Fatigue Experimental Analysis of Damaged Steel Beams Strengthened with Prestressed Unbonded CFRP Plates

-

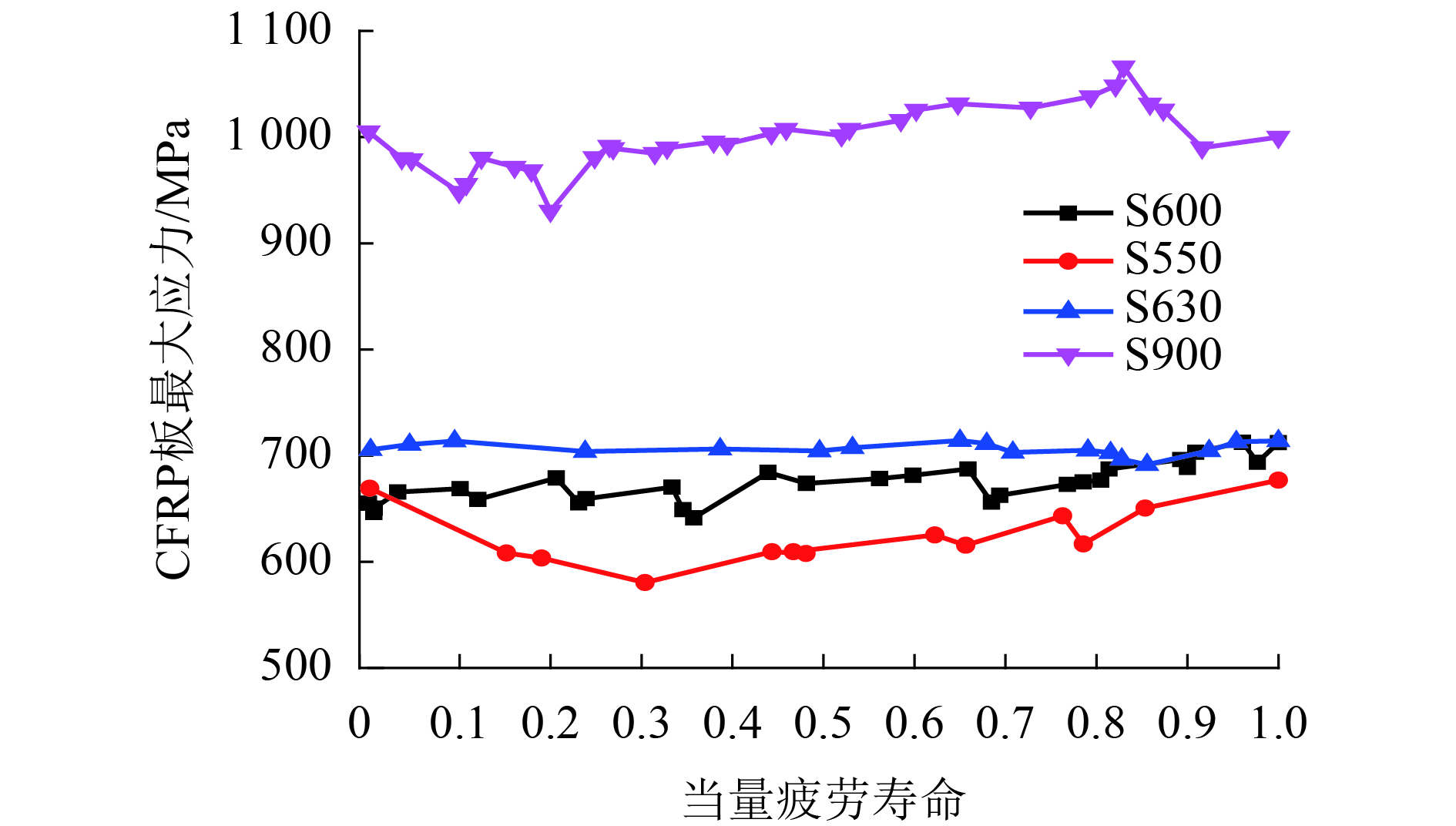

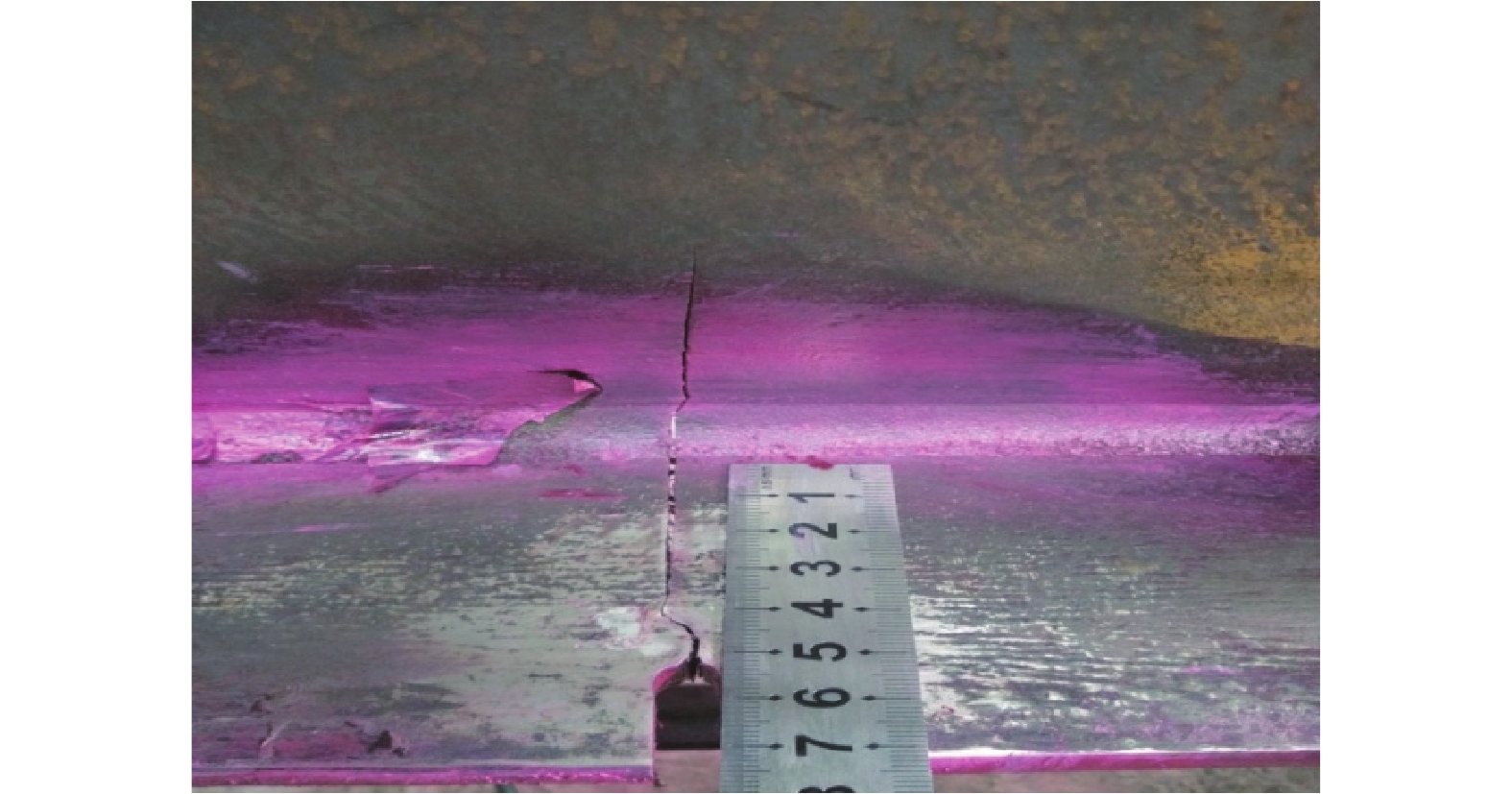

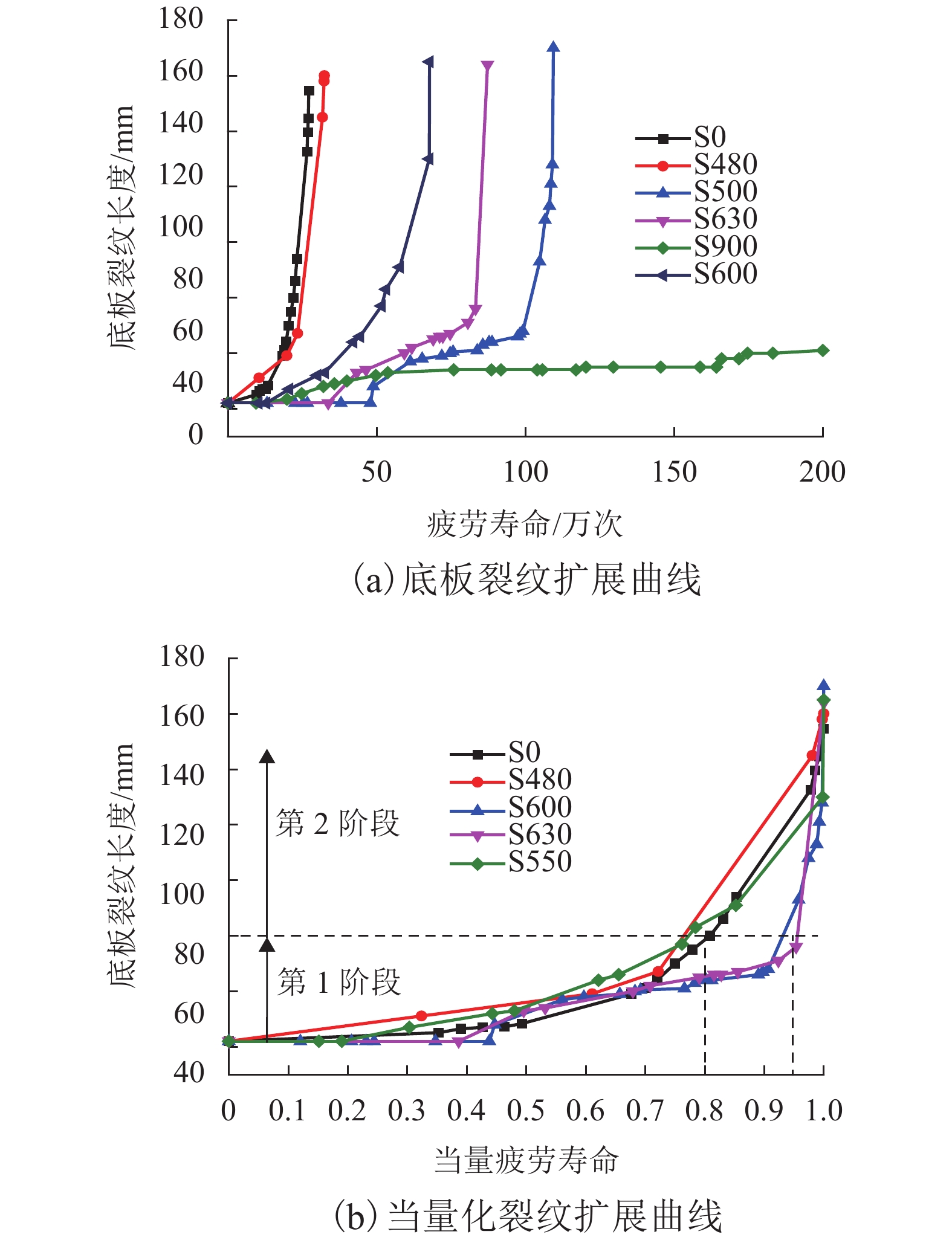

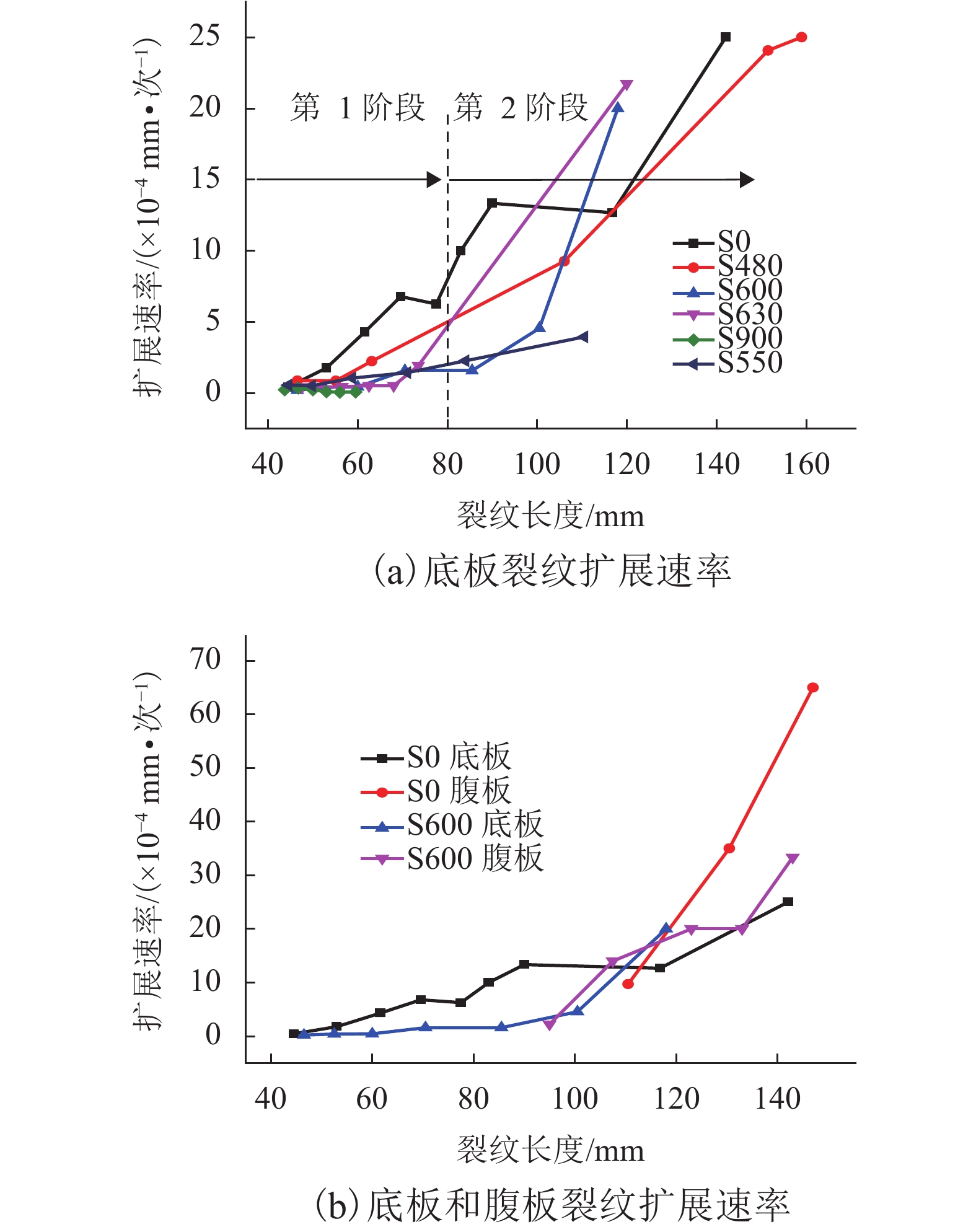

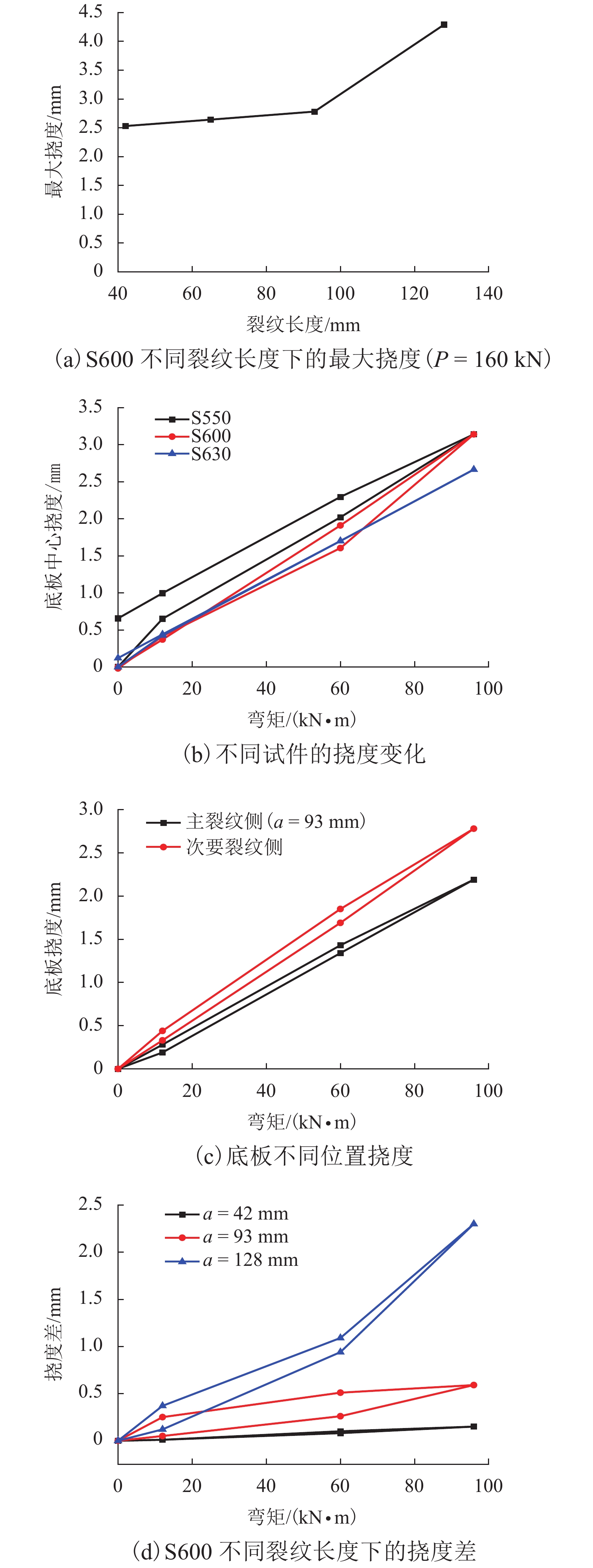

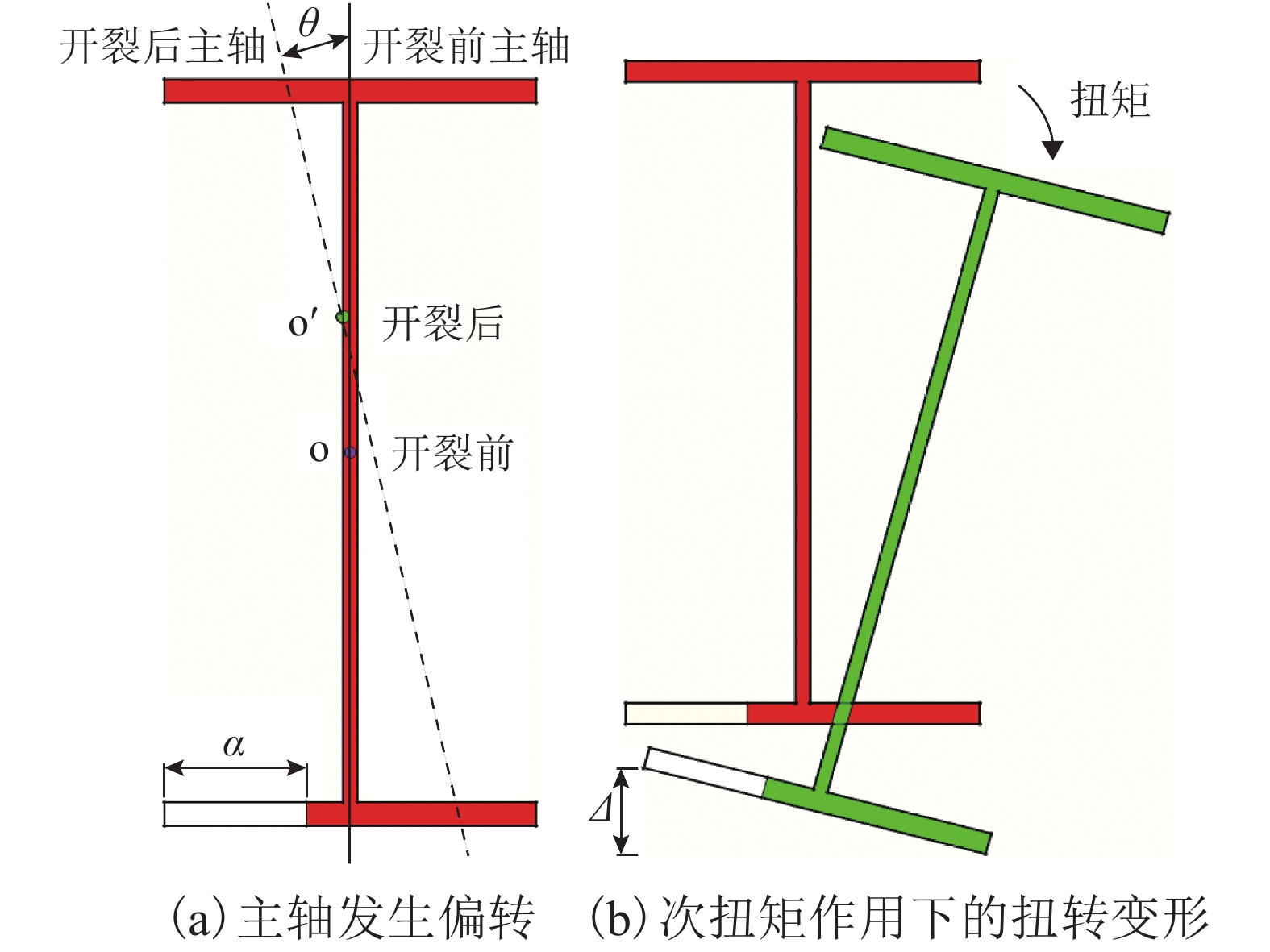

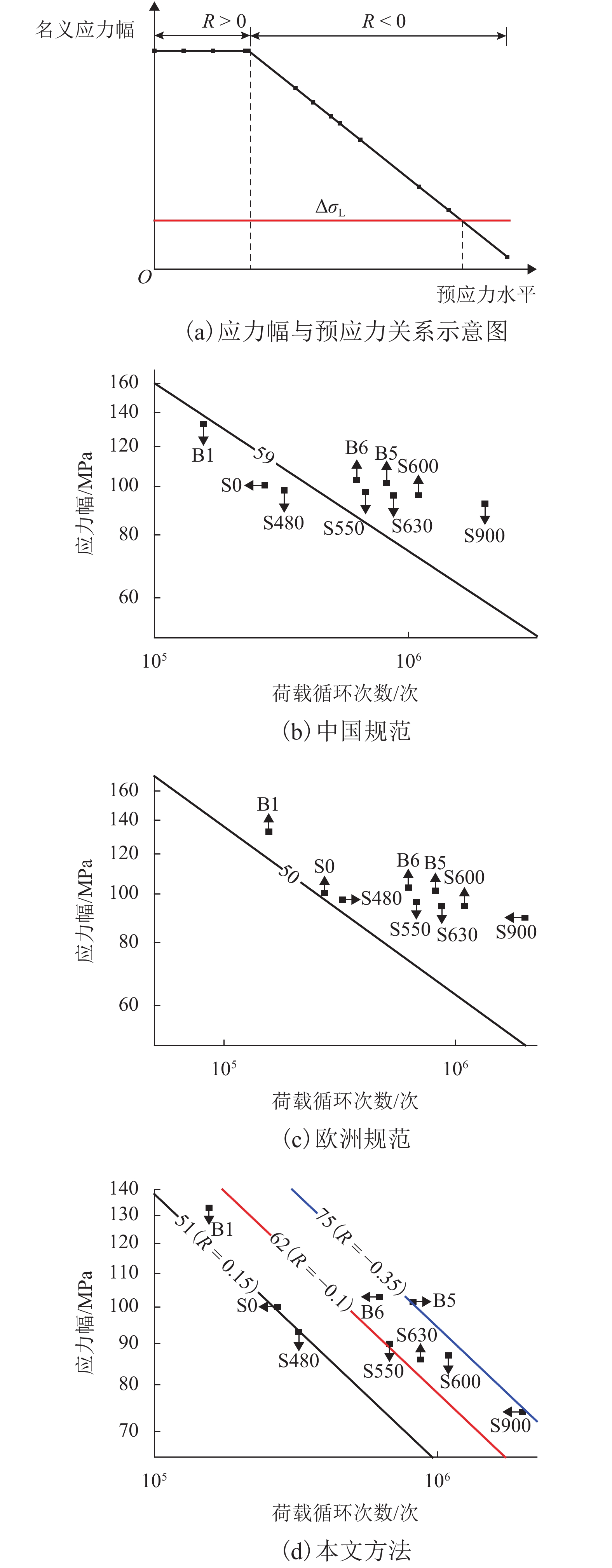

摘要: 老旧钢桥在长期运营过程中容易疲劳开裂,严重影响桥梁结构安全,为改善受损钢梁构件的疲劳性能,采用大比例疲劳模型试验对无粘结预应力碳纤维增强复合材料(CFRP)板加固受损钢梁进行研究,基于Paris公式提出疲劳强度-寿命(S-N)曲线的确定方法,并分析不同预应力水平对受损钢梁寿命影响. 对不同预应力水平CFRP板加固的双缺口受损钢梁在循环荷载下进行疲劳试验,结果表明:施加预应力可降低裂纹扩展速率和受损钢梁残余挠度超过40%,最少可延长受损钢梁的疲劳寿命3倍;最高预应力水平所加固的受损钢梁,其疲劳寿命最少提高了8倍,且预应力CFRP板加固后缺口钢梁疲劳强度等级由51 MPa提高到75 MPa. 理论预测结果与试验结果符合较好,可作为推荐方法.Abstract: Aged steel bridges are prone to fatigue cracking, which is a challenging problem for the safety of bridges during their service. An experimental and theoretical study was conducted to improve the fatigue performance of notched steel beams strengthened with prestressed unbounded carbon-fibre-reinforced polymer (CFRP) plates. The Paris law was used to obtain the S-N curve of the reinforced steel beam, and the effect of the prestress level on the fatigue life was presented. Double-edge-notched large-scale specimens were strengthened using an unbonded CFRP plate with different prestressing levels and were thereafter tested under cyclic loading. Experimental results show that prestress reduces both the crack growth rate and stiffness decay of the specimens by up to 40%, and thus, the fatigue life is extended by more than three times. The specimen with the highest prestress level exhibits the best performance, extending the fatigue life by more than eight times. Moreover, prestressed CFRP reinforcements upgrade the fatigue category of the notched beam from 51 MPa to 75 MPa. The theoretically predicted results are reasonably consistent with the experimental results, and the proposed method is recommended for lifetime evaluations of components.

-

Key words:

- steel structure /

- reinforcement /

- unbounded CFRP /

- fatigue strength /

- prestress level /

- S-N curve

-

表 1 试件的几何和力学性能

Table 1. Properties of specimens

材料 长度/mm 宽度/mm 厚度/mm 力学性能 钢梁 3 000 175 11(底板)

& 7(腹板)Es = 200 Gpa

Sy = 235 MPaCFRP 1 650 100 2 Ec = 180 GPa

Sut = 2 000 MPa表 2 试件细节

Table 2. Details of specimens

试件 有效预

应力/MPa最大名义

应力σmax/MPa最小名义

应力σmin/MPa应力比R S0 114.6 14.3 0.13 S480 480 93.0 –7.3 – 0.10 S550 550 89.8 –10.5 – 0.10 S600 600 87.6 –12.7 – 0.15 S630 630 86.2 –14.1 – 0.15 S900 900 74.1 –26.2 – 0.35 表 3 试件疲劳寿命

Table 3. Fatigue life of specimens

试件 有效预应力/MPa 疲劳寿命/万次 破坏模式 S0 — 27.2 完全断裂 S480 480 32.4 S550 550 67.8 S600 600 109.4 S630 630 87.3 S900 900 > 200.0 停止试验 表 4 试件疲劳寿命计算值与实测值比较

Table 4. Comparison between the test and predicted results

试件 试验值 规范公式计算值 本文方法 中国规范 欧洲规范 B1 15.6 17.5 10.7 11.2 B5 82.0 39.2 24.0 25.2 B6 62.6 37.6 23.1 24.2 S0 27.2 40.7 24.9 26.1 S480 32.4 43.4 27.2 51.7 S550 67.8 44.5 28.1 53.5 S600 109.4 46.5 29.7 56.4 S630 87.3 46.6 29.8 56.6 S900 >200.0 52.1 34.8 116.6 -

张喜刚,刘高,马军海,等. 中国桥梁技术的现状与展望[J]. 科学通报,2016,61(4): 415-425ZHANG Xigang, LIU Gao, MA Junhai, et al. Status and prospect of technical development for bridges in China[J]. China Science Bulletin, 2016, 61(4): 415-425 SEAN C J, SCOTTCIVJAN A. Application of fiber reinforced polymer overlays to extend steel fatigue life[J]. Journal of Composites for Construction, 2003, 7(4): 331-338 TAVAKKOLIZADEH M, SAADATMANESH H. Fatigue strength of steel girders strengthened with carbon fiber reinforced polymer patch[J]. Journal of Structural Engineering, 2003, 129(2): 186-196 KIM Y J, HARRIES K A. Fatigue behavior of damaged steel beams repaired with CFRP strips[J]. Engineering Structures, 2011, 33(5): 1491-1502 WU Gang, WANG Haitao, WU Zhishen, et al. Experimental study on the fatigue behavior of steel beams strengthened with different fiber-reinforced composite plates[J]. Journal of Composites for Construction, 2012, 16(2): 127-137 COLOMBI P, FAVA G. Fatigue crack growth in steel beams strengthened by CFRP strips[J]. Theoretical & Applied Fracture Mechanics, 2016, 85: 173-182 TÄLJSTEN B, HANSEN C S, SCHMIDT J W. Strengthening of old metallic structures in fatigue with prestressed and non-prestressed CFRP laminates[J]. Construction and Building material, 2009, 23(4): 1665-1677 BASSETTI A. Lamelles precontraintes en fibrescarbone pour le renforcement de pontsrivetesendommaees par fatigue (in French)[D]. Lausanne: EPFL, 2001 COLOMBI P, BASSETTI A, NUSSBAUMER A. Delamination effects on cracked steel members reinforced by prestressed Composite Patch[J]. Theoretical and Applied Fracture Mechanics, 2003, 39(1): 61-71 YE H W, KöNIG C, UMMENHOFER T, et al. Fatigue performance of tension steel plates strengthened with prestressed CFRP laminates[J]. Journal of Composites for Construction, 2010, 14(5): 609-615 YE H W, UMMENHOFER T, QIANG S Z. Experimental study of flexural fatigue performance of steel girder reinforced by prestressed CFRP plate[J]. Journal of Highway and Transportation Research and Development, 2009, 26(12): 50-55 GHAFOORI E, MOTAVALLI M, NUSSBAUMER A, et al. Determination of minimum CFRP pre-stress levels for fatigue crack prevention in retrofitted metallic beams[J]. Engineering Structures, 2015, 84(10): 29-41 何贤锋,彭晖,罗杰. 外部粘贴预应力碳纤维板技术加固桥梁结构的工程应用与评估[J]. 中国铁道科学,2007,28(2): 139-144HE Xianfeng, PENG Hui, LUO Jie. Engineering application and evaluation of the bridge structure strengthened with prestressed CFRP plate[J]. China Railway Science, 2007, 28(2): 139-144 TENG J G, YU T, FERNANDO D. Strengthening of steel structures with fiber reinforced polymer composites[J]. Journal of Constructional Steel Research, 2012, 78(6): 131-143 叶列平,冯鹏. FRP在工程结构中的应用与发展[J]. 土木工程学报,2006,39(3): 24-36YE Lieping, FENG Peng. Applications and development of fiber-reinforced polymer in engineering structures[J]. China Civil Engineering Journal, 2006, 39(3): 24-36 GHAFOORI E, MOTAVALLI M, NUSSBAUMER A, et al. Design criterion for fatigue strengthening of riveted beams in a 120-year-old railway metallic bridge using pre-stressed CFRP plates[J]. Composites Part B, 2015, 68: 1-13 邓军,黄培彦. CFRP板加固钢梁界面应力的理论与试验研究[J]. 华南理工大学学报 (自然科学版),2007,35(7): 10-14DENG Jun, HUANG Yanpei. Theoretical and experimental study on interfacial stresses of steel beam strengthened with CFRP plates[J]. Journal of South China University of Technology (Natural Science Edition), 2007, 35(7): 10-14 郑云,陈煊,李忠煜,等. 碳纤维加固钢结构的疲劳寿命分析[J]. 钢结构,2013,28(2): 1-6ZHENG Yun, CHEN Xuan, LI Zhongyu, et al. Fatigue life ansys of CFRP strengthened steel structure[J]. Steel Construction , 2013, 28(2): 1-6 GHAFOORI E, MOTAVALLI M, BOTSIS J, et al. Fatigue strengthening of damaged metallic beams using prestressedunbonded and bonded CFRP plates[J]. International Journal of Fatigue, 2012, 44(2): 303-15 European Committee Standardization. Eurocode 3: design of steel structures-part 1-9: fatigue BS EN 1993-1-9: 2005[S]. [S.l.]: The Authority of the Standards Policy and Strategy Committee, 2005 中华人民共和国住房和城乡建设部. 钢结构设计规范: GB50017—2017[S]. 北京: 中国建筑工业出版社, 2017 BARSOM J M, ROLFE S T. Fracture and fatigue control in structures: applications of fracture mechanics[M]. West Conshohocken: ASTM, 1999: 5-9 HOSSEINI A, GHAFOORI E, MOTAVALLI M, et al. Mode I fatigue crack arrest in tensile steel members using prestressed CFRP plates[J]. Composite Structures, 2017, 178: 119-134 -

下载:

下载: