Effect of Casting Defects on Mechanical Properties of Steel Structures with Cast Steel Joints

-

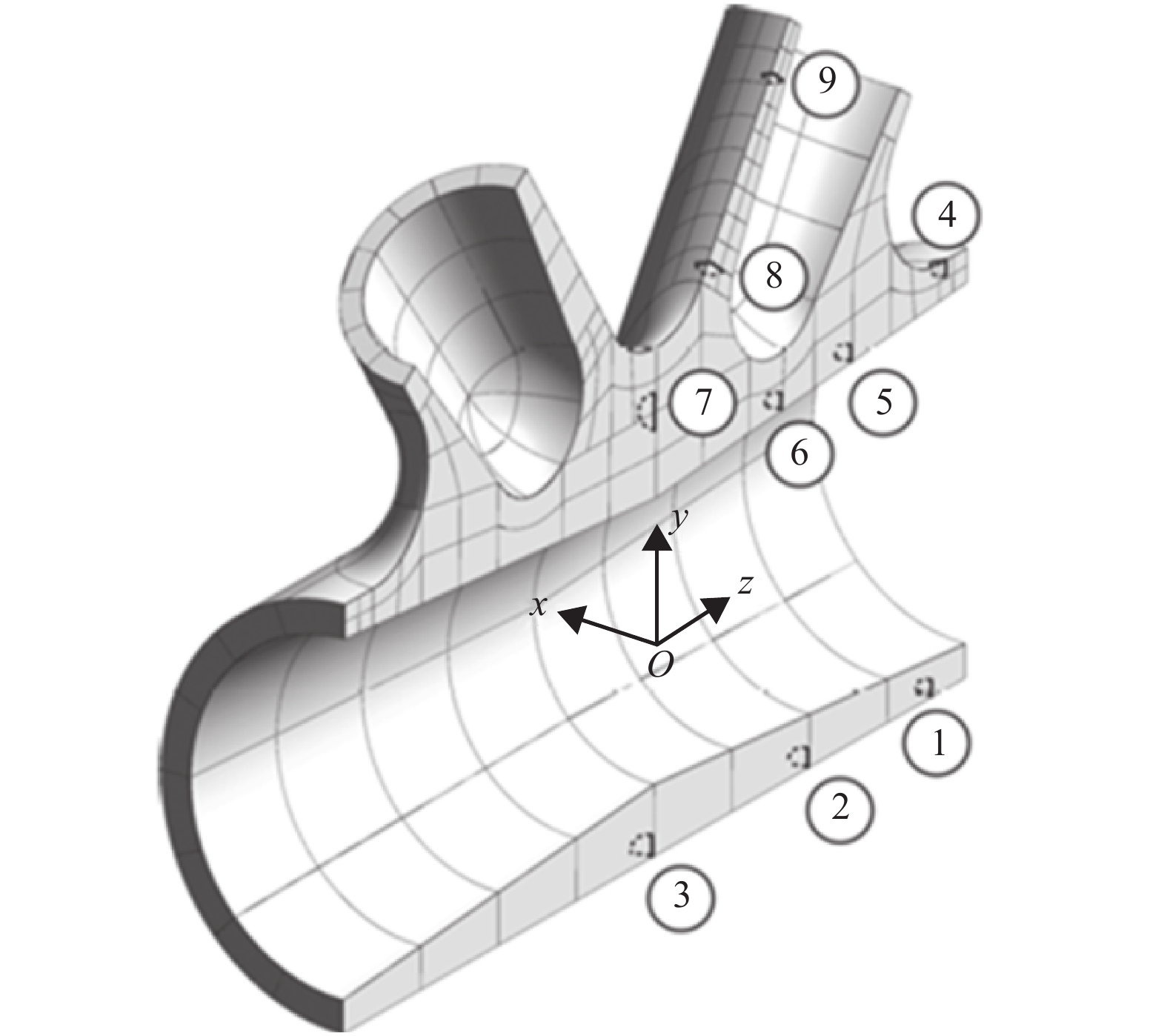

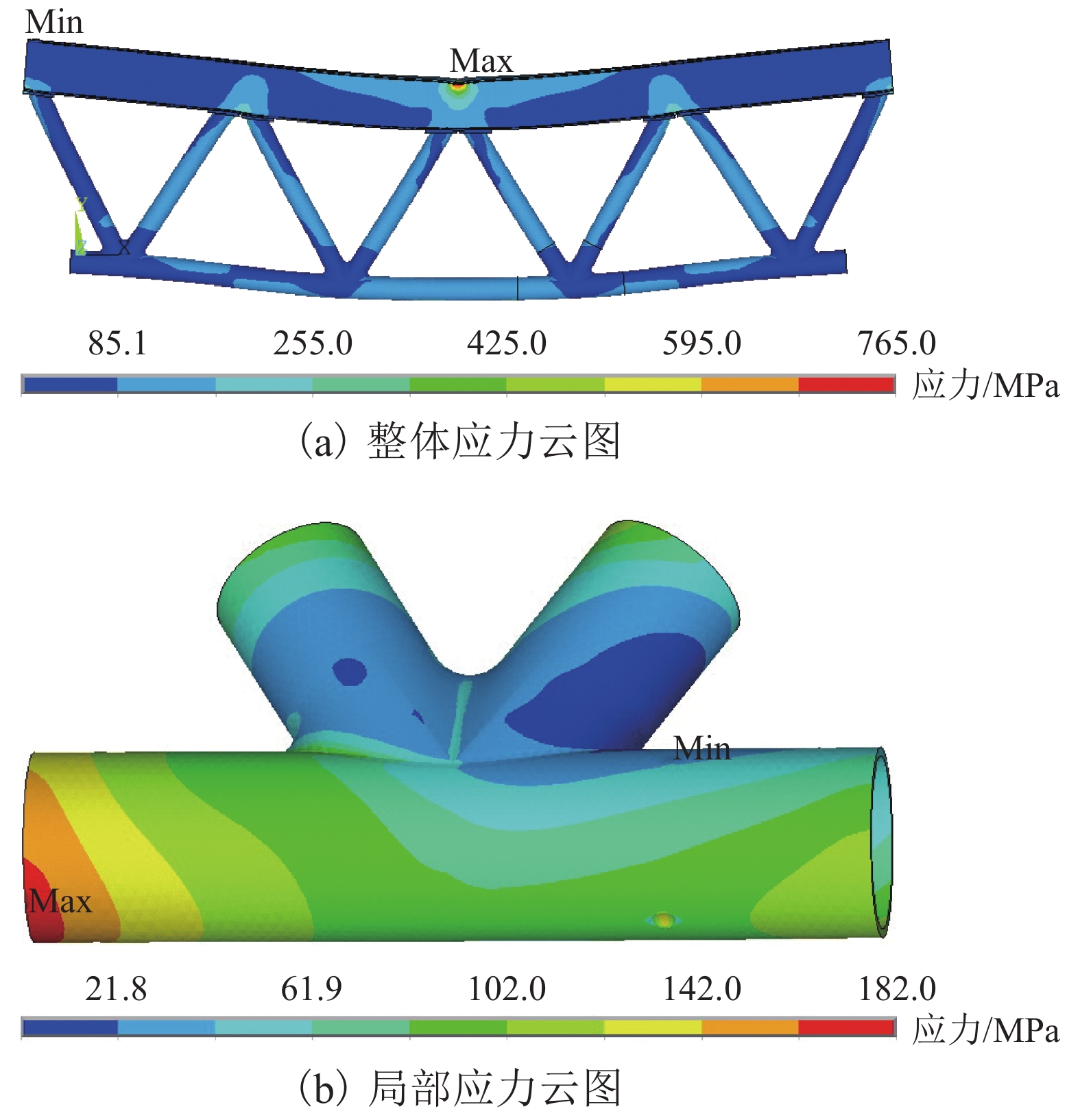

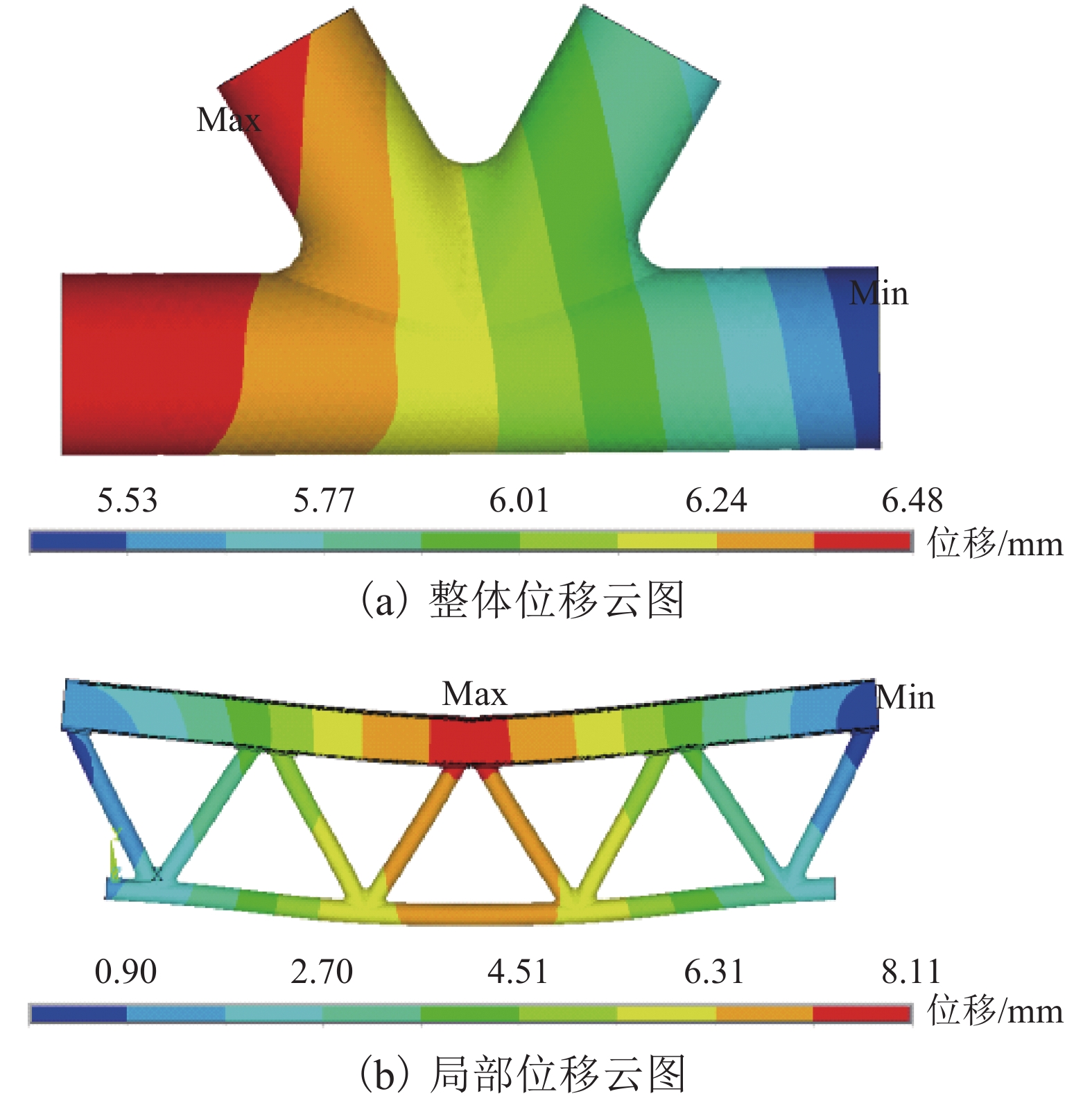

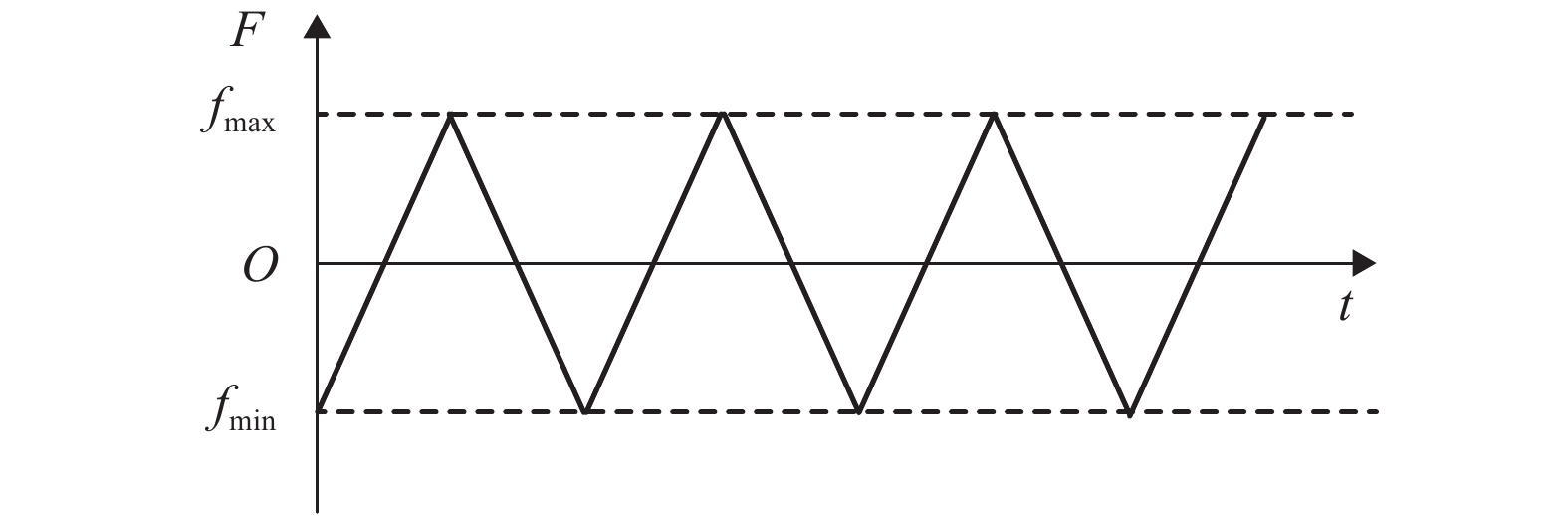

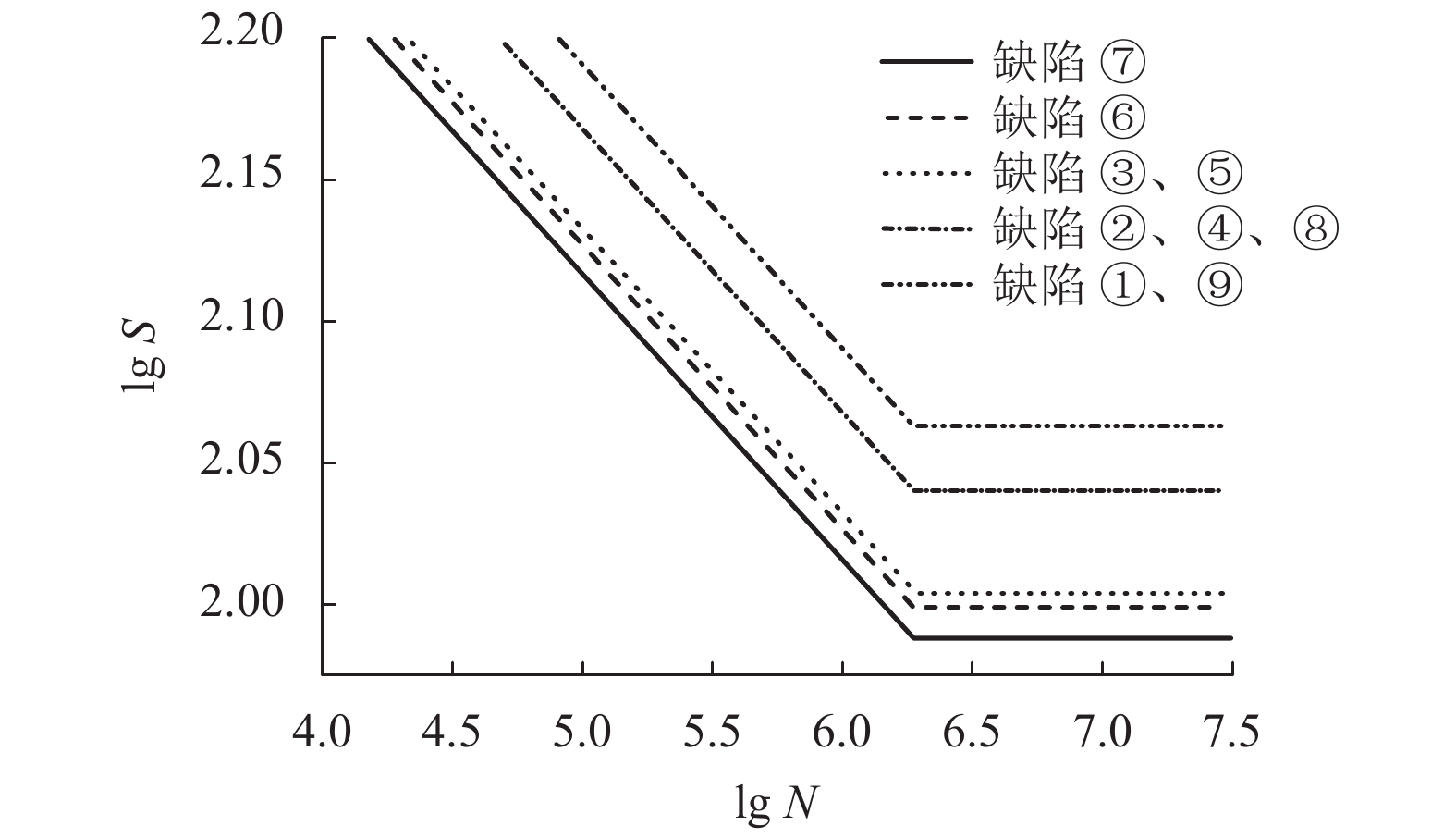

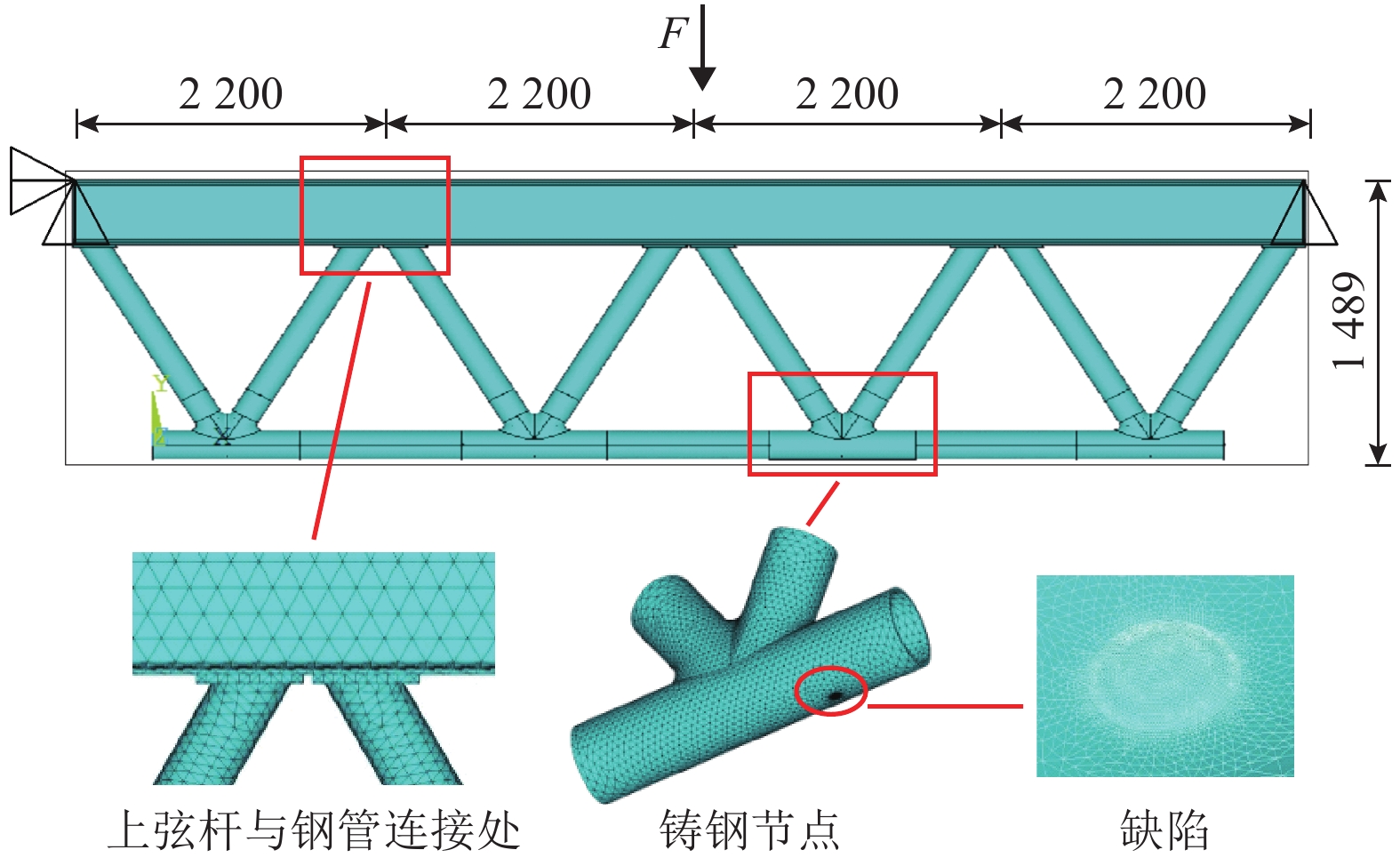

摘要: 为了研究铸钢件中铸造缺陷的等级大小、位置分布对其静力性能、疲劳性能的影响,通过Solidworks软件建立了包含铸钢节点的钢桁架结构的实体模型,根据已有研究成果确定了铸钢节点上缺陷的尺寸与位置;对带有不同铸造缺陷的桁架结构进行静力加载,通过分析结构的应力分布、位移分布情况确定铸造缺陷对其静力强度、静力刚度的影响;对带有不同铸造缺陷的桁架结构进行等幅疲劳加载,通过铸钢节点的修正应力疲劳寿命(S-N)曲线求得模型的局部疲劳寿命,明确铸造缺陷对结构疲劳性能的影响. 研究结果表明:当铸钢节点的不同位置含有相同大小的铸造缺陷时,不同模型的应力极值最大相差11.7%,不同模型的疲劳寿命相差两个数量级;当铸钢节点的同一位置含有不同大小的铸造缺陷时,不同模型的应力极值最大相差1.7%,不同模型的疲劳寿命相差一个数量级;以上两种情况对结构整体和局部的位移分布均没有明显影响;当铸钢节点中铸造缺陷的分布发生变化时,不同模型间应力极值的变化率为8.8%,不同模型的疲劳性能均劣于只包含单个铸造缺陷的模型.Abstract: In order to study the influence of the grade size and position distribution of casting defects on the static and fatigue properties of steel castings, firstly, a three-dimensional solid steel truss model with cast steel joints was built by Solidworks, and the size and location of casting defects on the cast steel joints were determined based on the published literature; then, the truss structures containing different casting defects were subjected to static loading, and the stress distribution and displacement distribution of the structure were analyzed to determine the influence of casting defects on its static strength and static stiffness; finally, the truss structures with different casting defects were subjected to equal amplitude fatigue loading, and the local fatigue life of the model was obtained through the modified S-N curve of the cast steel joint to clarify the effect of casting defects on it fatigue performance. The results show that when the different positions of the cast steel joints contain casting defects with the same size, the maximum difference in maximum stress of different models is 11.7%, the fatigue life of the different models differs by two orders of magnitude. When the same position of the cast steel joint contains casting defects of different sizes, the maximum difference in maximum stress of different models is 1.7%, the fatigue life of the different models differs by one orders of magnitude. In spite of the different positions of the cast steel joints contain casting defects with the same size or the same position of the cast steel joint contains casting defects of different sizes, there is no significant effect for the overall and local displacement distribution of the structure. When the distribution of casting defects in the cast steel joint changes, the rate of change of maximum stress between different models is 8.8%, the fatigue performance between different models is inferior to the model that only contains one casting defect.

-

Key words:

- cast steel joint /

- defect /

- mechanical property /

- casting quality evaluation

-

表 1 有限元模型的网格尺寸划分

Table 1. Mesh size of the finite element model

mm 模型分区 第 1 套 第 2 套 第 3 套 第 4 套 工字梁 50 79 79 100 钢管 15 20 30 40 铸钢节点 10 15 20 30 缺陷位置 1 2 4 5 表 2 集中载荷作用下各模型的应力极值

Table 2. Maximum stress of each model under concentrated load

模型 铸造缺陷

位置铸造缺陷

等级Mises应力

最大值/MPa1 ① 2级 200 2 ① 3级 202 3 ② 2级 182 4 ② 3级 182 5 ③ 2级 182 6 ③ 3级 182 7 ④ 2级 180 8 ④ 3级 183 9 ⑨ 2级 200 10 ⑨ 3级 200 表 3 不同模型的应力极值

Table 3. Maximum stress of different model

模型 铸造缺陷位置 铸造缺陷

等级Mises应力

最大值/MPa11 ①、②、③ 2级 182 12 ①、③、④ 2级 198 13 ②、⑦、⑨ 2级 182 14 ④、⑤、⑥ 2级 183 15 ①、②、③、⑧、⑨ 2级 186 表 4 各缺陷位置处的尺寸系数

Table 4. Size factor at defect locations

缺陷位置 ①、⑨ ②、④、⑧ ③、⑤ ⑥ ⑦ 尺寸系数 0.95 0.90 0.83 0.82 0.80 表 5 缺陷位置对模型疲劳寿命的影响

Table 5. The effect of defect location on fatigue life of models

模型 铸造缺

陷位置铸造缺

陷等级疲劳寿命/

(× 105 周次)A ① 2级 2.43 B ② 2级 3.49 C ③ 2级 1.91 D ④ 2级 — E ⑤ 2级 — F ⑥ 2级 — G ⑦ 2级 — H ⑧ 2级 49.4 I ⑨ 2级 23.65 注:—表示应力幅低于修正后的疲劳极限,达到无限寿命. 表 6 缺陷等级对模型疲劳寿命的影响

Table 6. The effect of defect size on fatigue life of models

模型 铸造缺

陷位置铸造缺

陷等级疲劳寿命/

(× 105 周次)J ① 3级 0.55 K ③ 3级 0.68 L ④ 3级 — M ⑨ 3级 2.90 注:—表示应力幅低于修正后的疲劳极限,达到无限寿命. 表 7 缺陷分布对模型疲劳寿命的影响

Table 7. The effect of defect distribution on fatigue life of models

模型 铸造缺

陷位置铸造缺

陷等级疲劳寿命/

(× 105 周次)N ① 2级 0.34 ② 2级 1.64 ③ 2级 1.64 O ① 2级 0.32 ③ 2级 1.64 ④ 2级 — P ② 2级 1.52 ⑧ 2级 — ⑨ 2级 8.67 Q ① 2级 0.36 ② 2级 1.64 ③ 2级 1.64 ⑧ 2级 — ⑨ 2级 8.67 注:—表示应力幅低于修正后的疲劳极限,达到无限寿命. -

劳唯中,周观根,游桂模. 杭州奥体博览中心主体育场铸钢节点关键技术[J]. 施工技术,2015,44(8): 37-40. doi: 10.7672/sgjs2015080037LAO Weizhong, ZHOU Guan’gen, YOU Guimo. The key technology of cast steel joint of Hangzhou olympic and international expo center[J]. Construction Technology, 2015, 44(8): 37-40. doi: 10.7672/sgjs2015080037 隋庆海. 新郑国际机场T2航站楼结构设计与分析[J]. 建筑结构,2015,45(7): 76-80.SUI Qinghai. Design and analysis of Xinzheng international airport T2 terminal[J]. Building Structure, 2015, 45(7): 76-80. SENTA S, NUSSBAUMER A, HIRT M A. Fatigue behavior of cast steel nodes in bridge structures[C]// Proceedings of the 10th International Symposium on Tubular Structures. [S.l.]: Balkema Publishers, 2003: 357-364. HALDIMANN-STURM S C, NUSSBAUMER A. Fatigue design of cast steel nodes in tubular bridge structures[J]. International Journal of Fatigue, 2008, 30(3): 528-537. doi: 10.1016/j.ijfatigue.2007.03.007 NUSSBAUMER A. Defect tolerances of steel castings in bridge structures: project IC 438[R]. Zurich: Swiss Federal Institute of Technology, 2005: 1-3. NUSSBAUMER A, HALDIMANN-STURM S C. Fatigue of bridge joints using welded tubes or cast steel node solution[C]//Proceedings of the 2006 IIW International Conference: Tubular Structures. Quebec City: [s.n.], 2006: 56-63. 陈海洲. 铸钢节点的疲劳性能与设计研究[D]. 上海: 同济大学, 2009. 靳慧,李菁,李爱群. 波浪载荷下海中观光塔铸钢节点疲劳强度验算[J]. 西南交通大学学报,2010,45(5): 692-697. doi: 10.3969/j.issn.0258-2724.2010.05.007JIN Hui, LI Jing, LI Aiqun. Checking calculation of fatigue strength for cast steel joints of offshore tour tower under wave loads[J]. Journal of Southwest Jiaotong University, 2010, 45(5): 692-697. doi: 10.3969/j.issn.0258-2724.2010.05.007 JIN H, LI J, MO J H, et al. Fatigue of girth butt weld for cast steel node connection in tower structure under wave loadings[J]. Structural Design of Tall and Special Buildings, 2014, 23(15): 1119-1140. doi: 10.1002/tal.1111 SHARP J V, MA A. Fatigue design of cast steel nodes in offshore structures based on research data[J]. Ice Proceedings Water Maritime & Energy, 1997, 124(2): 112-126. HARDIN R A, BECKERMANN C. Prediction of the fatigue life of cast steel containing shrinkage porosity[J]. Metallurgical & Materials Transactions A, 2009, 40(3): 581-597. 蔡建国,冯健,顾洪波,等. 大型铸钢节点的工程应用和分析[J]. 钢结构,2008,23(4): 13-17. doi: 10.3969/j.issn.1007-9963.2008.04.004CAI Jianguo, FENG Jian, GU Hongbo, et al. Practical application and analysis of complex cast-steel joint[J]. Steel Construction, 2008, 23(4): 13-17. doi: 10.3969/j.issn.1007-9963.2008.04.004 莫德锋,何国求,胡正飞,等. 孔洞对铸造铝合金疲劳性能的影响[J]. 材料工程,2010(7): 92-96. doi: 10.3969/j.issn.1001-4381.2010.07.020MO Defeng, HE Guoqiu, HU Zhengfei, et al. Effect of porosity on fatigue property in aluminum cast alloys[J]. Journal of Materials Engineering, 2010(7): 92-96. doi: 10.3969/j.issn.1001-4381.2010.07.020 机械工业部沈阳铸造研究所. 铸钢件超声探伤及质量评级标准: GB/T 7233—2009[S]. 北京: 中国标准出版社, 2009. COLLINI L, PIRONDI A. Fatigue crack growth analysis in porous ductile cast iron microstructure[J]. International Journal of Fatigue, 2014, 62(2): 258-265. KUMAR A, VARSHNEY A K, RAM M. Sensitivity analysis for casting process under stochastic modelling[J]. International Journal of Industrial Engineering Computations, 2015, 6(3): 419-432. doi: 10.5267/j.ijiec.2015.2.001 ROBERTS A P, GARBOCZI E J. Elastic properties of model porous ceramics[J]. Journal of the American Ceramic Society, 2000, 83(12): 3041-3048. doi: 10.1111/j.1151-2916.2000.tb01680.x NADOT Y, MENDEZ J, RANGANATHAN N. Influence of casting defects on the fatigue limit of nodular cast iron[J]. International Journal of Fatigue, 2004, 26(3): 311-319. doi: 10.1016/S0142-1123(03)00141-5 郑凯锋,衡俊琳,何小军,等. 厚边U肋正交异性钢桥面板的疲劳性能[J]. 西南交通大学学报,2019,54(4): 694-700.ZHENG Kaifeng, HENG Junlin, HE Xiaojun, et al. Fatigue performance of orthotropic steel decks with thickened edge U-ribs[J]. Journal of Southwest Jiaotong University, 2019, 54(4): 694-700. 刘晓春,金城,余志武,等. CRTSⅢ型板式无砟轨道横向弯曲疲劳试验[J]. 西南交通大学学报,2018,53(1): 23-30. doi: 10.3969/j.issn.0258-2724.2018.01.003LIU Xiaochun, JIN Cheng, YU Zhiwu, et al. Fatigue testing of CRTS Ⅲ ballastless slab track structures under transverse bending[J]. Journal of Southwest Jiaotong University, 2018, 53(1): 23-30. doi: 10.3969/j.issn.0258-2724.2018.01.003 莫建华. 铸钢节点的疲劳力学性能研究[D]. 南京: 东南大学, 2012. 李顺酩. 机械疲劳与可靠性设计[M]. 北京: 科学出版社, 2006: 47-67. 徐灏. 疲劳强度设计[M]. 北京: 机械工业出版社, 1981: 67-105. -

下载:

下载: