Effect of Wetting-Drying Cycles on Mass and Deformation of Cement and Emulsified Asphalt Mortar

-

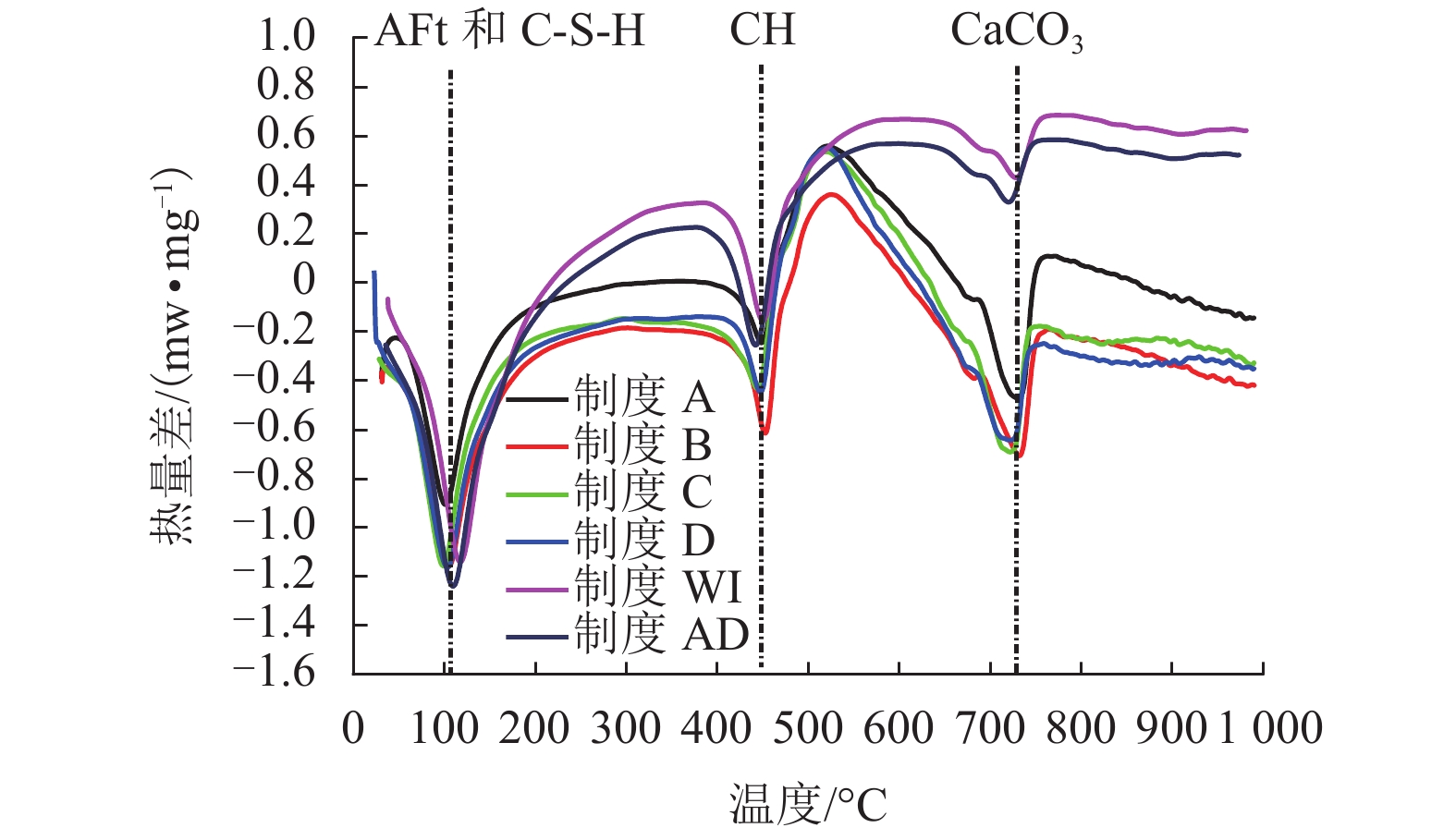

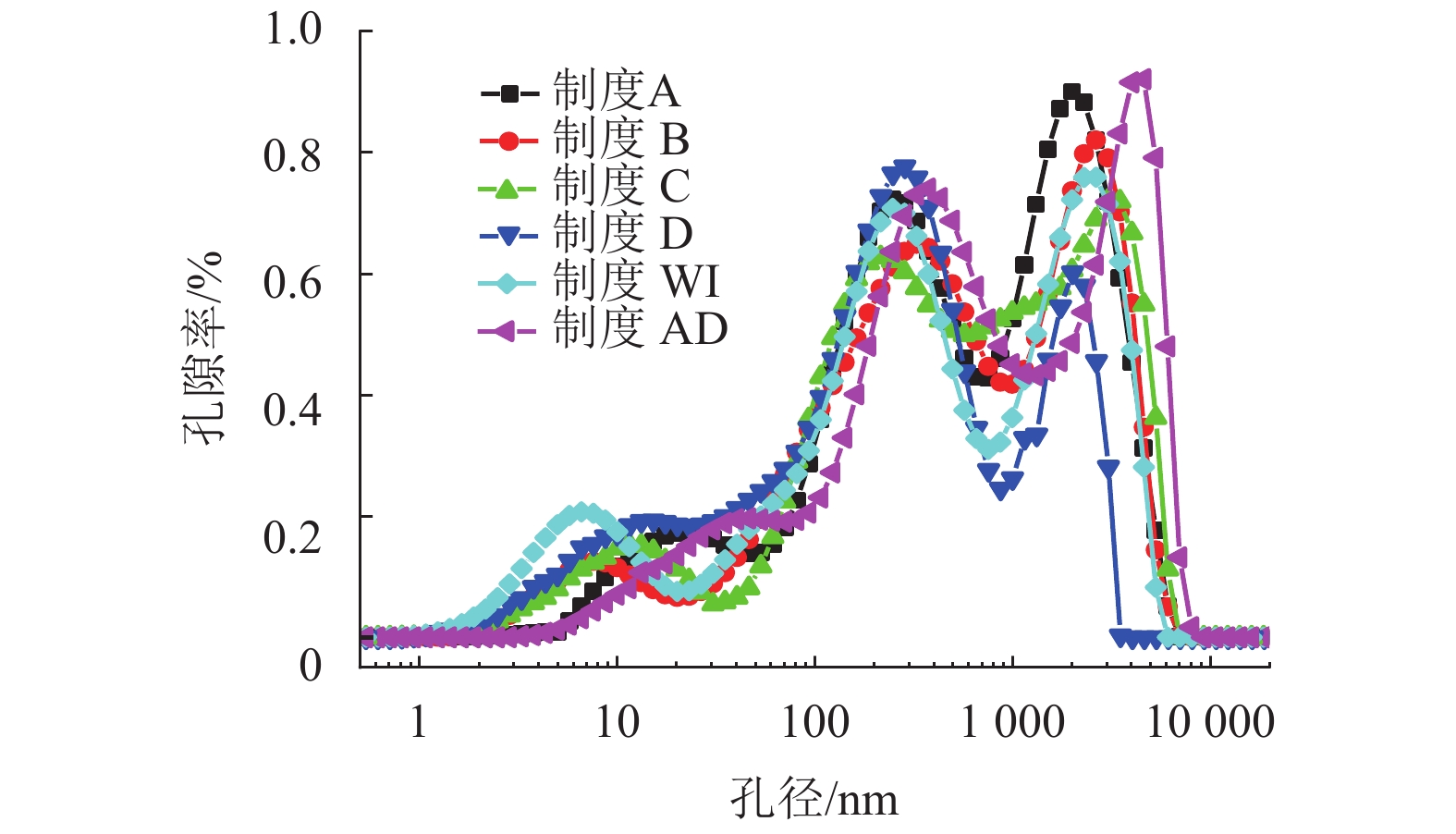

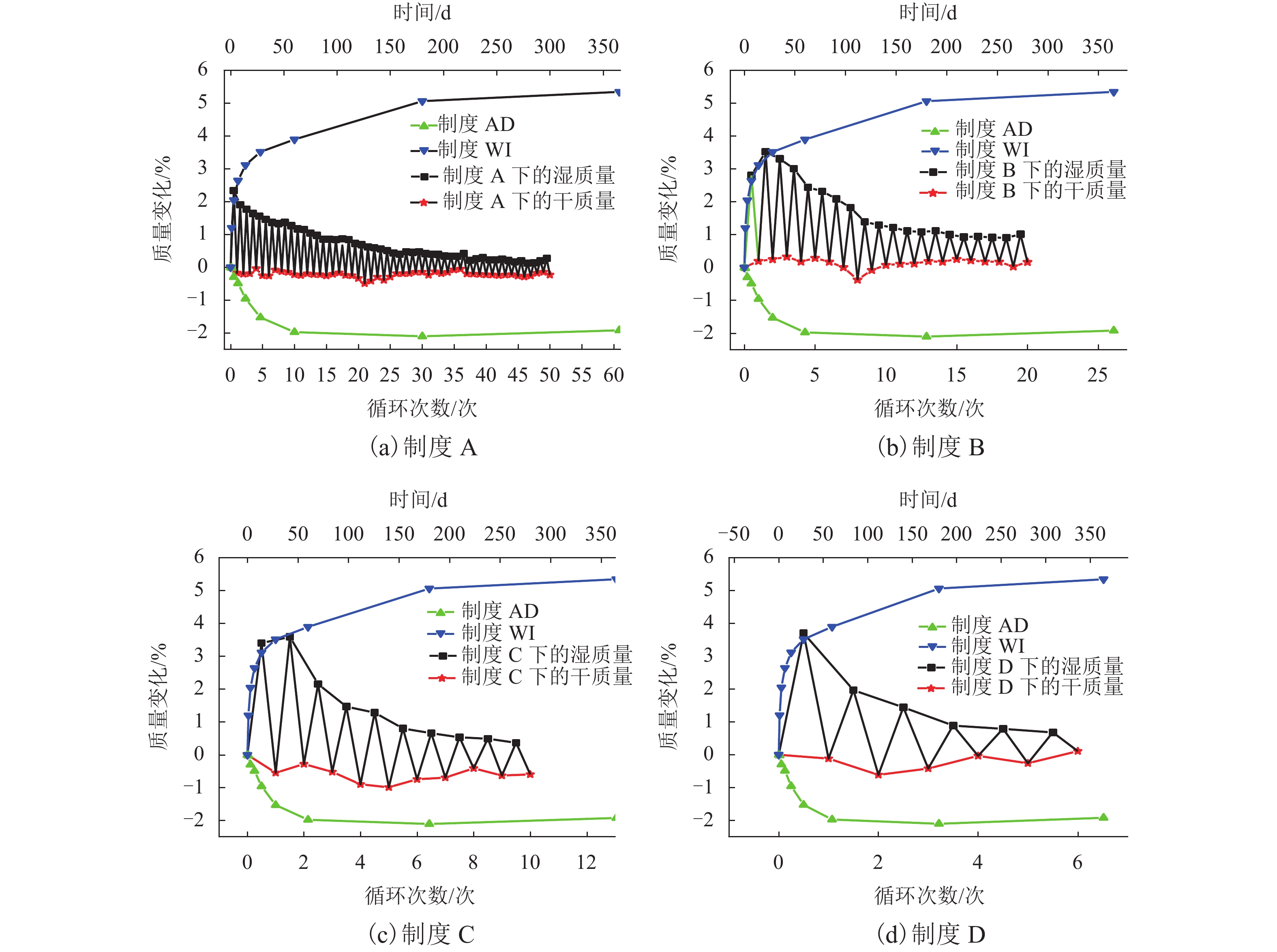

摘要: CA砂浆(cement and emulsified asphalt mortar)服役环境湿度因气候、天气因素的影响产生显著变化,会引起其质量和体积的变化,进而对轨道结构的几何尺寸产生影响. 为了解服役环境中湿度变化对CA砂浆质量、尺寸的影响,设计了6种干湿循环制度,测试了不同干湿循环制度下CA砂浆质量、长度变化;并采用低场核磁共振(NMR)及综合热分析(TG-DSC)对其孔结构和物相组成进行了分析,以揭示其变化机理. 研究结果表明:随着循环次数的增加,CA砂浆湿质量迅速增加并达到最大值,随后下降,并在140 d左右趋于稳定,干质量的变化很小;而其长度随循环次数的增加先减小后增加. 干湿循环中,CA砂浆质量与长度的变化均小于持续干燥、水浸泡条件下的变化. 在短周期干湿循环中,在约140 d前,CA砂浆湿质量与变形呈二次函数关系,而在约140 d后,质量与变形呈线性关系;在长周期中,二者相关性不强. NMR与DSC的分析结果表明,CA砂浆质量与长度变化是干湿循环过程中毛细孔水分的迁移、水泥水化、碳化以及孔结构变化等因素共同作用的结果.Abstract: The varying humidity of service environment due to the change of weather and climate has a significant influence on the mass and volume of CA (cement and emulsified asphalt) mortar, which further influences the geometrical size of track structure. To understand the effect of the variation of ambient humidity on the mass and size of CA mortar in service, 6 kinds of wetting-drying cycles were designed in which the mass and length changes of CA mortar were measured. To investigate the mechanism of length change, pore structure and phase composition were examined by low field nuclear magnetic resonance (NMR) and thermogravimetric analysis-differential scanning calorimetry (TGA-DSC). The results show that with the increase of cycle numbers, the wet mass of CA mortar firstly increases rapidly and reaches the maximum value, then starts to decline, and stabilizes at about 140 days, and the dry mass of CA mortar changes a little; however, the length change exhibits an initial decrease and then increase trend. In wetting-drying cycles, the mass and length changes of CA mortar are less than that under continuous air-drying or water immersion condition. During the wetting-drying cycles with short periods, an evident quadratic function relationship between mass change and deformation of CA mortar can be found before around 140 days, after which the correlation converts into a linear relationship; however, the correlation is not significant during the wetting-drying cycles with long periods. The results obtained from NMR and TG-DSC indicate that the migration of capillary water, hydration of cement, carbonization, and the change of pore structure are the joint reasons accounting for the mass and length changes of CA mortar.

-

Key words:

- CA mortar /

- wetting-drying cycle /

- mass change /

- deformation /

- pore structure

-

表 1 CA砂浆配比与新拌砂浆性能

Table 1. Mix proportion and properties of fresh CA mortar

乳化沥青/g 干粉料/g 水灰比 沥灰比 流动性/s 含气量/% 表观密度(g•cm–3) 500 1 100 0.79 0.83 21 9.00 1.61 表 2 干湿循环周期设计

Table 2. Design of wetting-drying cycles

项目 制度 A B C D WI AD 干燥时间/d ((20 ℃,65% RH)恒温恒湿箱 ) 3 7 14 28 水浸泡时间/d (20 ℃,自来水) 3 7 14 28 长期 长期 循环周期/d 6 14 28 56 表 3 4种制度下CA砂浆中结合水及碳酸钙含量

Table 3. Content of bound water and calcite in CA mortar exposed to four exposure conditions

制度 化学结合水/% 碳酸钙/% AD 14.0 21.1 A 16.2 26.6 B 17.5 24.3 C 17.8 24.9 D 18.9 23.4 WI 21.2 15.7 表 4 不同干湿循环制度下k及D值

Table 4. Slope of fitting line (k) & fractal dimension of pore volume (D) in different wetting-drying cycles

名称 制度AD 制度A 制度B 制度C 制度D 制度WI k 0.56 0.55 0.54 0.54 0.46 0.42 D 2.44 2.45 2.46 2.46 2.54 2.58 -

邓德华. 土木工程材料[M]. 北京: 中国铁道出版社, 2017: 30-218 HOBBS D W, MATTHEWS J D, MARSH B K. Minimum requirements of durable concrete: carbonation and chloride-induced corrosion, freeze-thaw attack and chemical attack[M]. Crowthorne: British Cement Association, 1998: 1-3 高原,张君,孙伟. 干湿循环下混凝土湿度与变形的测量[J]. 清华大学学报(自然科学版),2012,52(2): 144-149.GAO Yuan, ZHANG Jun, SUN Wei. Concrete deformation and interior humidity during dry-wet cycles[J]. Journal of Tsinghua University (Science and Technology), 2012, 52(2): 144-149. 庞超明,徐剑,王进. 混凝土干湿过程及循环制度的研 究[J]. 建筑材料学报,2013,16(2): 315-320. doi: 10.3969/j.issn.1007-9629.2013.02.024PANG Chaoming, XU Jian, WANG Jin, et al. Investigation of the process and regime of drying and wetting of concrete[J]. Journal of Building Materials, 2013, 16(2): 315-320. doi: 10.3969/j.issn.1007-9629.2013.02.024 马昆林,谢友均,龙广成,等. 水泥基材料在硫酸盐结晶侵蚀下的劣化行为[J]. 中南大学学报(自然科学版),2010,1(1): 303-309.MA Kunlin, XIE Youjun, LONG Guangcheng, et al. Deterioration behaviors of sulfate crystallization attack on cement-based material[J]. Journal of Central South University (Science and Technology), 2010, 1(1): 303-309. 邓德华,刘赞群,Geert DE SCHUTTER,等. 关于" 混凝土硫酸盐结晶破坏”理论的研究进展[J]. 硅酸盐学报,2012,40(2): 175-185.DENG Dehua, LIU Zanqun, Geert DE SCHUTTER, et al. Research progress on theory of ‘sulfate salt weathering on concrete’[J]. Journal of the Chinese Ceramic Society, 2012, 40(2): 175-185. 谢友均,曾晓辉,邓德华,等. 铁路无砟轨道水泥乳化沥青砂浆力学性能[J]. 建筑材料学报,2010,13(4): 483-486. doi: 10.3969/j.issn.1007-9629.2010.04.013XIE Youjun, ZENG Xiaohui, DENG Dehua, et al. Mechanical characteristics of China railway track system (CRTS) Ⅰ type slab tracks CA mortar under different strain rates[J]. Journal of Building Materials, 2010, 13(4): 483-486. doi: 10.3969/j.issn.1007-9629.2010.04.013 颜华,胡华锋,曾晓辉,等. 静水作用下板式无砟轨道CA砂浆力学性能变化[J]. 高速铁路技术,2014,5(4): 7-10. doi: 10.3969/j.issn.1674-8247.2014.04.002YAN Hua, HU Huafeng, ZENG Xiaohui, et al. Studies on mechanical changes of CA mortar for slab track under hydrostatic effect[J]. High Speed Railway Technology, 2014, 5(4): 7-10. doi: 10.3969/j.issn.1674-8247.2014.04.002 徐浩,王平,孙宏友,等. 不同浸水历时水泥乳化沥青砂浆动态受压试验[J]. 建筑材料学报,2015,18(5): 861-866. doi: 10.3969/j.issn.1007-9629.2015.05.026XU Hao, WANG ping, SUN Hongyou, et al. Experiment of dynamic compressive behaviors of cement asphalt mortar under different water immersion duration[J]. Journal of Building Materials, 2015, 18(5): 861-866. doi: 10.3969/j.issn.1007-9629.2015.05.026 李悦,孙宏友,曾晓辉,等. 不同浸水历时及温度对CA砂浆力学性能的影响研究[J]. 铁道标准设计,2015,59(2): 40-42.LI Yue, SUN Hongyou, ZENG Xiaohui, et al. Study of the effects of water immersion and temperature on mechanical properties of CA mortar[J]. Railway Standard Design, 2015, 59(2): 40-42. 周锡玲,郑克仁,谢友均,等. 湿含量对水泥乳化沥青砂浆热变形的影响[J]. 建筑材料学报,2013,16(10): 817-821.ZHOU Xiling, ZHENG Keren, XIE Youjun, et al. Effect of inner moisture on thermal deformation of cement and emulsified-asphalt mortar[J]. Journal of Building Materials, 2013, 16(10): 817-821. ZHOU Xiling, XIE Youjun, ZHENG Keren, et al. Thermal deformationn of cement-asphalt mortar under repetitive heating and cooling[C]//Advanced Materials Research. Switzerland: Tran Tech Publication, 2013: 304-308 铁道部. 客运专线铁路CRTS Ⅰ型板式无砟轨道混凝土轨道板暂行技术条件: 科技基[2008] 74号[S]. 北京: 中国铁道出版社, 2008 史才军, 元强. 水泥基材料测试分析方法[M]. 北京: 中国建筑工业出版社, 2018: 195 TAYLOR H F W. Cement chemistry[M]. USA: Thomas Telford, 1997: 101 邓德华,田青,刘赞群,等. 高速铁路用水泥乳化沥青浆体的物理结构[J]. 中国科学:技术科学,2014,44(7): 661-671.DENG Dehua, TIAN Qin, LIU Zanqun, et al. Physical structure of hardened cement asphalt paste for the slab track of high-speed railway[J]. Science China:Technol Science, 2014, 44(7): 661-671. MONTEIRO P J, MEHTA P K. Concrete: microstructure, properties and materials[M]. New York: McGraw-Hill Professional, 2013: 35-40 金珊珊,张金喜,陈春珍,等. 水泥砂浆孔结构分形特征的研究[J]. 建筑材料学报,2011,14(1): 92-97. doi: 10.3969/j.issn.1007-9629.2011.01.019JIN Shanshan, ZHANG Jinxi, CHEN Chunzhen, et al. Study of pore fractal characteristic of cement mortar[J]. Journal of Building Materials, 2011, 14(1): 92-97. doi: 10.3969/j.issn.1007-9629.2011.01.019 郭伟,秦鸿根,陈惠苏,等. 分形理论及其在混凝土材料研究中的应用[J]. 硅酸盐学报,2010,38(7): 1362-1368.GUO Wei, QIN Honggen, CHEN Huisu, et al. Fractal theory and its applications in the study of concrete materials[J]. Journal of the Chinese Ceramic Society, 2010, 38(7): 1362-1368. PANDEY S P, SHARMA R L. The influence of mineral additives on strength and porosity of OPC mortar[J]. Cem. Concr. Res., 2000, 30(1): 19-23. doi: 10.1016/S0008-8846(99)00180-5 傅强,郑克仁,谢友均,等. 水泥乳化沥青砂浆孔体积的分形特征[J]. 硅酸盐学报,2013,41(11): 1551-1557.FU Qiang, ZHENG Keren, XIE Youjun, et al. Fractal characteristic of pore volume of cement and asphalt mortar[J]. Journal of the Chinese Ceramic Society, 2013, 41(11): 1551-1557. -

下载:

下载: