Main Influencing Factors of Dust Removal Efficiency by Negative Ionization in Tunnel Construction

-

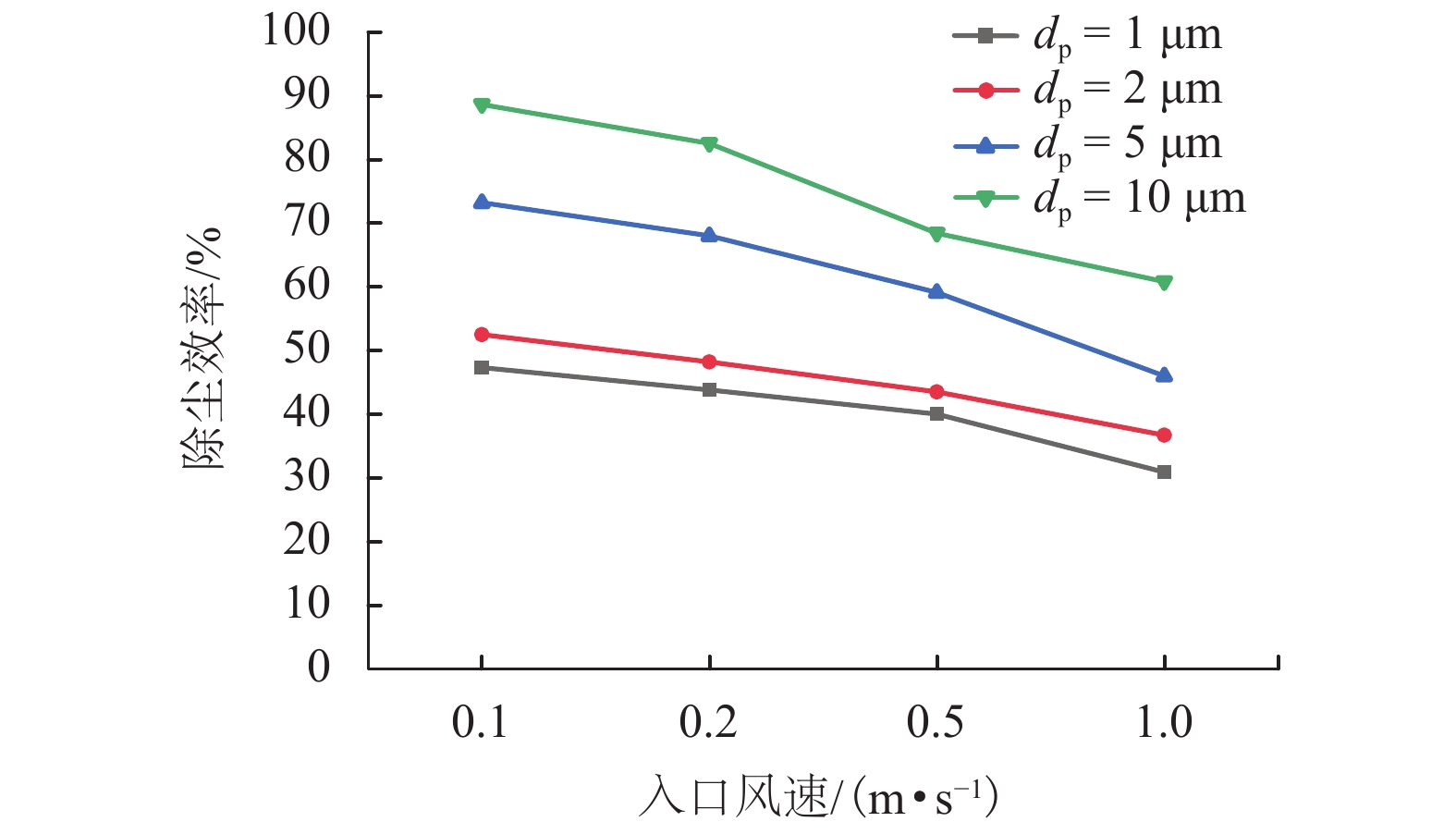

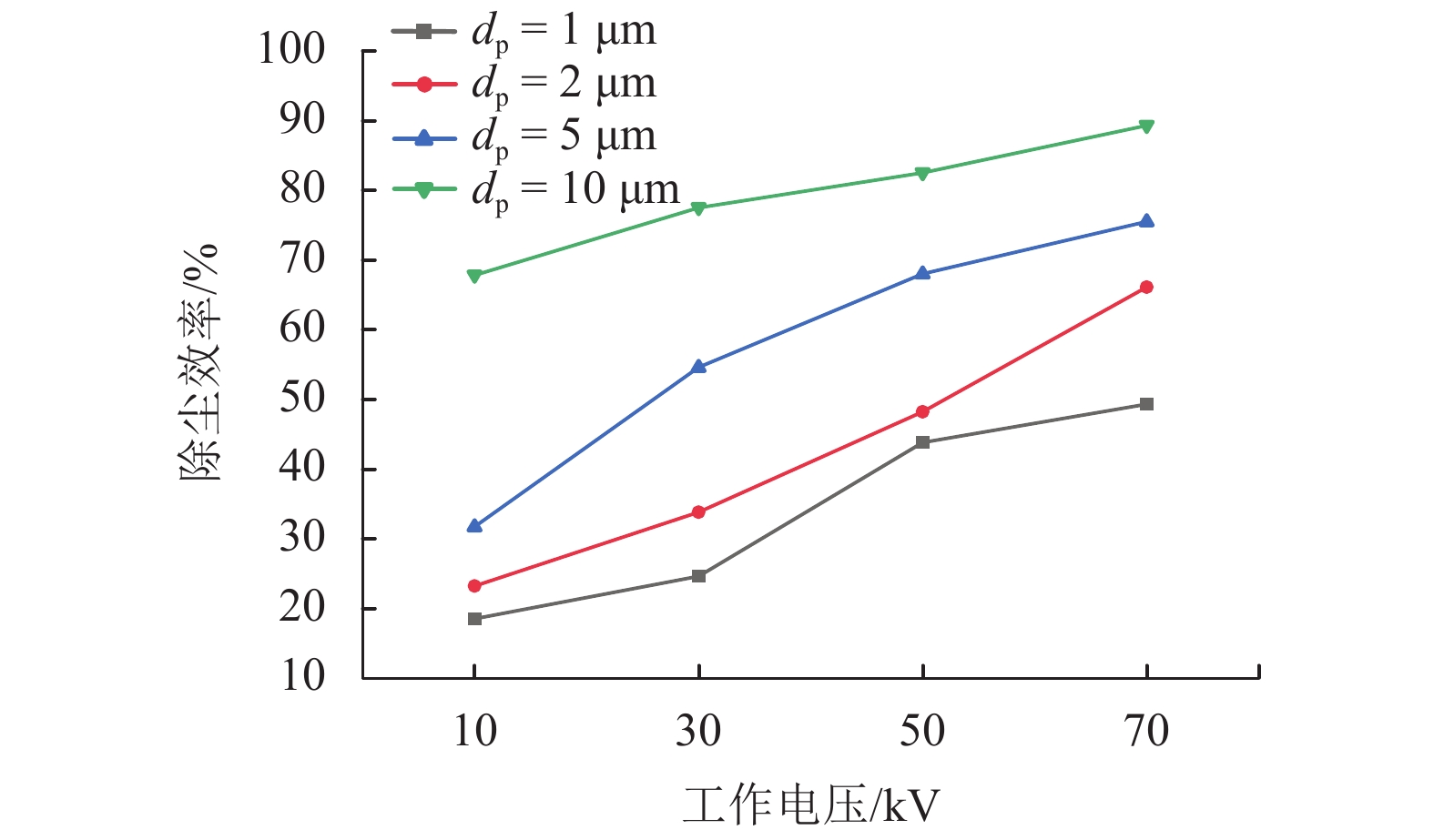

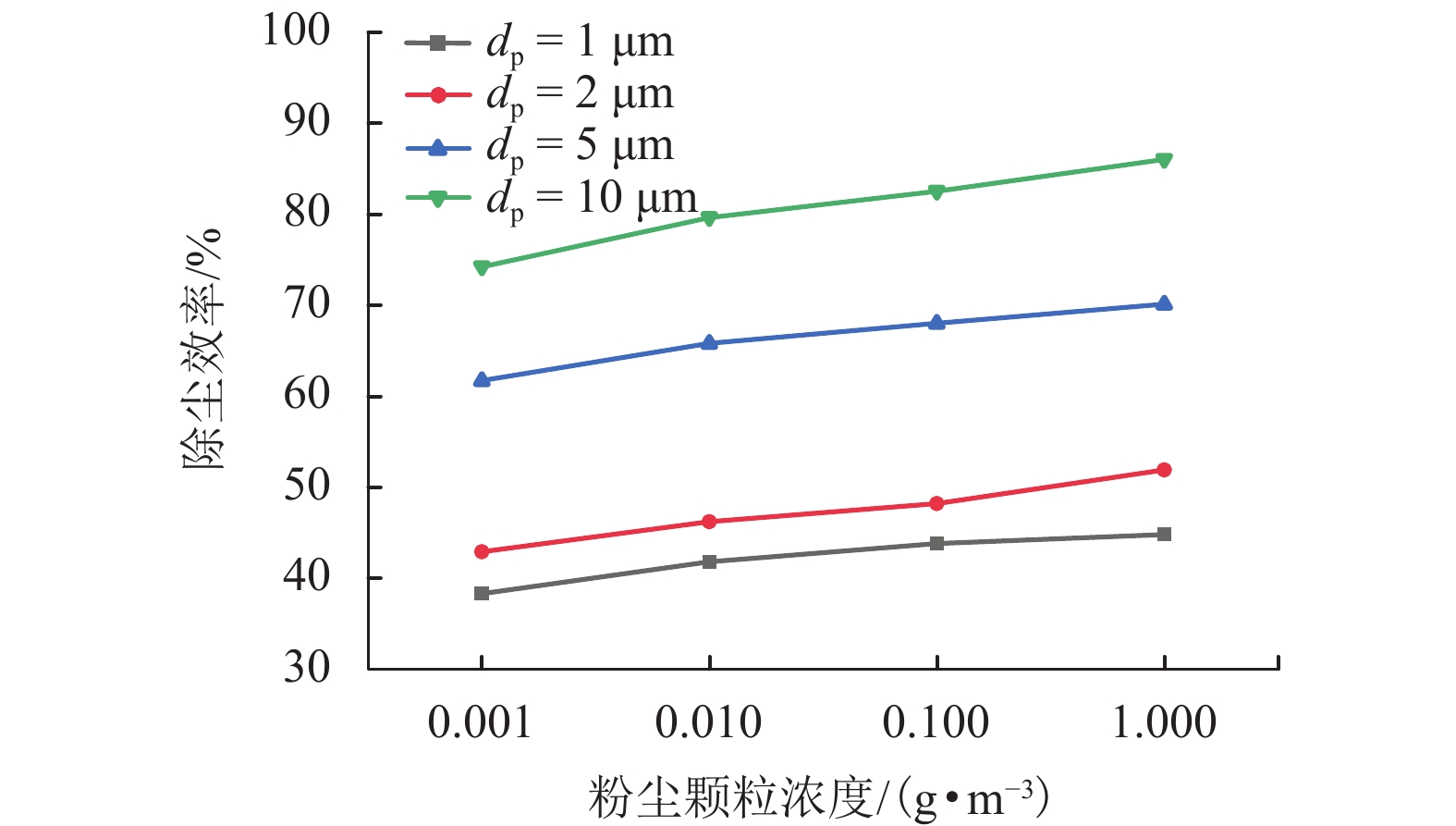

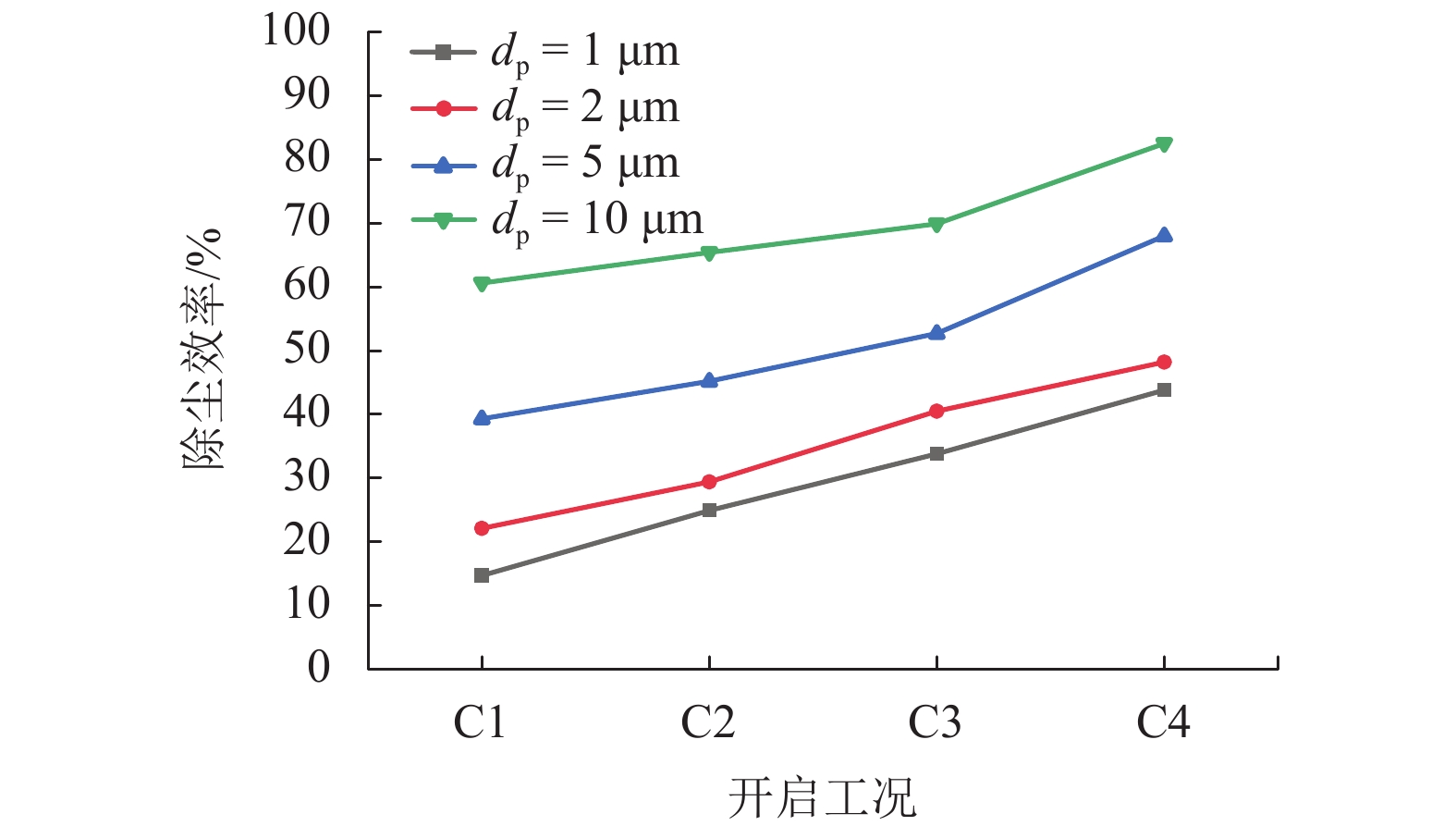

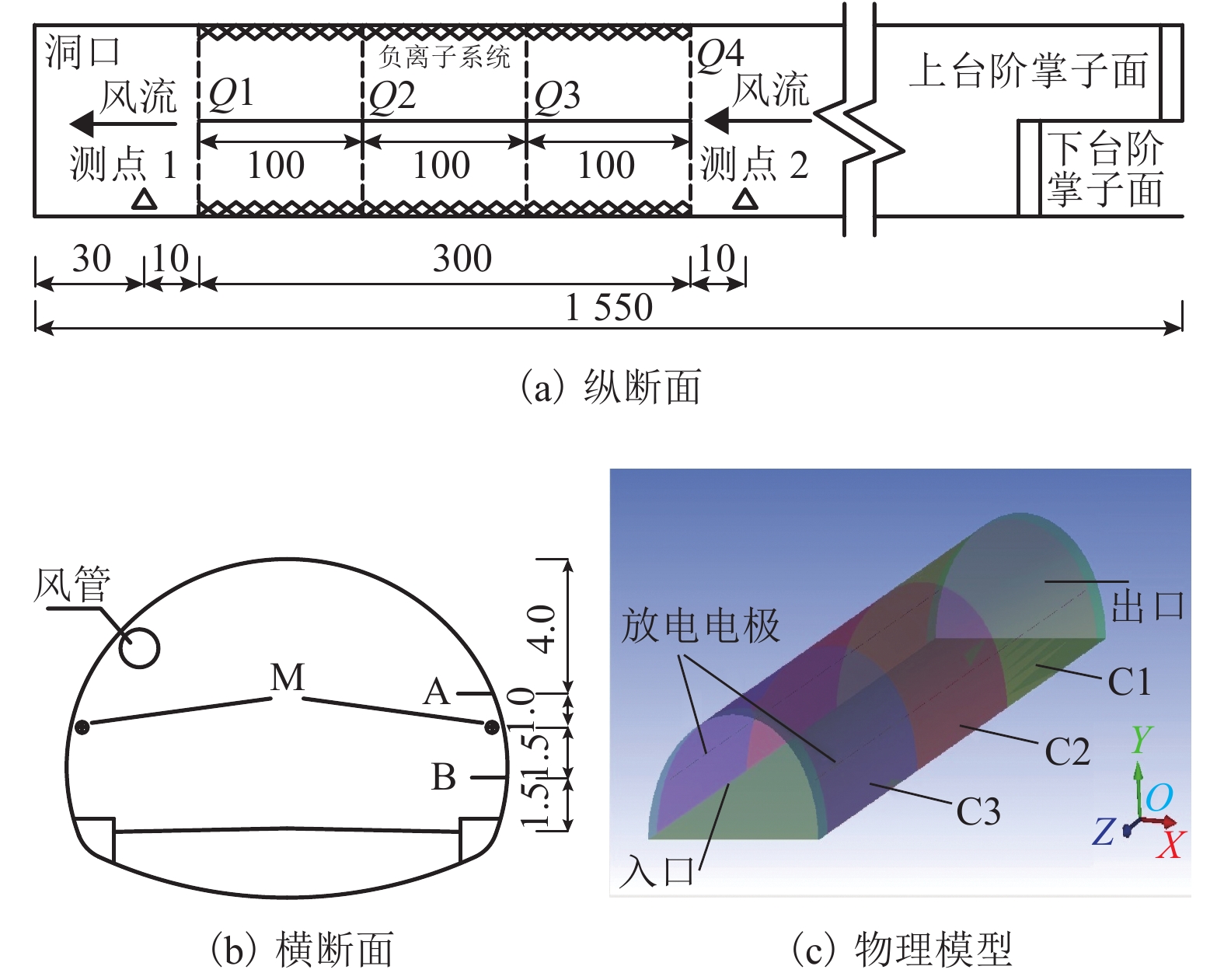

摘要: 为研究施工隧道内粉尘颗粒粒径、颗粒浓度、通风风速和负离子系统工作电压、纵向安装位置对负离子系统粉尘降除效率的影响,依据调研和实测选取隧道计算参数,建立隧道及负离子系统三维模型,采用RNG k-ε双方程湍流模型,并通过动量方程附加电场力源项的方法求解电流场,利用拉格朗日法求解粉尘颗粒的运动轨迹,用SIMPLE算法对颗粒运动与电场流场进行离散相和流体相相间耦合的数值模拟计算,并将模拟结果和隧道现场抽样试验结果对比分析. 研究结果表明:隧道粉尘粒径越大,浓度越大,风速越低,负离子系统工作电压越高,系统纵向安装位置越偏于上风口,负离子系统除尘效率越高;两组现场抽样试验与对应数值模拟所得的除尘效率分别为41.2%、56.7%和38.2%、51.1%,误差分别为15.5%和12.9%. 考虑施工隧道大空间复杂环境的影响,通过数值模拟的方法来研究负离子系统除尘效率及其与主要影响因素的关系是可行的.Abstract: In order to study the influence of dust particle size, particle concentration, ventilation velocity, the working voltage of a negative ion system and its longitudinal installation position on the dust removal efficiency of the negative ion system in tunnel construction, a three-dimensional model of tunnel and negative ion system is established and the tunnel calculation parameters are selected according to investigation and measurement for numerical simulations. The RNG k-ε dual equation turbulence model is used to solve the current field by the momentum equation with electric field force source term. The trajectory of dust particles is solved by Lagrange method. The SIMPLE (semi-implicit method for pressure linked equations) algorithm is used to simulate the coupling between discrete and fluid phases of electric field, flow field and particle motion. In addition, field tests in the tunnel were carried out to verify the accuracy of the simulation results. The results show that the dust removal efficiency of the negative ion system improves with larger dust particle size, greater dust concentration, lower wind speed of the tunnel, higher working voltage of the negative ion system, and closer installation position of the system to the tunnel working face. Dust removal efficiencies of two groups of field sampling tests were 41.2% and 56.7% while the counterparts of numerical simulations were 38.2% and 51.1%, hence deviations being 15.5% and 12.9%, respectively. Therefore, considering the influence of large space and complex environment of tunnel under construction, it is feasible to study the dust removal efficiency of negative ion system and its relationship with main influencing factors by numerical simulation.

-

Key words:

- tunnel engineering /

- dust particles /

- negative ion /

- numerical simulation /

- field test

-

表 1 边界条件

Table 1. Boundary conditions

位置 类型 离散相边界类型 进口 速度进口 反射 出口 压力出口 逃逸 电极 墙体 反射 地面 墙体 捕捉 墙面 墙体 捕捉 表 2 物理参数

Table 2. Physical parameters

物理参数 取值 a/(kg•(m•s) −1) 1.73 × 10−5 ε0 /(C2•(N•m2) −1) 8.85 × 10−12 kB/(J•K −1) 1.38 × 10−23 e/C 1.6 × 10−19 ρp/(kg•m−3) 2 500 ρ/(kg•m−3) 1.205 μl/(cm2•(V•s)−1) 1.8 Dl/(m2•s) 3.6 × 10−6 μ/(kg•(m•s)−1) 1.8 U0/kV 0 εr 1.000 59 T/℃ 20 U/kV 10、30、50、70 u /(m•s−1) 0.1、0.2、0.5、1.0 dp/(× 10−6 m) 1、2、5、10 c/(g•m−3) 0.001、0.010、0.100、1.000 C C1、C2、C3、C4 表 3 现场试验与数值模拟结果对比

Table 3. Comparison of the results obtained from field test and numerical simulation

参数 试验1 试验2 试验平均浓度(测点1)/(mg•m−3) 3.1 3.5 试验平均浓度(测点2)/(mg•m−3) 5.2 5.7 试验除尘效率/% 41.2 38.2 模拟除尘效率/% 56.7 51.1 误值/% 15.5 12.9 -

徐世强,任洪远,王明山,等. 施工隧道负离子除尘新方法[J]. 交通运输工程学报,2018,18(3): 84-93. doi: 10.3969/j.issn.1671-1637.2018.03.010XU Shiqiang, REN Hongyuan, WANG Mingshan, et al. New method of dust removal by negative ions in construc-tion tunnel[J]. Journal of Traffic and Transportation Engineering, 2018, 18(3): 84-93. doi: 10.3969/j.issn.1671-1637.2018.03.010 梁平. 低臭氧负离子发生器优化实验研究及其电源的设计[D]. 大连: 大连理工大学, 2005. 杨艺,周沛,赖志强. 通风管道内负离子传输的数值模拟及试验验证[J]. 环境科学研究,2016,29(12): 1913-1920.YANG Yi, ZHOU Pei, LAI Zhiqiang. Simulation of the transport of negative ions in air ventilation ducts and vali-dation by experimentation[J]. Research of Environmental Sciences, 2016, 29(12): 1913-1920. GRABARCZYK Z. Effectiveness of indoor air cleaning with corona ionizers[J]. Journal of Electrostatics, 2001, 51-52: 278-283. doi: 10.1016/S0304-3886(01)00058-4 MAYYA Y S, SAPRA B K, KHAN A. Aerosol removal by unipolar ionization in indoor environments[J]. Journal of Aerosol Science, 2004, 35(8): 923-941. doi: 10.1016/j.jaerosci.2004.03.001 曾艳华, 李杰, 张先富, 等. 不同排烟口开启状态下妈湾隧道的排烟技术[J]. 西南交通大学学报, 2019, 54(6): 1177-1186 .ZENG Yanhua, LI Jie, ZHANG Xianfu, et al. Smoke exhaust technology of different opening state of smoke vent in Mawan tunnel[J]. Journal of Southwest Jiaotong University, 2019, 54(6): 1177-1186 杨立新. 隧道钻爆排烟基于PC-STEL标准的风量计算方法[J]. 铁道工程学报,2016,33(11): 92-96. doi: 10.3969/j.issn.1006-2106.2016.11.017YANG Lixin. Air volume calculation method for discharge of smog induced by tunnel drilling and blasting based on PC-STEL standard[J]. Journal of Railway Engineering So-ciety, 2016, 33(11): 92-96. doi: 10.3969/j.issn.1006-2106.2016.11.017 孙忠强,方宝君. 钻爆法隧道施工钻孔过程粉尘分布规律研究[J]. 煤炭技术,2016,35(10): 155-157.SUN Zhongqiang, FANG Baojun. Study on dust distribu-tion regularity in drilling of drilling and blasting method tunnel construction[J]. Coal Technology, 2016, 35(10): 155-157. 苏明旭,朱芸,袁保宁,等. 管式电除尘器中粉尘颗粒运动轨迹的数值模拟[J]. 南京航空航天大学学报,2000,32(2): 169-174. doi: 10.3969/j.issn.1005-2615.2000.02.008SU Mingxu, ZHU Yun, YUAN Baoning, et al. Numerical simulation for particle-trajectory in tubular electrostatic precipitator[J]. Journal of Nanjing University of Aero-nautics & Astronautics, 2000, 32(2): 169-174. doi: 10.3969/j.issn.1005-2615.2000.02.008 ARIF S, BRANKEN D J, EVERSON R C. CFD modeling of particle charging and collection in electrostatic precipi-tators[J]. Journal of Electrostatics, 2016, 84: 10-22. doi: 10.1016/j.elstat.2016.08.008 SKODRAS G, KALDIS S P, SOFIALIDIS D, et al. Particulate removal via electrostatic precipitators—CFDsimulation[J]. Fuel Processing Technology, 2006, 87(7): 623-631. doi: 10.1016/j.fuproc.2006.01.012 龙正伟,冯壮波,姚强. 静电除尘器数值模拟[J]. 化工学报,2012,63(11): 3393-3401. doi: 10.3969/j.issn.0438-1157.2012.11.003LONG Zhengwei, FENG Zhuangbo, YAO Qiang. Nu-merical modeling of electrostatic precipitator[J]. CIESC Journal, 2012, 63(11): 3393-3401. doi: 10.3969/j.issn.0438-1157.2012.11.003 李艳. 高温静电除尘过程的数值模拟研究[D]. 杭州: 浙江大学, 2015. 王广地,周晓军,高波. 水下悬浮隧道管段结构流阻特性分析[J]. 西南交通大学学报,2007,42(6): 715-719. doi: 10.3969/j.issn.0258-2724.2007.06.014WANG Guangdi, ZHOU Xiaojun, GAO Bo. Flow re-sistance analysis of submerged floating tunnel[J]. Journal of Southwest Jiaotong University, 2007, 42(6): 715-719. doi: 10.3969/j.issn.0258-2724.2007.06.014 骆建军. 隧道入口侧风条件下高速铁路隧道内流场特性[J]. 西南交通大学学报,2017,52(4): 746-754. doi: 10.3969/j.issn.0258-2724.2017.04.013LUO Jianjun. Tunnel entrance field Characteristics induced by high speed train with crosswind at entrance[J]. Journal of Southwest Jiaotong University, 2017, 52(4): 746-754. doi: 10.3969/j.issn.0258-2724.2017.04.013 吴晓君. ESP粉尘收尘过程数值模拟[D]. 沈阳: 东北大学, 2011. 毕文剑,李艳,罗坤,等. 温度对静电除尘器内颗粒受力影响的数值模拟[J]. 中国科学院大学学报,2017,34(2): 172-178.BI Wenjian, LI Yan, LUO Kun, et al. Numerical simulation of temperature effect on particle forces in electrostatic precipitators[J]. Journal of University of Chinese Academy of Sciences, 2017, 34(2): 172-178. 李海英,多鹏,王茹,等. 静电除尘器内细微尘涡流现象的数值模拟[J]. 环境工程学报,2017,11(7): 4140-4148. doi: 10.12030/j.cjee.201605172LI Haiying, DUO Peng, WANG Ru, et al. Numerical simula-tion of fine dust vortex phenomenon in electrostatic precip-itator[J]. Chinese Journal of Environmental Engineering, 2017, 11(7): 4140-4148. doi: 10.12030/j.cjee.201605172 GOSMAN A D, IOANNIDES E. Aspects of computer simulation of liquid-fueled combustors[J]. Journal of Energy, 1983, 7(6): 482-490. 王为术,王鑫,张春杰,等. 锅炉烟道飞灰颗粒电除尘捕获特性研究[J]. 动力工程学报,2017,37(12): 1007-1014.WANG Weishu, WANG Xin, ZHANG Chunjie, et al. Capture performance of an electrostatic precipitator for fly ash particles from boiler flue ducts[J]. Journal of Chinese Society of Power Engineering, 2017, 37(12): 1007-1014. 南方电网技术研究中心. 特高压直流线路电磁环境参数限制: DL/T 1008—2008±800[S]. 北京: 中国电力出版社, 2008. 中交第一公路工程局有限公司. 公路隧道施工技术规范: JTG F60—2009[S]. 北京: 人民交通出版社, 2009. 安继刚. 电离辐射探测器[M]. 北京: 原子能出版社, 1995: 65-75. 何剑,徐国胜,周孝德,等. 公路隧道空气颗粒物净化实验研究[J]. 环境工程学报,2010,4(5): 1153-1155.HE Jian, XU Guosheng, ZHOU Xiaode, et al. Experi-mental study on particulate purification of road tunnel air[J]. Chinese Journal of Environmental Engineering, 2010, 4(5): 1153-1155. 甘晨浩,郑成航,杨正大,等. 蜂窝湿式静电除尘脱除燃煤细颗粒物实验研究[J]. 环境科学学报,2016,36(7): 2369-2374.GAN Chenhao, ZHENG Chenghang, YANG Zhengda, et al. Experimental study on honeycomb experimental-scale wet electrostatic precipitator removing coal-fired fine particulate matter[J]. Acta Scientiae Circumstantiae, 2016, 36(7): 2369-2374. 杨光,肖刚,倪明江,等. 高温线管式静电除尘过程三维模拟[J]. 热力发电,2017,46(5): 43-49. doi: 10.3969/j.issn.1002-3364.2017.05.043YANG Guang, XIAO Gang, NI Mingjiang, et al. 3D nu-merical simulation of particles collection in a high tem-perature wire-cylinder electrostatic precipitator[J]. Thermal Power Generation, 2017, 46(5): 43-49. doi: 10.3969/j.issn.1002-3364.2017.05.043 陈志强. 钻爆法隧道施工粉尘防治的研究[D]. 济南: 山东大学, 2008. 刘根凡,刘贤杰,周杰联,等. V形板除尘设备的数值模拟和试验研究[J]. 化工机械,2012,39(3): 284-286, 303. doi: 10.3969/j.issn.0254-6094.2012.03.007LIU Genfan, LIU Xianjie, ZHOU Jielian, et al. Numerical simulation and experimental study on V-plate dust collector[J]. Chemical Engineering & Machinery, 2012, 39(3): 284-286, 303. doi: 10.3969/j.issn.0254-6094.2012.03.007 -

下载:

下载: