Comparative Study on the Curving Performance of Chinese Railway Heavy Haul Freight Bogies

-

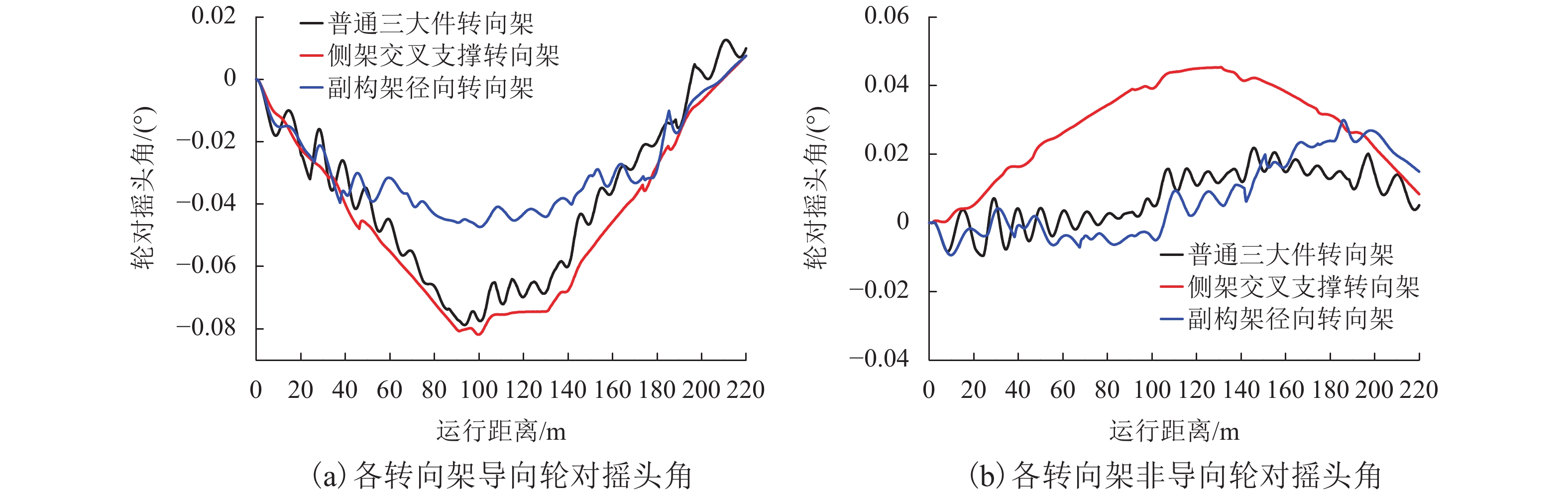

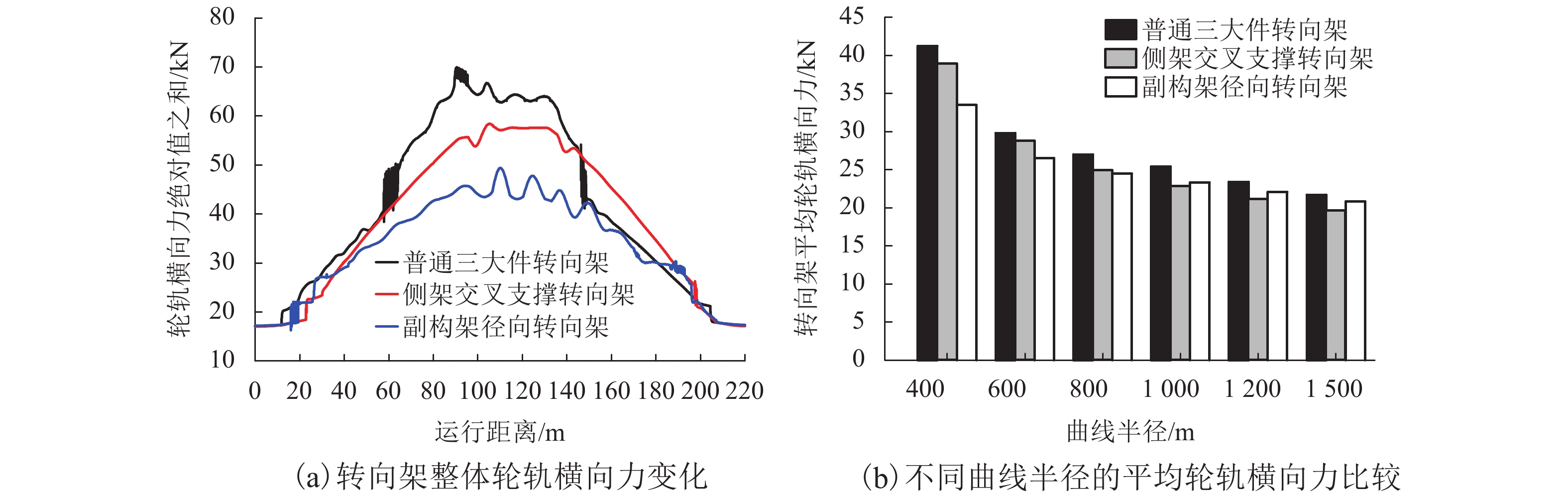

摘要: 为比较我国研制的27 t轴重侧架交叉支撑转向架和副构架径向转向架的低动力作用性能,基于车辆-轨道耦合动力学理论和两种转向架的具体结构,分别建立了车辆-轨道耦合动力学模型,应用车辆与线路最佳匹配设计方法,对两种转向架的曲线通过性能进行了仿真计算,并以轮对摇头角、轮轨横向力和轮轨磨耗功等参数与传统转向架进行了对比分析. 仿真结果表明:在曲线半径小于800 m 线路上,相对传统转向架,两种转向架能有效降低轮轨动力作用,且副构架径向转向架降低轮轨磨耗更具优势;但随曲线半径增大和受线路不平顺影响,径向转向架的径向作用会逐渐弱化;当曲线半径超过1 000 m后,两者的轮轨磨耗基本相当,即利用径向转向架来降低轮轨磨耗的效果不明显.Abstract: The low dynamic interaction performance of the 27 t axle load cross-braced bogie and the sub-frame radial bogie developed in China were compared in order to study their curving performance. Based on the theory of vehicle-track coupling dynamics and the actual structures of the two bogies, two vehicle-track coupling dynamic models were established separately. The optimum matching design method was adopted, and the curving performance of the two bogies were simulated. This method included parameters such as yaw of wheel-set, lateral force, and wear power to evaluate the curving performance, and the results were compared with the conventional three-piece bogie. The simulation results indicate that, on a curved track with a radius of less than 800 m, compared to the conventional three-piece bogie, both the bogies developed in China can lower the dynamic interaction. Furthermore, the sub-frame radial bogie has the advantage of reducing wheel/rail wear. However, with the increase in curve radius and excitation of track irregularities, the radial action of the sub-frame radial bogie weakens gradually. However, when the curve radius is greater than 1000 m, the wheel/rail wear of both bogies are equal, which means that using radial bogies to reduce wheel/rail wear has very little effect.

-

表 1 仿真计算工况

Table 1. Simulation working conditions

曲线半径/m 曲线外轨超高/mm 缓和曲线长/m 圆曲线长/m 车辆运行速度/(km•h–1) 线路激扰 400 150 90 40 80 考虑无线路不平顺激扰和中国三大重载提速干线谱激扰两种工况 600 120 90 40 80 800 150 60 40 100 1 000 120 40 40 100 1 200 100 40 40 100 1 500 80 40 40 100 表 2 车辆曲线通过的轮轨横向力极值和轮轨磨耗功均值(有线不平顺激扰)

Table 2. Peak values of lateral force and mean values of wear power while negotiating curve (with track irregularity excitation)

轮轨横向力和轮轨磨耗功 评价指标 普通三大件转向架 侧架交叉支撑转向架 副构架径向转向架 轮轨横向力最大值/kN 1位轮对外侧 52.67(33.74) 41.22(12.05) 52.38(15.21) 1位轮对内侧 40.7(26.11) 49.62(22.49) 43.73(15.31) 2位轮对外侧 39.66(12.05) 46.46(20.17) 44.71(19.74) 2位轮对内侧 40.64(5.03) 43.91(4.31) 38.38(4.47) 1、2位轮轨横向力之和 126.40(69.93) 128.37(58.39) 125.81(49.38) 轮轨磨耗功平均值/(N•m•m–1) 1位轮对外侧 56.06(52.93) 34.08(21.5) 24.50(12.83) 1位轮对内侧 46.50(40.98) 36.24(22.07) 28.42(10.75) 2位轮对外侧 24.33(15.05) 28.08(19.11) 14.66(3.54) 2位轮对内侧 24.91(16.42) 29.45(19.71) 18.01(2.15) 1、2位轮轨磨耗功合计 151.80(125.38) 127.86(82.39) 85.59(29.28) 注:括号中的数值是无线路激扰时的各对应值. -

钱立新. 世界重载铁路运输技术的最新进展[J]. 机车电传动,2010(1): 3-7.QIAN Lixin. Advanced development of heavy-haul railway technology in the world[J]. Electric Drive for Locomotives, 2010(1): 3-7. 穆鑫,杨春雷,李貌. 国外铁路重载运输对我国铁路货运发展的启示[J]. 铁道经济研究,2013(1): 31-35. doi: 10.3969/j.issn.1004-9746.2013.01.009MU Xin, YANG Chunlei, LI Mao. Inspiration for Chinese railway freight based on abroad heavy-haul transport[J]. Railway Economics Research, 2013(1): 31-35. doi: 10.3969/j.issn.1004-9746.2013.01.009 赵伟宏. 25 t轴重下交叉支撑转向架研制[J]. 铁道车辆,2000,38(8): 25-27. doi: 10.3969/j.issn.1002-7602.2000.08.006ZHAO Weihong. Development of 25 t cross sustaining bogie[J]. Railway Rolling Stocks, 2000, 38(8): 25-27. doi: 10.3969/j.issn.1002-7602.2000.08.006 李立东,杨爱国. 转K6型转向架的研制[J]. 铁道车辆,2005,43(10): 22-26. doi: 10.3969/j.issn.1002-7602.2005.10.005LI Lidong, YANG Aiguo. Development of ZHUAN K6 bogie[J]. Railway Rolling Stocks, 2005, 43(10): 22-26. doi: 10.3969/j.issn.1002-7602.2005.10.005 王璞. 转K7型转向架的研制[J]. 铁道车辆,2008,46(10): 19-21. doi: 10.3969/j.issn.1002-7602.2008.10.007WANG Pu. Development of ZHUAN K7 bogie[J]. Railway Rolling Stocks, 2008, 46(10): 19-21. doi: 10.3969/j.issn.1002-7602.2008.10.007 段仕会,徐世锋,李立东,等. DZ1型转向架的研制[J]. 铁道车辆,2016,54(6): 31-34. doi: 10.3969/j.issn.1002-7602.2016.06.010DUAN Shiyu, XU Shifeng, LI Lidong, et al. Development of type DZ1 bogie[J]. Railway Rolling Stocks, 2016, 54(6): 31-34. doi: 10.3969/j.issn.1002-7602.2016.06.010 李亨利,王妍,吴畅,等. 27 t轴重DZ3型转向架的研制[J]. 铁道车辆,2015,53(7): 26-28. doi: 10.3969/j.issn.1002-7602.2015.07.010LI Hengli, WANG Yan, WU Chang, et al. Development of 27 t type DZ3 bogie[J]. Railway Rolling Stocks, 2015, 53(7): 26-28. doi: 10.3969/j.issn.1002-7602.2015.07.010 翟婉明,赵春发. 现代轨道交通工程科技前沿与挑战[J]. 西南交通大学学报,2016,51(2): 209-226. doi: 10.3969/j.issn.0258-2724.2016.02.001ZHAI Wanming, ZHAO Chunfa. Frontier & challenges of modern rail transit engineering technology[J]. Journal of Southwest Jiaotong University, 2016, 51(2): 209-226. doi: 10.3969/j.issn.0258-2724.2016.02.001 JOLY R. 径向转向架和传统转向架的比较分析[J]. 国际铁路,1988(4): 31-42.JOLY R. Comparison between radial and conventional bogies[J]. Rail International, 1988(4): 31-42. SCHEFFEL H. 南非三大件转向架的改造[J]. 国外铁道车辆,1997(3): 34-38.SCHEFFEL H. Modifications of South Africa three-piece bogies[J]. Foreign Rolling Stock, 1997(3): 34-38. GARCIA J F. 不同类型径向转向架和传统转向架的比较分析[J]. 国外铁道车辆,2002,39(3): 13-22. doi: 10.3969/j.issn.1002-7610.2002.03.003GARCIA J F. Theoretical comparison between different configurations of radial and conventional bogies[J]. Foreign Rolling Stock, 2002, 39(3): 13-22. doi: 10.3969/j.issn.1002-7610.2002.03.003 SMITH R E. 铁路重载运输采用径向转向架的经济效益分析[J]. 国外铁道车辆,2007,44(1): 34-37. doi: 10.3969/j.issn.1002-7610.2007.01.008SMITH R E. The economic/performance benefits of a steered freight car truck for heavy haul[J]. Foreign Rolling Stocks, 2007, 44(1): 34-37. doi: 10.3969/j.issn.1002-7610.2007.01.008 SMITH R E. 自导向货车转向架和标准传统转向架的性能比较[J]. 国外铁道车辆,2001,38(6): 31-35.SMITH R E. Performance comparison of a steered freight car truck and a standard three-piece truck[J]. Foreign Rolling Stock, 2001, 38(6): 31-35. 李芾,付茂海,黄运华. 径向转向架原理和动力学性能研究[J]. 中国铁道科学,2002,23(5): 46-51. doi: 10.3321/j.issn:1001-4632.2002.05.009LI Fu, FU Maohai, HUANG Yunhua. Research of principle and dynamic characteristics of radial bogies[J]. China Railway Science, 2002, 23(5): 46-51. doi: 10.3321/j.issn:1001-4632.2002.05.009 李亨利,杨巨平,李芾. 重载货车径向转向架能耗分析[J]. 中国铁路,2014(2): 58-61. doi: 10.3969/j.issn.1001-683X.2014.02.016LI Hengli, YANG Juping, LI Fu. Energy consumption analysis of heavy-haul radial freight bogie[J]. Chinese Railway, 2014(2): 58-61. doi: 10.3969/j.issn.1001-683X.2014.02.016 李亨利,李芾,王新锐,等. 重载货车车轮磨耗与动力学性能演变[J]. 交通运输工程学报,2016(5): 49-56. doi: 10.3969/j.issn.1671-1637.2016.05.006LI Hengli, LI Fu, WANG Xinrui, et al. Evolution of wheel wear and dynamics performance of heavy haul freight car[J]. Journal of Traffic and Transportation Engineering, 2016(5): 49-56. doi: 10.3969/j.issn.1671-1637.2016.05.006 杨春雷,李芾,付茂海,等. 25 t轴载外径向臂径向转向架动力学分析[J]. 交通运输工程学报,2010(5): 30-37. doi: 10.3969/j.issn.1671-1637.2010.05.006YANG Chunlei, LI Fu, FU Maohai, et al. Dynamics analysis of the 25T axle load steering bogie with radial arm[J]. Journal of Traffic and Transportation Engineering, 2010(5): 30-37. doi: 10.3969/j.issn.1671-1637.2010.05.006 YANG Chunlei, LI Fu, HUANG Yunhua, et al. Comparative study on wheel-rail dynamic interactions of side-frame cross-bracing bogie and sub-frame radial bogie[J]. Journal of Modern Transportation, 2013, 21: 1-8. HU H B, XING S M, SHAO W D, et al. Application and development of frame brace bogie of railway freight car in China[C]//The 9th International Heavy Haul Conference Proceedings. Shanghai: [s.n.], 2009: 389-396 ZHOU B, GUAN Y. Research on application performance of K6 bogie[C]//The 3rd International Conference on Power Electronics and Intelligent Transportation System. Shenzhen: [s.n], 2010: 277-280 杨春雷. 重载货车轴重与速度匹配关系研究[D]. 成都: 西南交通大学, 2013 铁道第三勘察设计院集团有限公司, 中国铁道科学研究院. 重载铁路设计规范: TB10625—2017[S]. 北京: 中国铁道出版社, 2017 -

下载:

下载: