Refined Study on 3D Flow Characteristics around Bridge Piers

-

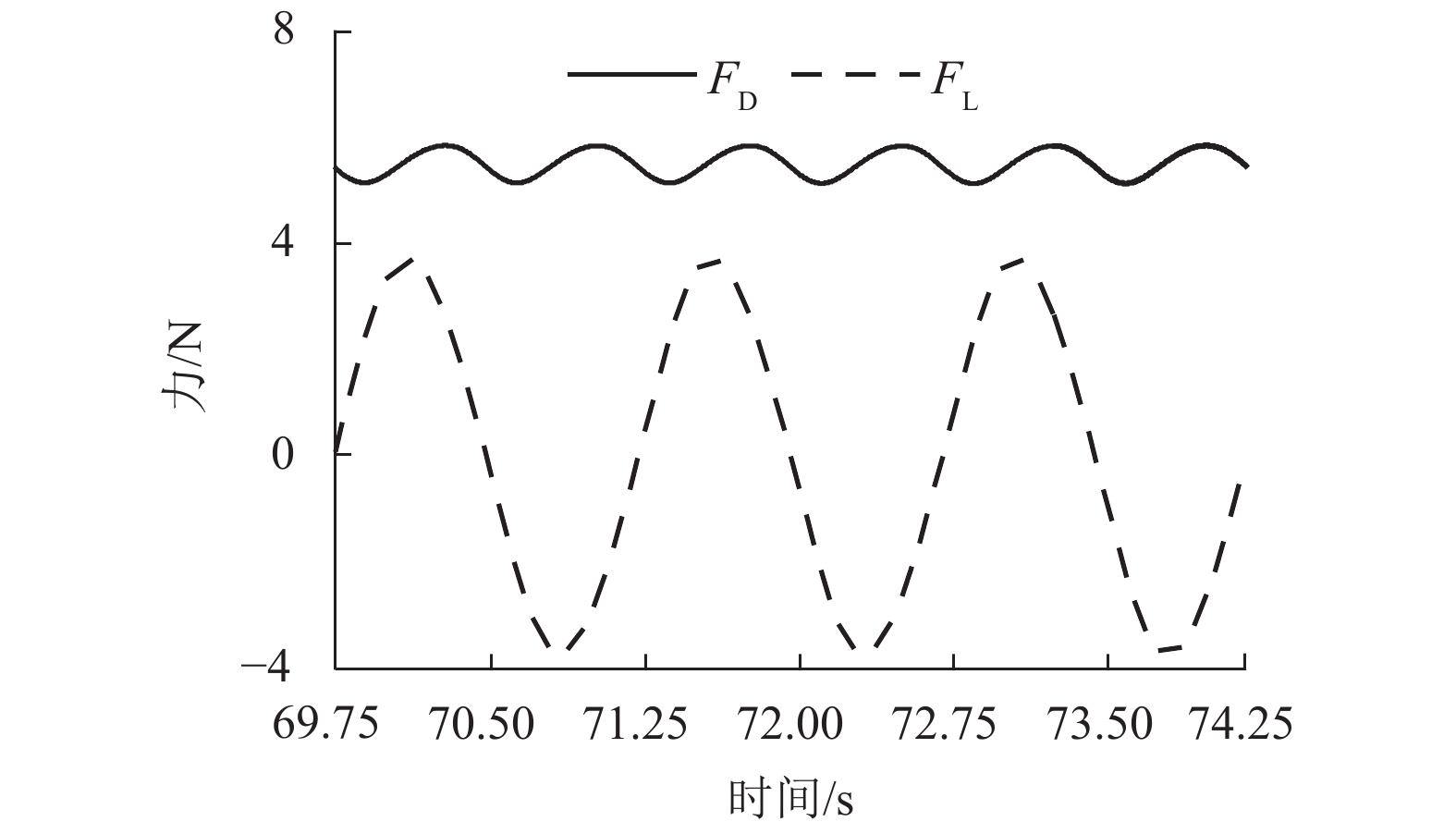

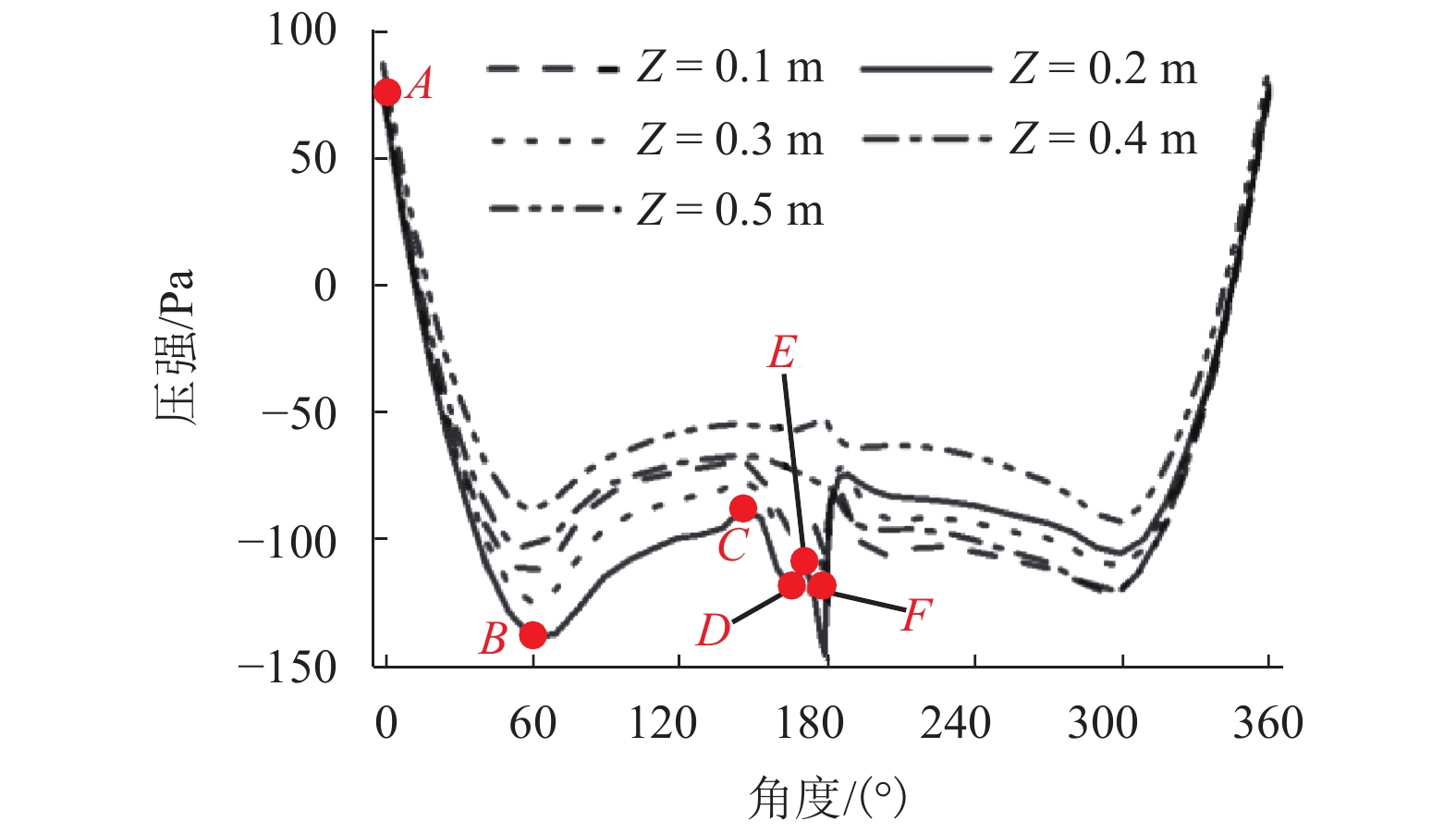

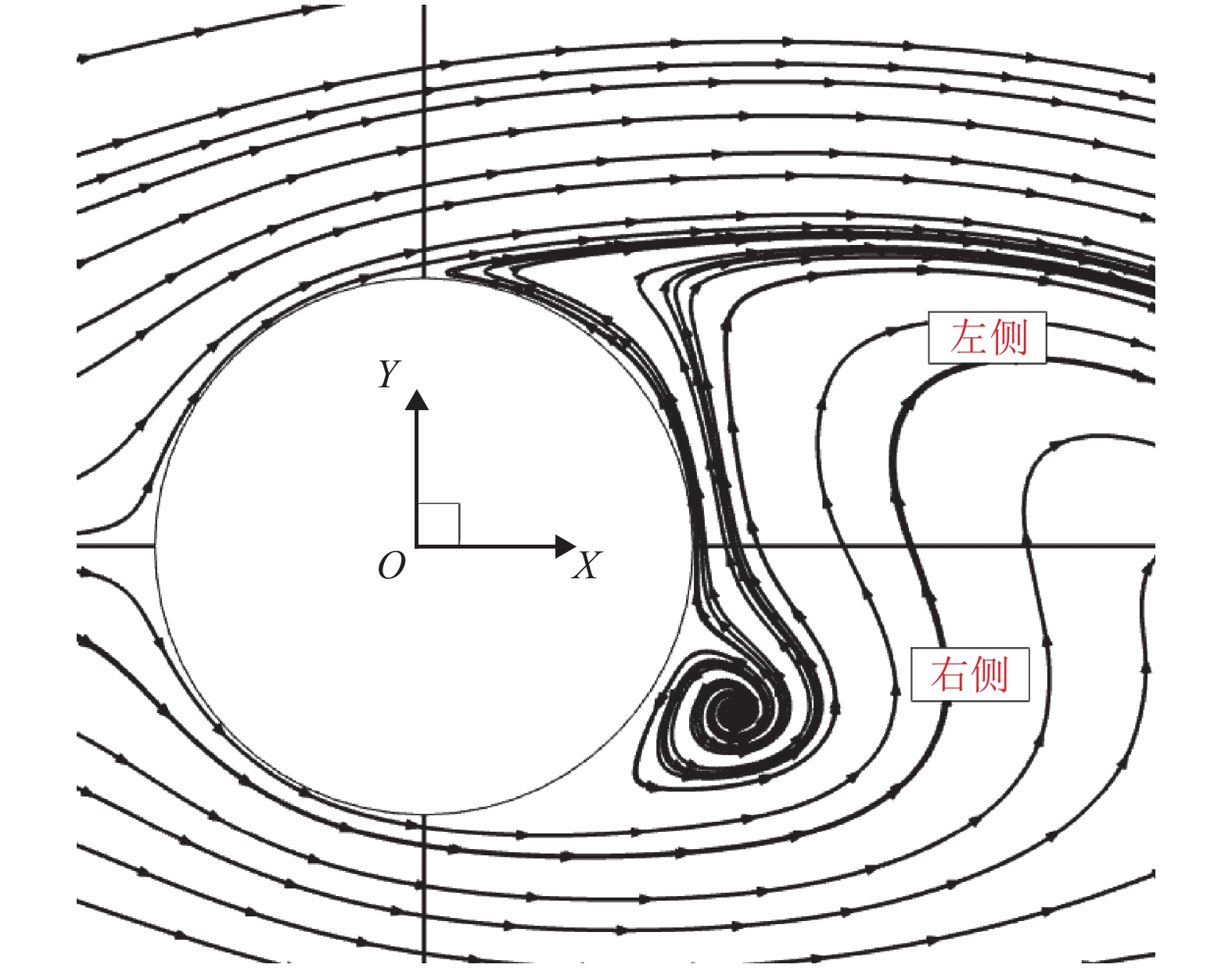

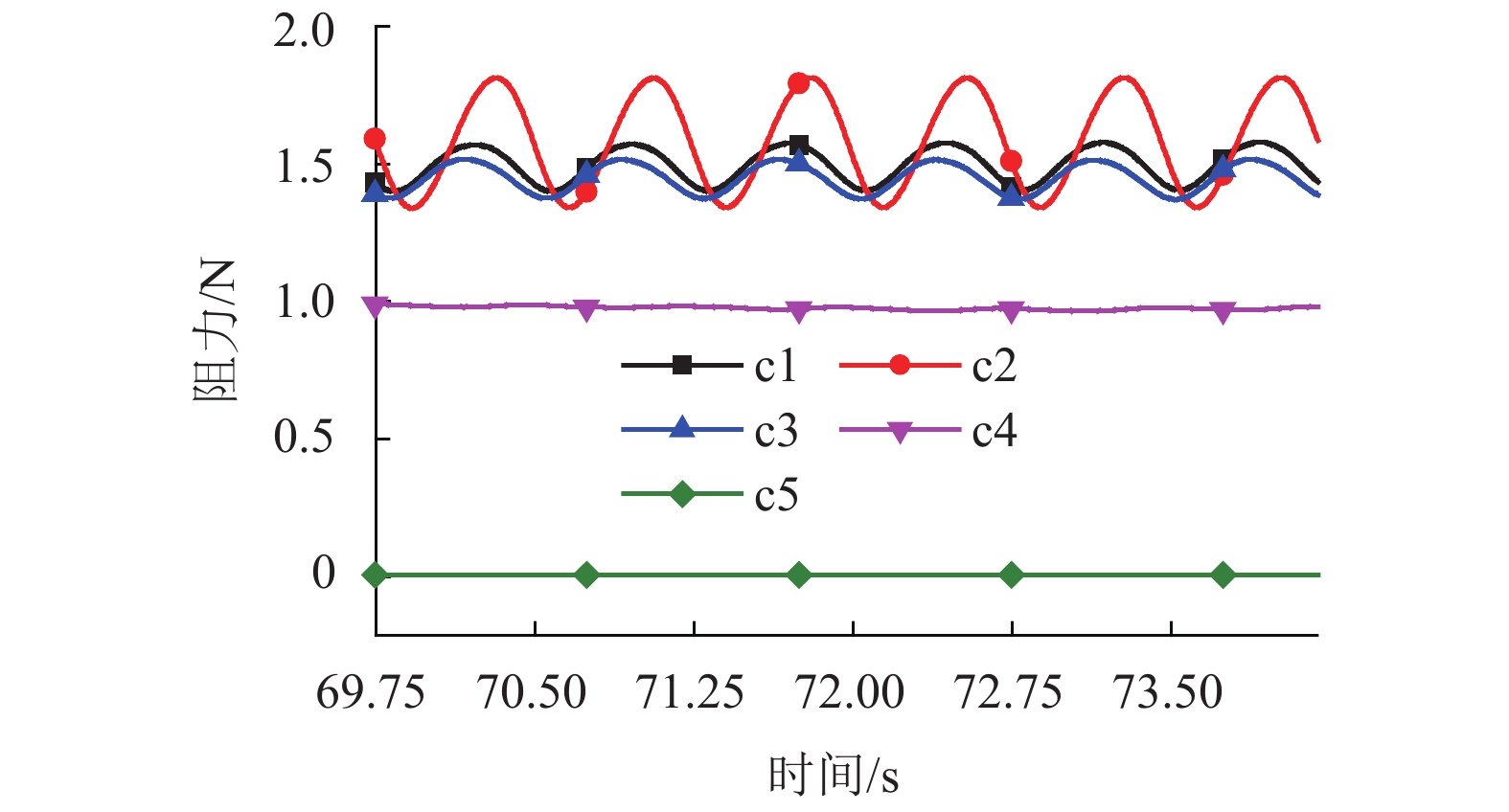

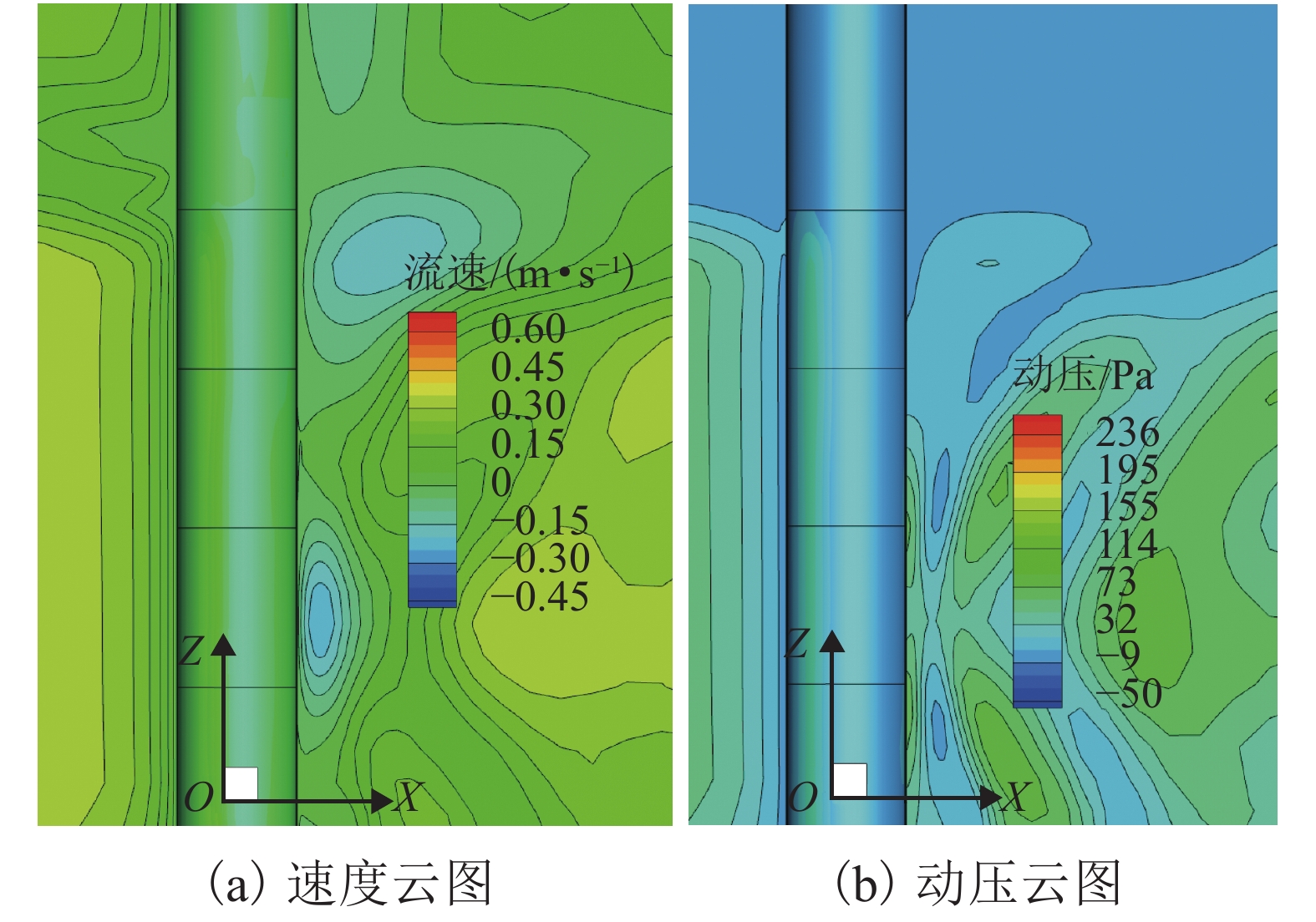

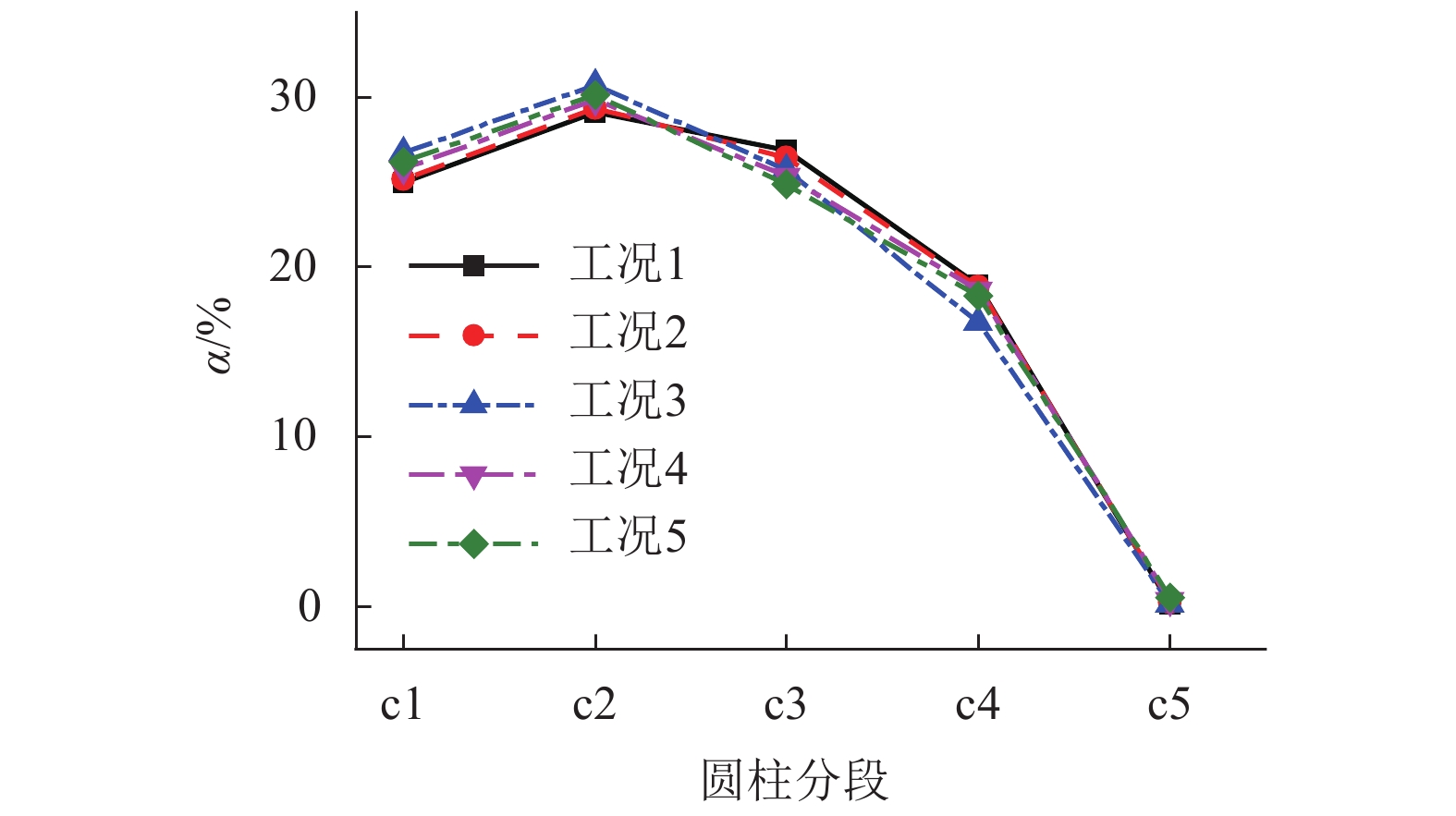

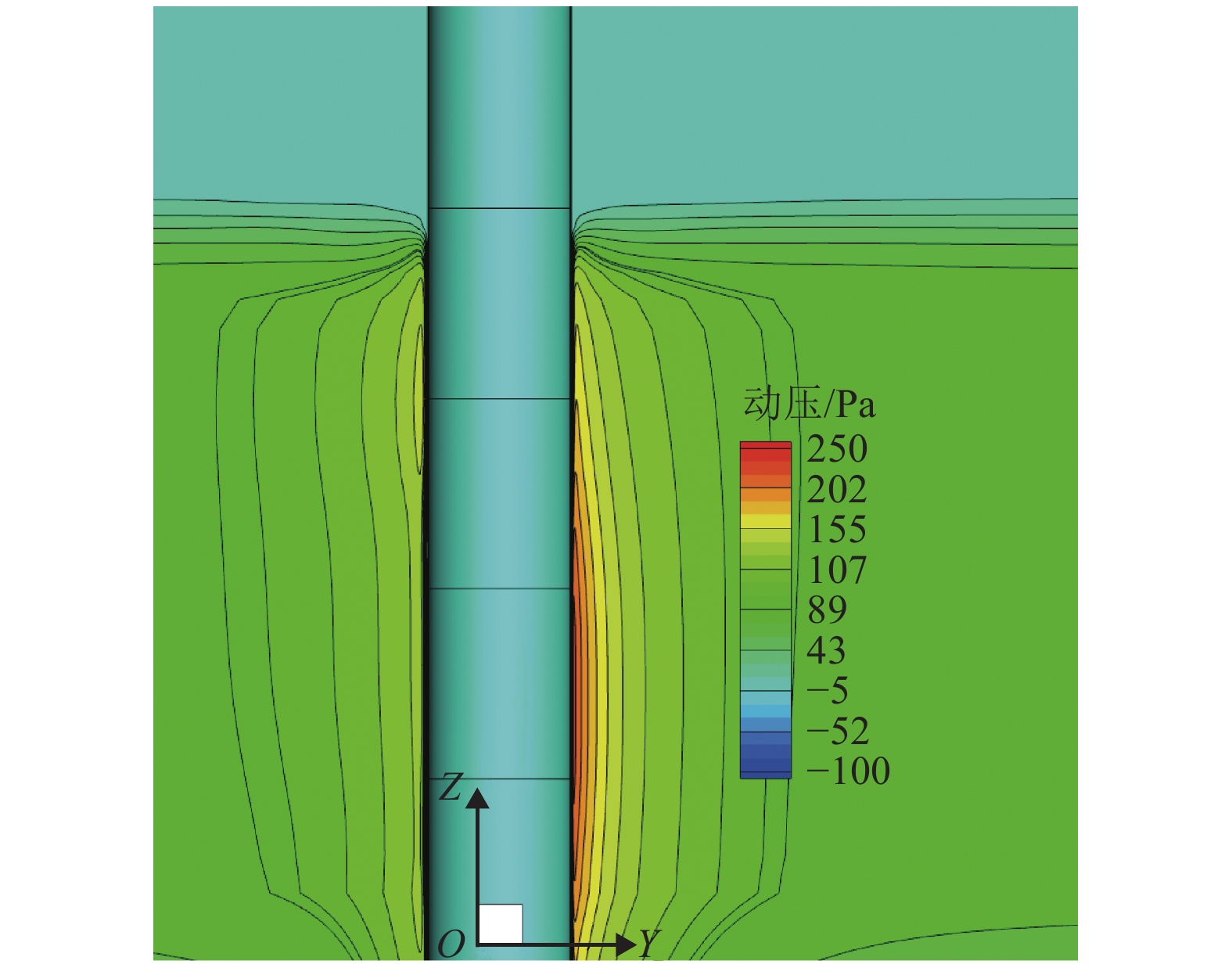

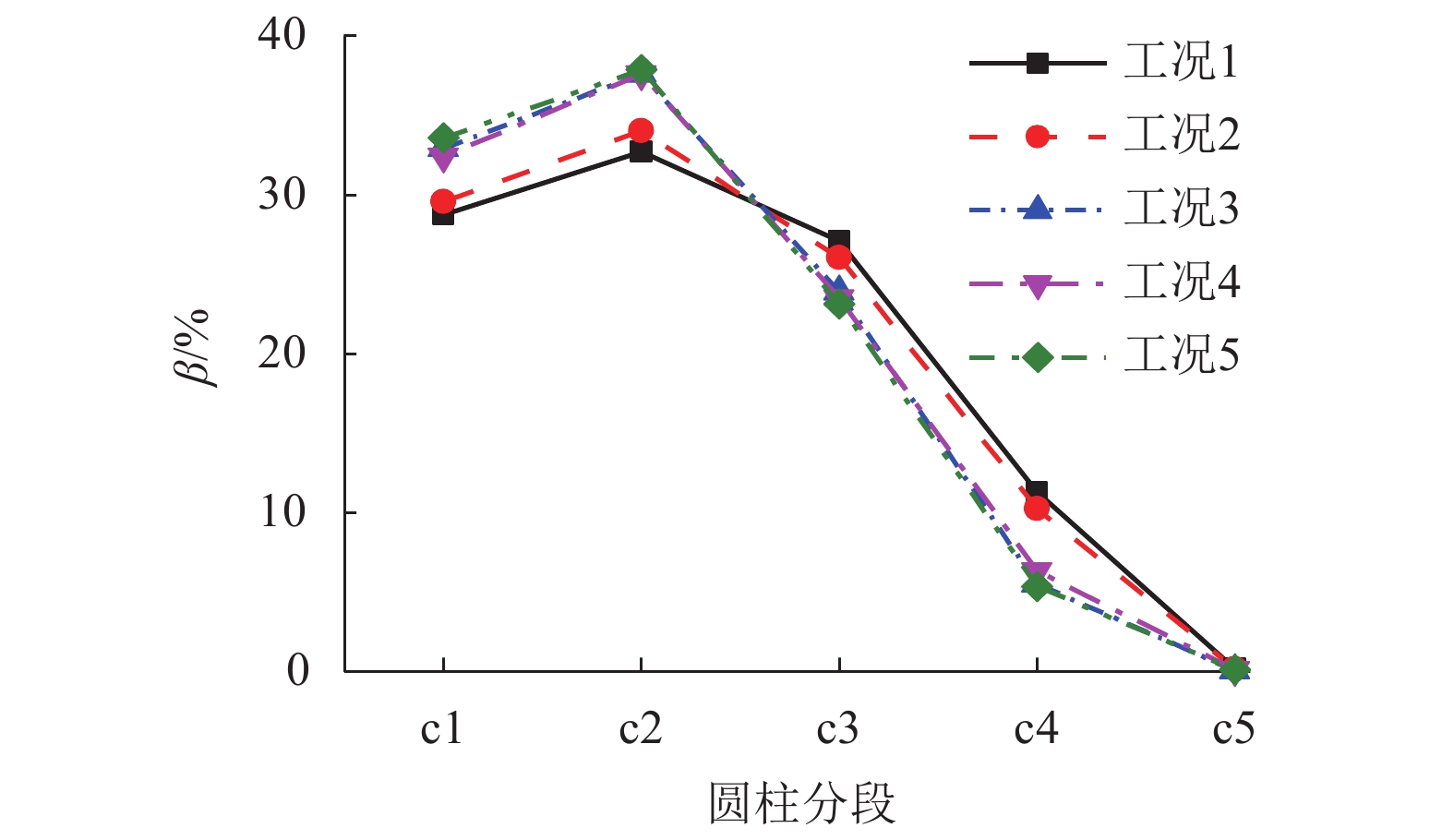

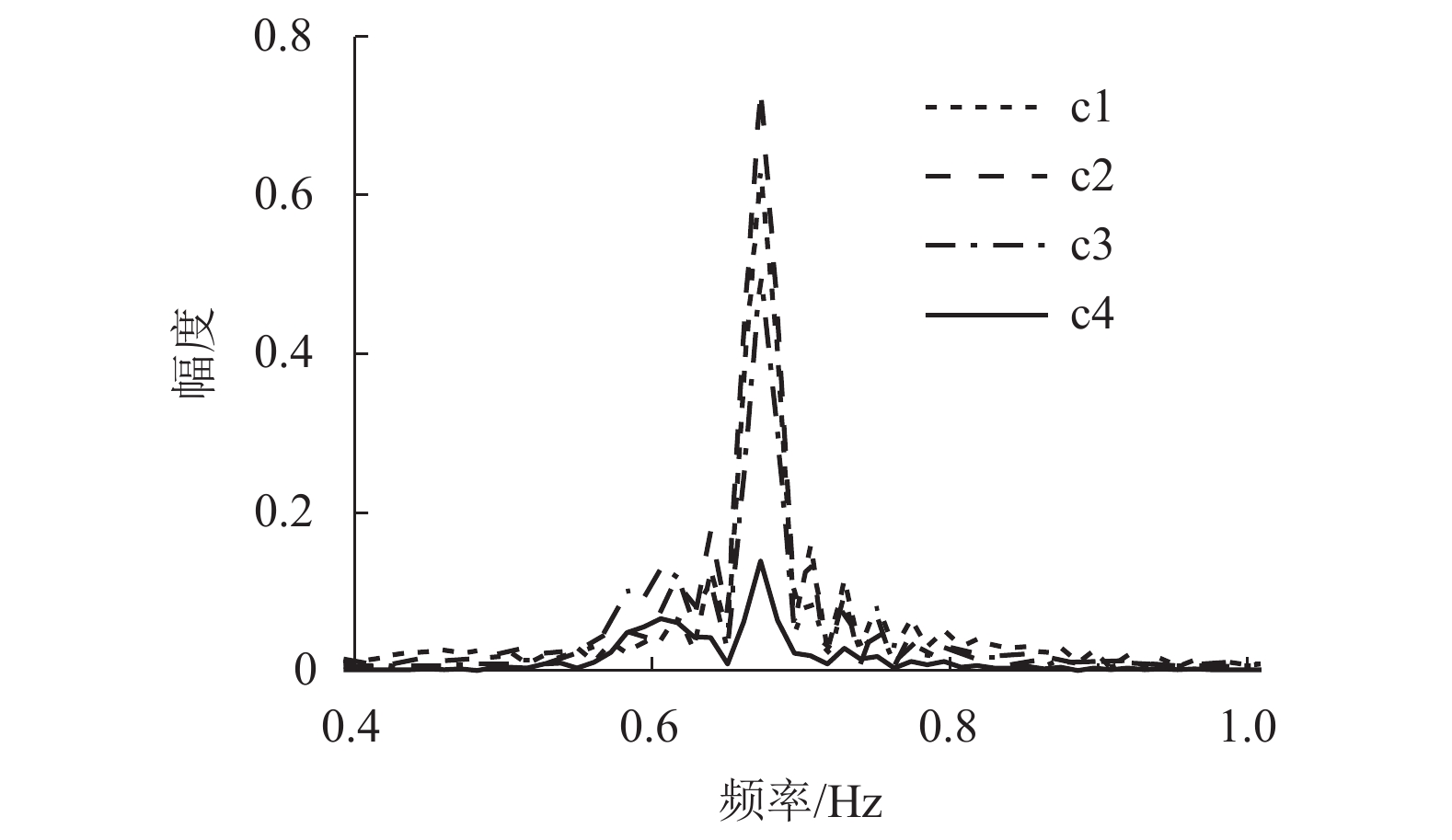

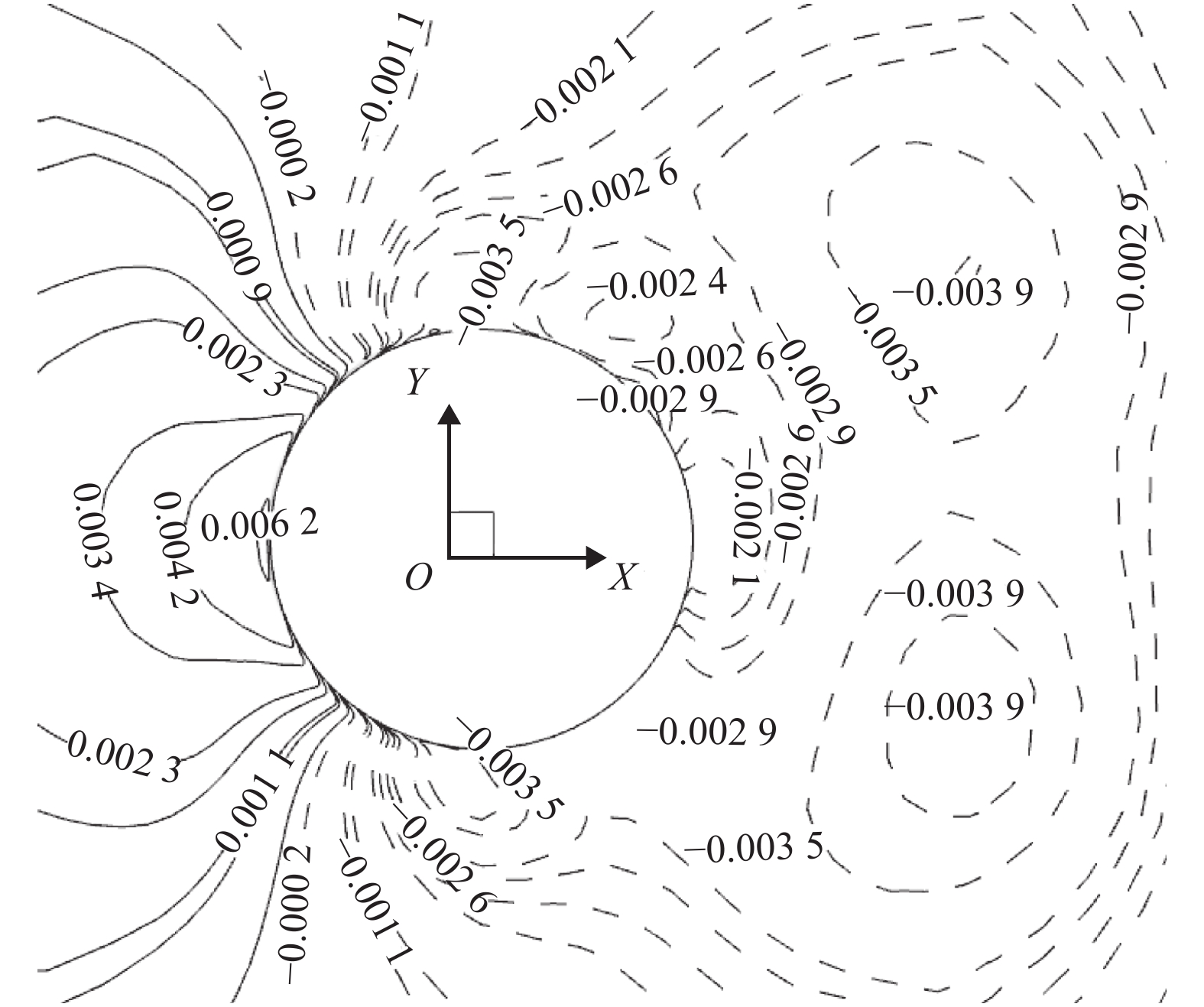

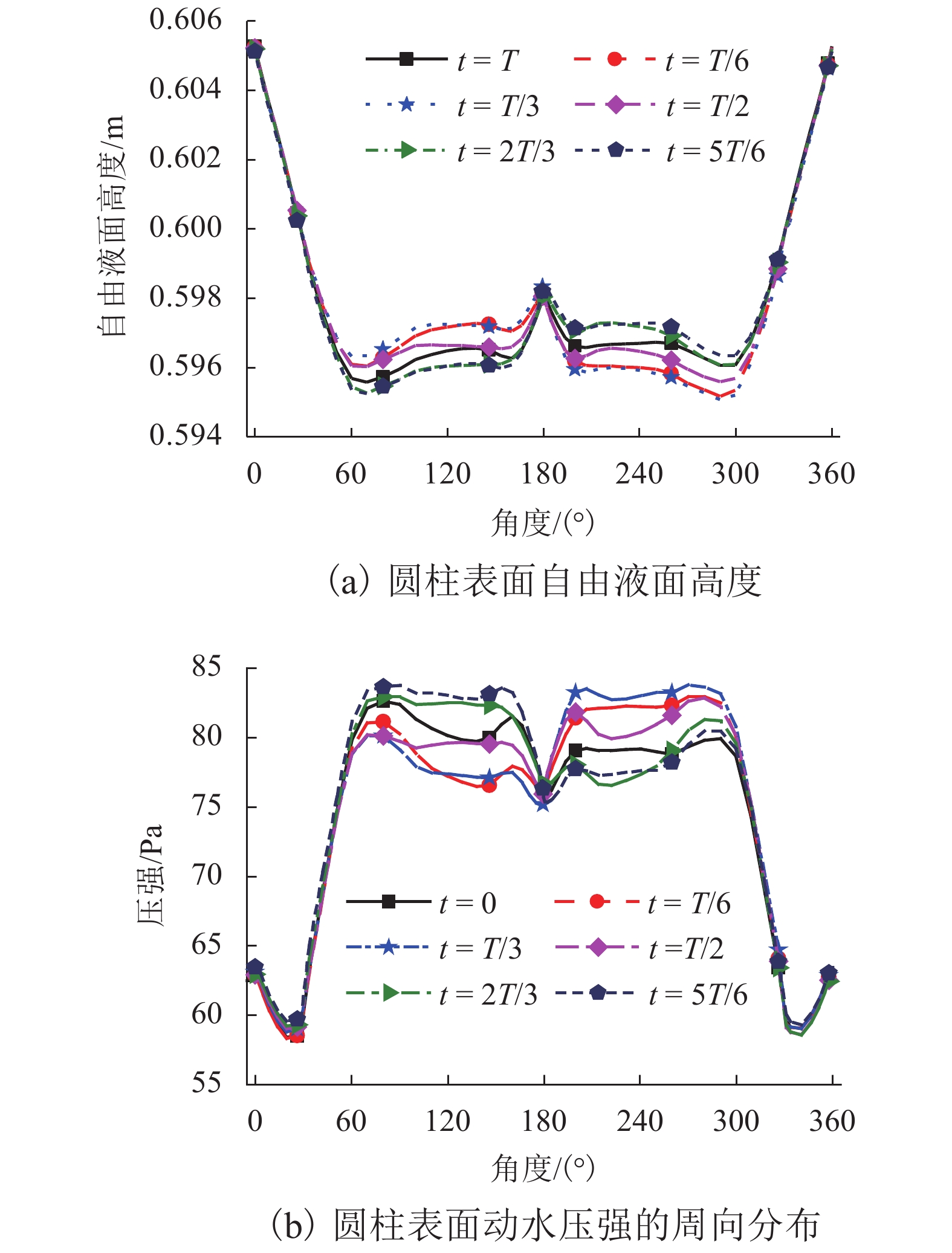

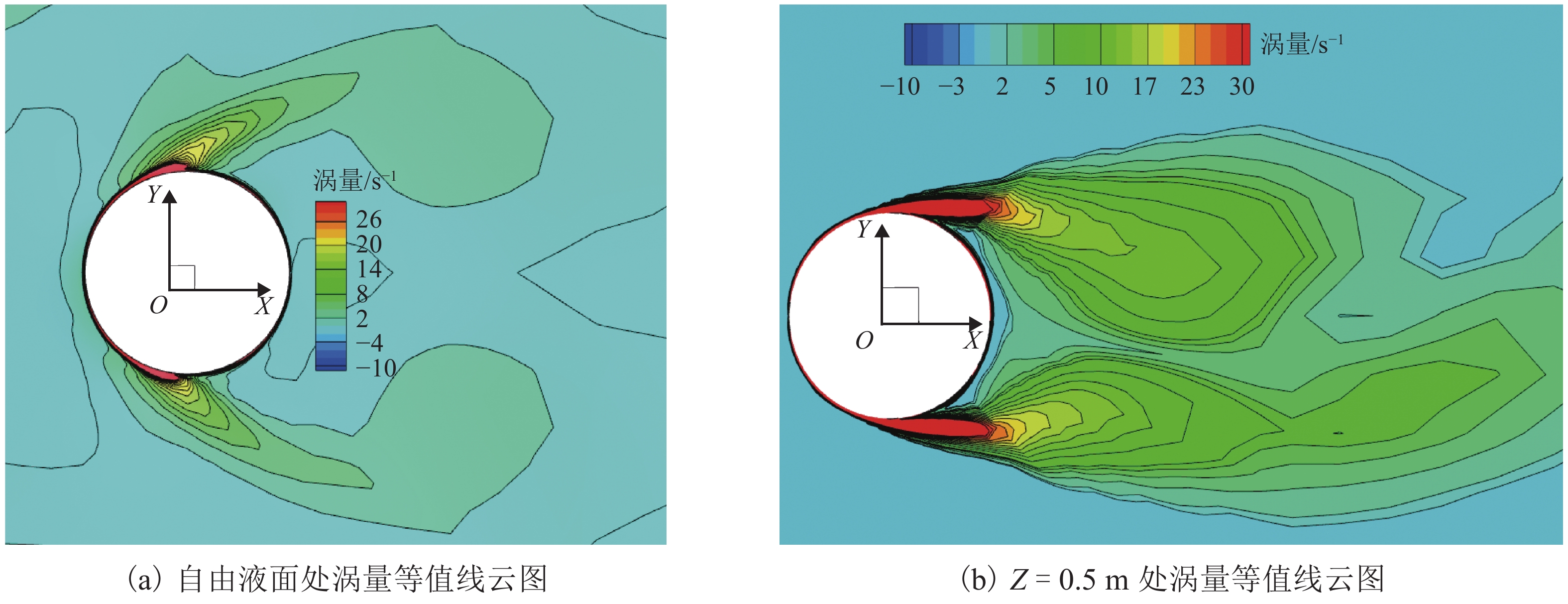

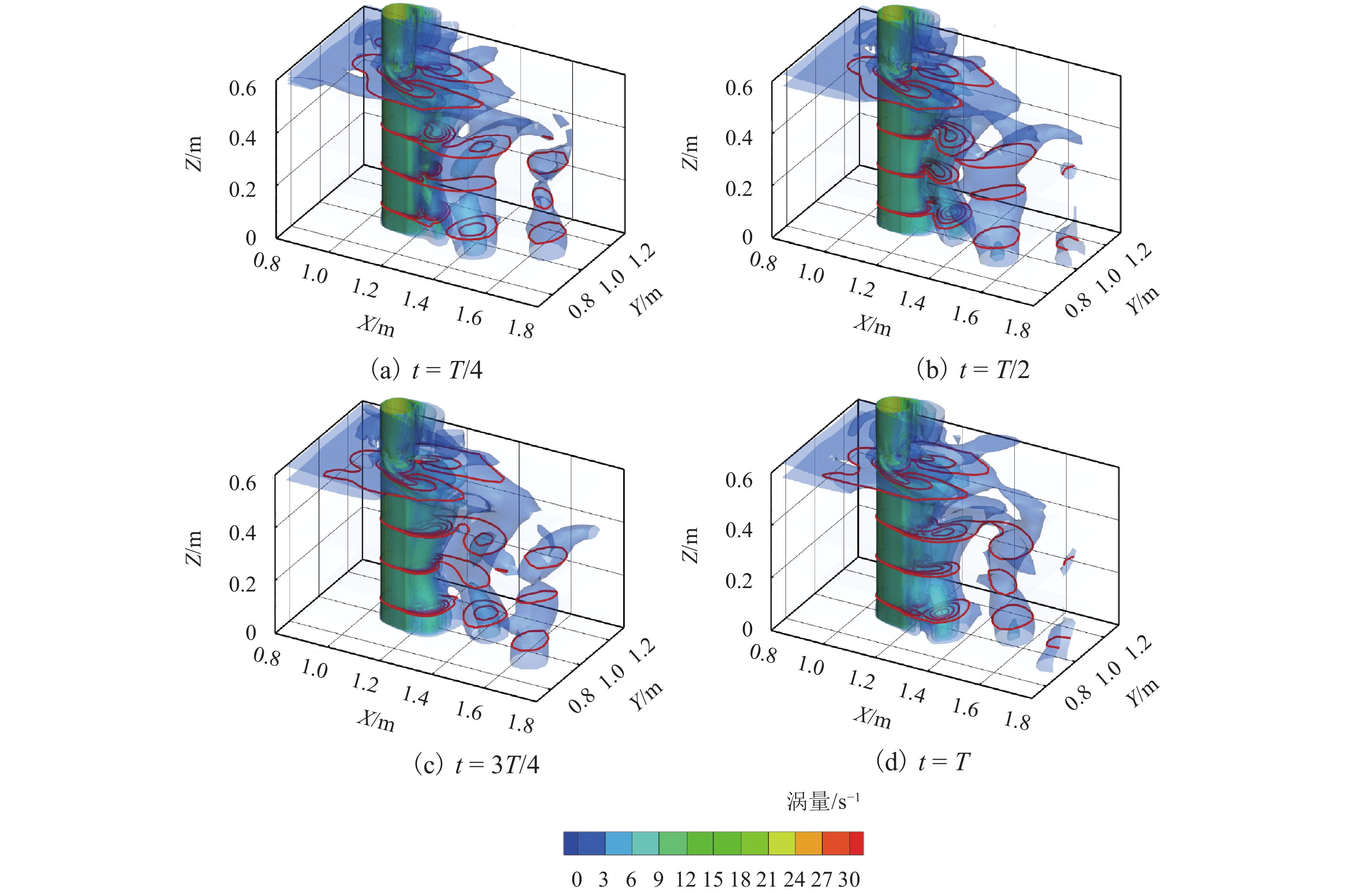

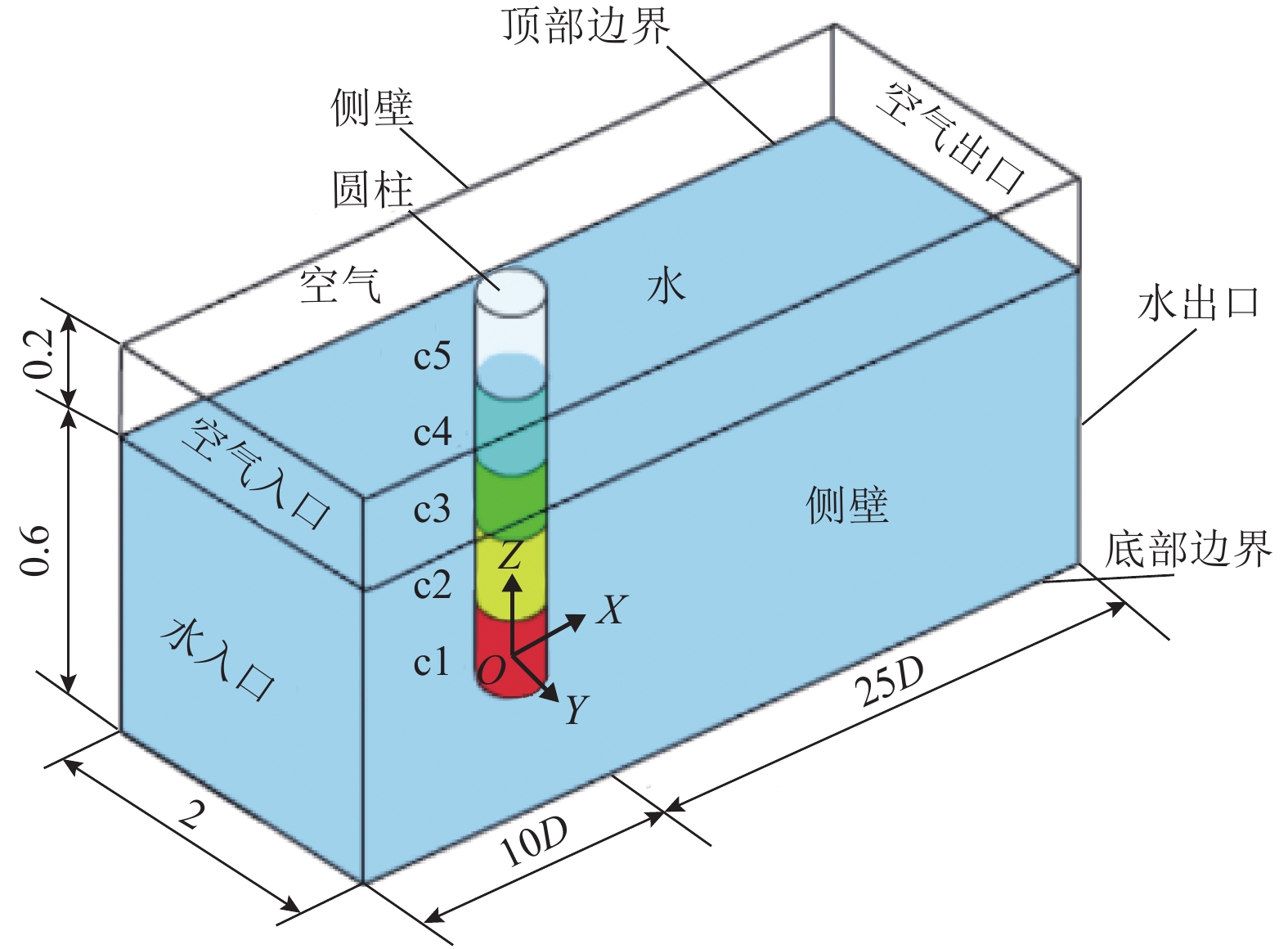

摘要: 为了深入研究桥梁墩柱水流力的特点及产生机理,对典型桥墩模型考虑自由液面影响时的三维绕流展开了精细化研究. 采用ANSYS FLUENT 作为数值模拟工具,研究了整个墩柱阻力和升力特点,并将墩柱模型从柱底到柱顶划分为5个分段,对比了各个分段阻力、升力特点及沿着水深的变化规律,进一步分析了自由液面、底部边界对漩涡结构的影响,阐述了流场三维特性与墩柱水流力之间的关系. 研究结果表明:墩柱水流力沿着水深是非一致分布的,墩柱分为5段(c1~c5),其中c1~c4分段阻力均值与圆柱整体受力的比值分别约为25%、30%、25%、20%,c5分段处于空气中受力贡献近似为0;另外阻力振幅、升力振幅中下部较大,而底部、中上部、液面处较小;漩涡交替脱落导致墩柱左右两侧自由液面交替起伏,自由液面对漩涡产生抑制作用,自由液面处产生多个尺度不同的漩涡,这与液面下仅有两个交替脱落的漩涡是不同的;墩柱中下部漩涡脱落比其余位置有所滞后,导致柱体不同分段处升力有明显的相位差;墩柱升力振幅与阻力均值分别为5.511 N和3.695 N,相差不大,升力引起的桥墩或桥梁的振动不可忽视.Abstract: In order to investigate into the characteristics and mechanism of the current forces on bridge piers, a refined study on 3D flow around the typical pier model was conducted considering the influence of the free surface. ANSYS FLUENT was employed to address the characteristics of the drag force and lift force on the whole pier model. The pier model was divided into five sections from the bottom to top of the cylinder, characteristics of the drag and lift forces on each section were compared, and the variation law of the drag and lift forces along the water depth was analyzed. Further, the influences of the free surface and the bottom condition on vortex structure were analyzed and the relationship between 3D flow field and current force was discussed. Results show that the current force on pier is not uniformly distributed along the water depth; i.e., the mean value of drag force on cylinder sections c1−c4 accounts for 25%, 30%, 25% and 20%, respectively, of the total drag force on pier, and c5 contributes almost zero due to its exposure to air. The amplitudes of the drag and lift forces in the middle-lower part are larger than those at the bottom, middle-upper, and free surface parts of the water depth. Besides, the alternating vortex shedding causes alternating fluctuations of the free surface at the left and right sides of the cylinder. The free surface suppresses the vortex shedding, and vortices of different scales exist at the free surface, which are quite different from the two alternately shedding vortexes under the free surface. The vortex shedding at the middle-lower part of the pier lags behind the rest parts, resulting in a significant phase difference in the lift force at different parts of the cylinder. The lift force is comparable in magnitude to the average value of the drag force, for example which are respectively 5.511 N, 3.695 N in case 3, showing that the possible vibration of the pier or bridge caused by the lift force cannot be ignored.

-

Key words:

- bridge pier /

- drag force /

- lift force /

- vortex /

- 3D flow field /

- free surface

-

表 1 网格无关性验证

Table 1. Verification of mesh independence

网格质量 网格数量/个 Re CD 用时/h 精细 约33万 44 330 1.033 21 中等 约18万 44 330 1.030 15 粗糙 约10万 44 330 1.006 13 文献[10] 未给出 50 000 0.977 未给出 表 2 数值模拟工况以及计算结果对比

Table 2. Numerical simulation cases and comparisons of calculated results

工况 流速/(m•s−1) Re CD CLrms f/Hz St 1 0.214 23 540 1.064 0.624 0.355 0.182 2 0.302 33 220 1.058 1.405 0.504 0.184 3 0.403 44 330 1.030 2.006 0.673 0.184 4 0.506 55 660 1.007 2.988 0.840 0.183 5 0.600 66 000 1.042 4.967 1.000 0.183 表 3 各分段及圆柱整体在各工况下的阻力系数

Table 3. Coefficients of drag forces onsections and the whole cylinder in different cases

工况 c1 c2 c3 c4 c5 c 1 1.108 1.157 1.136 0.848 0.005 1.064 2 1.107 1.156 1.122 0.837 0.008 1.058 3 1.119 1.184 1.084 0.730 0.004 1.030 4 1.055 1.119 1.046 0.794 0.015 1.007 5 1.098 1.166 1.069 0.811 0.023 1.042 -

詹昊,李万平,方秦汉,等. 不同雷诺数下圆柱绕流仿真计算[J]. 武汉理工大学学报,2008,30(12): 129-132.ZHAN Hao, LI Wanping, FANG Qinhan, et al. Numerical simulation of the flow around a circular cylinder at varies reynolds number[J]. Journal of Wuhan University of Technology, 2008, 30(12): 129-132. 雷娟棉,谭朝明. 基于Transition SST模型的高雷诺数圆柱绕流数值研究[J]. 北京航空航天大学学报,2017,43(2): 207-217.LEI Juanmian, TAN Zhaoming. Numerical simulation for flow around circular cylinder at high Reynolds number based on Transition SST model[J]. Journal of Beijing University of Aeronautics and Astronautics, 2017, 43(2): 207-217. AI Y, FENG D, YE H, et al. Unsteady numerical simulation of flow around 2-D circular cylinder for high Reynolds numbers[J]. Journal of Marine Science and Application, 2013, 12(2): 180-184. doi: 10.1007/s11804-013-1183-0 蒋科,张德华,戚昱,等. 亚临界雷诺数条件下圆柱绕流特性研究[J]. 海洋工程装备与技术,2017,4(1): 37-42. doi: 10.3969/j.issn.2095-7297.2017.01.008JIANG Ke, ZHANG Dehua, QI Yu, et al. Study on the characteristics of flow around cylinder at subcritical Reynolds number[J]. Ocean Engineering Equipment and Technology, 2017, 4(1): 37-42. doi: 10.3969/j.issn.2095-7297.2017.01.008 SUMNER D. Two circular cylinders in cross-flow: a review[J]. Journal of Fluids and Structures, 2010, 26(6): 849-899. doi: 10.1016/j.jfluidstructs.2010.07.001 DONG S, KARNIADAKIS G E. DNS of flow past a stationary and oscillating cylinder at Re=10 000[J]. Journal of Fluids and Structures, 2005, 20(4): 519-531. doi: 10.1016/j.jfluidstructs.2005.02.004 闵强利,张云海. 三维瞬态圆柱绕流数值模拟[J]. 水雷战与舰船防护,2008,16(1): 11-16, 62.MIN Qiangli, ZHANG Yunhai. 3D Transition cylinder flow numerical simulation[J]. Mine Warfare & Ship Self-Defence, 2008, 16(1): 11-16, 62. 蘧鑫晨, 高洋洋, 刘 彩, 等. 不同雷诺数下三维圆柱绕流数值模拟[C]//第十八届中国海洋(岸)工程学术讨论会论文集. 舟山: 海洋出版社, 2017: 240-249 KAWAMURA T, MAYER S, GARAPON A, et al. Large eddy simulation of a flow past a free surface piercing circular cylinder[J]. Transactions-American Society of Mechanical Engineers Journal of Fluids Engineering, 2002, 124(1): 91-101. 岳永威,李梦阳,孙龙泉,等. 具有自由液面效应的圆柱绕流三维数值模拟[J]. 船舶,2012,23(4): 16-22. doi: 10.3969/j.issn.1001-9855.2012.04.004YU Yongwei, LI Mengyang, SUN Longquan, et al. Numerical simulation of flow around a three-dimensional circular cylinder piercing free surface[J]. Ship & boat, 2012, 23(4): 16-22. doi: 10.3969/j.issn.1001-9855.2012.04.004 涂程旭,王昊利,林建忠. 圆柱绕流的流场特性及涡脱落规律研究[J]. 中国计量学院学报,2008,19(2): 98-102, 136.TU Chengxu, WANG Haoli, LIN Jianzhong. Experimental research on the flow characteristics and vortex shedding in the flow around a circular cylinder[J]. Journal of China Jiliang University, 2008, 19(2): 98-102, 136. 刘晓亮,许栋,黄雄合,等. 墩柱绕流水动力特性实验和大涡模拟研究[J]. 港工技术,2017,54(6): 20-23.LIU Xiaoliang, XU Dong, HUANG Xionghe, et al. Large eddy simulation study and hydrodynamics experiment of flow surrounding a pier[J]. Port Engineering Technology, 2017, 54(6): 20-23. 严建科,焦臣,龙涛,等. 单圆柱桥墩绕流流场试验究[J]. 西安建筑科技大学学报(自然科学版),2012,44(6): 779-785.YAN Jianke, JIAO Chen, LONG Tao, et al. Single-cylindrical pier experimental study on vertex flow field[J]. Journal of Xi’ an University of Architecture & Technology (Natural Science Edition), 2012, 44(6): 779-785. 段中喆. ANSYS FLUENT流体分析与工程实例[M]. 电子工业出版社, 2015: 144-147. 赵伟文,万德成. 用SST-DES和SST-URANS方法数值模拟亚临界雷诺数下三维圆柱绕流问题[J]. 水动力学研究与进展A辑,2016,31(1): 1-8.ZHAO Weiwen, WAN Decheng. Numerical study of 3D flow past a circular cylinder at subcritical Reynolds number using SST-DES and SST-URANS[J]. Chinese Journal of Hydrodynamics, 2016, 31(1): 1-8. -

下载:

下载: