Experiments on Material Proportions for Simulating Sandy Layer in Deep Sea

-

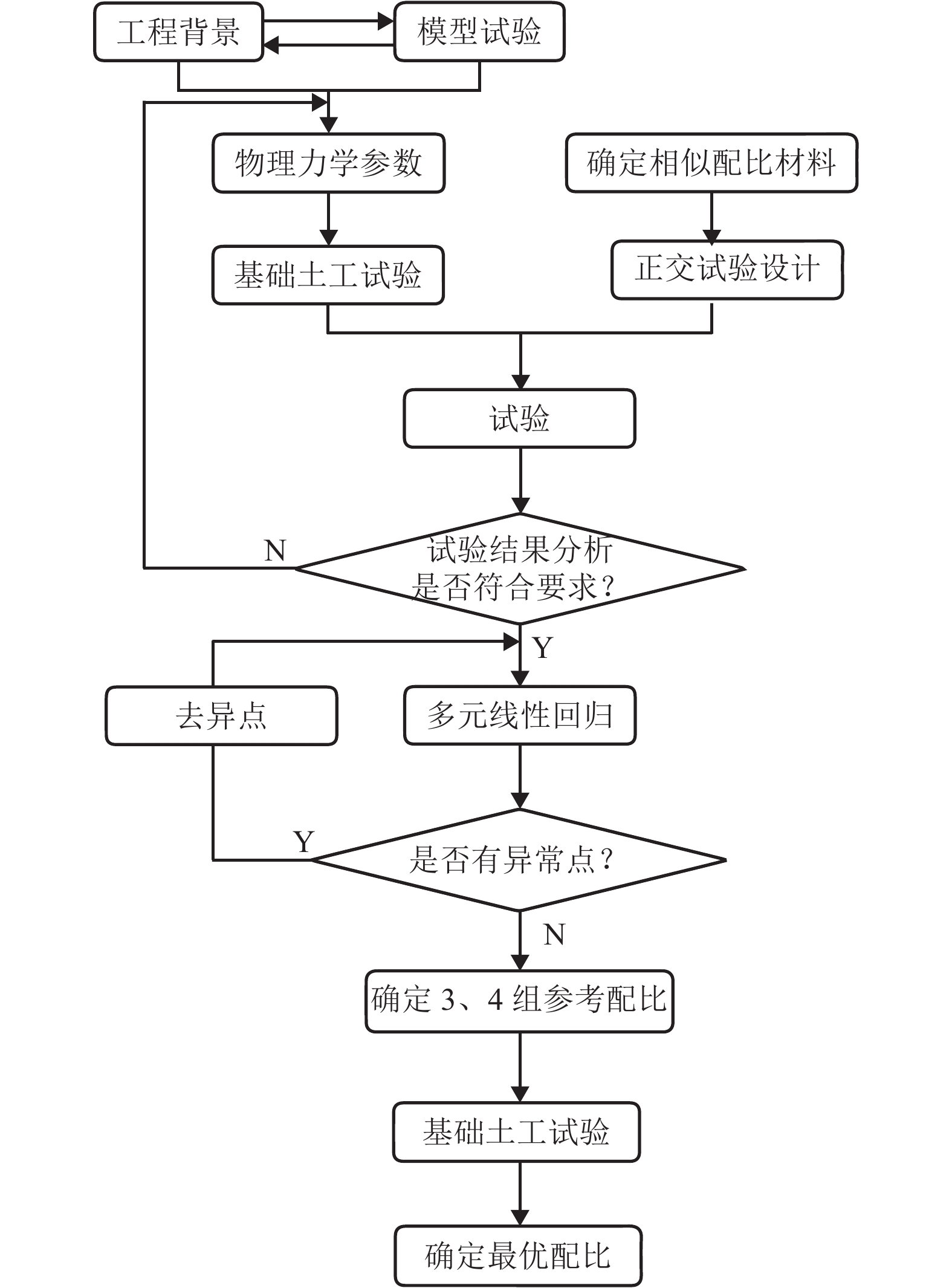

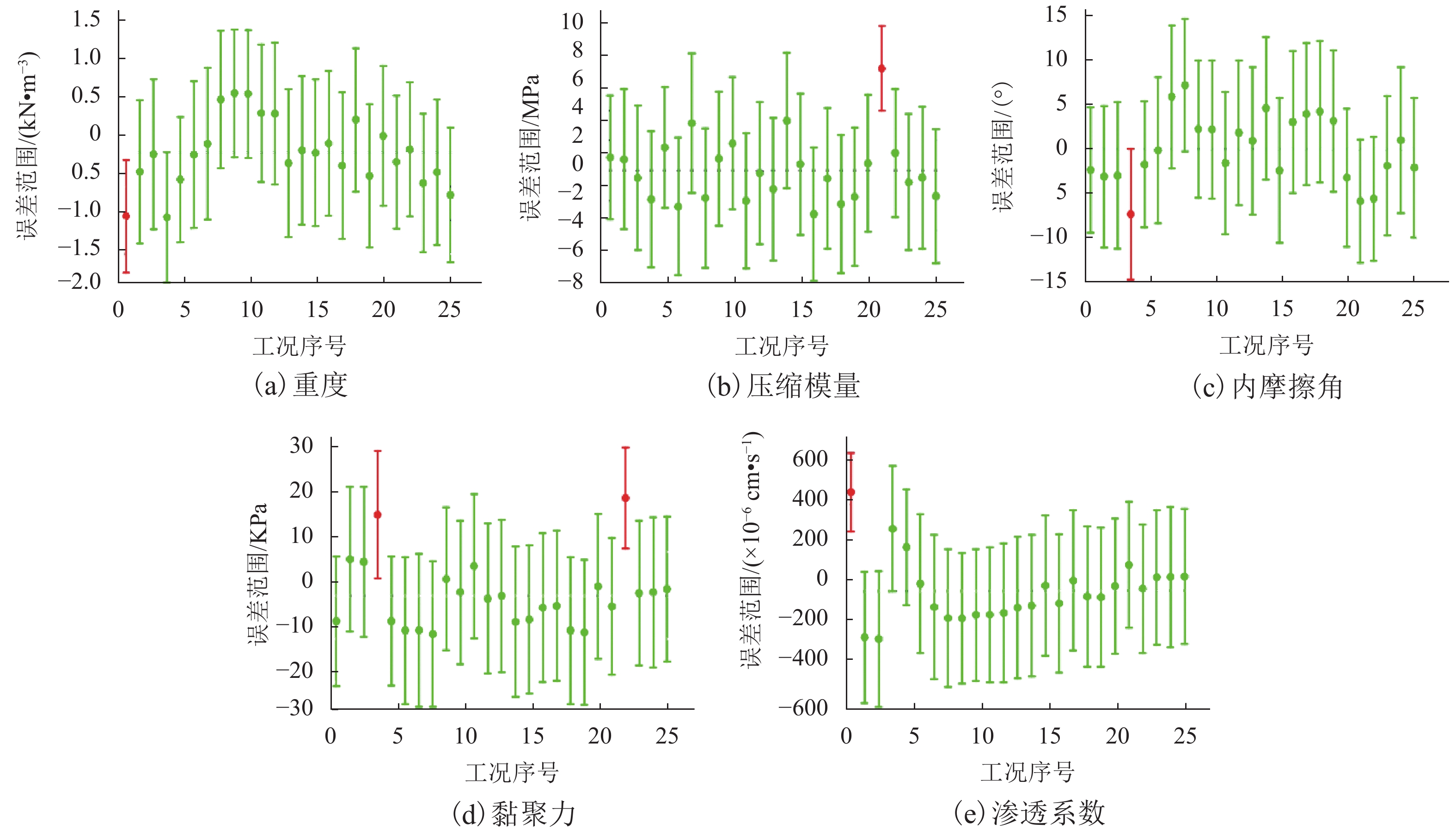

摘要: 为了研究可近似模拟琼州海峡深海环境下砂土地层的相似材料,基于正交试验法,以重晶石粉/标准砂、黏结剂浓度、凡硅比和石膏含量作为4个控制因素,对不同配比相似材料的物理力学参数的变化规律进行了分析. 首先确定标准砂、重晶石粉作为骨料,凡士林和硅油作为黏结剂,石膏粉作为调节剂,其次基于正交试验原理设计25组相似材料配比,分别进行密度试验、直剪试验、压缩试验以及渗流试验,得到了重度、内摩擦角、黏聚力、压缩模量以及渗透系数等物理力学指标,通过极差和显著性分析,研究了各个控制因素对材料参数的影响规律,并对25组试验结果进行了去异常点的多元线性回归分析. 研究结果表明:相似材料重度受重晶石粉/标准砂比值的影响最大,石膏的比例是控制压缩模量的主要因素,内摩擦角和黏聚力无主要控制因素,重晶石粉的比重主要控制着渗透系数的大小;适用于深海环境砂土地层条件下的相似材料配比为重晶石粉/标准砂0.4,黏结剂浓度4.5%,凡硅比3∶1,石膏含量3%.Abstract: In order to obtain the material proportions that can simulate the sandy layer in the deep sea of Qiongzhou Strait, using on the orthogonal experiment method, the physical and mechanical parameters of different material proportions were analyzed with four control factors of barite powder/standard sand, binder concentration, silicon ratio and gypsum content. Firstly, standard sand or barite powder is used as aggregate, petroleum jelly and silicone oil as binders and gypsum powder as modifier. Secondly, 25 groups of material proportions were designed on the basis of orthogonal experiment principle, and types of tests of density, direct shear, compression and seepage were performed to obtain physical and mechanical indices such as weight density, internal friction angle, cohesion force, compression modulus, and permeability coefficient. Through the range analysis and significance analysis, the influence of control factors on the material parameters was explored, and a multivariate linear regression analysis of test results was carried to eliminate outliers. The results show that the weight density is most affected by the ratio of barite powder to standard sand; gypsum content is the leading factor to control the compression modulus; the internal friction angle and cohesion force have no major controlling factors; and the proportion of barite powder mainly affects the permeability coefficient. The appropriate material proportions for the sandy layer in deep sea environment are barite powder /standard sand of 0.4), binder concentration of 4.5%, silicon ratio of 3∶1, and gypsum content of 3%.

-

表 1 原型砂土与模型相似材料物理力学参数

Table 1. Mechanical parameters of prototype sand and model materials

项目 重度/(kN•m−3) 压缩模量/MPa 黏聚力/kPa 内摩擦角/(°) 渗透系数/(× 10−6cm•s−1) 原型 17.8~20.1 35.30~66.80 13.00~25.10 25.3~32.1 100~600 模型 17.8~20.1 1.30~2.55 0.48~0.93 25.3~32.1 19~115 表 2 相似材料配比方案

Table 2. Test schemes of material proportions

试验工况 重晶石粉/

标准砂黏结剂

浓度/%凡硅比 石膏

含量/%1 0 2.0 1.0∶1.0 1.5 2 0 3.5 1.5∶1.0 3.0 3 0 5.0 2.0∶1.0 4.5 4 0 6.5 2.5∶1.0 6.0 5 0 8.0 3.0∶1.0 7.5 6 0.25 2.0 1.5∶1.0 4.5 7 0.25 3.5 2.0∶1.0 6.0 8 0.25 5.0 2.5∶1.0 7.5 9 0.25 6.5 3.0∶1.0 1.5 10 0.25 8.0 1.0∶1.0 3.0 11 0.50 2.0 2.0∶1.0 7.5 12 0.50 3.5 2.5∶1.0 1.5 13 0.50 5.0 3.0∶1.0 3.0 14 0.50 6.5 1.0∶1.0 4.5 15 0.50 8.0 1.5∶1.0 6.0 16 0.75 2.0 2.5∶1.0 3.0 17 0.75 3.5 3.0∶1.0 4.5 18 0.75 5.0 1.0∶1.0 6.0 19 0.75 6.5 1.5∶1.0 7.5 20 0.75 8.0 2.0∶1.0 1.5 21 1.00 2.0 3.0∶1.0 6.0 22 1.00 3.5 1.0∶1.0 7.5 23 1.00 5.0 1.5∶1.0 1.5 24 1.00 6.5 2.0∶1.0 3.0 25 1.00 8.0 2.5∶1.0 4.5 表 3 相似材料配比试验结果

Table 3. Experimental results of material proportions

试验工况 重度/

(kN•m−3)压缩模

量/MPa内摩擦

角/(°)黏聚

力/kPak20/

(× 10−6 cm•s−1)1 17.5 2.22 28.3 0.26 701.00 2 17.8 2.93 26.7 14.66 24.80 3 17.7 2.52 26.0 14.14 15.10 4 16.4 1.91 20.7 25.14 525.00 5 16.6 6.25 25.6 0.52 439.00 6 19.0 1.82 29.6 0.74 2 330.00 7 18.8 8.28 34.9 0.83 123.00 8 19.1 4.08 35.4 0.01 69.20 9 19.5 2.28 35.8 2.30 16.20 10 19.0 1.82 31.4 4.73 1.87 11 20.2 5.15 27.2 18.25 45.40 12 20.5 2.53 36.1 0.21 1.18 13 19.4 2.29 34.3 0.87 24.90 14 19.1 5.44 33.7 0.41 4.50 15 18.7 3.34 25.7 1.01 96.40 16 21.0 1.85 37.2 0.63 3.90 17 20.3 5.11 37.3 1.13 109.00 18 20.5 1.90 33.2 0.98 6.20 19 19.3 3.24 31.3 0.61 0.85 20 20.2 1.03 30.2 0.67 0.17 21 21.3 14.64 27.2 3.50 140.00 22 21.0 7.43 23.1 34.30 0.57 23 20.8 1.00 32.3 1.57 0.47 24 20.6 2.16 34.4 1.92 0.46 25 19.9 1.74 30.4 2.73 0.42 表 4 重度极差分析

Table 4. Range analysis of weight density

kN/m3 水平 重晶石粉/

标准砂黏结剂浓度 凡硅比 石膏含量 1 17.2 19.8 19.4 19.7 2 19.1 19.7 19.1 19.6 3 19.6 19.5 19.5 19.2 4 20.3 19.0 19.4 19.1 5 20.7 18.9 19.4 19.2 极差 3.5 0.9 0.4 0.5 表 5 压缩模量极差分析

Table 5. Range analysis of compression modulus

MPa 水平 重晶石粉/

标准砂黏结剂浓度 凡硅比 石膏含量 1 3.17 5.14 3.76 1.81 2 3.66 5.25 2.46 2.21 3 3.75 2.36 3.83 3.32 4 2.62 3.00 2.42 6.01 5 5.39 2.84 6.11 5.23 极差 2.77 2.89 3.69 4.20 表 6 内摩擦角极差分析

Table 6. Range analysis of internal friction angle

(°) 水平 重晶石粉/

标准砂黏结剂浓度 凡硅比 石膏含量 1 25.45 29.90 29.94 32.54 2 33.42 31.62 29.12 32.80 3 31.40 32.24 30.54 31.40 4 33.84 31.18 31.96 28.34 5 29.48 28.66 32.04 28.52 极差 7.97 3.58 2.92 4.46 表 7 黏聚力极差分析

Table 7. Range analysis of cohesion force

kPa 水平 重晶石粉/

标准砂黏结剂浓度 凡硅比 石膏含量 1 10.34 4.68 8.14 1.00 2 1.72 10.23 3.72 4.56 3 4.15 3.51 7.16 3.83 4 0.81 6.07 5.74 6.29 5 8.80 1.93 1.67 10.74 极差 9.53 8.30 6.47 9.74 表 8 渗透系数极差分析

Table 8. Range analysis of permeability coefficient

× 10−6 cm/s 水平 重晶石粉/

标准砂黏结剂浓度 凡硅比 石膏含量 1 341 224 143 144 2 88 109 71 11 3 34 108 37 72 4 24 53 120 178 5 28 23 146 111 极差 317 201 109 167 表 9 多因素显著性分析

Table 9. Multivariate significance analysis

参数 重晶石粉/

标准砂黏结剂浓度 凡硅比 石膏含量 重度 0.875 −0.270 0.28 −0.143 压缩模量 0.165 −0.330 0.224 0.512 内摩擦角 0.266 −0.092 0.222 −0.393 黏聚力 −0.184 −0.156 −0.176 0.242 渗透系数 −0.332 −0.304 −0.109 0.030 表 10 多元线性回归分析系数表

Table 10. Coefficients of multivariate linear regression analysis

i ${\beta _{0,i}}$ ${\beta _{1,i}}$ ${\beta _{2,i}}$ ${\beta _{3,i}}$ ${\beta _{4,i}}$ 1 18.87 3.29 −16.93 0.05 −8.93 2 0.26 1.37 −45.67 0.93 70.93 3 30.94 3.38 −19.47 1.41 −83.33 4 7.54 −2.08 −64.25 −2.18 141.35 5 246.91 −275.73 −1 168.62 11.12 675.61 表 11 多元线性回归分析系数(不含异常点)

Table 11. Multiple linear regression analysis coefficients (excluding abnormal points)

i ${\beta _{0,i}}$ ${\beta _{1,i}}$ ${\beta _{2,i}}$ ${\beta _{3,i}}$ ${\beta _{4,i}}$ 1 19.66 3.05 −20.88 −0.07 −12.88 2 0.15 1.11 −43.49 1.06 66.57 3 30.94 1.92 −7.29 1.77 −71.15 4 7.29 −3.68 −50.94 −0.56 32.21 5 −133.31 −161.60 732.50 68.10 2 576.70 表 12 参考组配比

Table 12. Material proportion of reference group

参考组 重晶石粉/

标准砂黏结剂浓度/% 凡硅比 石膏含量/% 1 0.50 5.0 3∶1 3 2 0.45 5.5 3∶1 3 3 0.40 4.5 3∶1 3 表 13 参考组试验结果

Table 13. Test results of reference group

参考组 重度/

(kN•m−3)压缩模

量/MPa内摩擦

角/(°)黏聚力/

kPak20/

( ×10−6 cm•s−1)1 19.4 2.29 34.3 0.87 24.9 2 19.2 1.89 32.1 0.81 36.8 3 18.9 2.01 31.7 0.63 52.1 -

左保成,陈从新,刘才华,等. 相似材料试验研究[J]. 岩土力学,2004,25(11): 1805-1808. doi: 10.3969/j.issn.1000-7598.2004.11.027ZUO Baocheng, CHEN Congxin, LIU Caihua, et al. Research on similar material of slope simulation experiment[J]. Rock and Soil Mechanics, 2004, 25(11): 1805-1808. doi: 10.3969/j.issn.1000-7598.2004.11.027 郭信君. 超大直径越江隧道泥水盾构掘进模型试验研究[J]. 铁道标准设计,2008(10): 71-75. doi: 10.3969/j.issn.1004-2954.2008.10.022GUO Xinjun. Model test study on slurry shield tunneling of super-large diameter river tunnel[J]. Railway Standard Design, 2008(10): 71-75. doi: 10.3969/j.issn.1004-2954.2008.10.022 何川,汪洋,方勇,等. 土压平衡式盾构掘进过程的相似模型试验[J]. 土木工程学报,2012,45(2): 162-169.HE Chuan, WANG Yang, FANG Yong, et al. Similarity model test of earth-pressure-balanced shield tunneling process[J]. China Civil Engineering Journal, 2012, 45(2): 162-169. 徐前卫. 盾构施工参数的地层适应性模型试验及其理论研究[D]. 上海: 同济大学, 2006. 韩伯鲤,陈霞龄,宋一乐,等. 岩体相似材料的研究[J]. 武汉水利电力大学学报,1997,4(2): 6-9.HAN Boli, CHEN Xialing, SONG Yile. Research on similar material of rockmass[J]. Journal of Wuhan University of Hydraulic and Electric Engineering, 1997, 4(2): 6-9. 张强勇,李术才,郭小红,等. 铁晶砂胶结新型岩土相似材料的研制及其应用[J]. 岩土力学,2008,29(8): 2126-2130. doi: 10.3969/j.issn.1000-7598.2008.08.021ZHANG Qiangyong, LI Shucai, GUO Xiaohong, et al. Research and development of new typed cementatious geotechnical similar material for iron crystal sand and its application[J]. Rock and Soil Mechanics, 2008, 29(8): 2126-2130. doi: 10.3969/j.issn.1000-7598.2008.08.021 孙吉主,肖文辉. 盾构模型试验研究现状及新设想[J]. 土工基础,2011,25(6): 49-52. doi: 10.3969/j.issn.1004-3152.2011.06.015SUN Jizhu, XIAO Wenhui. State of the art of shield tunnel model tests[J]. Soil Engineering and Foundation, 2011, 25(6): 49-52. doi: 10.3969/j.issn.1004-3152.2011.06.015 王凯,李术才,张庆松,等. 流-固耦合模型试验用的新型相似材料研制及应用[J]. 岩土力学,2016,37(9): 2521-2533.WANG Kai, LI Shucai, ZHANG Qingsong, et al. Development and application of new similar materials of surrounding rock for a fluid-solid coupling model test[J]. Rock and Soil Mechanics, 2016, 37(9): 2521-2533. 李术才,周毅,李利平,等. 地下工程流-固耦合模型试验新型相似材料的研制及应用[J]. 岩石力学与工程学报,2012,31(6): 1128-1137. doi: 10.3969/j.issn.1000-6915.2012.06.006LI Shucai, ZHOU Yi, LI Liping, et al. Development and application of a new similar material for underground engineering fluid-solid coupling model test[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(6): 1128-1137. doi: 10.3969/j.issn.1000-6915.2012.06.006 李树刚,赵鹏翔,林海飞,等. 煤岩瓦斯“固-气”耦合物理模拟相似材料特性实验研究[J]. 煤炭学报,2015,40(1): 80-86.LI Shugang, ZHAO Pengxiang, LIN Haifeng, et al. Study on character of physical simulation similar material of coal-rock and gas solid-gas coupling[J]. Journal of the China Coal Society, 2015, 40(1): 80-86. 武伯弢, 朱合华, 徐前卫, 等. Ⅳ级软弱围岩相似材料的试验研究[J]. 岩土力学, 2013, 34(增刊1): 109-116.WU Botao, ZHU Hehua, XU Qianwei, et al. Experimental study of similar material for weak surrounding rock mass of class Ⅳ[J]. Rock and Soil Mechanics, 2013, 34(S1): 109-116. 史小萌,刘保国,肖杰. 水泥和石膏胶结相似材料配比的确定方法[J]. 岩土力学,2015,36(5): 1357-1362.SHI Xiaomeng, LIU Baoguo, XIAO Jie. A method for determining the ratio of similar materials with cement and plaster as bonding agents[J]. Rock and Soil Mechanics, 2015, 36(5): 1357-1362. 董金玉,杨继红,杨国香,等. 基于正交设计的模型试验相似材料的配比试验研究[J]. 煤炭学报,2012,37(1): 44-49.DONG Jinyu, YANG Jihong, YANG Guoxiang, et al. Research on similar material proportioning test of model test based on orthogonal design[J]. Journal of the China Coal Society, 2012, 37(1): 44-49. 窦远明,王建宁,田贵州,等. 基于正交试验的软弱土质相似材料配比研究[J]. 铁道科学与工程学报,2017,14(3): 480-487. doi: 10.3969/j.issn.1672-7029.2017.03.007DOU Yuanming, WANG Jianning, TIAN Guizhou, et al. Orthogonal test study on the mixture ratio of soft soil similar material[J]. Journal of Railway Science and Engineering, 2017, 14(3): 480-487. doi: 10.3969/j.issn.1672-7029.2017.03.007 曹玉茹. 虚拟变量回归在SPSS中的分析与实现[J]. 统计与决策,2018,34(10): 66-69.CAO Yuru. Analysis and implementation of virtual variable regression in SPSS[J]. Statistics and Decision, 2018, 34(10): 66-69. -

下载:

下载: