Performance and Application of Adjustable Height Support

-

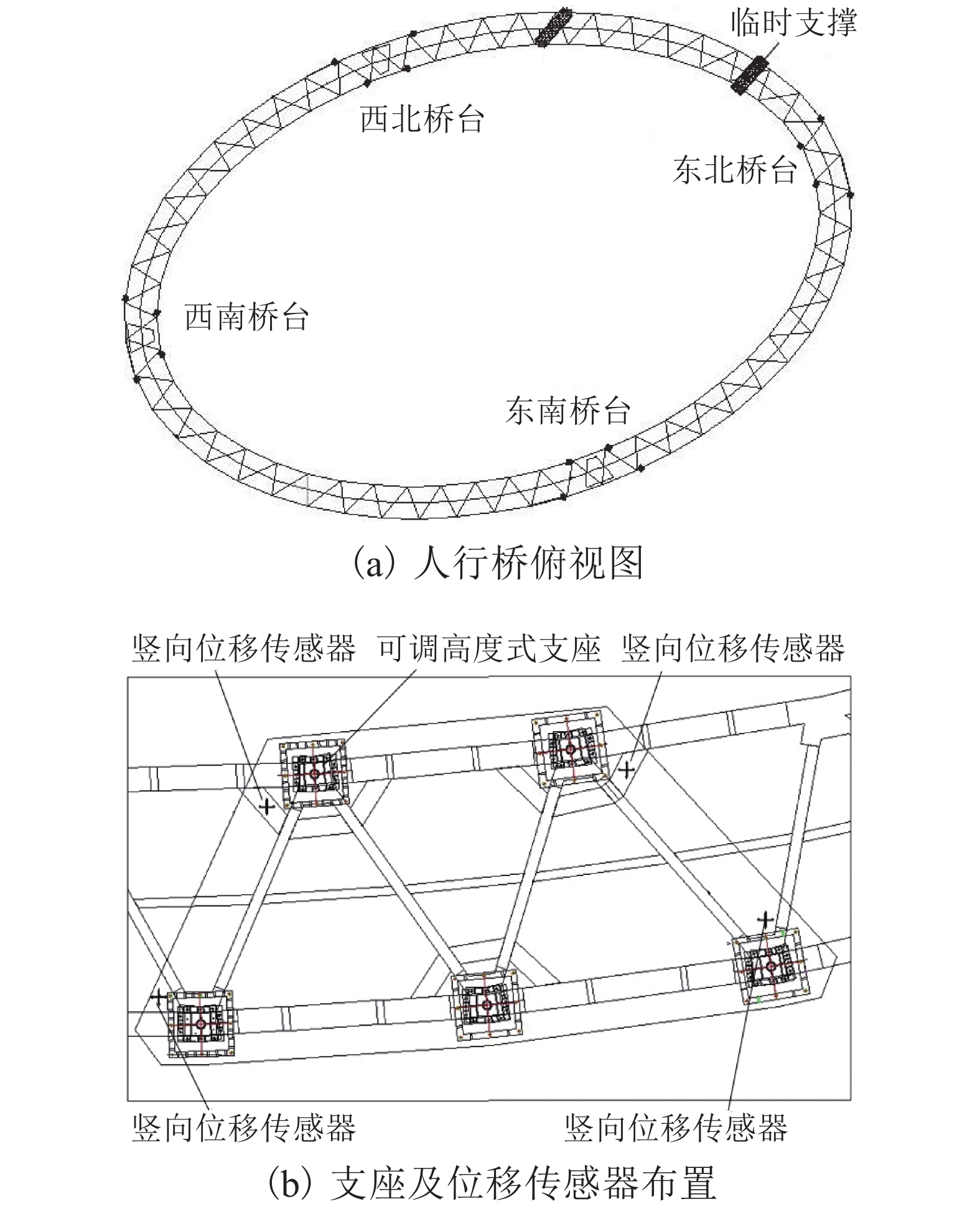

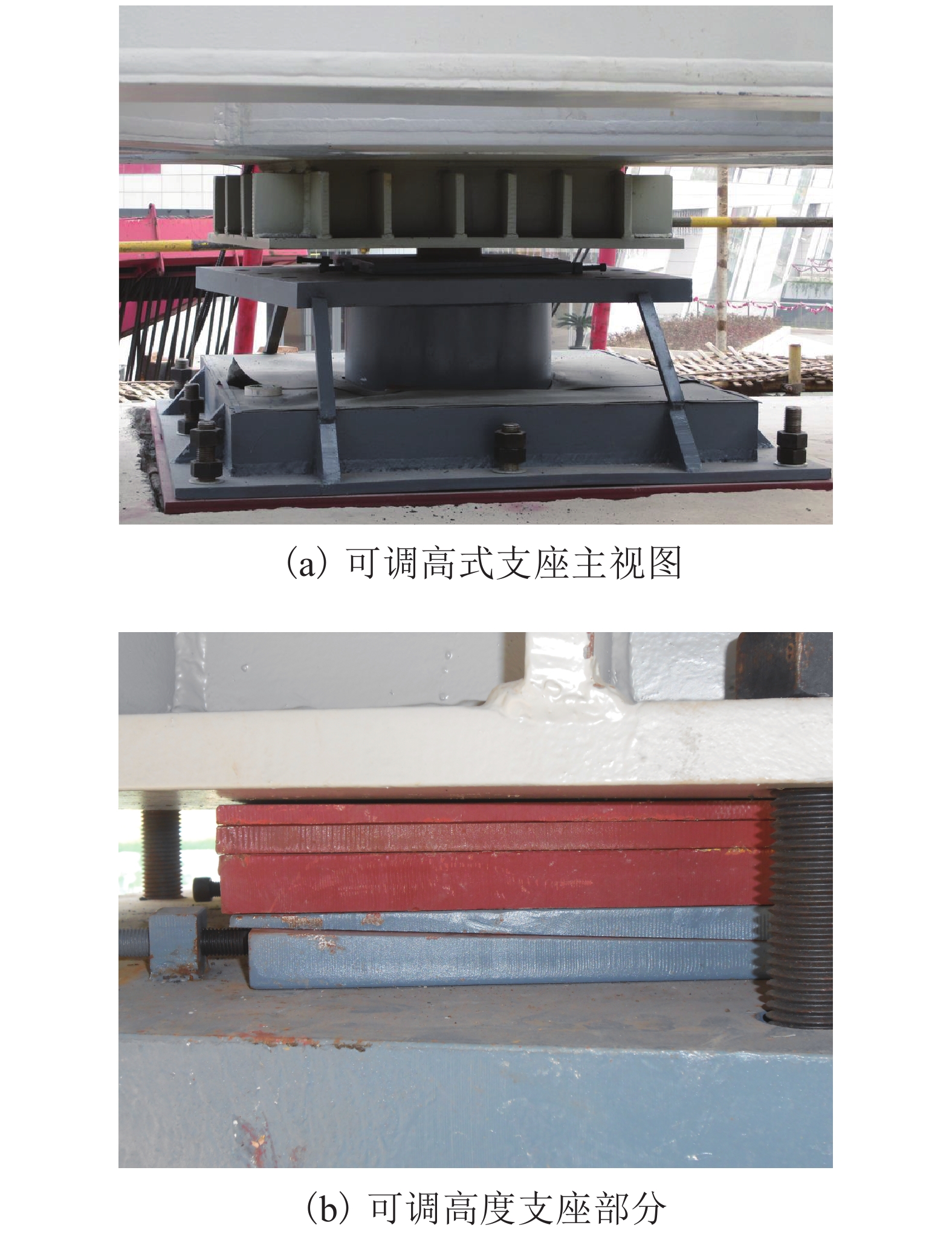

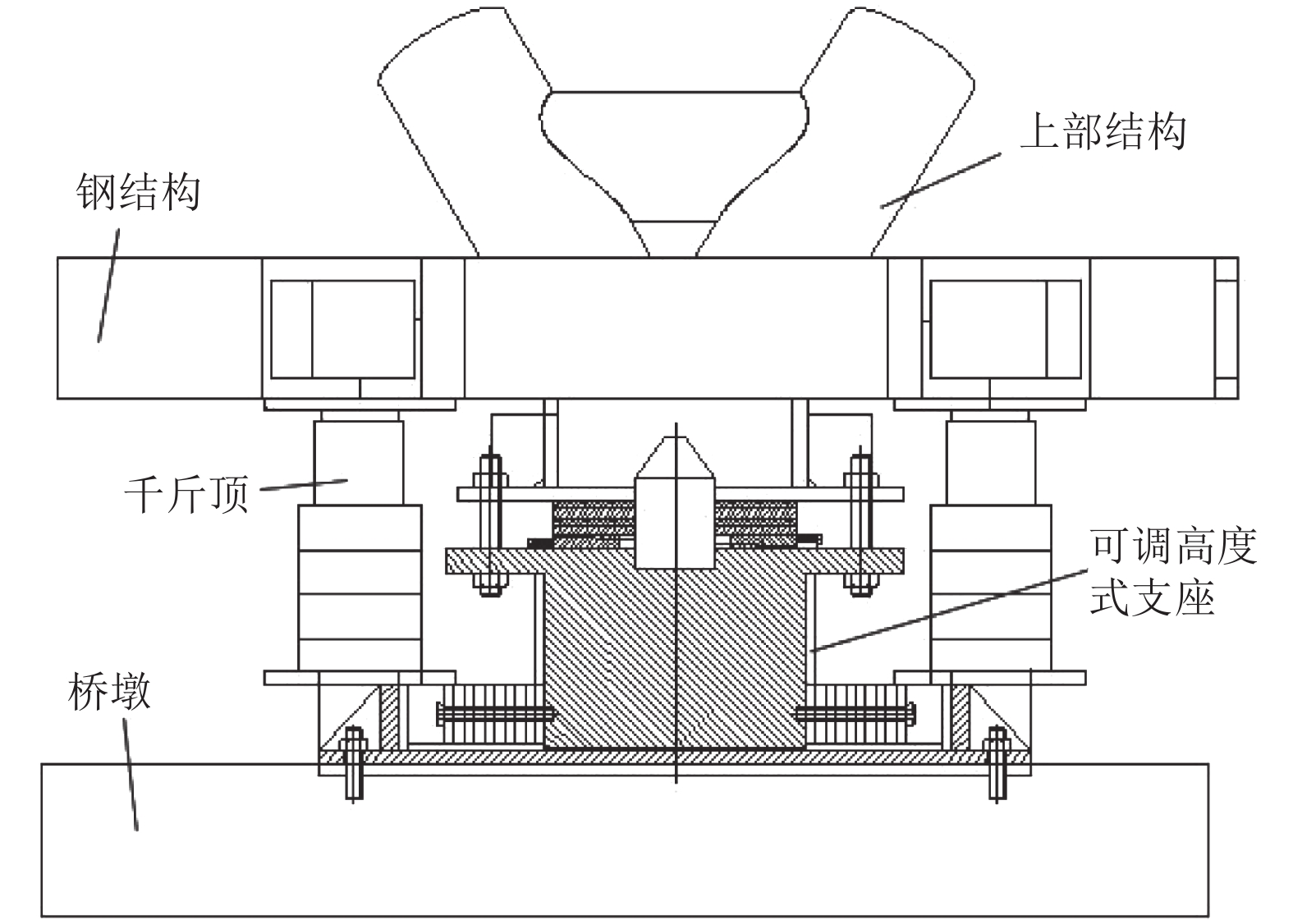

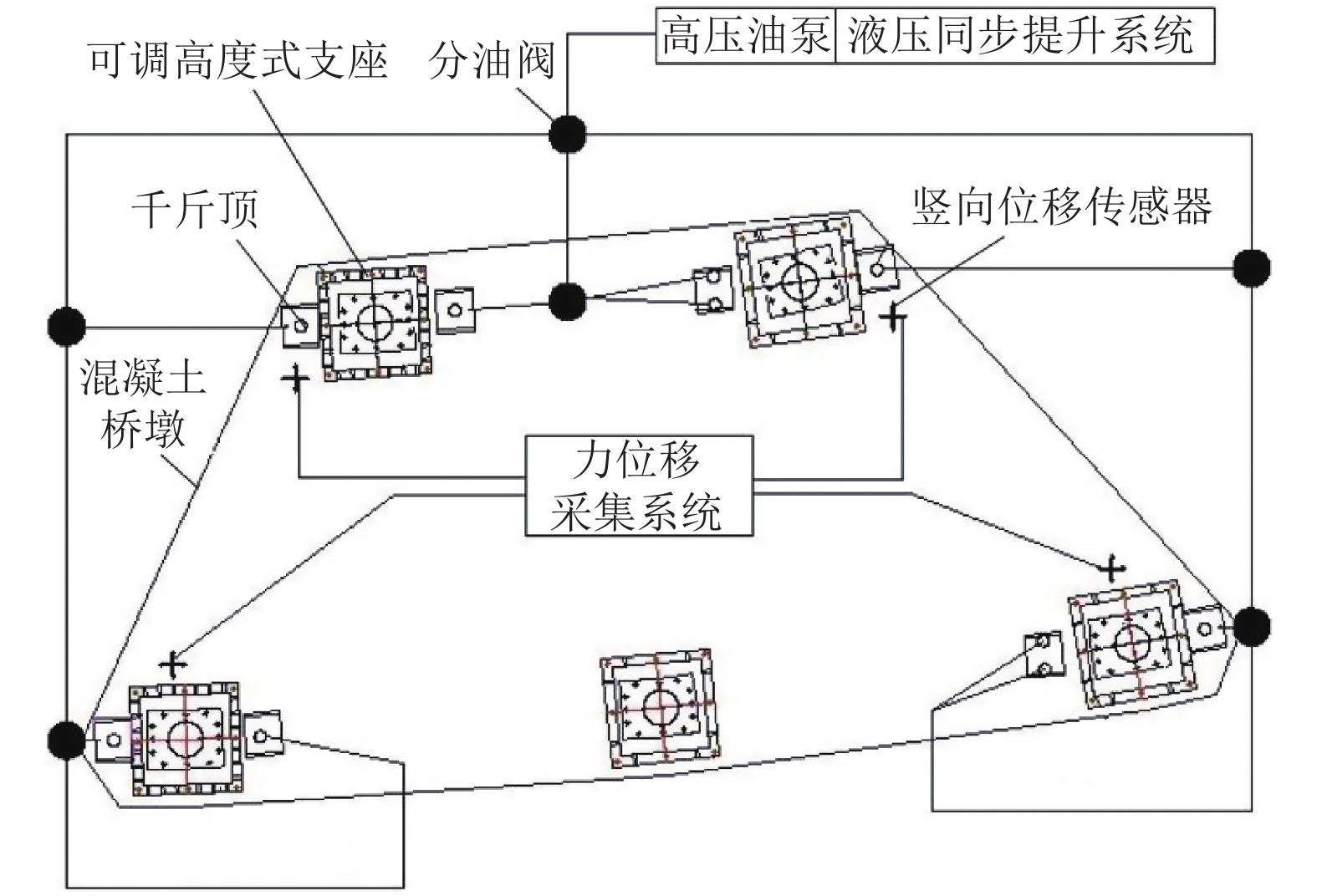

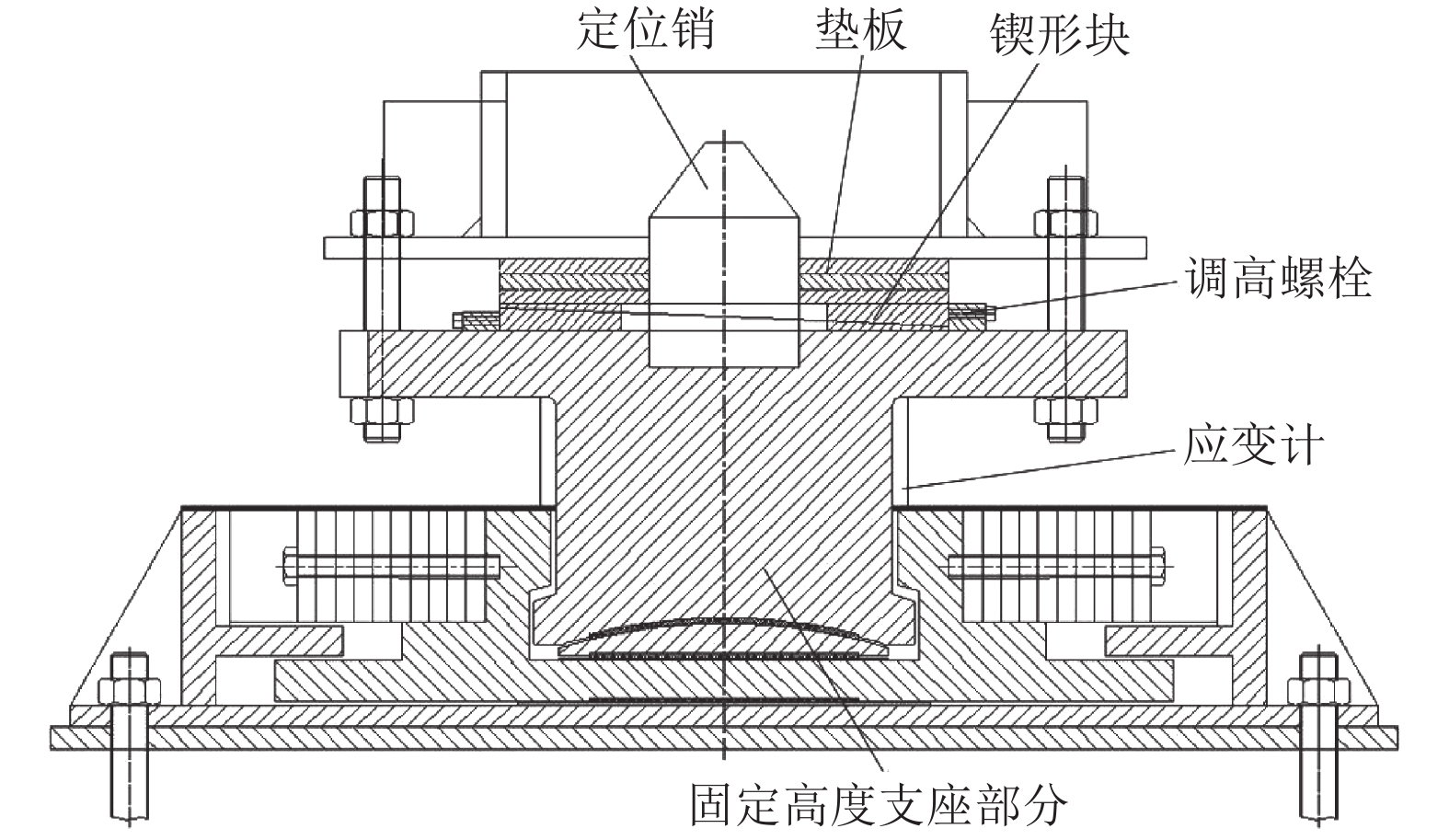

摘要: 为克服现有工程中钢支座难以调节高度的缺陷,提出了可在一定范围内调节自身高度的可调高度式支座,以适应现场施工条件的复杂性和多变性,确保工程结构构件的精准支承并提高工作效率,该支座的调高系统分为粗调和精调. 调节高度前,在支座和支撑结构之间设置千斤顶,对千斤顶施压后顶起上部结构,然后通过增减垫板的数量进行粗调,再通过旋钮调高螺栓调整锲块的位置(精调). 以该支座在某人行天桥项目中的应用进行分析,详细介绍了支座的布置位置、施工流程及所使用的位移、应力应变健康监测系统,以支座合力作为不同施工阶段中支座调高的依据. 研究结果表明:该支座可实时监测支座反力并调节支座高度,能够使支座间的压力数值差距显著减小,同时可以消除拉力项,如东南桥台,最大压力差由调节前的2 266.8 kN减小为调节后的39.4 kN;使各个桥台的支座合力值相近,各桥墩及基础受力趋向均匀,能够提高桥墩及基础的安全性及耐久性.Abstract: To overcome the defaults of difficult to adjust the height in existing steel supports, an adjustable height support was proposed, whose height could be adjusted in a range, to adapt to the complexity and variability of the site construction conditions, ensure the precision bearing, and improve the work efficiency. The bearing system could be divided into two parts: coarse and fine parts. Before adjusting the height, the jack should be set between the support and the support structure, and then adjusted the position of the cheese block by adjusting the knob. The application of the adjustable height support in a real project was proposed, the support arrangement locations, construction processes and the displacement, stress and strain health monitoring system were all discussed in detail, and the support resultant force was taken as the basis of the support elevation in different construction stages. The results show that the support can monitor the reaction force and adjust the height of the support in real time. For example, the maximum pressure difference of southeast abutment decreases from 2 266.8 kN before adjustment to 39.4 kN after adjustment. The bearing force value of abutments is similar, and the stress on piers and foundations tends to be uniform. It is beneficial to ensure the safety and durability of piers and foundations.

-

Key words:

- steel support /

- adjustable height support /

- health monitoring /

- construction phase /

- in-situ test

-

表 1 东北桥台支座受力测试记录

Table 1. Force test for the northeast bridge abutment

kN 支座 临时支

撑拆除前临时支

撑拆除后桥梁

卸载后第 1 次

浇筑混

凝土前西跨浇筑

混凝土,东跨

未浇混凝土第 1 次

浇筑后支座

调节前仅西北

桥台支座

调高后支座均

调高后第 2 次

浇筑混

凝土后支座钢板

增减厚度

/mm1 −904.0 −863.0 −1 827.0 −2 000.0 −2 041.5 −2 594.7 −1 431.0 −1 367.7 −1 913.1 −2 285.4 +15.0 2 −1 262.3 200.0 1 400.0 1 661.0 1 053.3 922.6 1 120.5 1 153.4 −1 654.0 −2 293.7 +9.0 3 −3 154.0 −1 140.5 −2 635.0 −4 755.0 −5 684.3 −6 910.4 −5 984.5 −5 988.4 −2 496.7 −3 082.5 −7.0 4 −2 814.6 −2 245.2 −2 616.0 −2 845.0 −2 999.1 −2 957.4 −2 530.8 −2 712.5 −2 861.5 −3 062.0 −3.0 合力 −8 134.9 −4 048.7 −5 678.0 −7 939.0 −9 671.7 −11 540.0 −8 825.8 −8 915.2 −8 925.1 −10 723.6 表 2 东南桥台支座受力测试记录

Table 2. Force test of the north south bridge abutment

kN 支座 临时支

撑拆除前临时支

撑拆除后桥梁

卸载后第 1 次

浇筑混

凝土前西跨浇筑

混凝土,东跨

未浇混凝土第 1 次

浇筑后支座

调节前仅西北

桥台支座

调高后支座均

调高后第 2 次

浇筑混

凝土后支座钢板

增减厚度

/mm1 −2 566.5 −2 042.4 −3 210.0 −3 057.3 −3 190.8 −3 025.0 −3 075.0 −2 934.7 −1 876.1 −2 076.8 +1.0 2 −299.7 550.0 1 220.0 1 220.0 698.0 −223.7 −257.0 −44.9 −1 802.5 −2 116.2 +6.0 3 −1 124.5 −995.0 −1 025.0 −1 517.3 −426.2 −774.2 −832.5 −697.6 −1 782.9 −2 077.6 +7.0 4 −2 459.7 −1 076.8 −3 696.0 −3 234.1 −3 505.8 −2 809.0 −2 777.6 −3 196.7 −1 854.5 −2 109.6 0.0 合力 −6 450.4 −3 564.2 −6 711.0 −6 588.7 −6 424.8 −6 831.8 −6 960.1 −6 873.9 −7 316.0 −8 380.2 表 3 西北桥台支座受力测试记录

Table 3. Force test of the west north bridge abutment

kN 支座 临时支

撑拆除前临时支

撑拆除后桥梁

卸载后第 1 次

浇筑混

凝土前西跨浇筑

混凝土,东跨

未浇混凝土第 1 次

浇筑后支座

调节前仅西北

桥台支座

调高后支座均

调高后第 2 次

浇筑混

凝土后支座钢板

增减厚度

/mm1 −1 126.2 −1 019.4 −1 806.0 −2 100.7 −1 665.3 −1 151.6 −1 096.2 −3 661.1 −2 451.2 −2 649.9 +7.0 2 −954.4 −1 114.4 −620.0 4 569.0 3 884.0 3 663.3 −895.0 −1 106.5 −1 759.0 −2 115.6 +19.0 3 −1 520.5 −1 271.0 −2 890.0 −3 236.9 −3 921.7 −4 964.5 −4 113.0 −1 853.9 −2 259.0 −2 411.9 −5.0 4 −833.5 −833.5 −2 850.0 −3 475.1 −3 300.0 −3 179.9 −3 141.0 −2 526.2 −2 730.5 −3 042.3 +8.0 合力 −4 434.6 −4 238.3 −8 166.0 −4 242.9 −5 003.0 −5 632.7 −9 245.2 −9 147.7 −9 199.7 −10 219.7 表 4 西南桥台支座受力测试记录

Table 4. Force test of the west south bridge abutment

kN 支座 临时支

撑拆除前临时支

撑拆除后桥梁

卸载后第 1 次

浇筑混

凝土前西跨浇筑

混凝土,东跨

未浇混凝土第 1 次

浇筑后支座

调节前仅西北

桥台支座

调高后支座均

调高后第 2 次

浇筑混

凝土后支座钢板

增减厚度

/mm1 −1 479.8 −1 654.1 −595.0 927.6 −1 487.9 −1 441.2 −1 529.5 −1 205.6 −2 062.2 −2 337.4 +10.0 2 −1 845.0 −1 983.0 −1 683.0 −1 335.3 −2 476.7 −2 484.5 −2 486.5 −2 683.7 −2 038.7 −2 293.2 −3.0 3 −2 615.0 −1 878.7 −2 985.0 −3 165.0 −3 004.8 −2 782.2 −2 601.6 −2 519.0 −2 392.2 −2 790.1 −3.0 4 −3 076.0 −3 551.7 −2 743.0 −3 403.2 −3 524.4 −3 126.1 −3 335.2 −3 098.8 −3 662.0 −4 140.6 +5.0 合力 −9 015.8 −9 067.5 −8 006.0 −6 975.8 −10 493.8 −9 834.0 −9 412.8 −9 507.1 −10 155.1 −11 561.3 -

施卫星,刘凯雁,王立志. 网架减震球型钢支座减震性能振动台试验研究[J]. 西北地震学报,2009,31(4): 344-348.SHI Weixing, LIU Kaiyan, WANG Lizhi. Shaking table test study on damping performance of steel ball-bearing for grid structure[J]. Northwestern Seismological Journal, 2009, 31(4): 344-348. 易江,李建中. 地震中斜拉桥支座脱空现象及控制方法研究[J]. 中国公路学报,2017,30(12): 110-118. doi: 10.3969/j.issn.1001-7372.2017.12.012YI Jiang, LI Jianzhong. Research on effect and control method of end span uplift for cable-stayed bridge during earthquakes[J]. China Journal of Highway and Transport, 2017, 30(12): 110-118. doi: 10.3969/j.issn.1001-7372.2017.12.012 于敬海,张中宇,赵腾. 弹性球型钢支座力学性能有限元分析方法[J]. 结构工程师,2017,33(5): 36-42. doi: 10.3969/j.issn.1005-0159.2017.05.006YU Jinghai, ZHANG Zhongyu, ZHAO Teng. Finite element analysis method for mechanical properties of elastic steel ball bearings[J]. Structural Engineers, 2017, 33(5): 36-42. doi: 10.3969/j.issn.1005-0159.2017.05.006 石岩,王东升,韩建平,等. 桥梁减隔震技术的应用现状与发展趋势[J]. 地震工程与工程振动,2017,37(5): 118-128.SHI Yan, WANG Dongsheng, HAN Jianping, et al. Application status of seismic isolation for bridges and its development tendency[J]. Earthquake Engineering and Engineering Dynamics, 2017, 37(5): 118-128. 高山,彭泽友,史春娟,等. 弹塑性钢减隔震支座在桥梁抗震设计中的应用[J]. 世界桥梁,2015,43(5): 44-48.GAO Shan, PENG Zeyou, SHI Chunjuan, et al. Application of elasto-plastic steel seismic isolators to bridge anti-seismic design[J]. World Bridges, 2015, 43(5): 44-48. 郑晓龙,薛鹏,樊启武,等. 多向测力球型钢支座力学性能分析及参数选取[J]. 铁道建设,2015,8(1): 16-19.ZHENG Xiaolong, XUE Peng, FAN Qiwu, et al. Mechanical property analysis and parameter selection of multi directional force spherical steel bearings[J]. Railway Engineering, 2015, 8(1): 16-19. CHEN P C, TSAI K C, LIN P Y. Real-time hybrid testing of a smart base isolation system[J]. Earthquake Engineering and Structural Dynamics, 2014, 43(1): 139-158. doi: 10.1002/eqe.2341 CHEN X, YANG H T Y, SHAN J, et al. Bio-inspired passive optimized base-isolation system for seismic mitigation of building structures[J]. Journal of Engineering Mechanics, 2016, 142(1): 04015061.1-04015061.12. doi: 10.1061/(ASCE)EM.1943-7889.0000971 施笃铮,程坤,唐国斌. 基于可调高度垫石的空心板桥支座病害处置技术[J]. 公路工程,2016,41(5): 144-146. doi: 10.3969/j.issn.1674-0610.2016.05.029SHI Duzheng, CHENG Kun, TANG Guobin. Disposal technique for bearing disease of hollow slab bridges based on height-adjustable cushion stone[J]. Highway Engineering, 2016, 41(5): 144-146. doi: 10.3969/j.issn.1674-0610.2016.05.029 杨海旭,郭迅,王海飙,等. 高度可调摩擦摆隔震支座的力学性能[J]. 辽宁工程技术大学学报(自然科学版),2012,31(1): 61-64.YANG Haixu, GUO Xun, WANG Haibiao, et al. Mechanical performance of an isolation bearing with height-adjustable friction pendulum[J]. Journal of Liaoning Technical University (Natural Science), 2012, 31(1): 61-64. 施卫星,王梁坤,严俊,等. 改进的自调频单摆式TMD的减振性能研究[J]. 华中科技大学学报(自然科学版),2018,46(2): 40-45.SHI Weixing, WANG Liangkun, Yan Jun, et al. Performance of semi-adaptive pendulum-type tuned mass damper[J]. Journal of Huazhong University of Science and Technology (Natural Science Edition), 2018, 46(2): 40-45. -

下载:

下载: