Leakage Analysis and Volumetric Efficiency of Symmetrical Multiple Output Gear Motors

-

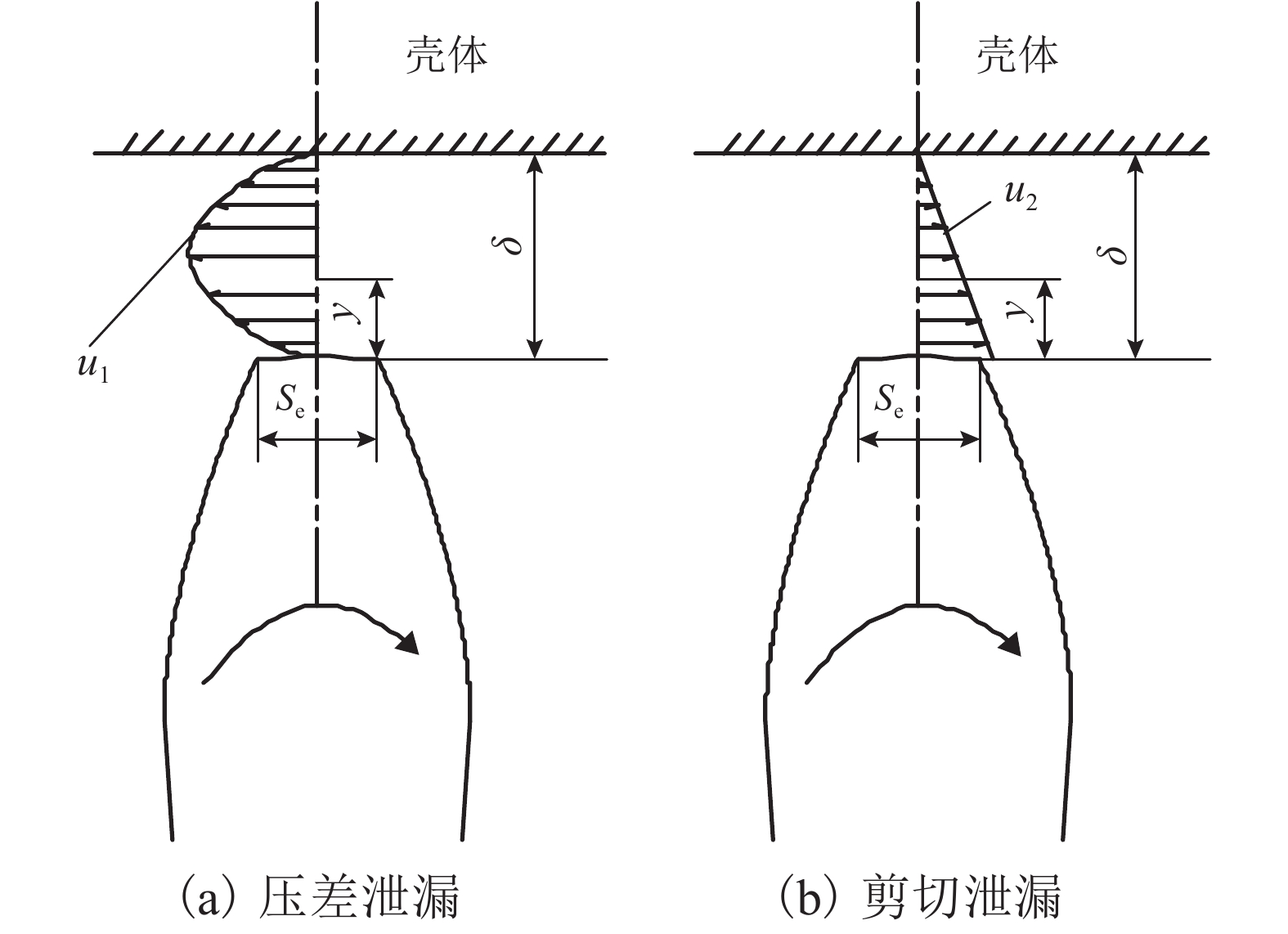

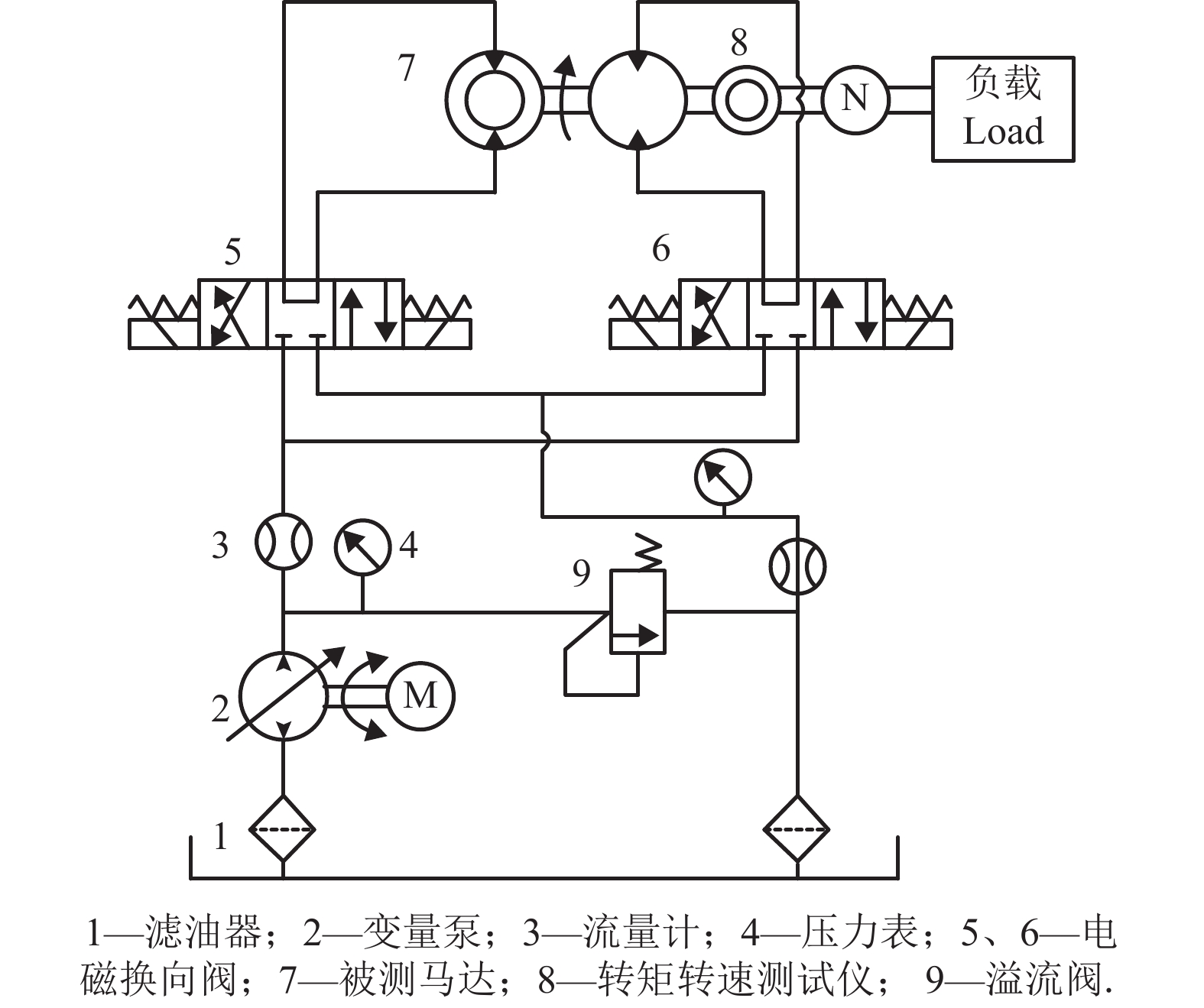

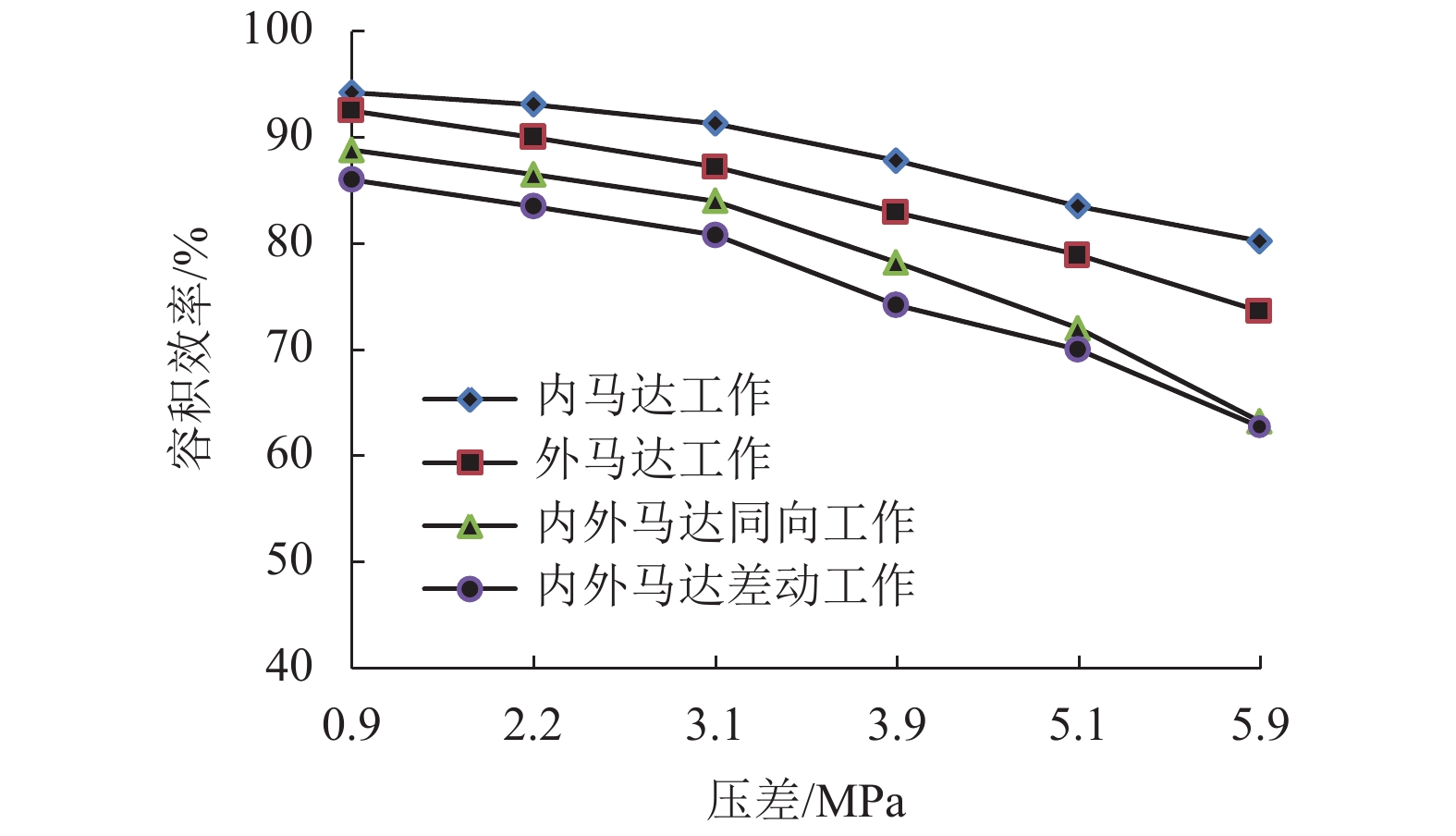

摘要: 为了研究对称型多输出齿轮马达的泄漏与容积效率,通过对称型多输出齿轮马达的内部结构计算出内外马达不同连接方式下的几何排量,分析了马达的主要泄漏途径,通过建立泄漏的数学模型归纳不同连接下泄漏的一般表达式;同时搭建试验平台测试对称型多输出齿轮马达的容积效率. 研究结果表明:当马达的进出口压力由0.9 MPa增加至5.9 MPa时,内马达工作时容积效率由94.2%下降至80.2%,外马达容积效率由92.5%下降至73.6%,内外马达同时工作时容积效率由88.8%下降至63.2%,差动连接时容积效率由86.0%下降至62.7%;当进出口压差为5.9 MPa时,内马达单独工作容积效率最高为80.2%,差动连接下马达的容积效率最低为62.7%.Abstract: In order to study the leakage and volumetric efficiency of a symmetrical multi-output geared motor, the geometric displacements of the internal and external motors under different connection modes were calculated based on the internal structure of the symmetric multi-output gear motor. The main leakage paths of the motor were analyzed. By establishing a mathematical model of the leakage, general expressions of leakage under different connections were summarized. At the same time, an experimental platform was built to test the volumetric efficiency of the symmetrical multi-output geared motor. The results show that when the inlet and outlet pressure of the motor increase from 0.9 MPa to 5.9 MPa, the volumetric efficiency of the internal motor decreases from 94.2% to 80.2%, and the volumetric efficiency of the external motor decreases from 92.5% to 73.6%. The efficiency drops from 88.8% to 63.2%, and the volumetric efficiency decreases from 86.0% to 62.7% during differential connection. When the pressure difference between the inlet and outlet is 5.9 MPa, the volumetric efficiency of the internal motor alone is 80.2%, and the volumetric efficiency of the motor is 62.7%.

-

Key words:

- hydraulic motor /

- leakage /

- geometric displacement /

- volumetric efficiency /

- test

-

表 1 不同连接方式下马达的泄漏量

Table 1. Leakage of the motor under different connection modes

马达工作方式 泄漏量 内马达 外马达 工作 不工作 $\Delta {Q_2} + \Delta {Q'_2}$ 不工作 工作 $\Delta {Q_1} + \Delta {Q'_1}$ 工作 工作 $\Delta {Q_1} + \Delta {Q'_1} + \Delta {Q_2} + \Delta {Q'_2}$ 表 2 马达的共齿轮设计参数

Table 2. Co-gear design parameters of the motor

主要设计参数 取值 共齿轮齿宽/mm 40 共齿轮的外齿轮高压腔的包角/rad π/4 共齿轮的内齿轮高压腔的包角/rad π/2 共齿轮的外齿轮齿顶圆半径/mm 37.5 共齿轮的内齿轮齿顶圆半径/mm 15.8 共齿轮的外齿轮齿根圆半径/mm 30.8 共齿轮的内齿轮齿根圆半径/mm 19.1 共齿轮的外齿轮齿轴半径/mm 27 共齿轮的内齿轮齿轴半径/mm 24 共齿轮外齿轮齿顶厚度/mm 2.1 共齿轮内齿轮齿顶厚度/mm 1.7 共齿轮外齿轮过渡区的齿数/个 17 共齿轮内齿轮过渡区的齿数/个 11 表 3 马达的大齿轮设计参数

Table 3. Large Motor gear design parameters

主要设计参数 取值 大齿轮齿宽/mm 40 大齿轮高压腔的包角/rad π/3 大齿轮齿顶圆半径/mm 27 大齿轮齿根圆半径/mm 20.3 大齿轮齿轴半径/mm 17 大齿轮齿顶厚度/mm 2 大齿轮过渡区的齿数/个 11 表 4 马达的小齿轮设计参数

Table 4. Design parameters of motor pinion

主要设计参数 取值 小齿轮齿宽/mm 40 小齿轮高压腔的包角/rad 2π/3 小齿轮齿顶圆半径/mm 12 小齿轮齿根圆半径/mm 12 小齿轮齿轴半径/mm 8.6 小齿轮齿顶厚度/mm 1 大齿轮过渡区的齿数/个 5 齿轮马达的端面间隙/mm 0.015 齿轮马达的径向间隙/mm 0.03 表 5 理论与实际泄漏对比

Table 5. Comparison of theoretical and actual leakage

工作

方式理论泄漏/(L•min−1) 理论容积效率/% 实际泄漏/(L•min−1) 实际容积效率/% 内马达 1.6 91.6 3.8 80.2 外马达 2.7 85.8 4.3 73.6 内外马达同时 4.2 78.1 7.0 63.2 内外马达差动 4.5 76.4 7.6 60.7 表 6 内马达工作试验数据

Table 6. Test data of internal motors working

压差

/MPa输入流量

/(L•min−1)理论流量

/(L•min−1)容积效率

/%0.9 5.2 4.9 94.2 2.2 7.2 6.7 93.1 3.1 9.2 8.4 91.3 3.9 12.3 10.8 87.8 5.1 15.4 12.9 83.5 5.9 19.1 15.3 80.2 表 7 外马达工作试验数据

Table 7. Test data of external motors working

压差

/MPa输入流量

/(L•min−1)理论流量

/(L•min−1)容积效率

/%0.9 5.2 4.7 92.5 2.2 7.2 6.5 90.0 3.1 9.2 8.0 87.2 3.9 12.3 10.1 82.9 5.1 15.4 12.1 78.9 5.9 19.1 14.8 73.6 表 8 内外马达同时工作试验数据

Table 8. Test data of internal and external motors working simultaneously

压差

/MPa输入流量

/(L•min−1)理论流量

/(L•min−1)容积效率

/%0.9 5.2 4.6 88.8 2.2 7.2 6.2 86.5 3.1 9.2 7.7 84.0 3.9 12.3 9.7 78.2 5.1 15.4 11.1 72.0 5.9 19.1 12.1 63.2 表 9 内外马达差动工作试验数据

Table 9. Test data of internal and external motor differential working

压差

/MPa输入流量

/(L•min−1)理论流量

/(L•min−1)容积效率

/%0.9 5.2 4.6 86.0 2.2 7.2 6.2 83.5 3.1 9.2 7.7 80.8 3.9 12.3 9.7 74.2 5.1 15.4 10.1 70.0 5.9 19.1 12.0 62.7 -

闻德生, 吕世君, 闻佳. 新型液压传动(多泵多马达液压元件及系统)[M]. 北京: 化学工业出版社, 2016: 260-264. 刘峰. 输出轴力平衡型多输入齿轮马达的研究[D]. 秦皇岛: 燕山大学, 2016. 李壮云. 液压元件与系统[M]. 北京: 机械工业出版社, 2010: 52-59. 田光辉,沈明荣,杨瑞芳,等. 锯齿形结构面剪切流变及非线性本构模型分析[J]. 西南交通大学学报,2018,53(5): 1017-1025. doi: 10.3969/j.issn.0258-2724.2018.05.019TIAN Guanghui, SHEN Mingrong, YANG Ruifang, et al. Analysis of shear rheology and nonlinear constitutive model of zigzag structural surface[J]. Journal of Southwest Jiaotong University, 2018, 53(5): 1017-1025. doi: 10.3969/j.issn.0258-2724.2018.05.019 闻德生,刘春晓,王雷,等. 非对称式凸轮转子型双定子叶片泵及流量特性分析[J]. 西南交通大学学报,2019,54(5): 962-970.WEN Desheng, LIU Chunxiao, WANG Lei, et al. Analysis of asymmetric cam rotor type dual stator vane pump and its flow characteristics[J]. Journal of Southwest Jiaotong University, 2019, 54(5): 962-970. 曹健,李尚义,赵克定. 新型低速电液伺服叶片马达的控制策略研究[J]. 中国机械工程,2003,14(17): 1469-1471. doi: 10.3321/j.issn:1004-132X.2003.17.010CAO Jian, LI Shangyi, ZHAO Keding. Research on control strategy of new low-speed electro-hydraulic servo blade motor[J]. China Mechanical Engineering, 2003, 14(17): 1469-1471. doi: 10.3321/j.issn:1004-132X.2003.17.010 WEN Desheng. Theoretical analysis of output speed of multi-pump and multi-motor driving system[J]. Science China:Technological Sciences, 2011, 54(4): 992-997. doi: 10.1007/s11431-011-4321-4 闻德生,周瑞彬,吕建森,等. 双转子凸轮马达的转速与转矩分析[J]. 华南理工大学学报(自然科学版),2014,42(4): 105-110.WEN Desheng, ZHOU Ruibin, LÜ Jiansen, et al. Analysis of the speed and torque of a double rotor cam motor[J]. Journal of South China University of Technology (Natural Science Edition), 2014, 42(4): 105-110. 闻德生,吕世君,杜孝杰,等. 双定子液压马达差动连接理论分析[J]. 农业机械学报,2011,42(9): 219-224.WEN Desheng, LÜ Shijun, DU Xiaojie, et al. Theoretical analysis of differential connection of double stator hydraulic motor[J]. Journal of Agricultural Machinery, 2011, 42(9): 219-224. 白桂香. 直线共轭内啮合齿轮泵特性分析与研究[D]兰州: 兰州理工大学, 2012. 张海竹,卢勇,张薇,等. 高压叶片泵流体泄漏研究[J]. 流体机械,2009,37(3): 1-5. doi: 10.3969/j.issn.1005-0329.2009.03.001ZHANG Haizhu, LU Yong, ZHANG Wei, et al. High pressure vane pump fluid leakage research[J]. Fluid Machinery, 2009, 37(3): 1-5. doi: 10.3969/j.issn.1005-0329.2009.03.001 张雪彪,刘德全,胡建忠. 叶片泵泄漏流量脉动的研究[J]. 大连轻工业学院学报,2001,20(2): 5-28.ZHANG Xuebiao, LIU Dequan, HU Jianzhong. Research on leakage flow pulsation of vane pump[J]. Journal of Dalian Institute of Light Industry, 2001, 20(2): 5-28. 高殿荣, 吴晓明. 工程流体力学[M]. 北京: 机械工业出版社, 1999: 115-122. 姜万录,杨超,牛慧峰. 液压泵/马达试验台技术概况[J]. 机床与液压,2005(8): 1-3. doi: 10.3969/j.issn.1001-3881.2005.08.001JIANG Wanlu, YANG Chao, NIU Huifeng. Hydraulic pump,motor test bench technology overview[J]. Machine Tool and Hydraulics, 2005(8): 1-3. doi: 10.3969/j.issn.1001-3881.2005.08.001 闻德生,商旭东,顾攀,等. 双定子摆动液压马达泄漏与容积效率分析及密封改进[J]. 农业工程学报,2017,33(12): 74-80. doi: 10.11975/j.issn.1002-6819.2017.12.010WEN Desheng, SHANG Xudong, GU Pan, et al. Double stator swing hydraulic motor leakage and volumetric efficiency analysis and sealing improvement[J]. Journal of Agricultural Engineering, 2017, 33(12): 74-80. doi: 10.11975/j.issn.1002-6819.2017.12.010 -

下载:

下载: