Load Characteristics of Anti-rolling Torsion Bar of High-Speed Train

-

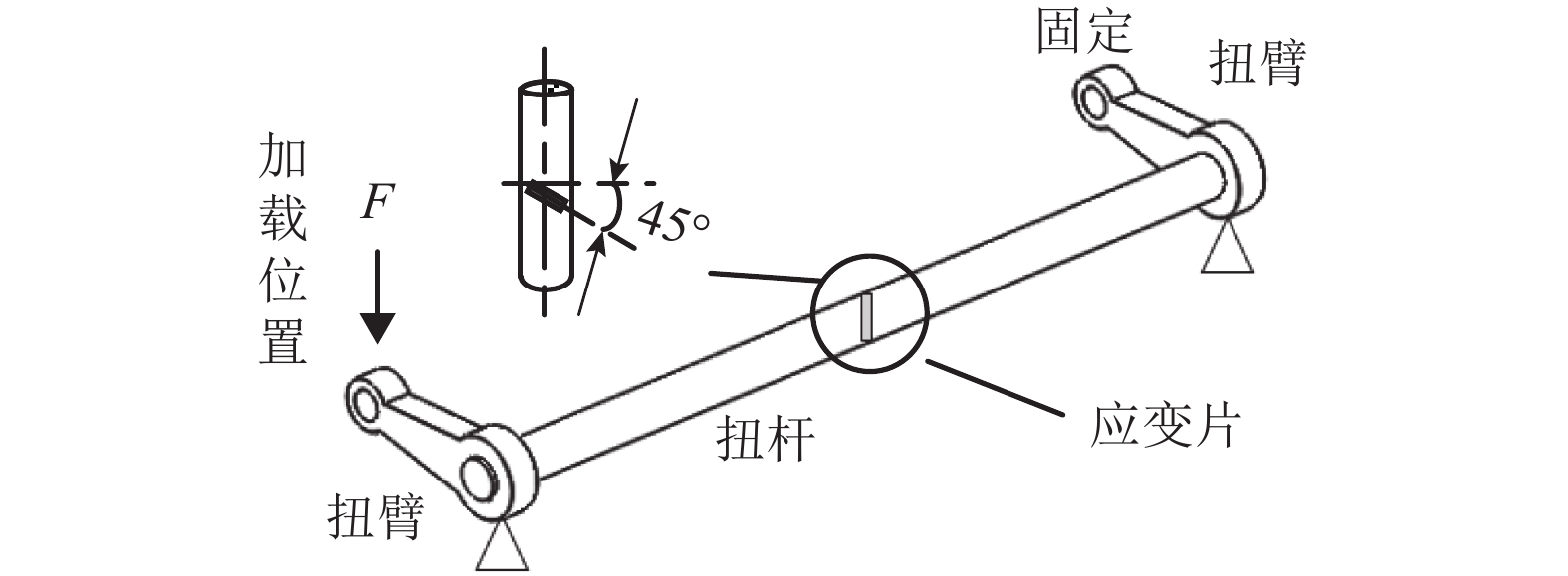

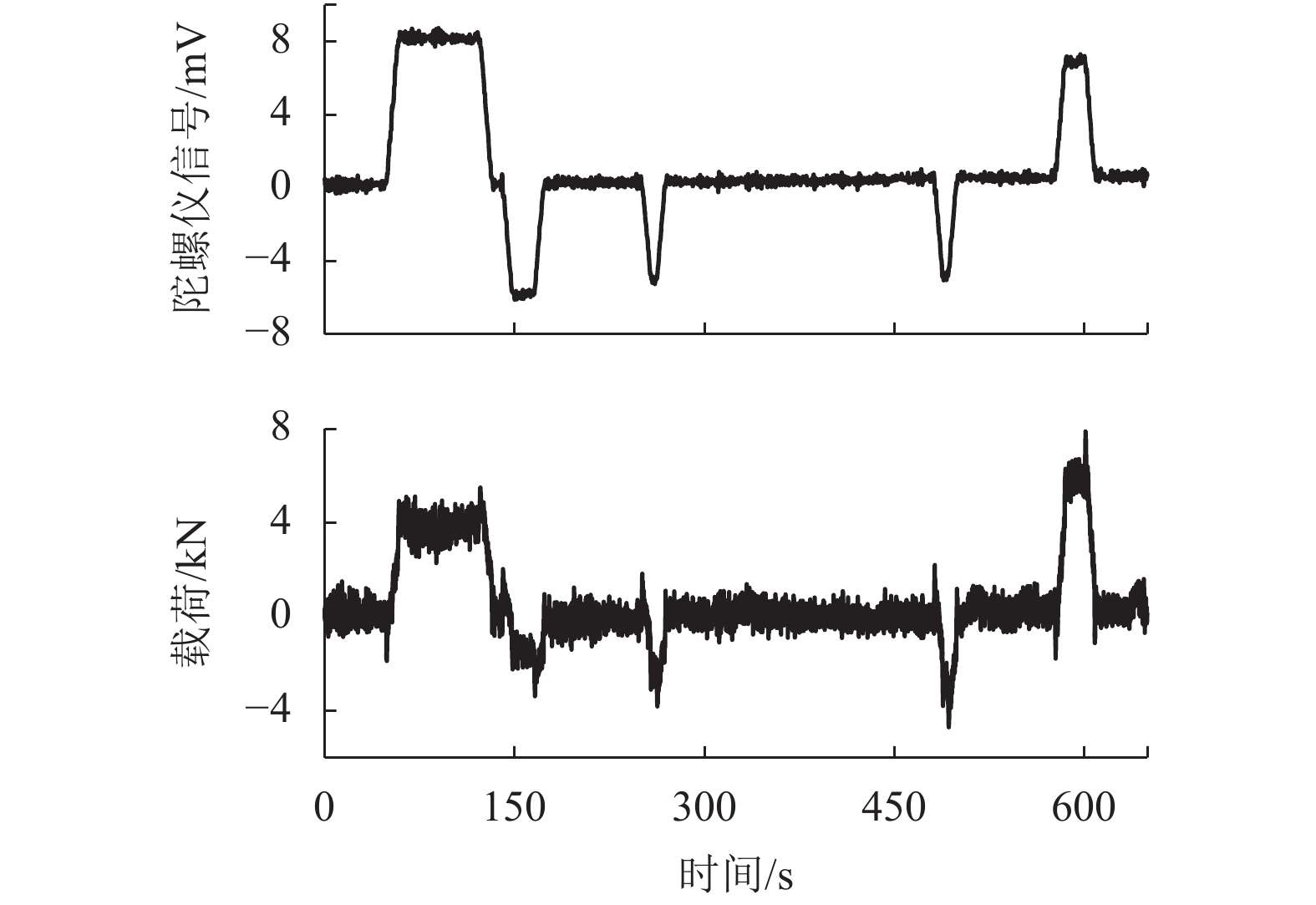

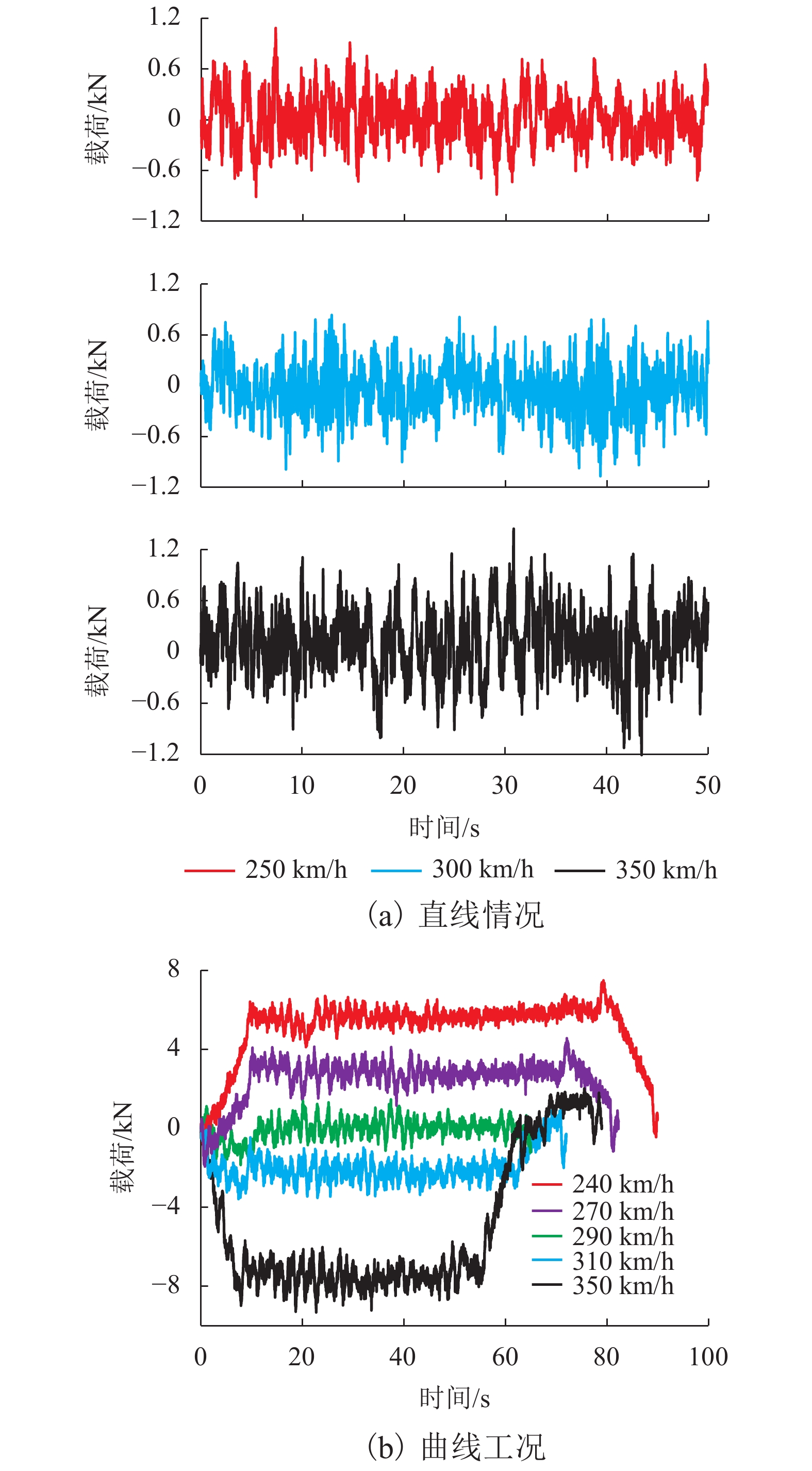

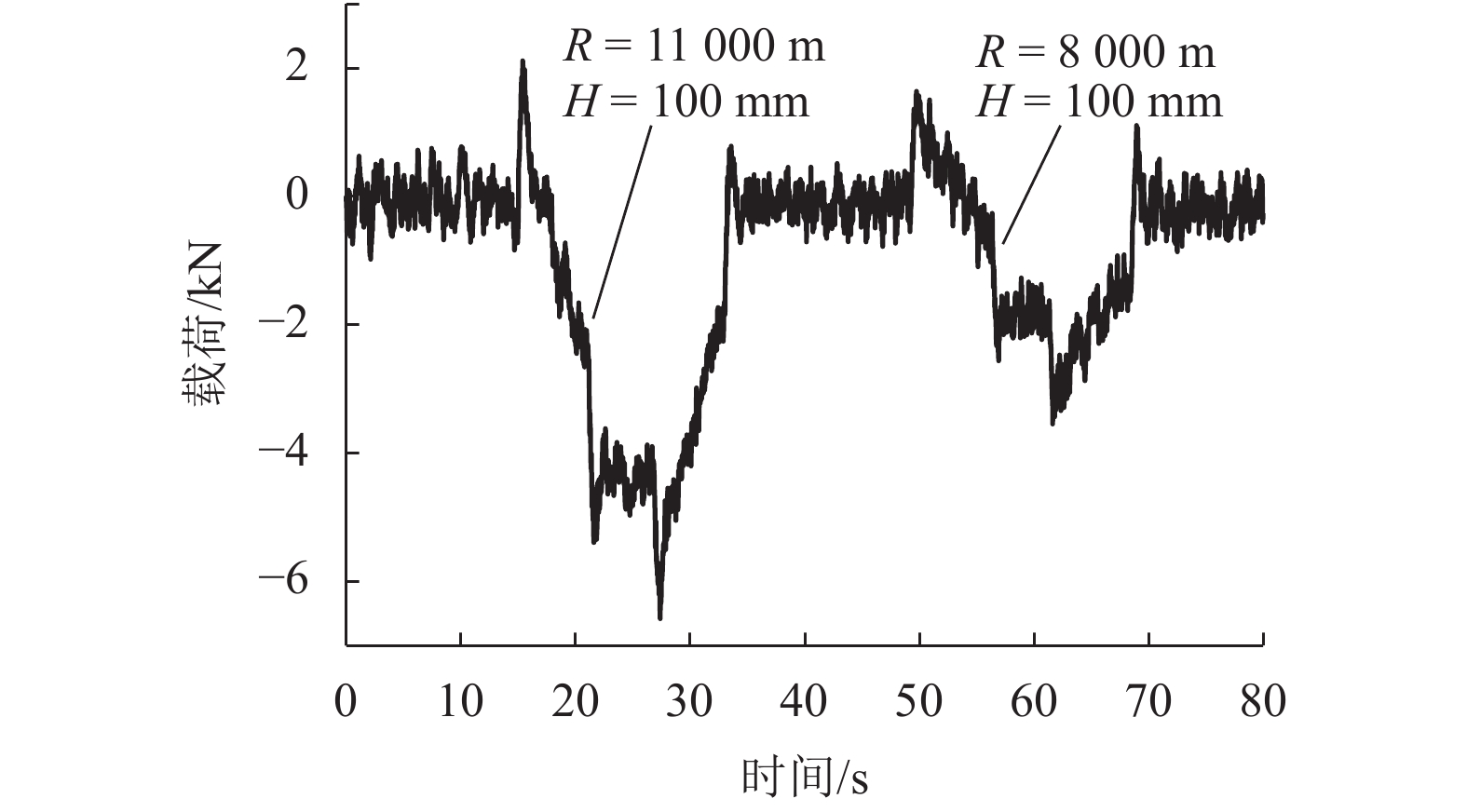

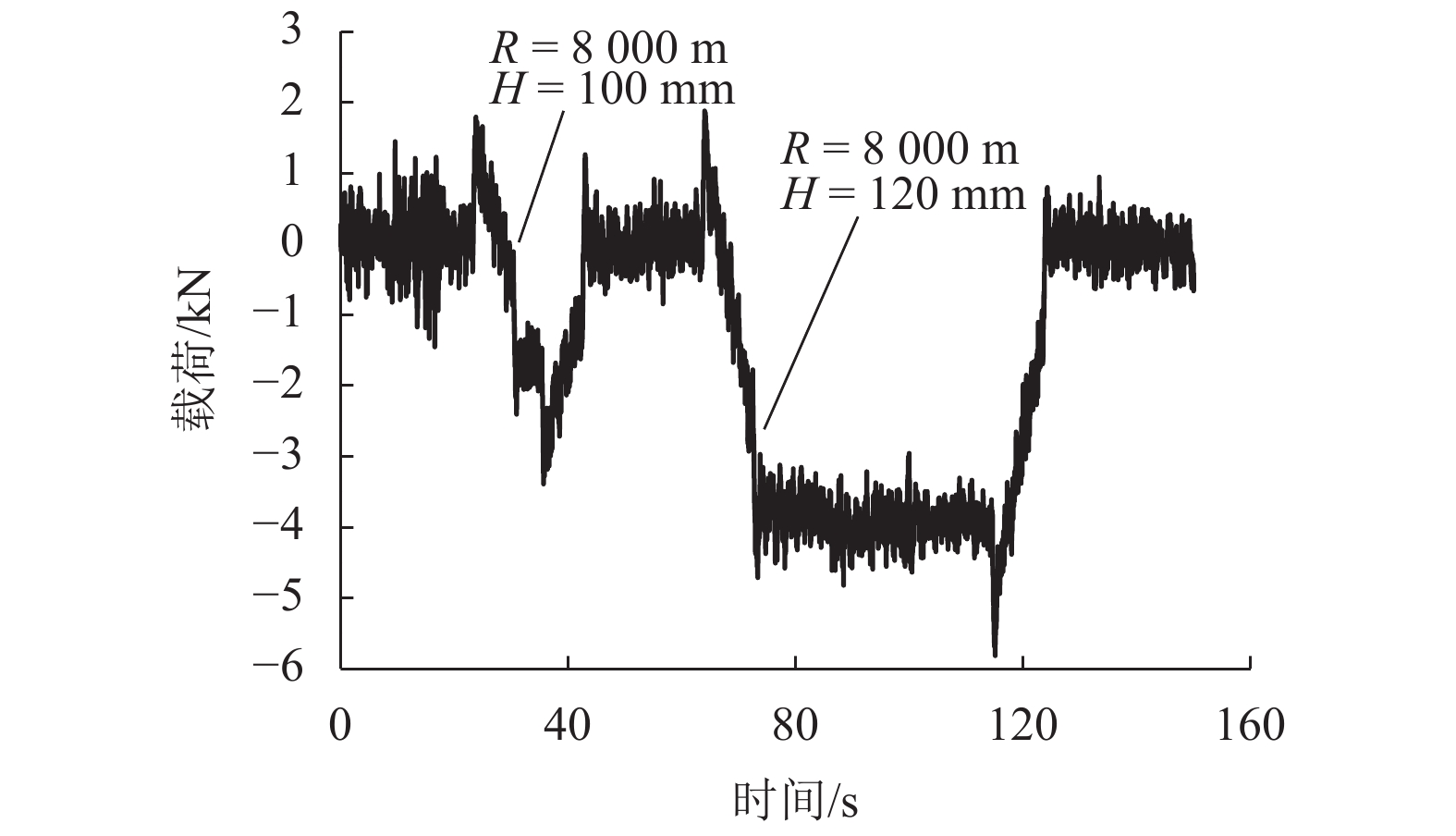

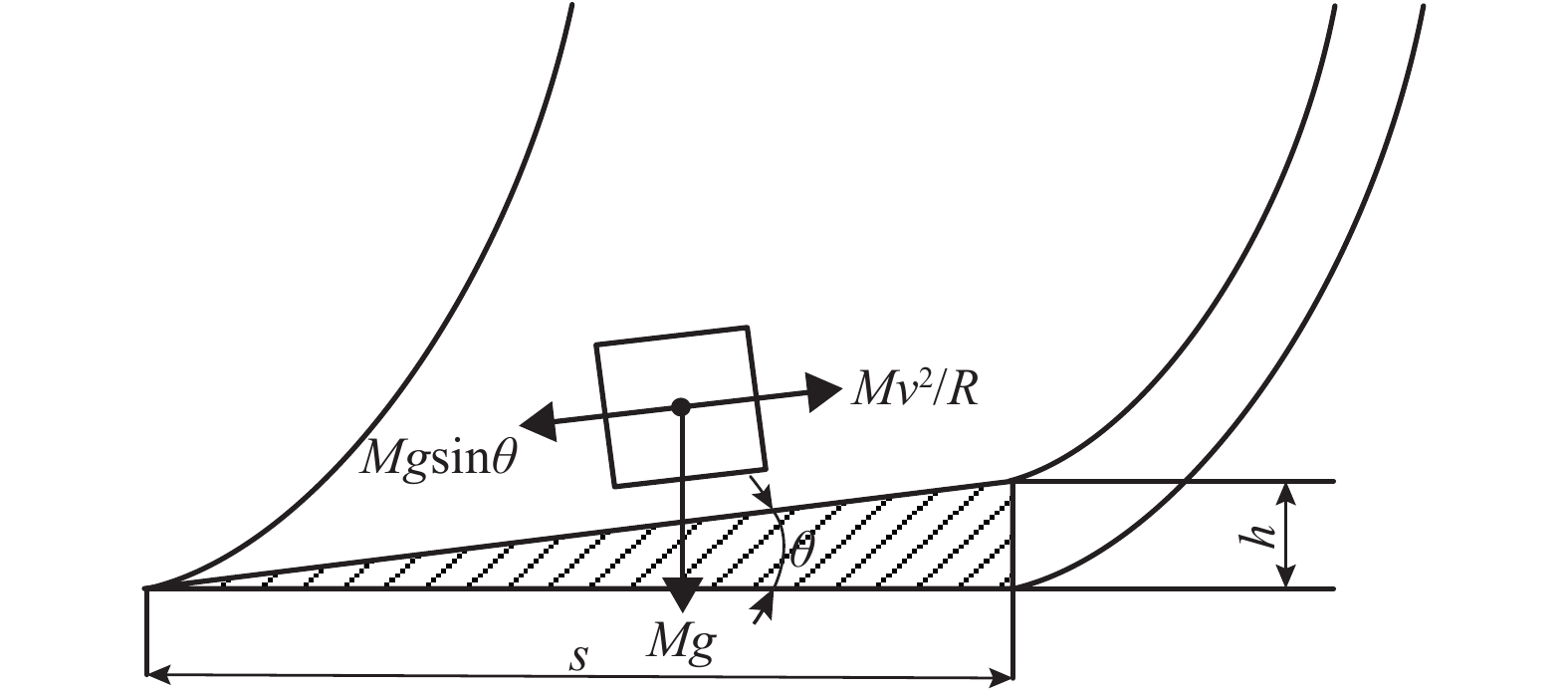

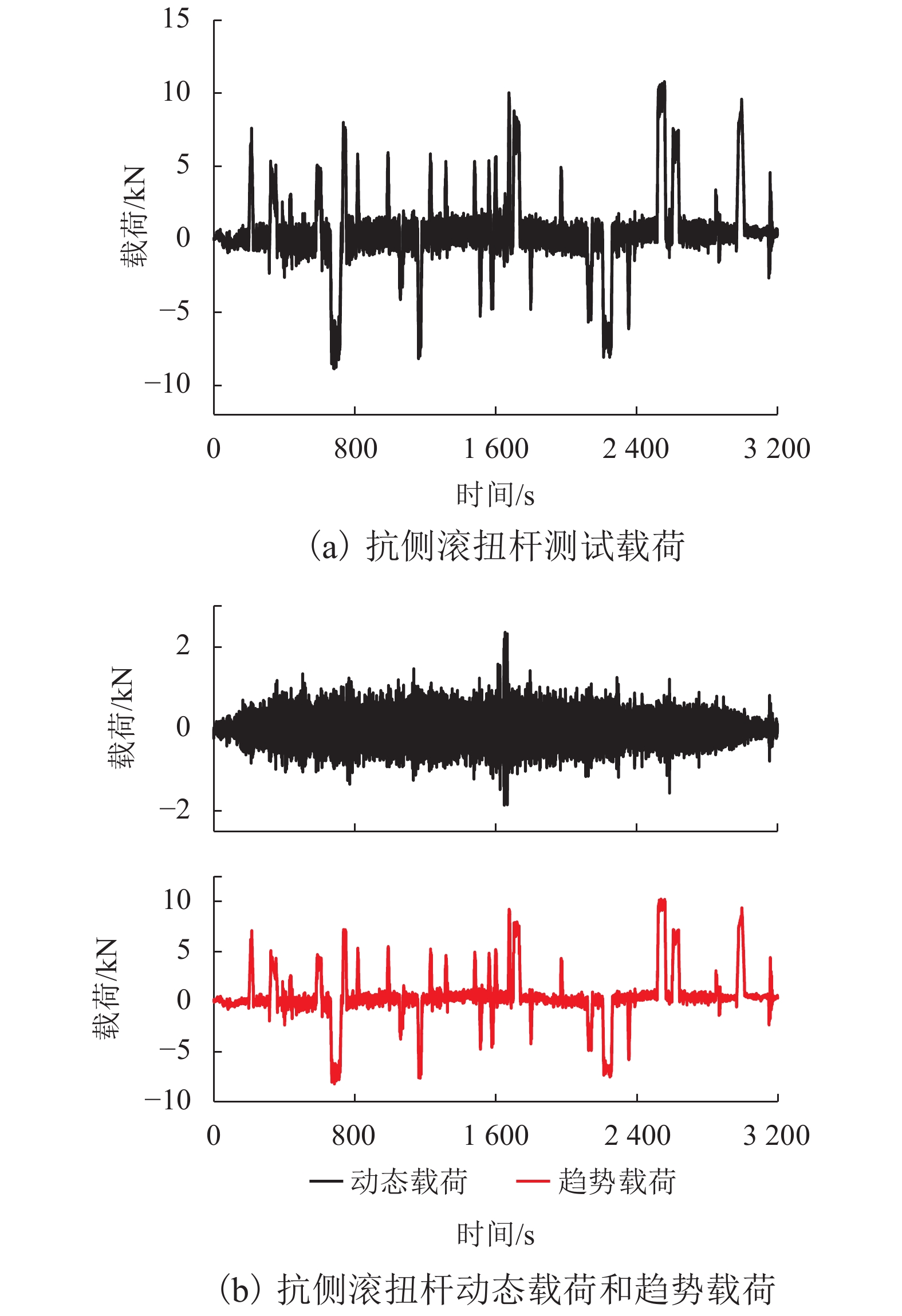

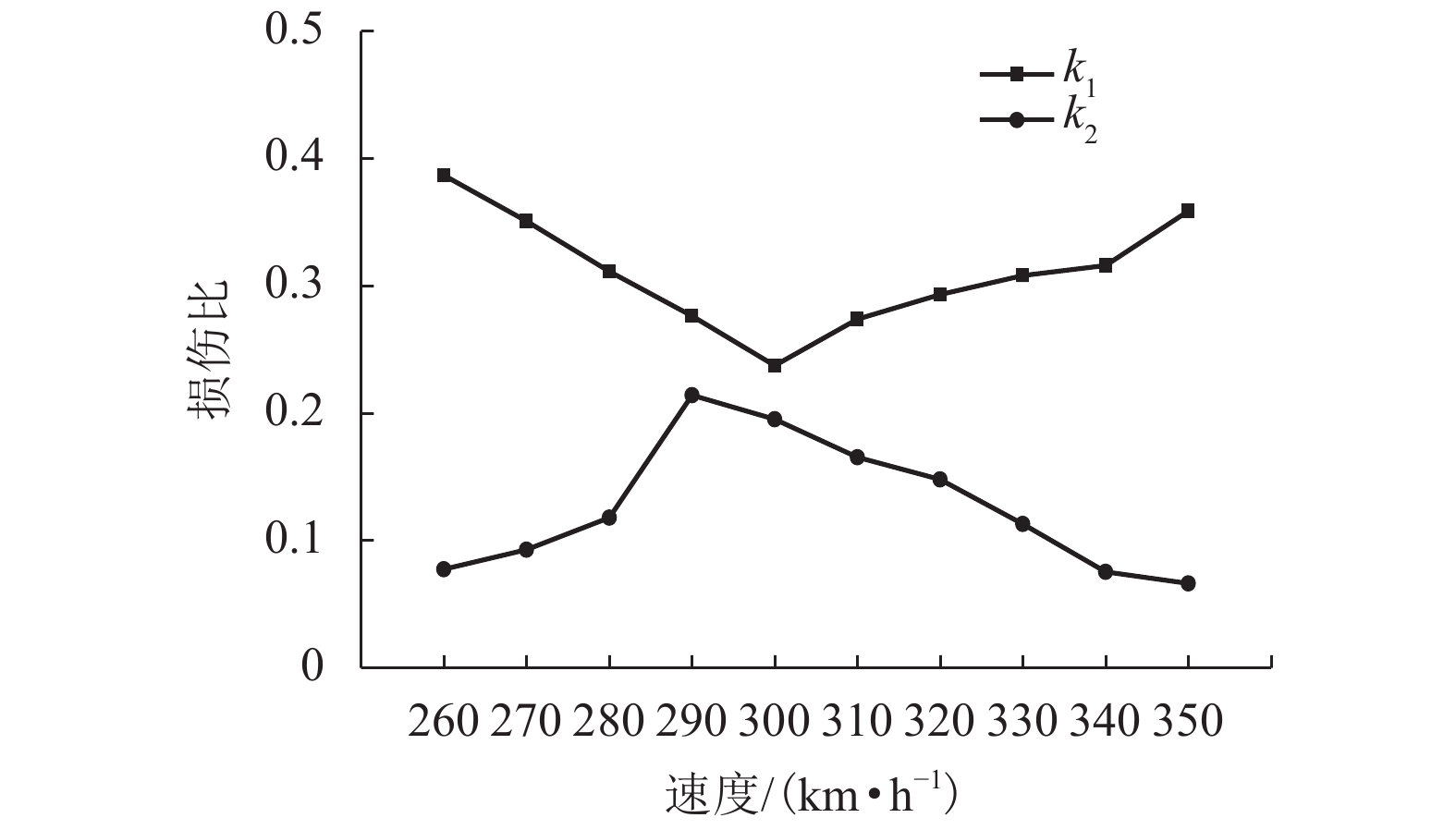

摘要: 为获得抗侧滚扭杆在动车组运行时所受载荷的变化情况,结合陀螺仪和速度信号,研究了抗侧滚扭杆载荷随列车运行速度、曲线半径和曲线超高的变化规律;统计了不同速度级下抗侧滚扭杆载荷最值,并编制测试载荷谱、趋势载荷谱和动态载荷谱,计算趋势载荷与动态载荷在整个测试载荷中贡献的损伤比. 研究结果表明:直线工况下,抗侧滚扭杆动态载荷幅值随列车运行速度的增加而增加,当运行速度由250 km/h增大到350 km/h时,抗侧滚扭杆载荷幅值最大值增大了30%;在一定的过超高条件下,抗侧滚扭杆趋势载荷幅值随曲线半径减小而减小,240 km/h运行速度下最大载荷幅值由6.61 kN减小为3.54 kN;在曲线半径一定的条件下,抗侧滚扭杆趋势载荷幅值随曲线超高的增大而增大,240 km/h运行速度下最大载荷幅值由3.36 kN增大为5.80 kN.Abstract: In order to obtain the load characteristics of the anti-rolling torsion bar during the high-speed train operation, first, the change rules of the load with the train speed, curve radius, and curve superelevation were studied by combining the gyroscope and the speed signal. Second, the maximum loads of the anti-rolling torsion bar at different speed levels were obtained, and the load spectrum, trend load spectrum, and dynamic load spectrum were compiled to calculate the damage ratio of the trend load to dynamic load in the whole test load. The results show that the dynamic load amplitude of the anti-rolling torsion bar increases with the increasing of the train running speed under straight running condition. When the speed increases from 250 km/h to 350 km/h, the maximum load amplitude increases by 30%. At a given surplus superelevation condition, the maximum trend load amplitude of the anti-roll torsion bar decreases with the decreasing of the curve radius, which is from 6.61 kN to 3.54 kN at the operation speed of 240 km/h. For the same curve radius, the trend load amplitude increases with the increasing of the curve superelevation and the maximum load amplitude increases from 3.36 kN to 5.80 kN at the operation speed of 240 km/h.

-

Key words:

- anti-rolling torsion bar /

- trend load /

- dynamic load /

- load spectrum /

- damage

-

表 1 抗侧滚扭杆测试载荷最值

Table 1. Test load values of anti-rolling torsion bar

速度/(km•h−1) 最大值/kN 最小值/kN 幅值/kN 260 9.01 −6.08 7.54 270 9.05 −5.97 7.51 280 8.54 −5.45 6.99 290 7.10 −3.15 5.12 300 9.31 −3.92 6.61 310 8.42 −4.66 6.54 320 8.37 −5.55 6.96 330 8.88 −6.79 7.83 340 9.72 −8.77 9.24 350 10.76 −8.91 9.83 表 2 抗侧滚扭杆载荷谱

Table 2. Load spectrum of anti-rolling torsion bar

级数 测试载荷 趋势载荷 动态载荷 幅值/kN 频次/次 幅值/kN 频次/次 幅值/kN 频次/次 1 0.31 399 400 0.28 22 010 0.08 395 500 2 0.93 1 124 0.84 45 0.23 9 151 3 1.55 101 1.41 3 0.38 3 060 4 2.17 8 1.97 2 0.53 1 478 5 2.79 3 2.53 6 0.68 717 6 3.41 4 3.09 4 0.83 310 7 4.03 5 3.65 1 0.98 136 8 4.66 3 4.22 4 1.13 72 9 5.28 4 4.78 1 1.28 27 10 5.90 0 5.34 1 1.44 16 11 6.52 0 5.90 0 1.59 8 12 7.14 0 6.47 0 1.74 3 13 7.76 0 7.03 1 1.89 1 14 8.38 1 7.59 0 2.04 1 15 9.00 1 8.15 1 2.19 1 16 9.62 1 8.71 1 2.34 1 -

赵双阳. 抗侧滚扭杆轴用弹簧钢材料的性能研究[D]. 株洲: 湖南工业大学, 2013. 梁鑫,罗世辉,马卫华. 抗侧滚扭杆对地铁车辆动力学性能影响的研究[J]. 内燃机车,2011,446(4): 5-12. doi: 10.3969/j.issn.1003-1820.2011.04.002LIANG Xin, LUO Shihui, MA Weihua. Study of the impact on dynamics perform once of metro cars by anti-rolling torsion bar[J]. Diesel Locomotives, 2011, 446(4): 5-12. doi: 10.3969/j.issn.1003-1820.2011.04.002 段华东. 抗侧滚扭杆对轨道车辆抗侧滚性能的影响研究[J]. 电力机车与城轨车辆,2007,30(5): 14-16. doi: 10.3969/j.issn.1672-1187.2007.05.004DUAN Huadong. A study of the impact on anti-roll perform of railway vehicle by anti-roll bar[J]. Electric Locomotives & Mass Transit Vehicles, 2007, 30(5): 14-16. doi: 10.3969/j.issn.1672-1187.2007.05.004 崔志国,邹敏佳,刘文松,等. CRH6型城际动车组抗侧滚扭杆装置的研制[J]. 机车电传动,2013,5: 62-79. doi: 10.3969/j.issn.1000-128X.2013.05.016CUI Zhiguo, ZOU Minjia, LIU Wensong, et al. Research and manufacture of anti-rolling torsion bar equipment for CRH6 inter-city EMUs[J]. Electric Drive for Locomotives, 2013, 5: 62-79. doi: 10.3969/j.issn.1000-128X.2013.05.016 吕士勇,刘文松,程海涛,等. 380 km/h动车组用抗侧滚扭杆系统的研制[J]. 铁道机车车辆,2011,31(6): 16-18.LÜ Shiyong, LIU Wensong, CHENG Haitao, et al. Research and manufacture of anti-roll bar system for a type of 380 km/h EMU[J]. Railway Locomotive & Car, 2011, 31(6): 16-18. 严隽髦. 车辆工程[M]. 3版. 北京: 中国铁道出版社, 2004: 67-68. 刘鸿文. 材料力学[M]. 4版. 北京: 高等教育出版社, 2004: 80-85. 范钦珊, 唐靖林. 材料力学[M]. 3版. 北京: 清华大学出版社, 2015: 59-63. 于洪传. 典型地铁路况特征识别方法研究[D]. 北京: 北京交通大学, 2016. 任尊松. 车辆动力学基础[M]. 北京: 中国铁道出版社, 2009: 19-21. CHENG Junsheng, YU Dejie, YANG Yu. Research on the intrinsic mode function (IMF) criterion in EMD method[J]. Mechanical Systems and Signal Processing, 2006, 20(4): 817-824. doi: 10.1016/j.ymssp.2005.09.011 姜涛,付志翼,王安麟. 一种非平稳随机循环工况下的参数化载荷模型[J]. 东北大学学报(自然科学版),2016,37(6): 845-850. doi: 10.3969/j.issn.1005-3026.2016.06.018JIANG Tao, FU Zhiyi, WANG Anlin. Parameterized load model under non-stationary random cyclic conditions[J]. Journal of Northeastern University (Natural Science), 2016, 37(6): 845-850. doi: 10.3969/j.issn.1005-3026.2016.06.018 SWAMIA, MENDEL J M. ARMA Parameter estimation using only output cumulants[J]. IEEE Transactions on Acoustics Speed & Signal Processing, 1988, 38(7): 193-198. 刘志明. 随机载荷下焊接构架疲劳寿命及可靠性研究[D]. 北京: 北京交通大学, 2001. 周素霞,李福胜,谢基龙,等. 基于损伤容限的动车组车轴实测载荷谱等效应力评价[J]. 机械工程学报,2015,51(8): 131-136.ZHOU Suxia, LI Fusheng, XIE Jilong, et al. Equivalent stress evaluation of the load spectrum measured on the EMU axle based on damage tolerance[J]. Journal of Mechanical Engineering, 2015, 51(8): 131-136. 薛海,李强,胡伟钢,等. 重载货车车钩疲劳试验载荷谱的编制方法[J]. 中国铁道科学,2017,38(2): 106-110.XUE Hai, LI Qiang, HU Weigang, et al. Compilation method for fatigue test load spectrum of coupler on heavy haul freight car[J]. China Railway Science, 2017, 38(2): 106-110. -

下载:

下载: