Mechanical Behavior of Intercalation Plate Joints of Concrete-Filled Steel Tubular Wind Turbine Tower

-

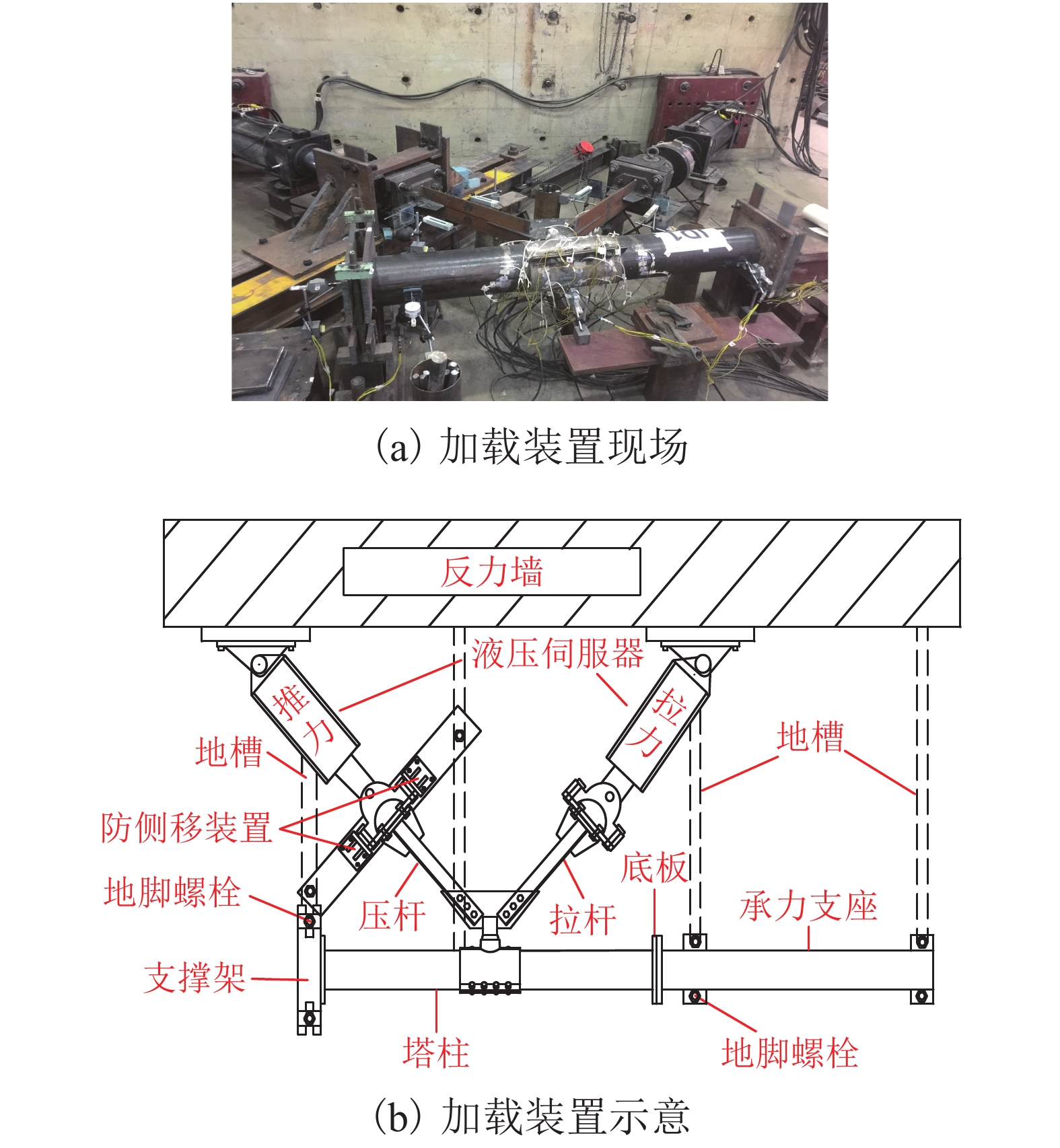

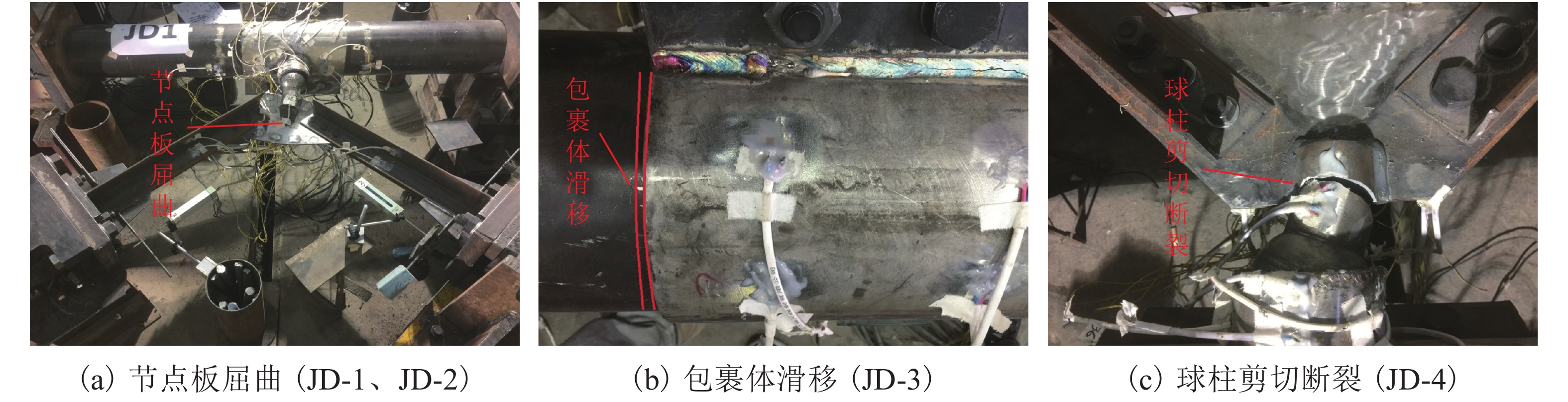

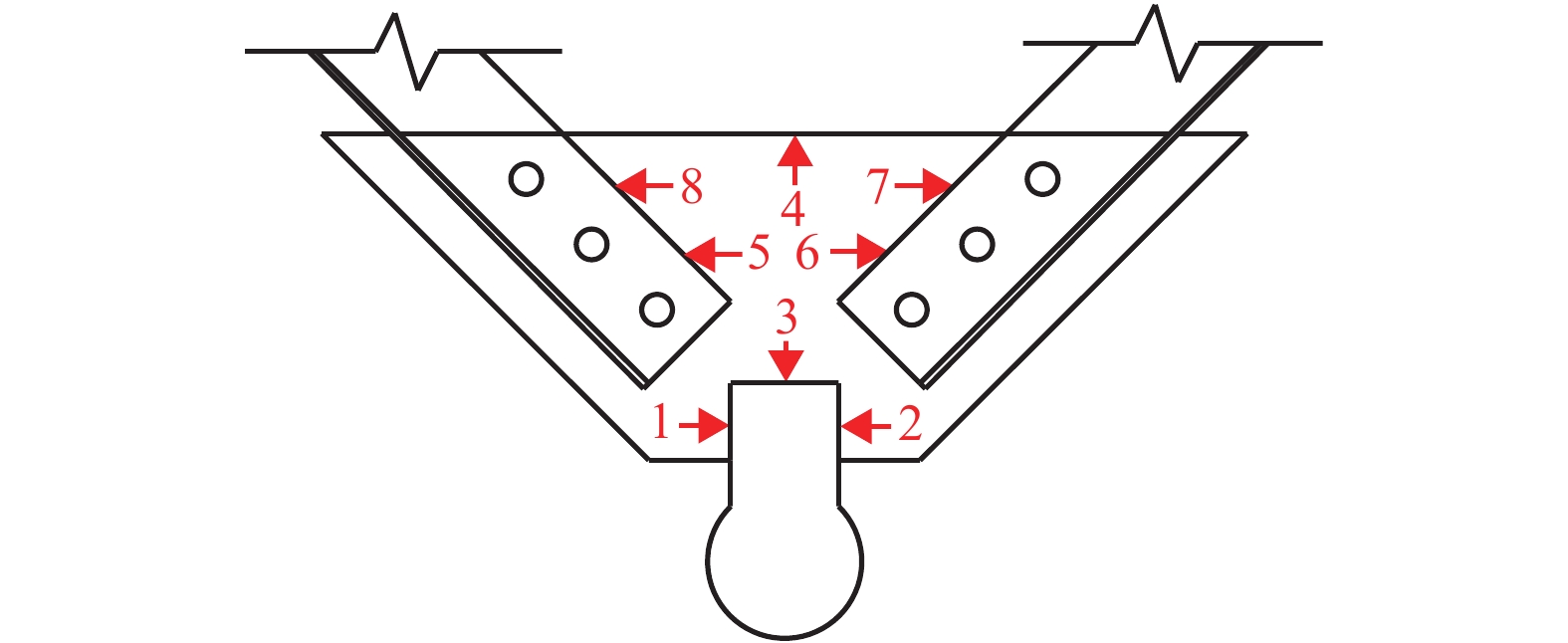

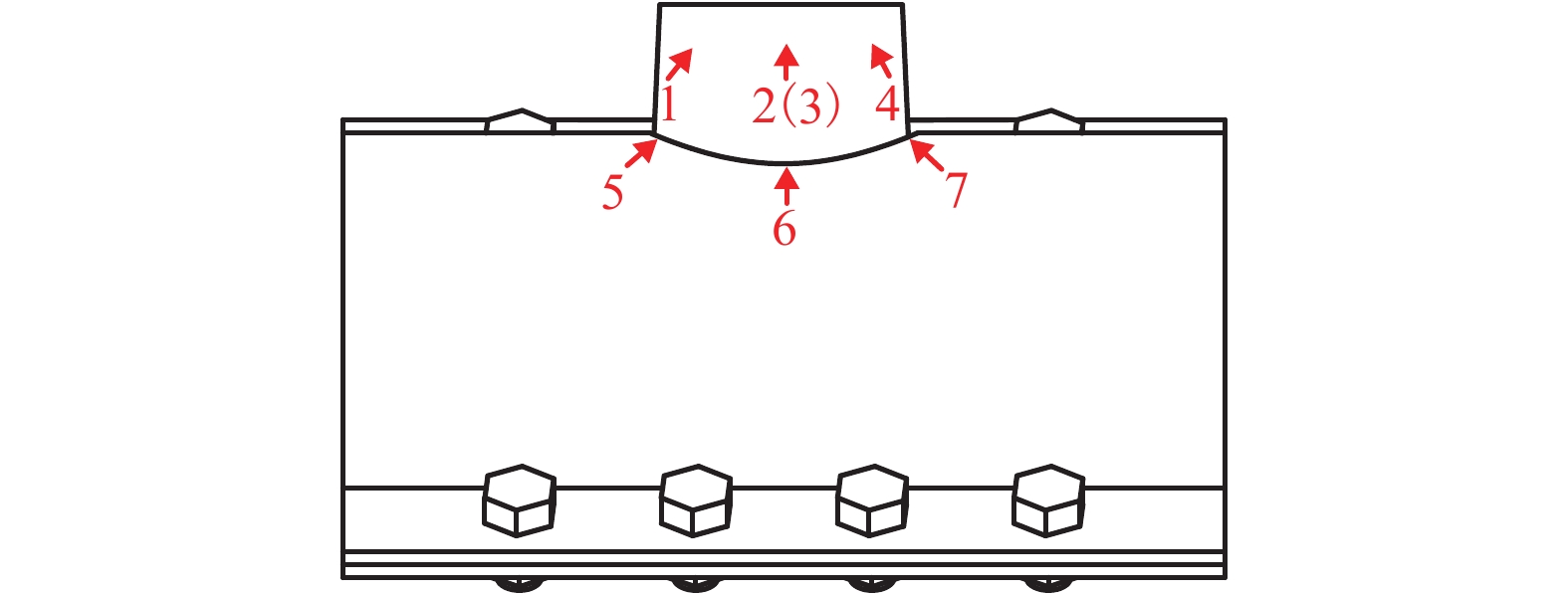

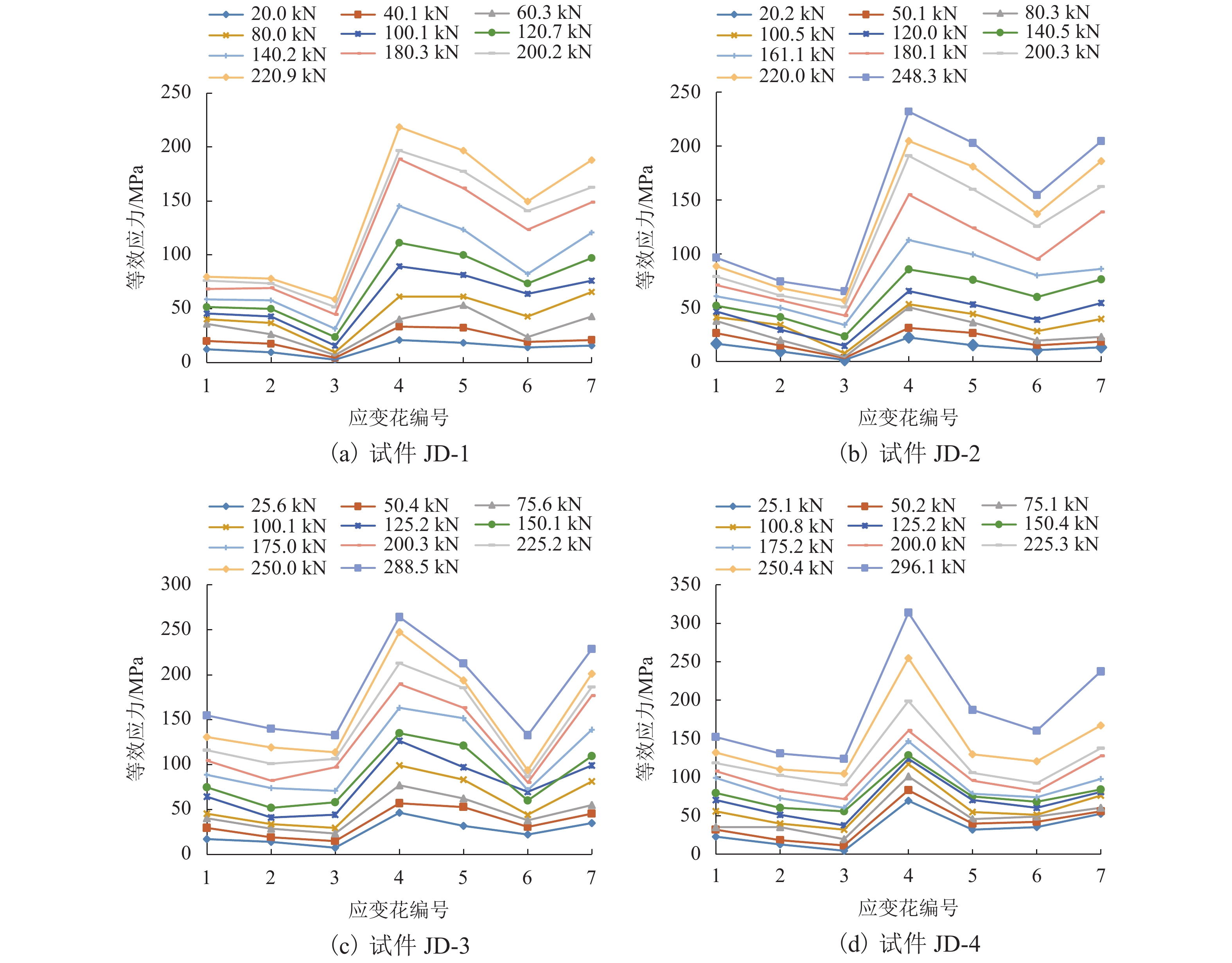

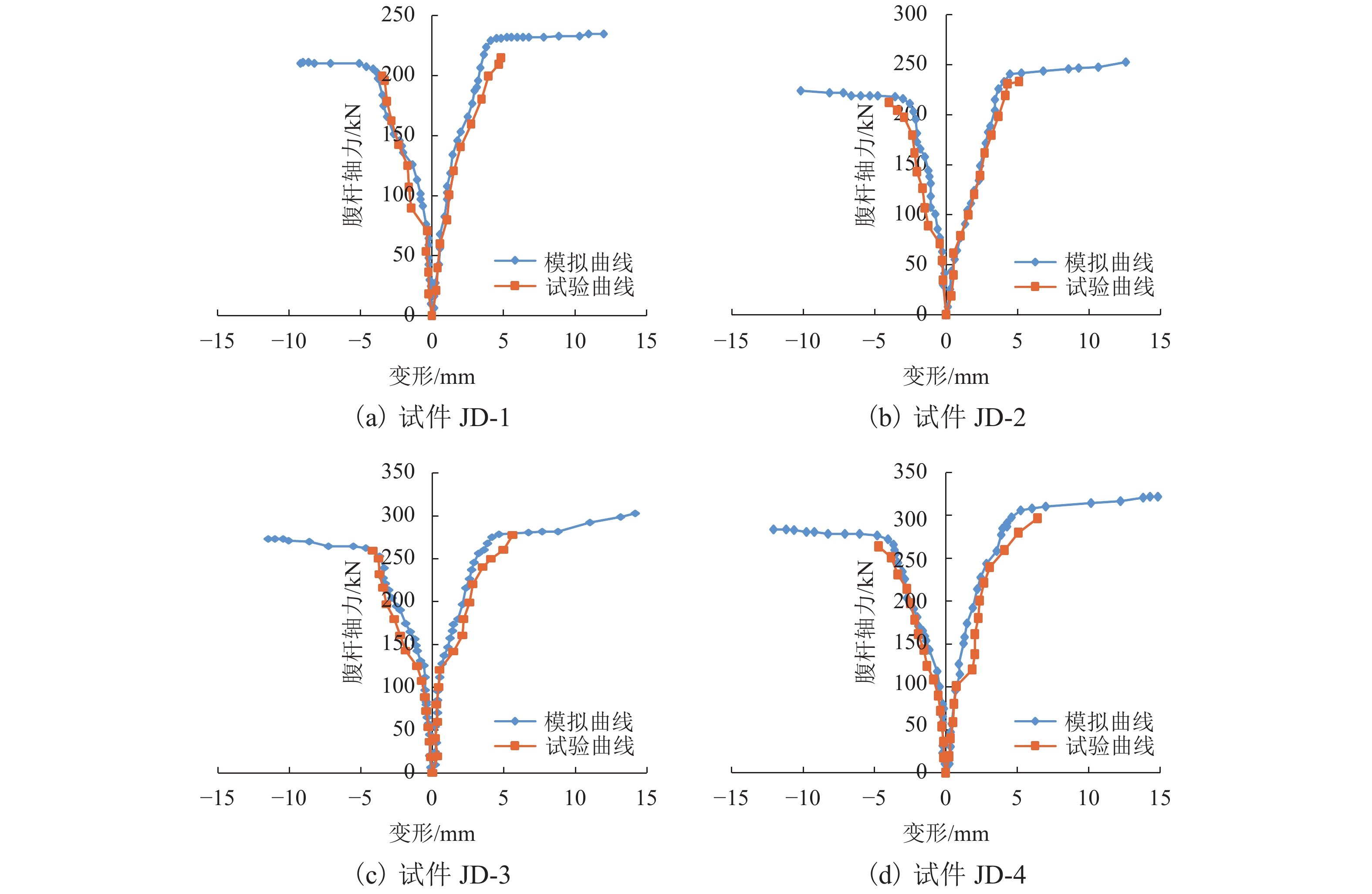

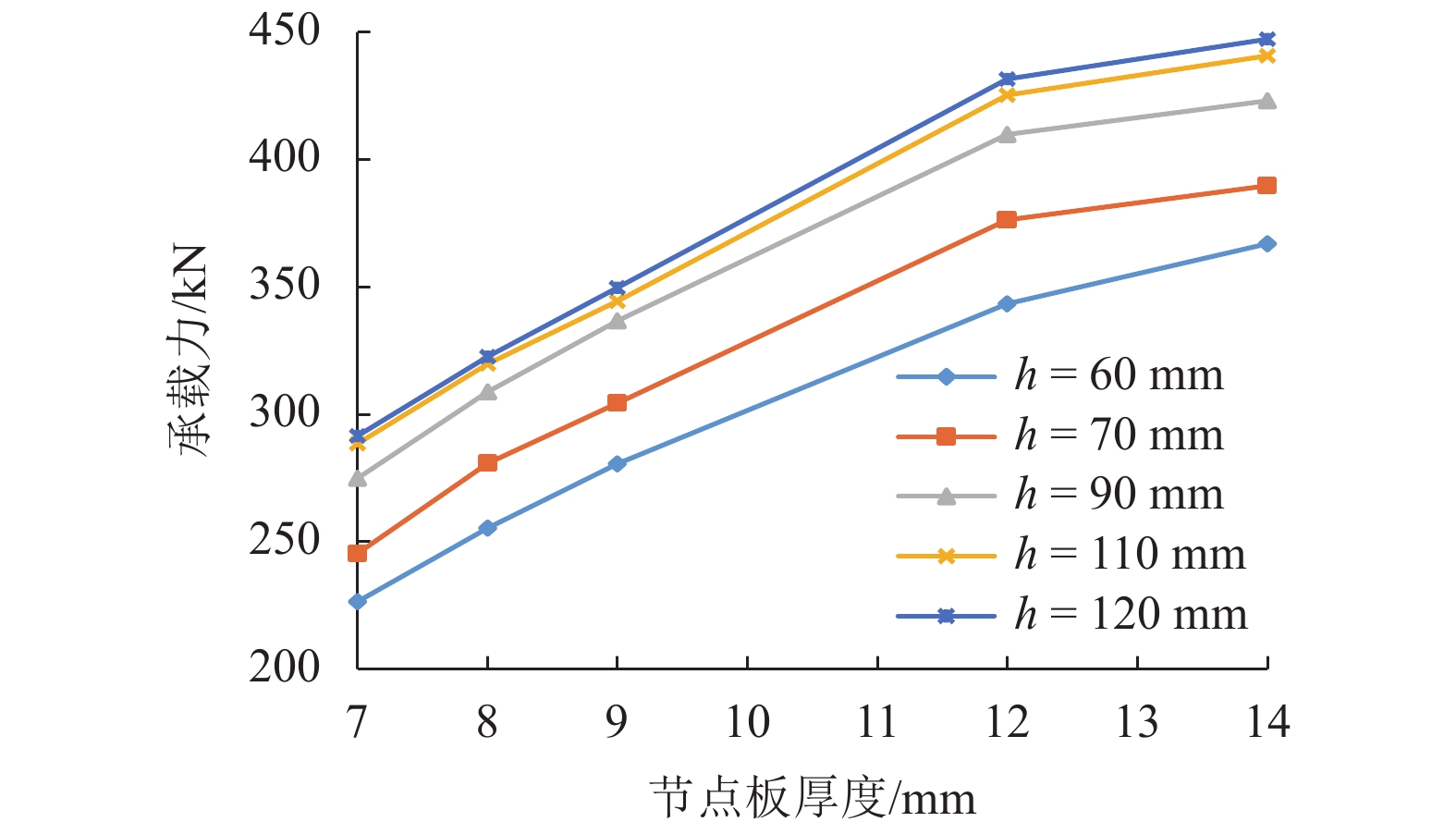

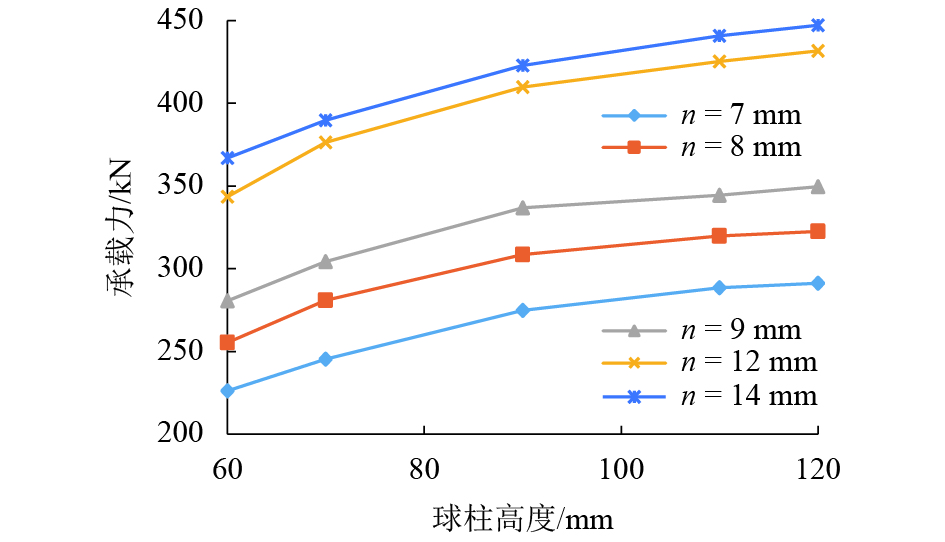

摘要: 为了掌握格构式钢管混凝土风电塔架插板式节点的受力性能,进行了4个插板式节点缩尺模型的静力试验,并在此基础上采用ABAQUS进行参数扩展的有限元非线性分析;通过节点板厚度和球柱高度的变化,对节点的节点板等效应力分布、锥台区等效应力分布等性能指标进行了分析. 研究结果表明:插板式节点的破坏形态可分为节点板屈曲破坏模式、包裹体滑移破坏模式和球柱剪切破坏模式,分别取决于节点板厚度、包裹体握裹力和球柱高度;节点板为节点的薄弱部位,随着节点板厚度和球柱高度的变化,其高应力区均集中在节点板下部与球柱相交处;假定腹杆不发生屈曲破坏,在球柱高度相同时,当节点板厚度n ≤ 12 mm时,节点承载力随着n的增大而增加,当n > 12 mm时,随着n的增大,节点承载力增长幅度明显放缓;在节点板厚度相同时,当球柱高度h ≤ 90 mm时,节点承载力随着h的增大而增加,当h > 90 mm时,随着h的增大,节点承载力增长幅度明显放缓;此类节点在实际工程设计使用时节点板厚度n ≤ 12 mm较为合理、球柱高度h ≤ 90 mm较为合理.Abstract: In order to understand mechanical behavior of intercalation plate joints of concrete-filled steel tubular wind turbine tower, static test of four split-type nodes was carried out, and finite element nonlinear analysis of parameters expansion was carried out by ABAQUS. Effect force distribution of the gusset plate and equivalent stress distribution in cone were analyzed by change the thickness of the gusset plate and the height of the spherical column. The results show that failure modes include buckling failure mode, inclusion slip failure mode, and spherical column shear failure mode, which depend on the thickness of the gusset plate, the holding force of the inclusion, and the height of the spherical column. The gusset plate is the weak part of the node, which varied with the thickness of the gusset plate and the height of the spherical column, the high stress zone concentrate at the intersection between lower part of the gusset plate and the spherical column. If brace buckling failure do not occur, the spherical column at the same height, the thickness of the gusset plate is no more than 12 mm (n ≤ 12 mm), the bearing capacity of the node increases with the gusset plate thickness, when the gusset plate thickness is larger than 12 mm (n > 12 mm), with the increase of the gusset plate thickness, the increase of the node bearing capacity slows down significantly. when the gusset plate thickness is the same, the sphere cylinder height is no more than 90 mm (h ≤ 90 mm), the bearing capacity of the node obviously increases with the increase of the ball column height, when the sphere cylinder height is larger than 90 mm (h > 90 mm), the bearing capacity of the node slows down with the increase of the sphere cylinder height obviously. It suggests that the gusset plate thickness is no more than 12 mm (n ≤ 12 mm), the ball column height is no more than 90 mm (h ≤ 90 mm) is more reasonable for such nodes in actual engineering design.

-

Key words:

- concrete-filled steel tube /

- joint /

- failure mode /

- bearing capacity /

- experimental study

-

表 1 试件几何参数

Table 1. Geometrical parameters of specimens

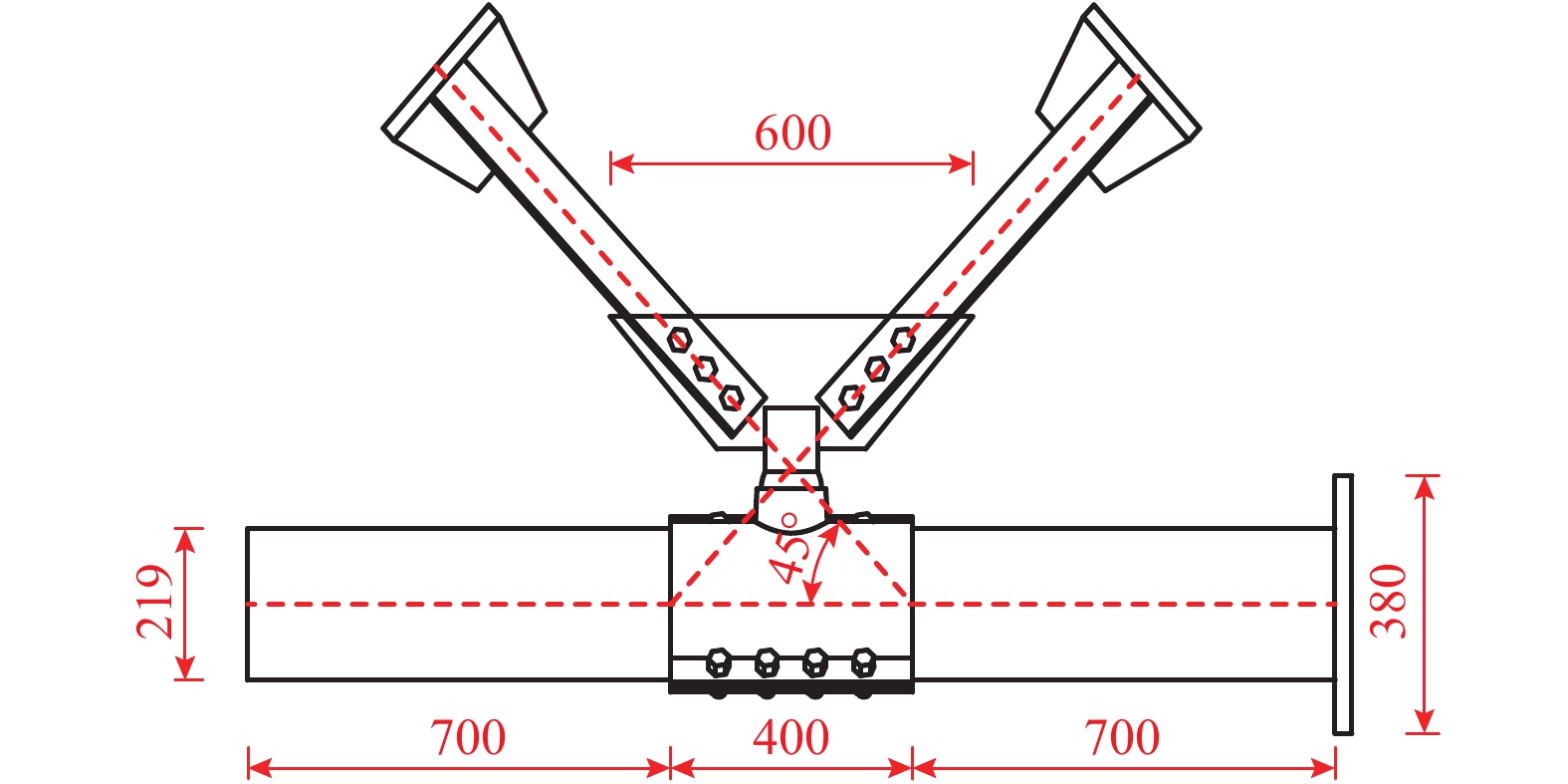

mm 试件编号 塔柱截面 包裹体截面 腹杆截面(双支角钢) 球柱 节点板截面 外径 壁厚 长度 外径 壁厚 长度 宽 厚 长度 直径 高 长 斜边 厚 JD-1 219 6 1 800 235 8 400 80 6 700 70 80 600 300 6 JD-2 219 6 1 800 235 8 400 80 6 700 70 100 600 300 6 JD-3 219 6 1 800 235 8 400 80 6 700 70 80 600 300 10 JD-4 219 6 1 800 235 8 400 80 6 700 70 100 600 300 10 表 2 钢材力学性能指标

Table 2. Mechanical properties of steel

构件 屈服强度

fy /MPa极限强度

fu /MPa弹性模量

Es/GPa腹杆 258 462 192 球柱 325 474 225 节点板: n = 6 mm 294 478 196 节点板: n = 10 mm 272 458 202 表 3 试件极限承载力

Table 3. Ultimate bearing capacity of specimen

试件编号 试验承载力/kN 模拟承载力/kN 误差/% JD-1 218 235 7.8 JD-2 228 249 9.2 JD-3 282 309 9.2 JD-4 294 321 8.9 表 4 参数扩展分析

Table 4. Parameter expansion analysis

节点编号 n/mm h/mm 极限承载力/kN A-1 7 60 226.4 A-2 7 70 245.4 A-3 7 90 274.9 A-4 7 110 288.5 A-5 7 120 291.4 B-1 8 60 255.3 B-2 8 70 280.8 B-3 8 90 308.7 B-4 8 110 319.7 B-5 8 120 322.6 C-1 9 60 280.5 C-2 9 70 304.2 C-3 9 90 336.7 C-4 9 110 344.3 C-5 9 120 349.7 D-1 12 60 343.4 D-2 12 70 376.3 D-3 12 90 409.7 D-4 12 110 425.3 D-5 12 120 431.6 E-1 14 60 366.8 E-2 14 70 389.6 E-3 14 90 422.9 E-4 14 110 440.7 E-5 14 120 447.1 -

王长路,王伟功,张立勇. 中国风电产业发展分析[J]. 重庆大学学报(自然科学版),2015,38(1): 148-154.WANG Changlu, WANG Weigong, ZHANG Liyong. The analysis of China wind power industry[J]. Journal of Chongqing University (Natural Science Edition), 2015, 38(1): 148-154. 刘晓峰,俞黎萍. 风力机混凝土塔架最小成本优化设计[J]. 太阳能学报,2017,38(3): 691-698.LIU Xiaofeng, YU Liping. Minimum cost design of the concrete wind turbine tower[J]. Acta Energiae Solaris Sinica, 2017, 38(3): 691-698. 刘香,王敏,李建. 格构式钢管混凝土风力发电塔架的受力分析[J]. 武汉理工大学学报,2010,32(9): 175-177,265. doi: 10.3963/j.issn.1671-4431.2010.09.041LIU Xiang, WANG Min, LI Jian. The force analysis of concrete-filled steel tube of lattice wind tower turbine[J]. Journal of Wuhan University of Technology, 2010, 32(9): 175-177,265. doi: 10.3963/j.issn.1671-4431.2010.09.041 李斌,文昊天,高春彦. 钢管混凝土格构式新型风力发电机塔架风振响应[J]. 噪声与振动控制,2018,38(4): 144-148. doi: 10.3969/j.issn.1006-1355.2018.04.028LI Bin, WEN Haotian, GAO Chunyan. Wind vibration response of lattice type wind turbine towers made of concrete-filled steel-tubes[J]. Noise and Vibration Control, 2018, 38(4): 144-148. doi: 10.3969/j.issn.1006-1355.2018.04.028 单蕾. 风力机塔架结构选型与受力性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2009. 李斌, 杨晓云, 高春彦. 风力发电机锥台型塔筒和格构式塔架的抗震性能试验研究与对比分析[J]. 建筑结构学报, 2013, 34(增刊1): 161-166.LI Bin, YANG Xiaoyun, GAO Chunyan. Experimental research and comparative analysis on seismic performance of wind turbine frustum tower drum and latticed tower[J]. Journal of Building Structures, 2013, 34(S1): 161-166. 高春彦,李斌,史治宇. 钢管混凝土风电塔架节点非线性有限元分析[J]. 建筑结构学报,2013,34(1): 140-146.GAO Chunyan, LI Bin, SHI Zhiyu. Nonlinear finiteelement analysis of concrete-filled steel tubular wind turbine tower joints[J]. Journal of Building Structures, 2013, 34(1): 140-146. 闻洋,孟春才,刘书坛. 格构式钢管混凝土风电塔架双拼节点性能研究[J]. 西南交通大学学报,2016,51(6): 1113-1120. doi: 10.3969/j.issn.0258-2724.2016.06.010WEN Yang, MENG Chuncai, LIU Shutan. Performance of double-limb splice joints of latticed concrete-filled steel tubular wind turbine tower[J]. Journal of Southwest Jiaotong University, 2016, 51(6): 1113-1120. doi: 10.3969/j.issn.0258-2724.2016.06.010 高春彦,史治宇,牛丽华. 圆钢管混凝土K型焊接管板节点试验研究和有限元分析[J]. 中南大学学报(自然科学版),2017,48(3): 769-778.GAO Chunyan, SHI Zhiyu, NIU Lihua. Experimental study and finite element analysis of concrete-filled circular steel tubular K-type welded tube-gusset joints[J]. Journal of Central South University (Science and Technology), 2017, 48(3): 769-778. 赵必大,刘成清,余丛迪,等. 圆钢管-横向板相贯连接节点轴向刚度研究[J]. 西南交通大学学报,2017,52(5): 977-984. doi: 10.3969/j.issn.0258-2724.2017.05.019ZHAO Bida, LIU Chengqing, YU Congdi, et al. Axial rigidity of unstiffened transverse plate-to-circular hollow section (CHS) joints[J]. Journal of Southwest Jiaotong University, 2017, 52(5): 977-984. doi: 10.3969/j.issn.0258-2724.2017.05.019 赵必大,刘成清,章圣冶,等. Y型圆钢管相贯节点轴向刚度计算模型[J]. 西南交通大学学报,2015,50(5): 872-878. doi: 10.3969/j.issn.0258-2724.2015.05.016ZHAO Bida, LIU Chengqing, ZHANG Shengye, et al. Calculation model for axial rigidity of CHS Y-Type joints[J]. Journal of Southwest Jiaotong University, 2015, 50(5): 872-878. doi: 10.3969/j.issn.0258-2724.2015.05.016 闻洋,屈琳琳,管丽佩. 格构式钢管混凝土风电塔架KT型节点受力性能试验研究[J]. 建筑结构学报,2015,36(9): 110-116.WEN Yang, QU Linlin, GUAN Lipei. Experimental study on mechanical behavior of KT-type joints of latticed concrete-filled steel tubular wind turbine tower[J]. Journal of Building Structures, 2015, 36(9): 110-116. 宋谦益. 圆钢管混凝土-钢管K形节点的力学性能研究[D]. 北京: 清华大学, 2010. 陈娟, 孙伟健, 聂建国. 钢管混凝土KK形相贯节点空间效应研究[J]. 建筑结构学报, 2017, 38(增刊1): 402-408.CHEN Juan, SUN Weijian, NIE Jianguo. Study on spatial effect of concretefilled steel tubular KKjoints[J]. Journal of Building Structures, 2017, 38(S1): 402-408. 陈娟,聂建国,周成野. 钢管混凝土T形相贯节点应力集中系数研究[J]. 建筑结构学报,2018,39(3): 149-157.CHEN Juan, NIE Jianguo, ZHOU Chengye. Study on stress concentration factor of concrete-filled steel tubular T-joints[J]. Journal of Building Structures, 2018, 39(3): 149-157. 高春彦. 新型风力发电高塔节点的失效机理和极限承载力研究[D]. 南京: 南京航空航天大学, 2018. 赵必大, 李克, 刘成清, 等. 支主管夹角对X形圆钢管节点轴向性能的影响[J/OL]. 西南交通大学学报, [2019-12-22]. http://kns.cnki.net/kcms/detail/51.1277.U.20190903.1538.004.html.ZHAO Bida, LIU Ke, LIU Chengqing, et al. Effect of brace-to-chord angle on the performance of unstiffened CHS X-joints under brace axial force[[J/OL]. Journal of Southwest Jiaotong University, [2019-12-22]. http://kns.cnki.net/kcms/detail/51.1277.U.20190903.1538.004.html. -

下载:

下载: