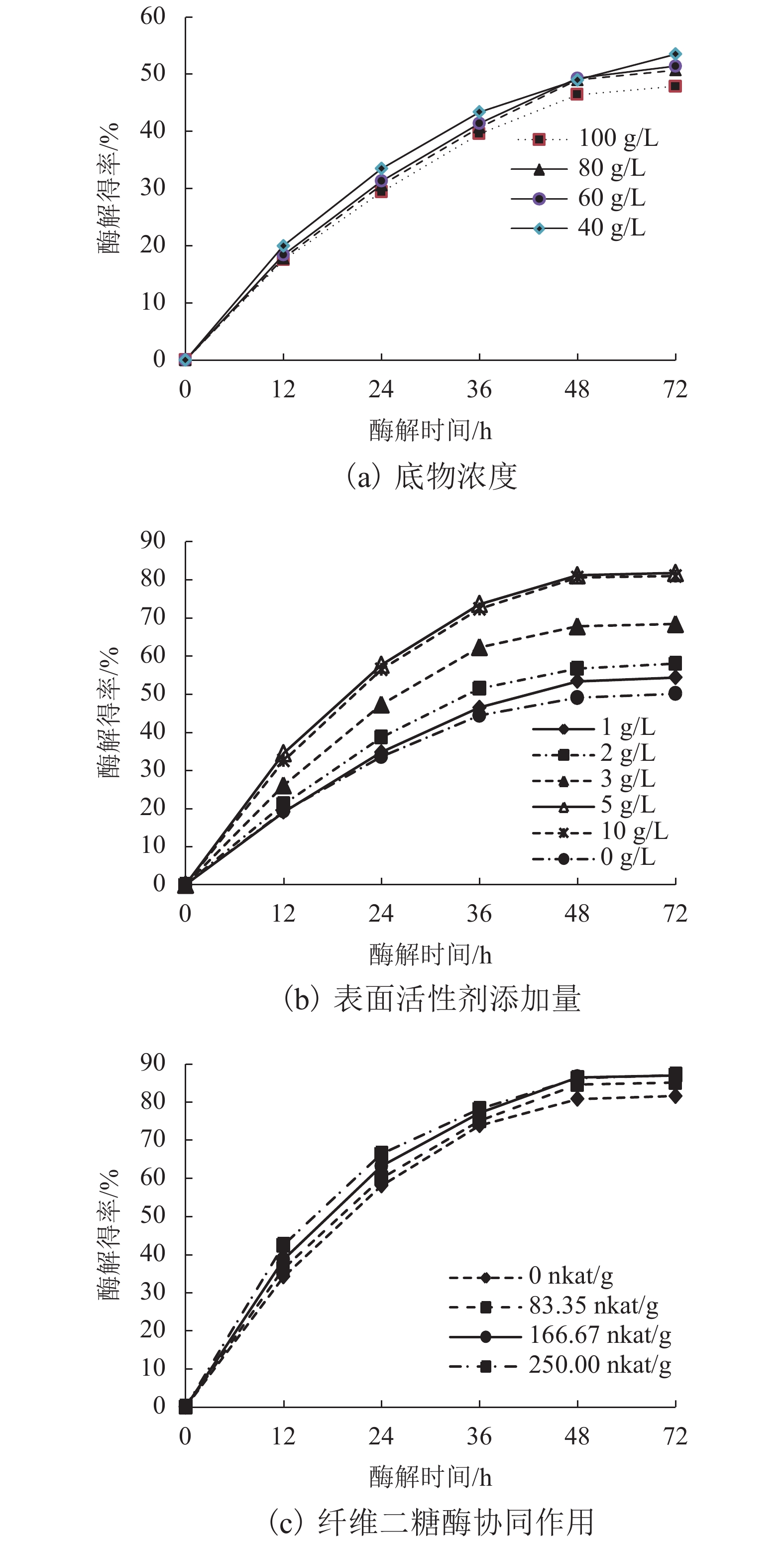

摘要: 为了提高纤维素乙醇的生产效率,对高效产纤维素酶曲霉W-10的产酶条件进行优化,利用其发酵所得的粗酶液对预处理后的水稻秸秆粉进行酶解,并用酿酒酵母通过同步糖化发酵(simultaneous saccharification and fermentation, SSF)工艺生物转化纤维素乙醇. 首先通过定时取样测定还原糖量,研究不同底物浓度、不同表面活性剂添加量、纤维二糖酶的协同作用等因素对酶解过程的影响. 然后利用所得优化后的酶解条件进行同步糖化实验,研究不同的发酵温度、发酵时间、初始pH值等影响因素对同步糖化发酵乙醇的影响. 结果表明,当底物浓度为80 g/L、表面活性剂吐温-80添加浓度为5 g/L、酶解体系外纤维二糖酶补加量为166.67 nkat/g时,粗酶液的酶解率最高;在35 ℃的培养温度、初始pH值为5的条件下发酵4 d时,发酵液中乙醇含量最高,乙醇得率可达0.43 g/g(底物干重). 优化高效产纤维素酶曲霉W-10酶解水稻秸秆的反应条件,可促进纤维素乙醇生物转化技术的发展,有利于可再生的清洁能源生物乙醇的商业化生产和应用.Abstract: Biotransformation of bioethanol was innovatively processed with crude enzyme to hydrolyse rice straw from a high-yield cellulase-producing Aspergillus W-10 and by simultaneous saccharification and fermentation (SSF) with Saccharomyces cerevisiae. Hydrolysis and saccharification of pretreated rice straw by crude enzyme with cellulase and cellobiase was measured at regular sampling of reducing sugar. Meanwhile, the impacts of substrate concentration, the amount of surfactant and synergism of cellobiase on hydrolysis process were studied. Then, the effects of fermentation temperature, fermentation time and initial pH value on the SSF were also explored on the bassis of the optimized hydrolysis conditions. The results show that when the concentration of substrate was 80 g/L, the concentration of surfactant Tween-80 was 5 g/L, and the amount of cellobiase was 166.67 nkat/g, the highest efficiency of hydrolysis of crude enzyme was observed. When the fermentation temperature was 35℃, the fermentation time was 4 d, and the initial pH value was 5, the concentration of ethanol in fermentation broth was the highest, reaching 0.43 g/g (dry weight of substrate). The optimization of the reaction conditions of high yield cellulase-producing Aspergillus W-10 can promote the bioconversion technology development of lignocellulosic ethanol, which is beneficial to the large-scale commercial production and application of bioethanol as a renewable clean energy.

-

表 1 水稻秸秆的纤维素、半纤维素、木质素质量分数

Table 1. Mass fraction of cellulose,hemicellulose and lignin in rice stalk

% 纤维素 半纤维素 木质素 42.48 29.40 10.73 -

李玉琦. 高效降解水稻秸秆复合菌群的构建及其降解效能[D]. 哈尔滨: 哈尔滨工业大学, 2016 GNANSOUNOU E. Production and use of lignocellulosic bioethanol in Europe:current situation and perpectives[J]. Bioresource Technology, 2010, 101: 4842-50. doi: 10.1016/j.biortech.2010.02.002 KOSSATZ H L, ROSE S H, VILJOEN B M. Production of ethanol from steam exploded triticale straw in a simultaneous saccharification and fermentation process[J]. Process Biochemistry, 2016, 53: 10-16. BELAL E B. Bioethanol production from rice straw residues[J]. Brazilian Journal Microbiology, 2013, 44(1): 225-234. doi: 10.1590/S1517-83822013000100033 赵蒙蒙,姜曼,周祚万. 几种农作物秸秆的成分分析[J]. 材料导报,2011,25(16): 122-125.ZHAO Mengmeng, JIANG Man, ZHOU Zuowan. The components analysis of several kinds of agricultural residues[J]. Materials Review, 2011, 25(16): 122-125. 刘会影,李国立,薛冬桦. 近红外光谱法测定玉米秸秆纤维素和半纤维素含量[J]. 中国农学通报,2013,29(35): 182-186. doi: 10.11924/j.issn.1000-6850.2013-0091LIU Huiying, LI Guoli, XUE Donghua. Determination of cellulose and hemicellulose contents in corn straw using near-infrared spectroscopy[J]. Chinese Agricultural Science Bulletin, 2013, 29(35): 182-186. doi: 10.11924/j.issn.1000-6850.2013-0091 车莉. 农作物秸秆资源量估算、分布与利用潜力研究[D]. 大连: 大连理工大学, 2014 谢丽萍. 大肠杆菌中乙醇生物合成途径的构建[D]. 无锡: 江南大学, 2001 AZHARA S H M, ABDULLAAB R, JAMBOA S A, et al. Yeasts insustainable bioethanol production:a review[J]. Biochemistry and Biophysics Reports, 2017, 10: 52-61. doi: 10.1016/j.bbrep.2017.03.003 孙金凤,徐敏,张峰,等. 利用木糖和葡萄糖合成乙醇的新型重组大肠杆菌的研究[J]. 微生物学报,2004,44(5): 600-604. doi: 10.3321/j.issn:0001-6209.2004.05.010SUN Jinfeng, XU Min, ZHANG Feng, et al. Novel recombinant Escherichia coli producing ethanol from glucose and xylose[J]. Acta Microbiologica Sinica, 2004, 44(5): 600-604. doi: 10.3321/j.issn:0001-6209.2004.05.010 MARTINEZ A, GRABAR T B, SHANMUGAM K T. et al. Low salt medium for lactate and ethanol production by recombinant Escherichia coli B[J]. Biotechnology Letters, 2007, 29(3): 397-404. doi: 10.1007/s10529-006-9252-y SOO C S, YAP W S, HON W M. Improvement of hydrogen yield by ethanol producing Escherichia coli recombinants in acidic condition[J]. Electronic Journal of Biotechnology, 2017, 26: 27-32. doi: 10.1016/j.ejbt.2016.12.007 刘炳全,李学凤,高文. 木质纤维素制取燃料乙醇菌种的研究[J]. 可再生能源,2007,25(4): 53-55. doi: 10.3969/j.issn.1671-5292.2007.04.015LIU Bingquan, LI Xuefeng, GAO Wen. Study on ethanol production from biomass[J]. Renewable Energy Resources, 2007, 25(4): 53-55. doi: 10.3969/j.issn.1671-5292.2007.04.015 路鹏. 抗水解液中抑制物的秸秆乙醇发酵菌剂构建及其功能研究[D]. 北京: 中国农业大学, 2007 张文博. 木质纤维素组成和结构与里氏木霉产酶关联性的研究[D]. 南京: 南京林业大学, 2016 任勰珂,陈莉,卢红梅. 多菌种混合固态发酵秸秆的研究[J]. 食品工业科技,2017(7): 130-134.REN Xieke, CHEN Li, LU Hongmei. Study on the solid state fermentation of straw with multiple strains[J]. Science and Technology of Food Industry, 2017(7): 130-134. ERDEI B, BARTA Z, SIPOS B, et al. Ethanol production from mixtures of wheat straw and wheat meal[J]. Biotechnol Biofuels, 2010, 3: 16-1-16-9. doi: 10.1186/1754-6834-3-16 VIIKARI L, VEHMAANPERA J, KOIVULA A. Lignocellulosic ethanol:from science to industry[J]. Biomass & Bioenergy, 2012, 46: 13-24. NOVY V, KRAHULEC S, WEGLEITER M, et al. Process intensification through microbial strain evolution:mixed glucose-xylose fermentation in wheat straw hydrolyzates by three generations of recombinant saccharomyces cerevisiae[J]. Biotechnology for Biofuels, 2014, 7: 49-1-49-12. doi: 10.1186/1754-6834-7-49 王晓娟,王斌,冯浩. 木质纤维素类生物质制备生物乙醇研究进展[J]. 石油与天然气化工,2007,36(6): 452-461. doi: 10.3969/j.issn.1007-3426.2007.06.005WANG Xiaojuan, WANG Bin, FENG Hao. Research development of bioethanol preparation from lignocellulosic biomass[J]. Modern Chemical Industry, 2007, 36(6): 452-461. doi: 10.3969/j.issn.1007-3426.2007.06.005 ISHOLA M M, BRANDBERG T, TAHERZADEH M J. Simultaneous glucose and xylose utilization for improved ethanol production from lignocellulosic biomass through SSFF with encapsulated yeas[J]. Biomass Bioenergy, 2015, 77: 192-199. doi: 10.1016/j.biombioe.2015.03.021 WATANABE I, MIYATA N, ANDO A, et al. Bioresource technology ethanol production by repeated-batch simultaneous saccharification and fermentation (SSF) of alkali-treated rice straw using immobilized Saccharomyces cerevisiae cells[J]. Bioresource Technology, 2012, 123: 695-698. doi: 10.1016/j.biortech.2012.07.052 NOVY V, LONGUS K, NIDETZKY B. From wheat straw to bioethanol:integrative analysis of a separate hydrolysis and co-fermentation process with implemented enzyme production[J]. Biotechnology for Biofuels, 2015, 8(1): 46-1-46-12. doi: 10.1186/s13068-015-0232-0 LIU Y, QIU Z P, WANG G C. Optimized alkaline pretreatment technology of rice straw for ethanol production[J]. Advances in Engineering Research, 2015: 1169-1173. PENG Y, WU S. The structural and thermal characteristics of wheat straw hemicellulose[J]. Journal of Analytical and Applied Pyrolysis, 2010, 88(2): 134-139. doi: 10.1016/j.jaap.2010.03.006 杨贵明,蒋爱华,薛秋生. 用DNS光度法测定还原糖的条件研究[J]. 安徽农业科学,2006,34(14): 3258-3264. doi: 10.3969/j.issn.0517-6611.2006.14.005YANG Guiming, JIANG Aihua, XUE Qiusheng. Study on the determination factor of reduced sugar with DNS spectrophotometry[J]. Journal of Anhui Agricultural Sciences, 2006, 34(14): 3258-3264. doi: 10.3969/j.issn.0517-6611.2006.14.005 何敏超, 许敬亮, 陈小燕, 等. 用于生物质酶解过程的纤维素酶研究进展[J]. 农业工程学报, 2016, 32(增刊1): 290-296HE Minchao, XU Jingliang, CHEN Xiaoyan, et al. Progress of cellulase that using for biomass hydrolysis process[J]. Transactions of the Chinese Society of Agricutural Engineer, 2016, 32(S1): 290-296 赵海峰. 液体深层发酵产纤维二糖酶及其在木质纤维素协同水解中的应用[D]. 杭州: 浙江大学, 2012 王金成. Fe−Mn−Mg离子对稻草秸秆酶解糖化的影响[D]. 重庆: 重庆大学, 2015 CHMIELEWSKA J. Selected biotechnological features of hybrids of Saccharomyces cerevisiae and Yamadazyma stipitis[J]. Biotechnology, 2003, 6(1): 1-13. CUEVAS M, SÁNCHEZ S, GARCIA J F, et al. Enhanced ethanol production by simultaneous saccharification and fermentation of pretreated olive stones[J]. Renewable Energy, 2015, 74: 839-847. doi: 10.1016/j.renene.2014.09.004 崔雨潇. 里氏木霉菌种选育及秸秆同步糖化发酵的研究[D]. 长春: 吉林大学, 2015 AKHTAR N, GOYAL D, GOYAL A. Characterization of microwave-alkali-acid pre-treated rice straw for optimization of ethanol production via simultaneous saccharification and fermentation (SSF)[J]. Energy Conversion and Management, 2017, 141: 133-144. doi: 10.1016/j.enconman.2016.06.081 赵鹏翔,卜令习,赵正凯. 提高菌株KE6-12对爆破秸秆同步糖化发酵适应性研究[J]. 可再生能源,2014,32(11): 23-27.ZHAO Pengxiang, BU Lingxi, ZHAO Zhengkai. Adaptability research on improve the strain KE6-12 for simultaneous saccharification and fermentation of blasting straw[J]. Renewable Energy Resources, 2014, 32(11): 23-27. ASADA C, SASAKI C, TAKAMATSU T. Conversion of steam-exploded cedar into ethanol using simultaneous saccharification,fermentation and detoxification process[J]. Bioresource Technology, 2015, 176: 203-209. doi: 10.1016/j.biortech.2014.11.039 -

下载:

下载: