Temperature Rise Characteristic Analysis and Liquid Cooling Structure Design of Lithium Battery

-

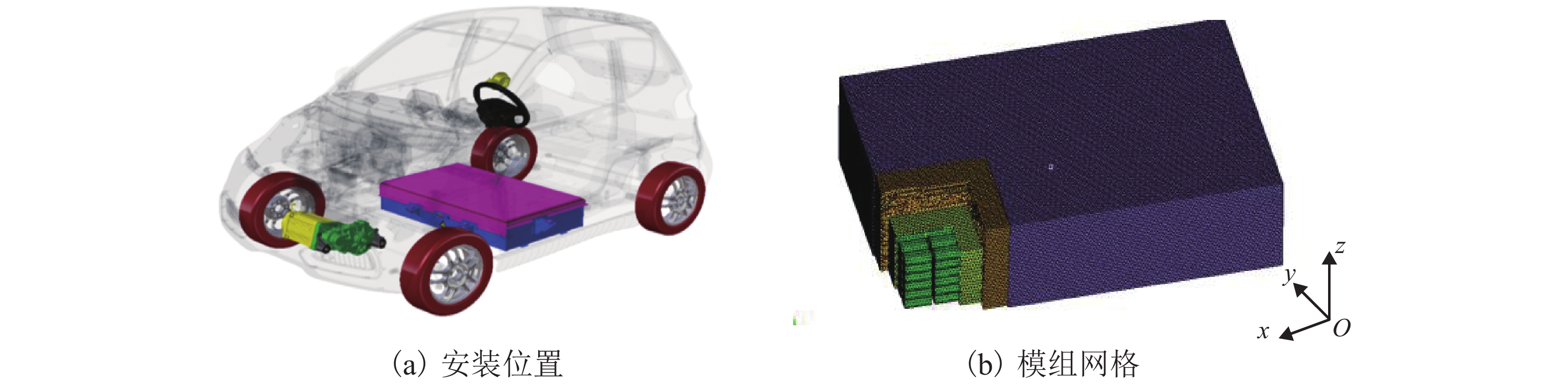

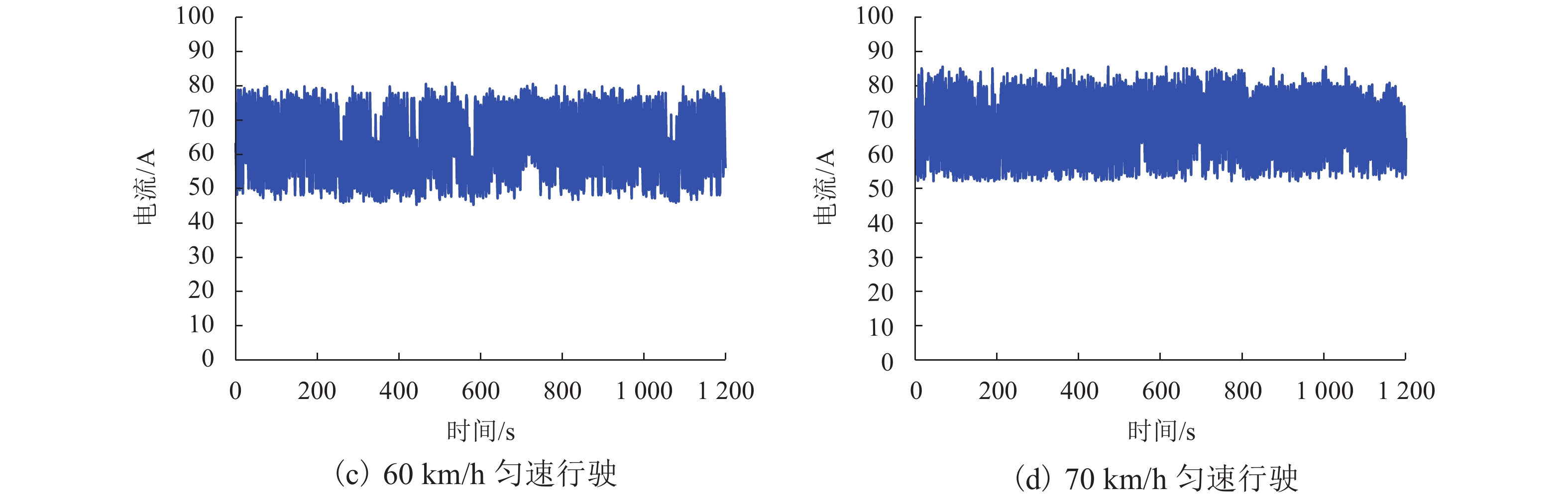

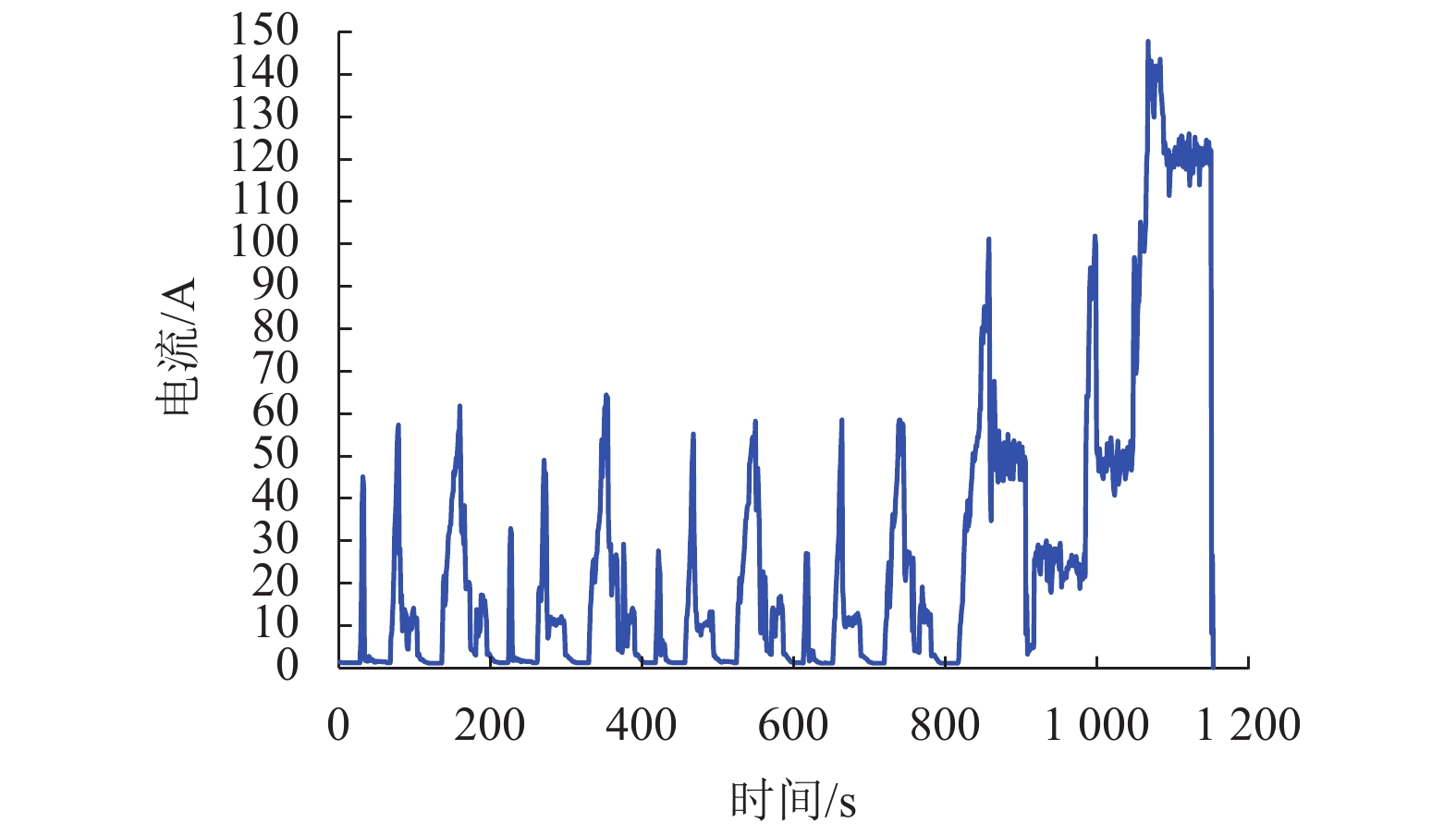

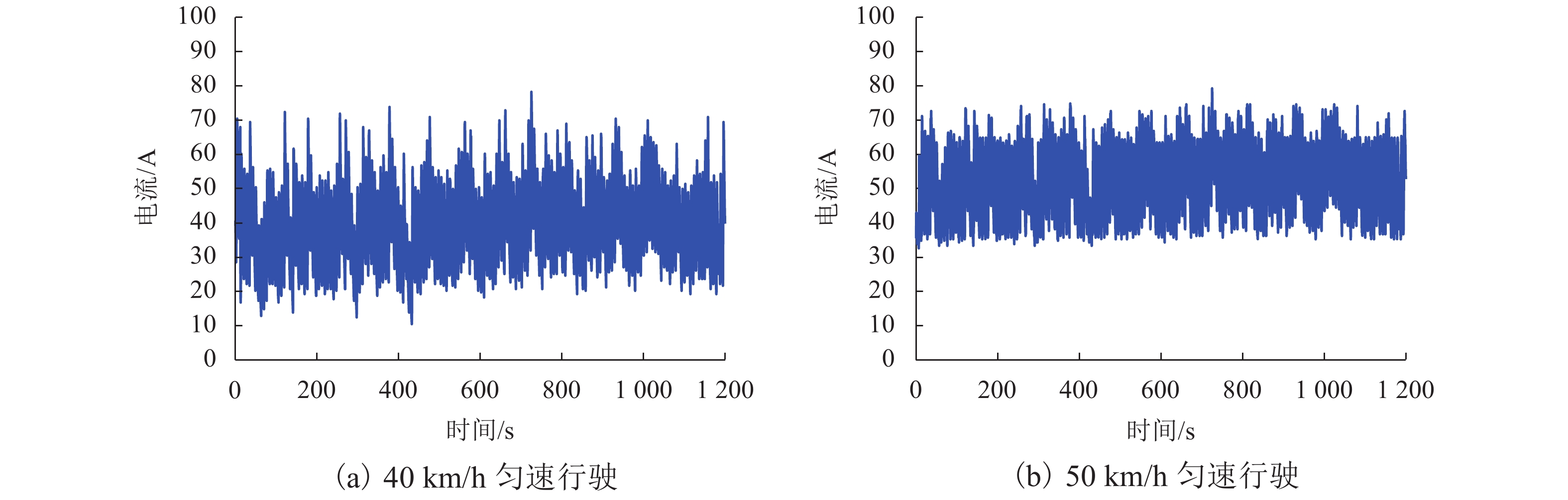

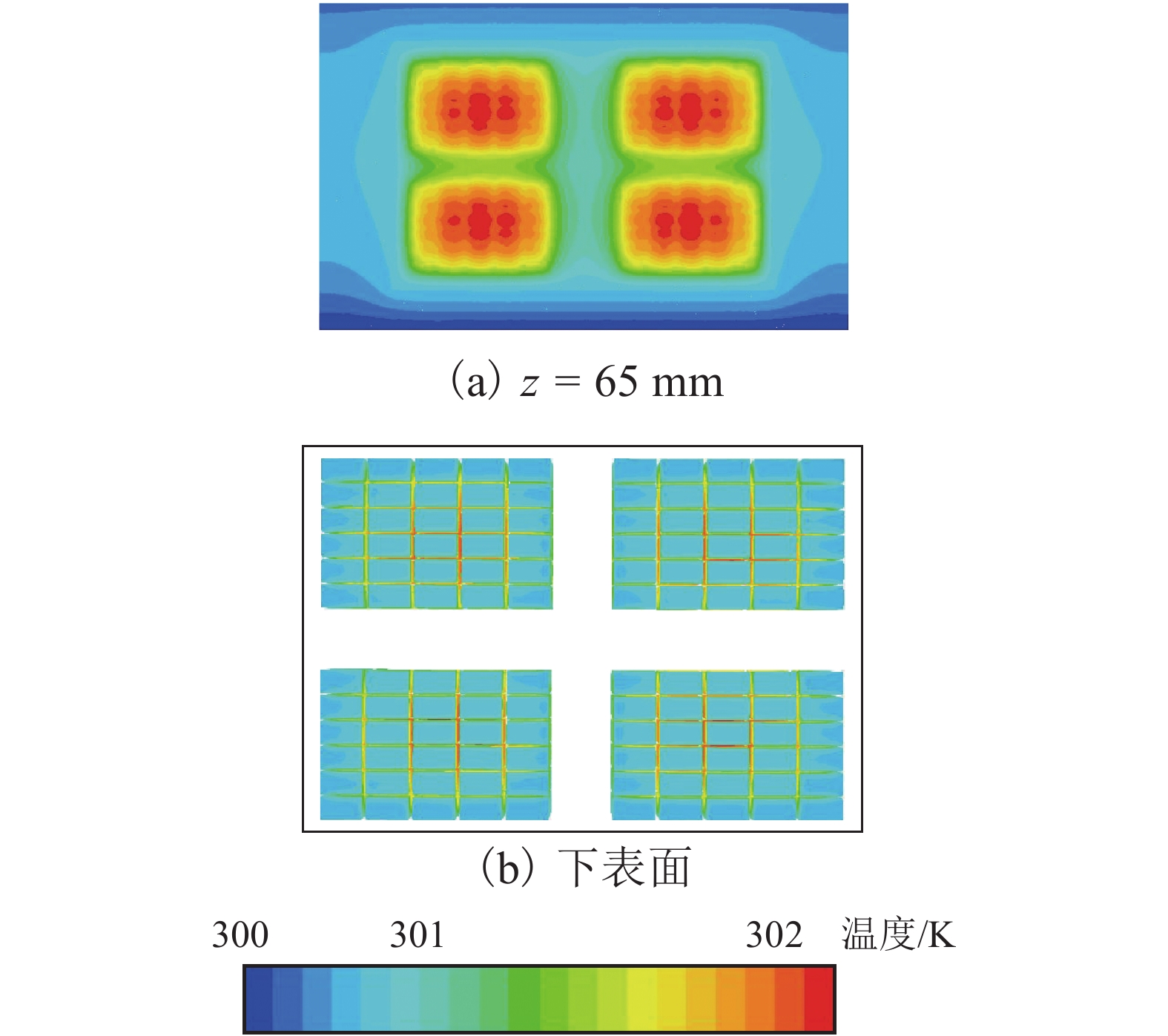

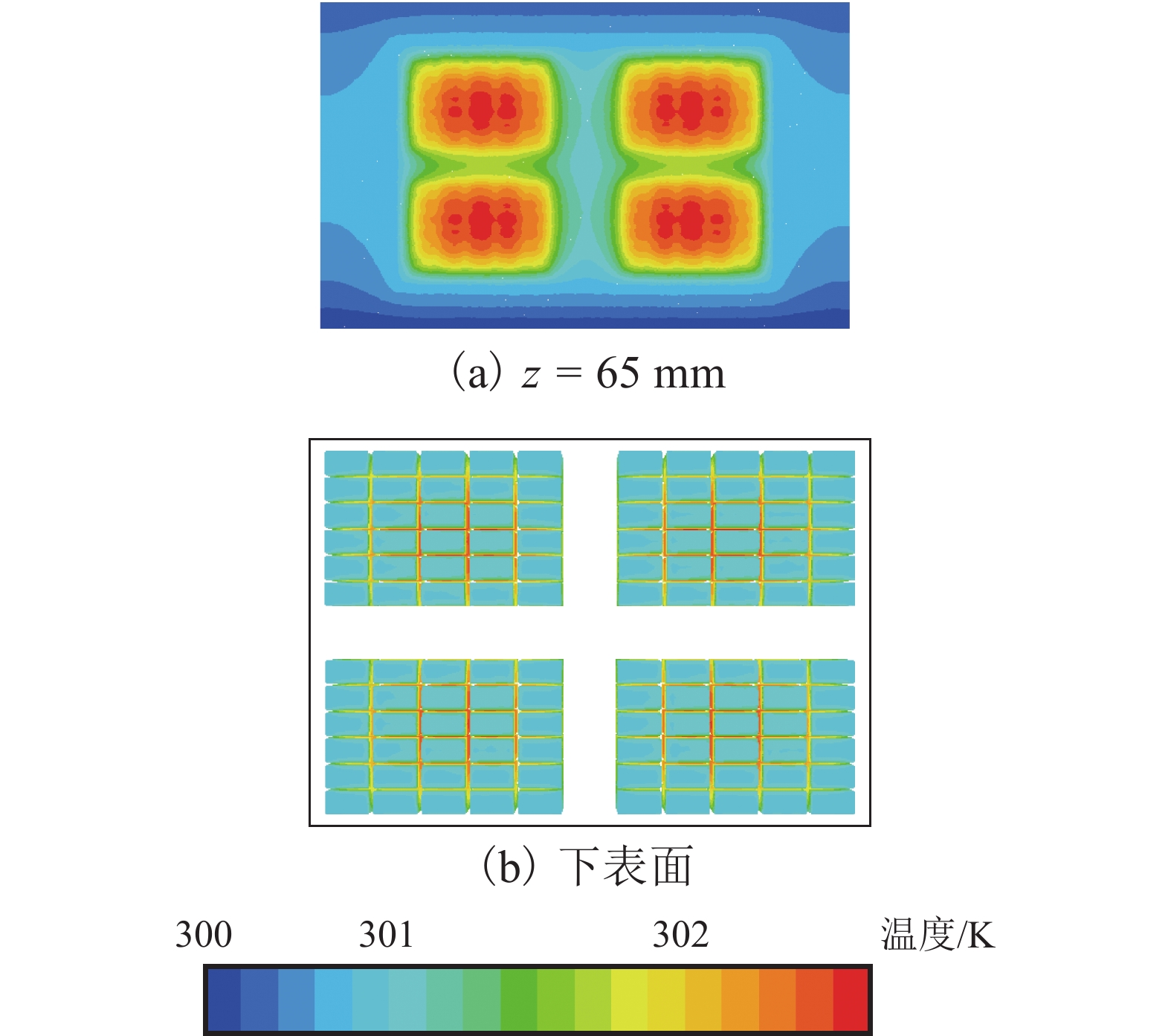

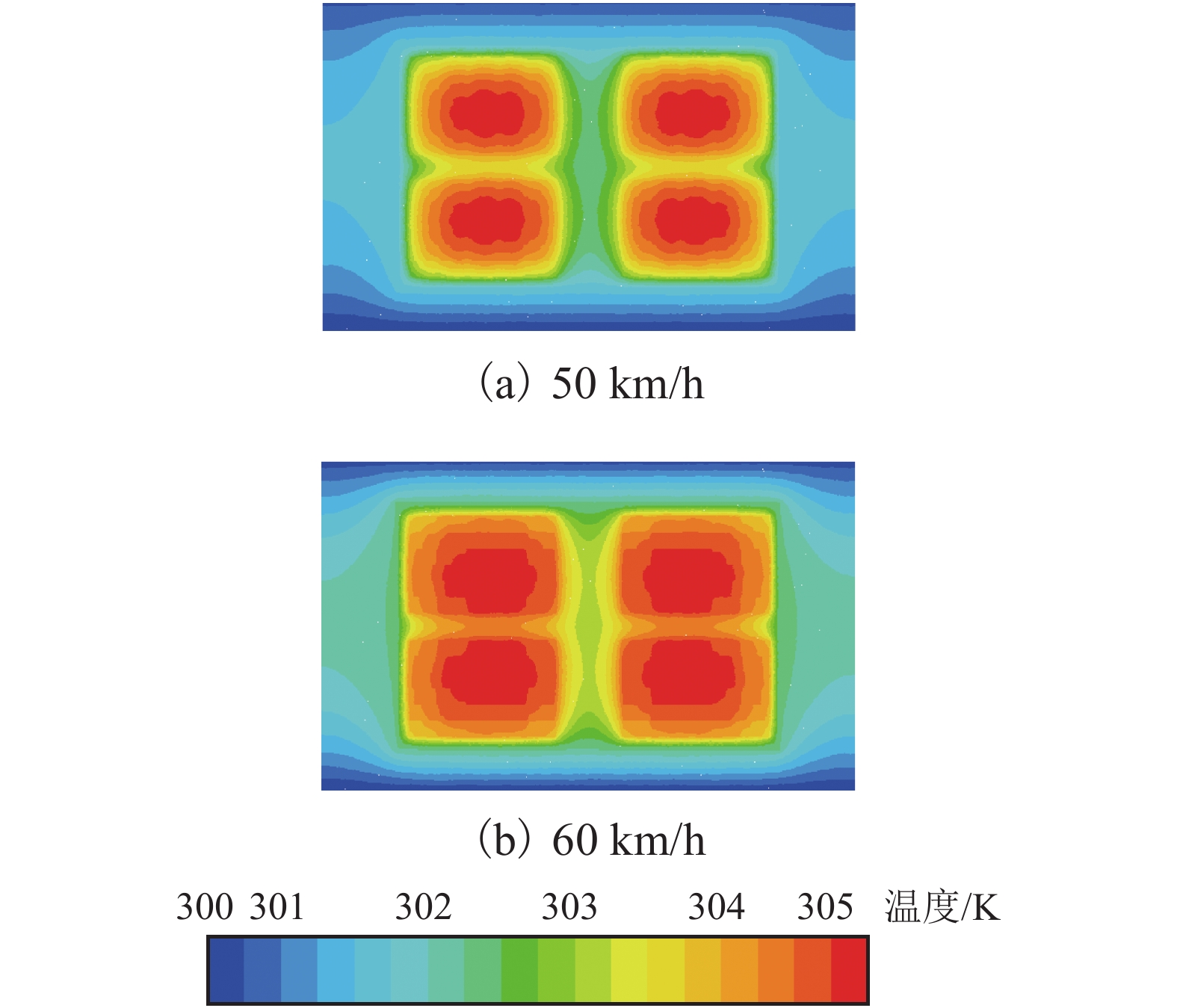

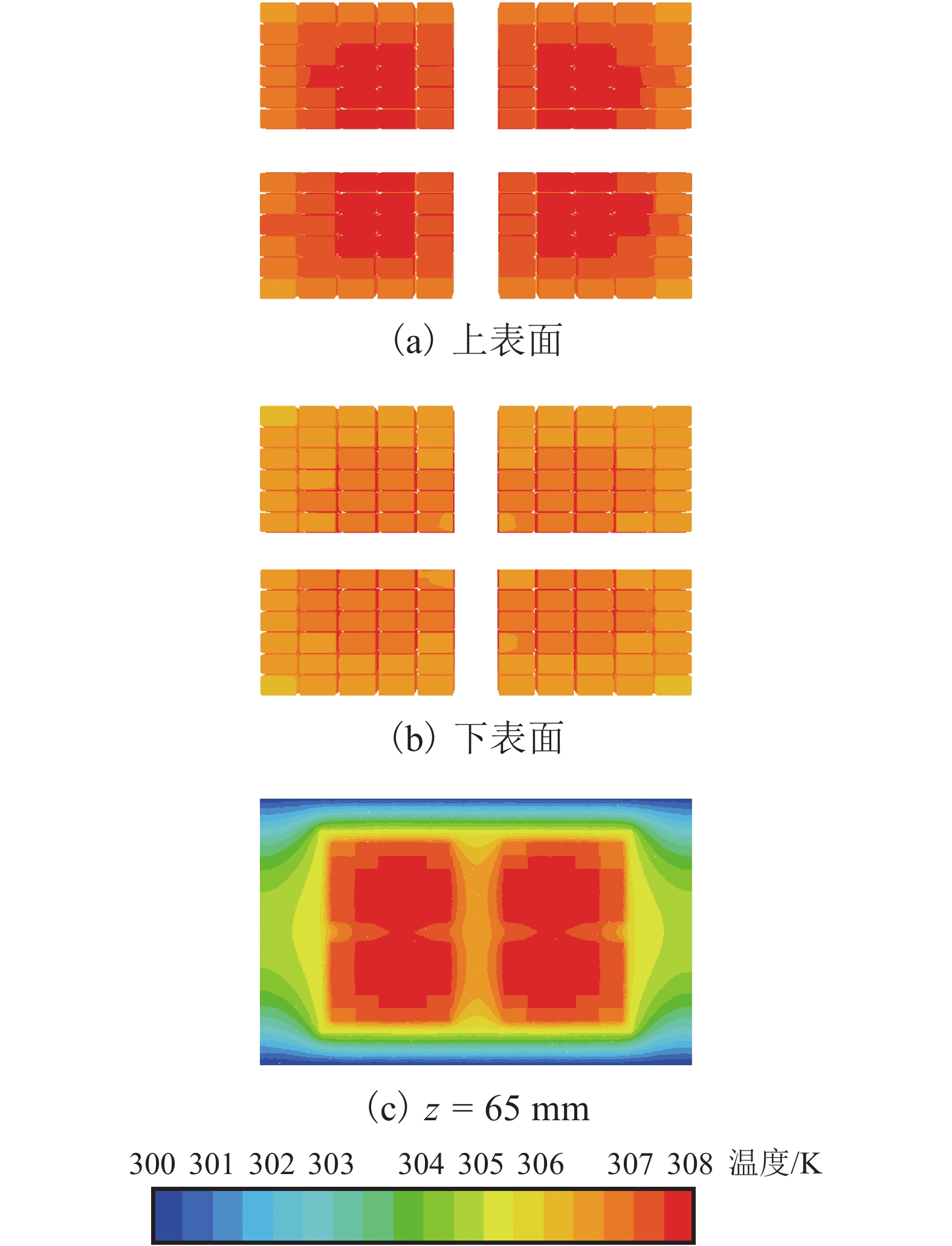

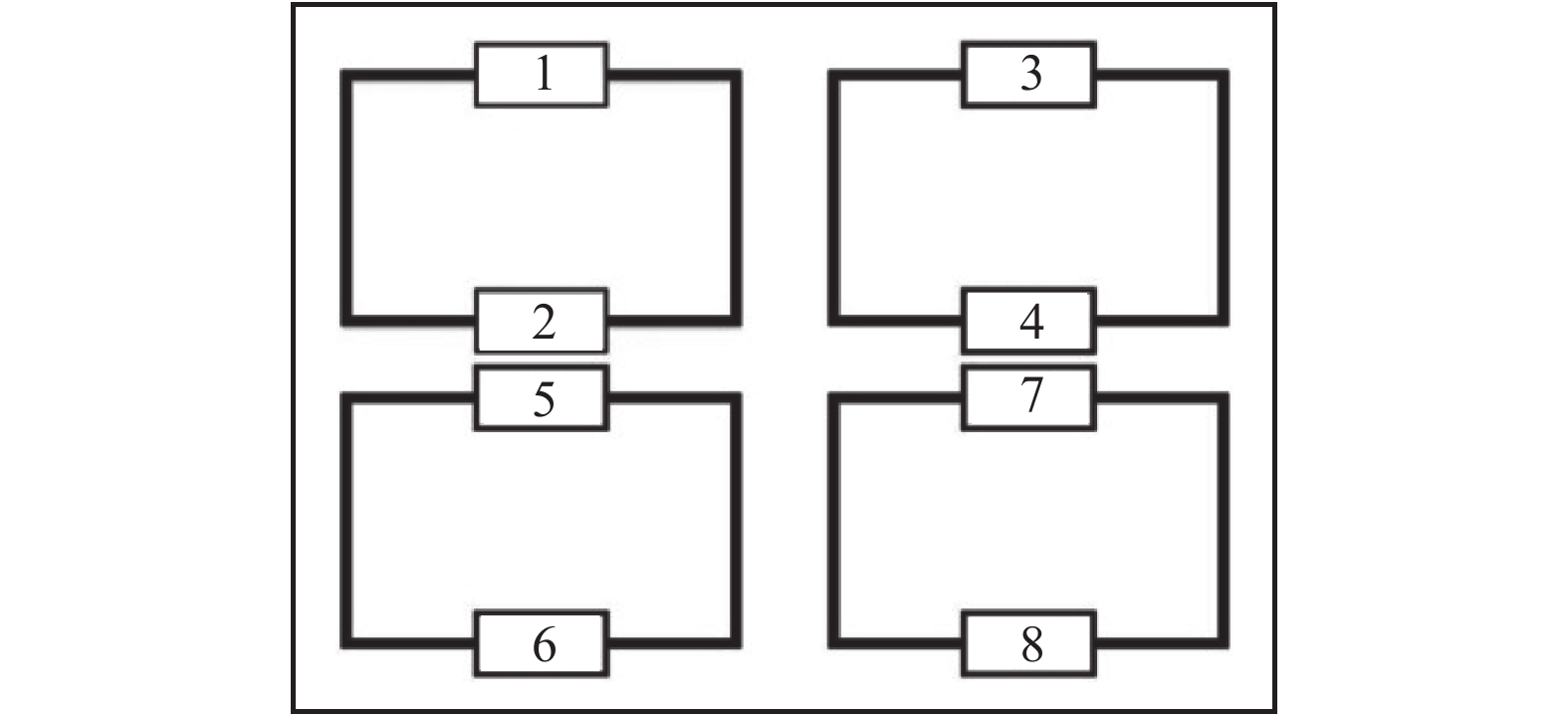

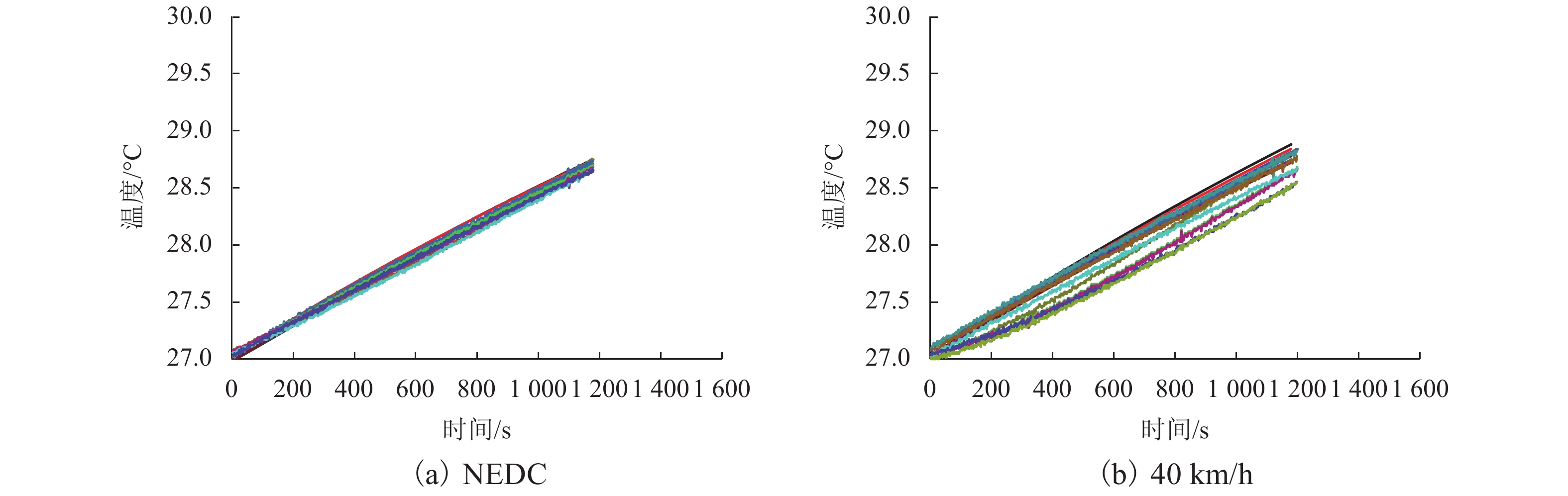

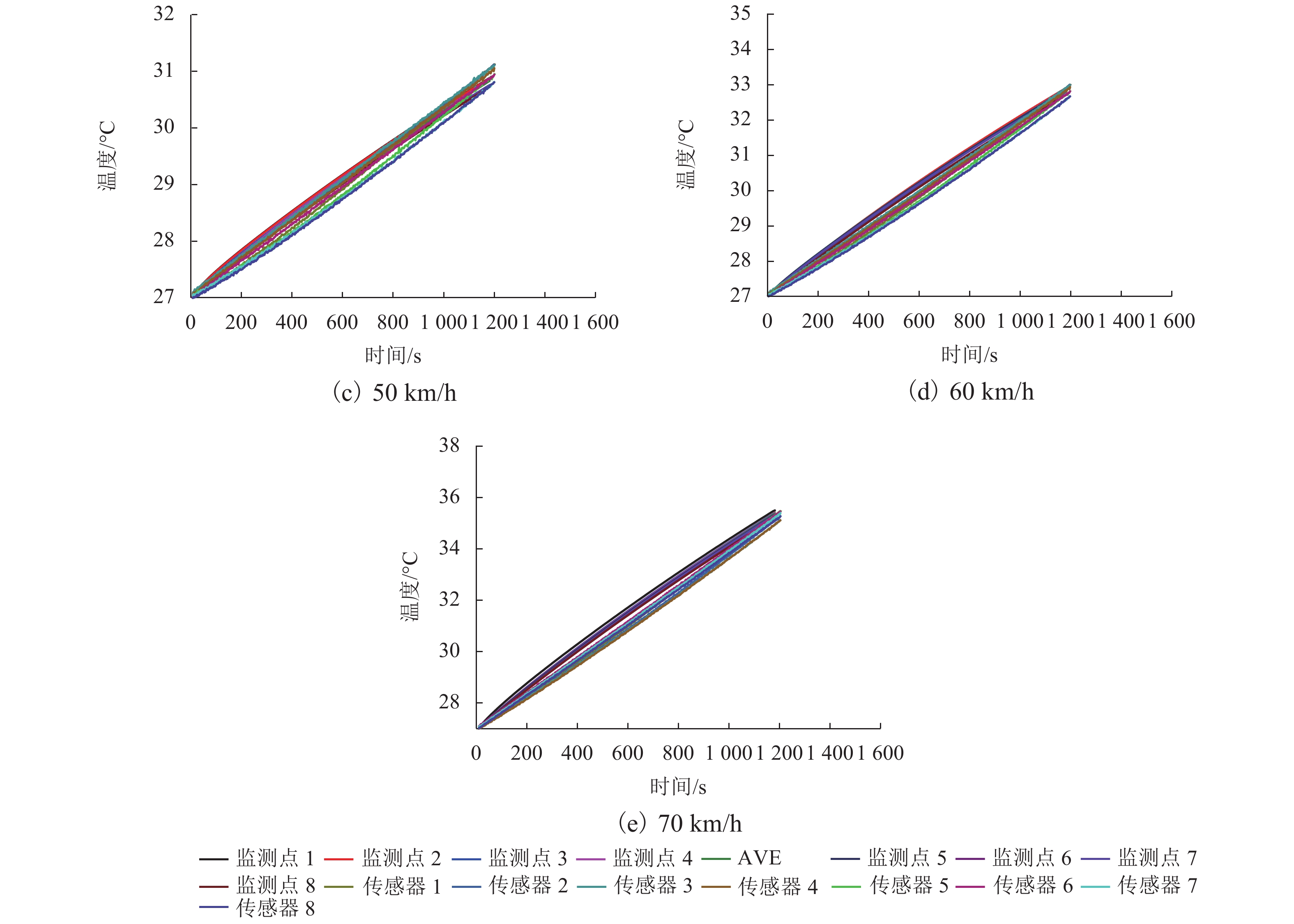

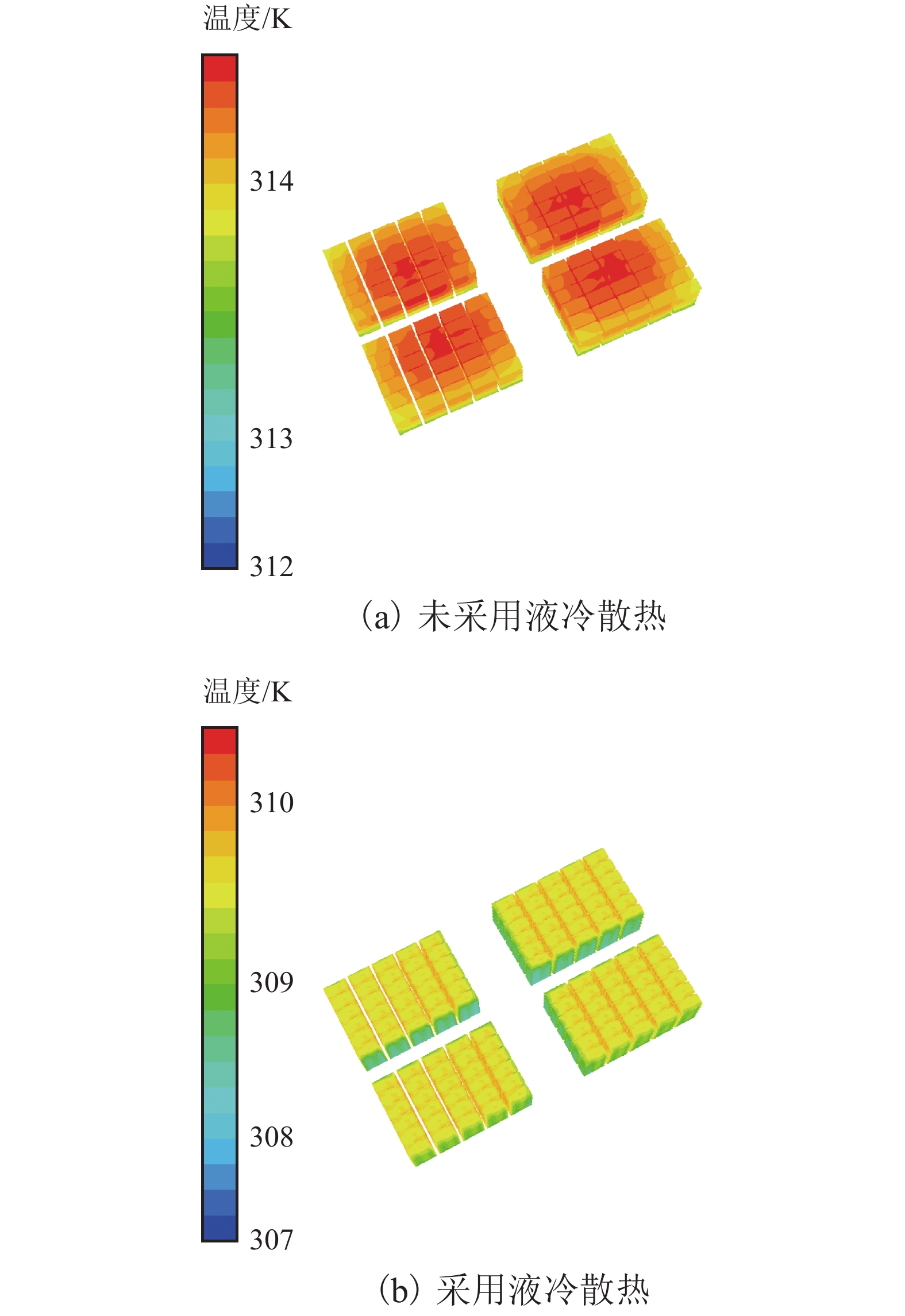

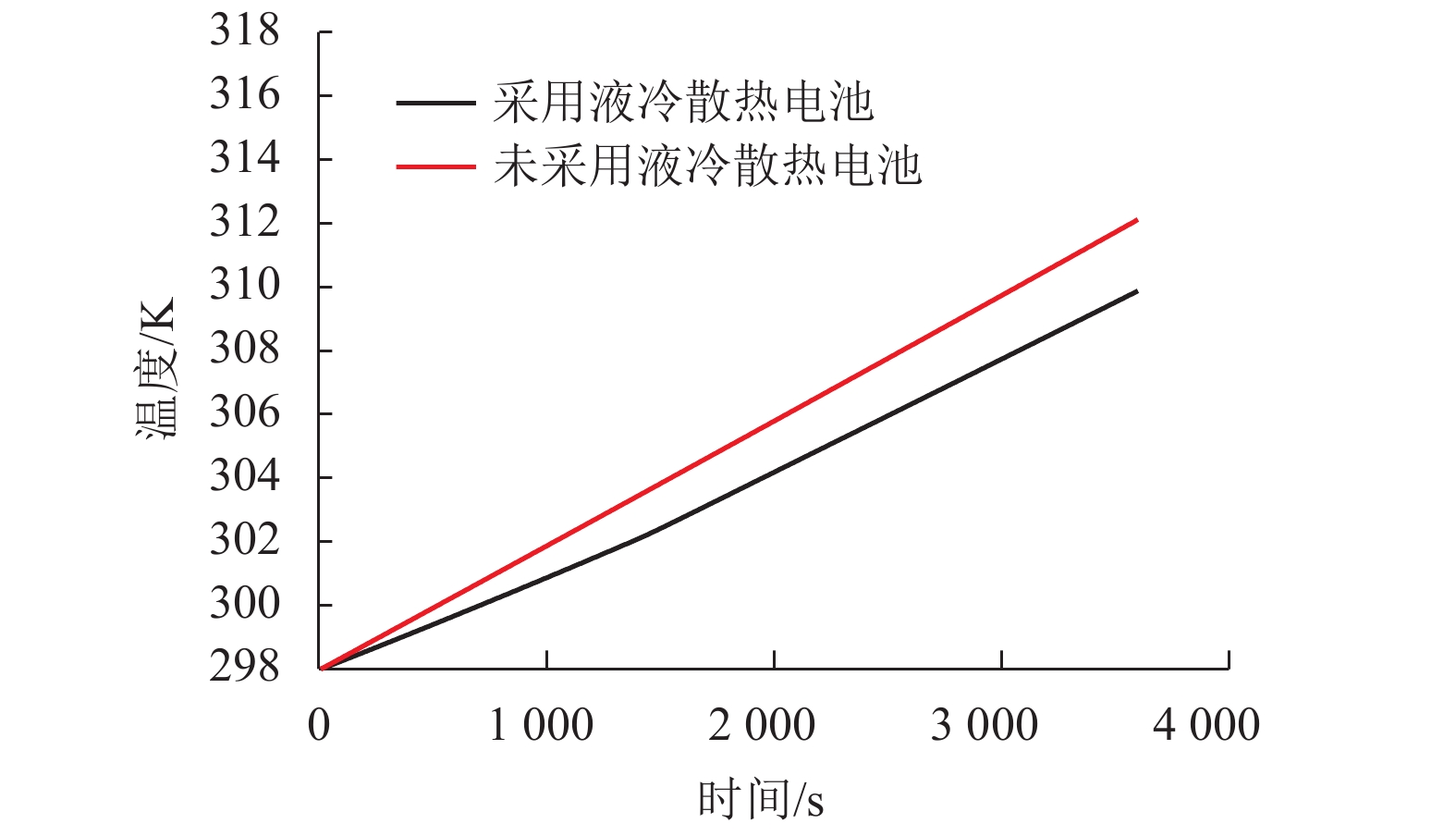

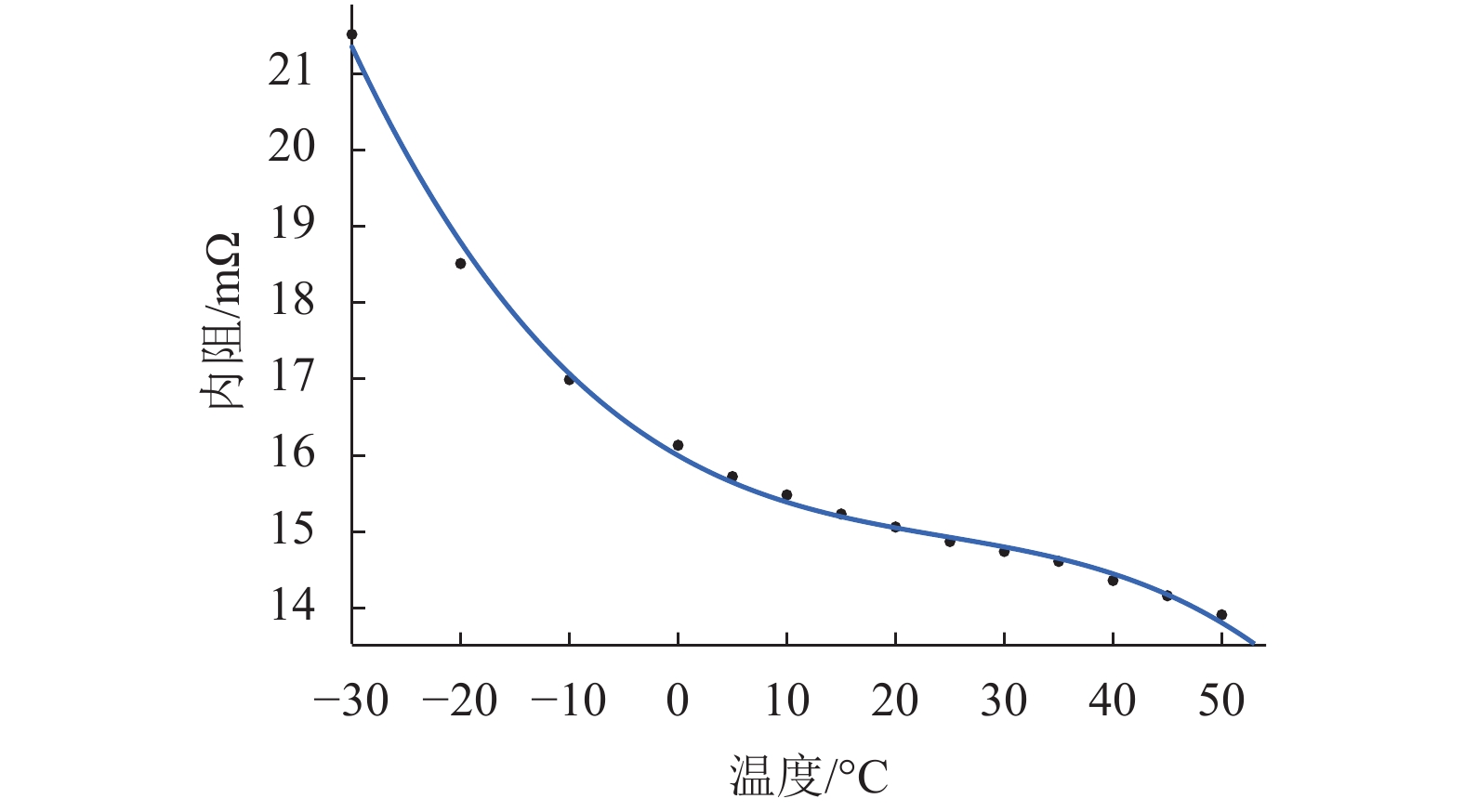

摘要: 针对电动汽车动力电池的温升发热导致温度分布不均及过热现象,根据电池的热物性参数及不同环境温度下的内阻,建立电池包生热分析模型;测试采集并拟合电动汽车的母线电流,通过仿真分析得到不同车速下电动汽车电池包的温升情况;进行典型城市工况实车试验,测取不同车速下电池包内温度测点的温升数据并拟合成温升曲线,通过仿真与试验结果对比,验证所建立的热分析模型的准确性;在此基础上,设计双进双出的液冷散热管道结构方案,分析在1C放电倍率下该液冷散热方案的散热效果. 研究结果表明:锂电池在高温(50 ℃)下,内阻仅为13.9 mΩ,而在低温(−30 ℃)时,内阻却达到了21.5 mΩ;电动汽车在新欧洲行驶工况(NEDC工况)和匀速工况(40、50、60、70 km/h)下的最高温升分别为1.8、2.6、3.6、5.3、8.0 ℃;所设计的U型结构液冷管道可以有效地降低电池包温升,提高电池包的温度均匀度.

-

关键词:

- 锂电池 /

- 匀速工况 /

- 新欧洲行驶工况(NEDC工况) /

- 温升 /

- 液冷管道

Abstract: Concerning the phenomenon of uneven temperature distribution and excessive temperature of power battery heat generation in electric vehicles, the thermal analysis model of the battery package was established on the basis of thermal physical parameters of the battery and internal resistance at different temperatures. The bus current value of the electric vehicle collected by the test was fitted, and then the temperature rise of the battery package in different driving speeds could be obtained by the simulation. Finally, the vehicle test on typical urban conditions was conducted to measure the temperature rise dates of the test points in the battery package at different constant speeds, and then the curves were fitted by the temperature rise dates. The comparisons between the simulation and the test verified that the thermal analysis model was accurate and effective. On the basis, the double inlet and double outlet liquid cooling pipe structure scheme was designed to analyze the cooling effect of the liquid cooling scheme at the 1C discharge rate. The results show that the internal resistance of lithium battery is only 13.9 mΩ at high temperature (50 ℃), while it reaches 21.5 mΩ at low temperature (−30 ℃); the maximum temperature rise of electric vehicle under new European driving cycle (NEDC) and constant speed conditions (40, 50, 60, 70 km/h) reach 1.8, 2.6, 3.6, 5.3, and 8.0 ℃ respectively; the U-shaped structure liquid cooling pipe can reduce the temperature rise of battery pack effectively and improve the temperature uniformity of the battery pack. -

表 1 电池PACK各组件具体参数

Table 1. Specific parameters of each component of battery PACK

材料 导热系数/

(W•(m•K)−1)比热容/

(J•(kg•K)−1)密度/

(kg•m−3)电池 1.24/1.24/0.62 840 2 260 空气 0.024 2 1 026 1.23 电池箱 16.27 503 8 025 -

刘振军,林国发,秦大同,等. 电动汽车锂电池组温度研究及其结构优化[J]. 汽车工程,2012,34(1): 80-84. doi: 10.3969/j.issn.1000-680X.2012.01.018LIU Zhenjun, LIN Guofa, QIN Datong, et al. A study on the temperature field of lithium-ion battery pack in an electric vehicle and its structural optimization[J]. Automotive Engineering, 2012, 34(1): 80-84. doi: 10.3969/j.issn.1000-680X.2012.01.018 JARRETT A, KIM Y. Design optimization of electric vehicle battery cooling plates for thermal performance[J]. Journal of Power Sources, 2011, 196(23): 10359-10368. doi: 10.1016/j.jpowsour.2011.06.090 MIN J K, LEE C H. Numerical study on thermal management system of a molten sodium sulfur battery module[J]. Journal of Power Sources, 2012, 210: 101-109. doi: 10.1016/j.jpowsour.2012.03.028 李哲,韩雪冰,卢兰光,等. 动力型磷酸铁锂电池的温度特性[J]. 机械工程学报,2011,47(18): 115-120.LI Zhe, HAN Xuebing, LU Languang, et al. Temperature characteristics of power LiFePO4 batteries[J]. Journal of Mechanical Engineering, 2011, 47(18): 115-120. 李仲兴,李颖,周孔亢,等. 纯电动汽车不同行驶工况下电池组的温升研究[J]. 机械工程学报,2014,50(16): 180-185.LI Zhongxing, LI Yin, ZHOU Kongkang, et al. Temperature study of pure electric vehicles battery pack at different driving conditions[J]. Journal of Mechanical Engineering, 2014, 50(16): 180-185. 俆晓明,赵又群. 不同工况下电池冷板液冷系统散热性能试验研究[J]. 汽车工程,2014(9): 1057-1062.XU Xiaoming, ZHAO Youqun. An experimental study on the heat dissipation performance of cooling-plate liquid cooling system for electric vehicle in different conditions[J]. Automotive Engineering, 2014(9): 1057-1062. 张志杰,李茂德. 锂离子电池内阻变化对电池温升影响分析[J]. 电源技术,2010,34(2): 128-130. doi: 10.3969/j.issn.1002-087X.2010.02.011ZHANG Zhijie, LI Maode, et al. Effect of internal resistance on temperatre rising of lithium-ion battery[J]. Journal of Power Sources, 2010, 34(2): 128-130. doi: 10.3969/j.issn.1002-087X.2010.02.011 FORGEZ C, DO D V, et al. Thermal modeling of a cylindrical LiFePO 4/graphite lithium-ion battery[J]. Journal of Power Sources, 2010, 195(9): 2961-2968. doi: 10.1016/j.jpowsour.2009.10.105 YE Y, SHI Y, CAI N, et al. Electro-thermal modeling and experimental validation for lithium ion battery[J]. Journal of Power Sources, 2012, 199(1): 227-238. HANAI Y, YOSHIMURA K, MATSUKI J, et al. A basic study of a coordinated control method for heat pump water heaters and electric vehicle battery chargers in residence with pv systems[J]. Transactions of the Korean Institute of Power Electronics, 2014, 1(1): 97-103. 张庭芳,郭伟春,付艳恕. 车载动力电池组温升特性仿真及实验研究[J]. 电源技术,2015,39(1): 43-46. doi: 10.3969/j.issn.1002-087X.2015.01.012ZHANG Tingfang, GUO Weichun, FU Yanshu. Research on temperature characteristics simulation and of lithium-ion battery pack for electric vehicle[J]. Chinese Journal of Power, 2015, 39(1): 43-46. doi: 10.3969/j.issn.1002-087X.2015.01.012 ZOU Huiming, WANG Wei, ZHANG Guiying, et al. Experimental investigation on an integrated thermal management system with heat pipe heat exchanger for electric vehicle[J]. Energy Conversion and Management, 2016, 118: 88-95. doi: 10.1016/j.enconman.2016.03.066 CHO G Y, CHOI J W, PARK J H, et al. Transient modeling and validation of lithium ion battery pack with air cooled themal management system for electric vehicles[J]. International Journal of Automotive Technology, 2014, 15(5): 795-803. doi: 10.1007/s12239-014-0083-x LIU H, LIU W. Thermal-structuralanalysis theplatelet heat-pipe-cooled leading edge of hypersonicvehicle[J]. Acta Astronautica, 2016, 127: 13-19. doi: 10.1016/j.actaastro.2016.05.014 罗玉涛,何小颤. 动力锂离子电池热安全性影响因素的研究[J]. 汽车工程,2012,34(4): 333-338. doi: 10.3969/j.issn.1000-680X.2012.04.012LUO Yutao, HE Xiaochan. Research on temperature characteristics simulation and of lithium-ion battery pack for electric vehicle[J]. Automotive Engineering, 2012, 34(4): 333-338. doi: 10.3969/j.issn.1000-680X.2012.04.012 -

下载:

下载: