Axial Compressive Experiment on Steel-Jacket Retrofitted Column with Recycled Aggregate Concrete

-

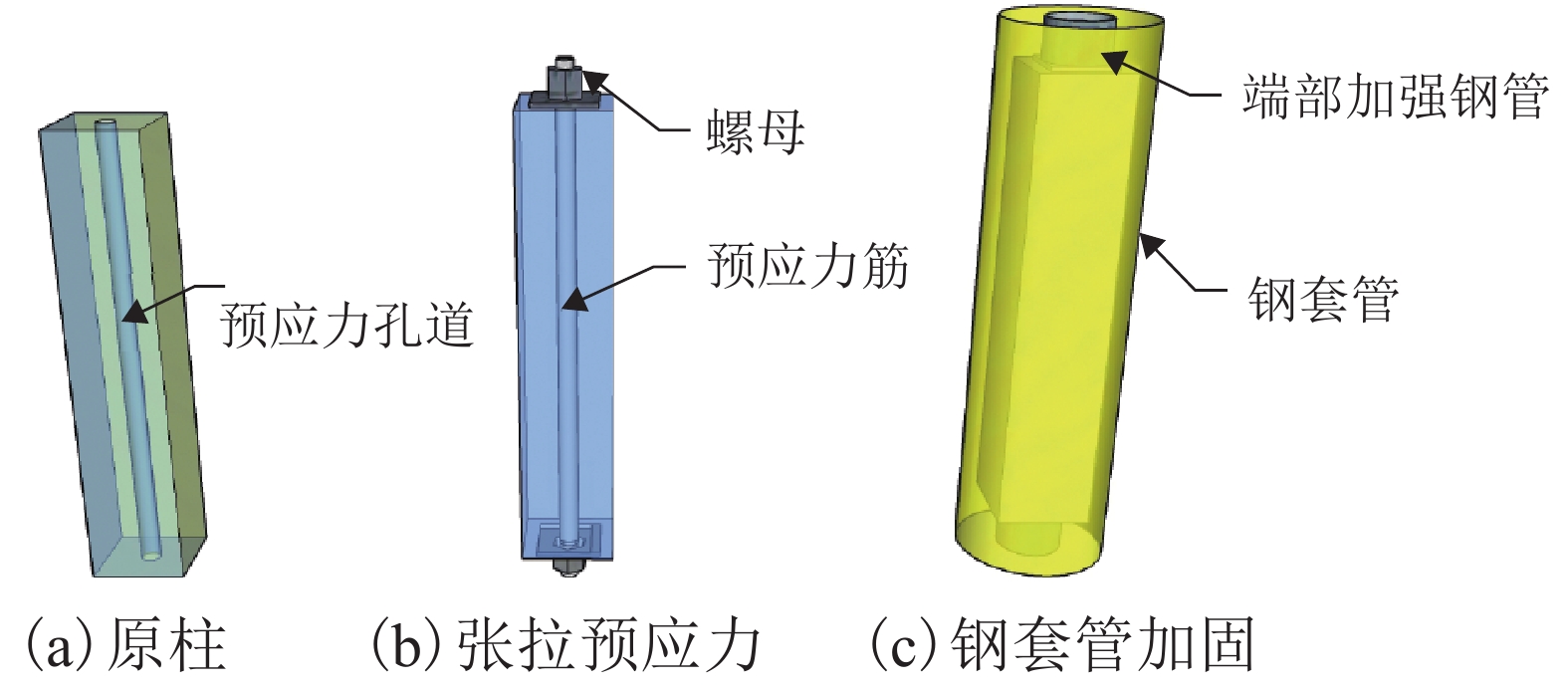

摘要: 为实现建筑业节能减排的目标,提出了钢套管再生混凝土加固柱的新加固方法,对1个未加固柱、12个钢套管再生混凝土加固柱以及2个钢管混凝土柱进行轴压试验,并对试件的承载力和变形特点进行分析,并讨论了该加固柱的承载力计算方法.研究结果表明:加固后试件的承载力提高2.19~3.98倍,且加固柱的刚度、延性均比原柱有明显提高;钢套管再生混凝土加固柱的承载力为钢套管普通混凝土加固柱承载力的91.8%~97.0%;当填充再生混凝土强度由27.0 MPa增加到32.9 MPa时,加固柱的承载力仅提高2.67%;对于再生粗骨料取代率为50%的试件,当钢套管厚度由1.81 mm增加到3.84 mm和5.84 mm时,承载力分别提高了34.0%和77.8%;考虑原柱初始应力后,试件峰值应变减小47.1%~59.3%;钢套管加固柱与钢管混凝土柱具有类似的受力性能.采用不同规范计算试件的承载力,结果表明EC4规范公式的计算精度最高,稳定性最佳.Abstract: To realise the goals of energy saving and emissions reduction in the construction industry, a new retrofitting method of steel-jacket retrofitted columns with recycled aggregate concrete is presented. An unstrengthened column, twelve steel-jacket retrofitted columns, and two concrete-filled steel-tube columns were tested under concentric compressive loading. The axial resistance and deformation capacity were analysed, and the method for calculating the strength of the retrofitted column was evaluated. The experimental results indicated that the strength of the retrofitted columns is 2.19–3.98 times higher than that of the unstrengthened one. In addition, the stiffness and ductility of the steel-jacketed columns increased notably. The strengths of the retrofitted columns with recycled aggregate concrete were 91.8%–97.0% of that of the column with normal infill concrete. As the strength of the infill recycled concrete increased from 27.0 MPa to 32.9 MPa, the strength of the retrofitted column increased by only 2.67%. For specimens with the replacement ratio of recycled coarse aggregate of 50%, the strength of the retrofitted column was enhanced by 34.0% and 77.8% as the thickness of the steel jacket increased from 1.81 mm to 3.84 mm and to 5.84 mm, respectively. After considering the preload of the original column, the strains corresponding to the peak load of the retrofitted column decreased by 47.1%–59.3%. The performance of the steel-jacket retrofitted column was similar to that of the concrete-filled steel-tube columns. Various methods from current design codes were adopted to calculate the axial resistance of the steel-jacket retrofitted column and it was seen that the design code EC4 provides the most accurate and stable predictions.

-

Key words:

- steel jacket /

- recycled aggregate concrete /

- retrofit /

- axial compression test /

- preload

-

表 1 试件参数及试验结果

Table 1. Parameters and experimental results of the specimen

编号 t/mm l/cm η/% Ppre/kN fc1/MPa fc2/MPa Ec/MPa 钢管滑移线 Ps/kN Pu/kN Ps/Pu εb Pu/Pu-A0 A0 — 100 — — 34.2 — — — — 1 512 — — 1.00 A1 3.84 100 0 0 34.2 29.8 29 029 较明显 4 855 4 941 0.98 0.020 0 3.27 A2 3.84 100 25 0 34.2 28.3 27 226 较明显 4 382 4 547 0.96 0.024 8 3.01 A3 3.84 100 50 0 34.2 27.0 26 605 较明显 4 527 4 538 1.00 0.020 2 3.00 A4 3.84 100 75 0 34.2 26.9 25 367 较明显 4 520 4 793 0.94 0.026 7 3.17 A5 3.84 100 100 0 34.2 24.7 17 214 较明显 4 223 4 661 0.91 0.028 8 3.08 A6 3.84 100 50 0 34.2 32.9 26 619 较明显 4 340 4 659 0.93 0.028 5 3.08 A7 3.84 130 25 125 34.2 33.7 28 561 不明显 — 4 682 — 0.010 0 3.10 A8 3.84 130 25 316 34.2 33.7 28 561 不明显 — 4 868 — 0.008 0 3.22 A9 1.81 100 0 0 34.2 30.4 29 029 最明显 3 213 3 309 0.97 0.014 2 2.19 A10 5.84 100 0 0 34.2 30.4 29 029 不明显 — 6 003 — 0.032 0 3.97 A11 1.81 100 50 0 34.2 28.2 26 605 最明显 3 220 3 386 0.95 0.010 8 2.24 A12 5.84 100 50 0 34.2 28.2 26 605 不明显 — 6 021 — 0.029 0 3.98 E1 3.84 100 100 0 — 23.7 — 较明显 4 207 4 217 1.00 0.015 2 2.79 E2 3.84 100 0 0 — 43.6 — 较明显 5 400 5 522 0.98 0.010 2 3.65 表 2 混凝土配合比

Table 2. Mixing proportions of the concrete

试件 设计强度 η/% 水灰比 砂率 水/kg 水泥/kg 砂/kg 天然骨料/kg 再生骨料/kg A1、A9、A10、E2、 C30 0 0.49 0.37 205 422 633 1079 0 A2、A7、A8 C30 25 0.49 0.37 230 422 634 809 270 A3、A11、A12 C30 50 0.49 0.37 256 422 634 540 540 A4 C30 75 0.49 0.37 281 422 634 270 810 A5、E1 C30 100 0.49 0.37 306 422 634 0 1080 A6 C35 50 0.42 0.37 254 484 615 523 523 注:由于搅拌机容量限制,不同批次搅拌的混凝土强度存在差异,各试件的混凝土强度实测值见表1. 表 3 钢材力学性能指标

Table 3. Material properties of the steel

指标 钢筋 Ф6 钢筋 Ф12 预应力

钢筋 Ф32钢管厚度/mm 1.81 3.84 5.84 fy/MPa 375 435 — 432 400 356 fu/MPa 593 654 — 570 550 509 Es/GPa 182.4 150.2 169.5 220.6 183.8 173.4 表 4 各国规范承载力计算结果对比

Table 4. Comparisons of the results predicted by design codes

数据

来源试件

编号套箍

系数ξ试验

结果Pu/kNJCJ01—89 CECS28—2012 Eurocode 4 AIJ-CFT ANSI/AISC 文献[9]公式 Pcal

/kNPcal

/PuPcal

/kNPcal

/PuPcal

/kNPcal

/PuPcal

/kNPcal

/PuPcal

/kNPcal

/PuPcal

/kNPcal

/Pu本文 A1 0.809 4 941 5 042 1.020 5 446 1.102 4 651 0.941 3 994 0.808 3 601 0.729 5 646 1.143 A2 0.835 4 623 5 080 1.099 5 528 1.196 4 679 1.012 4 000 0.865 3 606 0.780 5 744 1.242 A3 0.836 4 537 4 991 1.100 5 369 1.183 4 594 1.013 3 962 0.873 3 540 0.780 5 620 1.239 A4 0.853 4 793 4 861 1.014 5 279 1.101 4 479 0.934 3 837 0.801 3 463 0.723 5 403 1.127 A5 0.818 4 738 4 879 1.030 5 064 1.069 4 485 0.947 3 971 0.838 3 449 0.728 5 478 1.156 A6 0.780 4 660 5 088 1.092 5 513 1.183 4 705 1.010 4 024 0.864 3 662 0.786 5 658 1.214 A7 0.772 4 682 5 119 1.093 5 546 1.185 4 736 1.012 4 050 0.865 3 689 0.788 5 694 1.216 A8 0.772 4 868 5 056 1.039 5 472 1.124 4 681 0.962 4 005 0.823 3 652 0.750 5 588 1.148 A9 0.405 3 310 3 653 1.104 3 905 1.180 3 490 1.054 2 986 0.902 2 826 0.854 3 492 1.055 A10 1.115 6 003 5 881 0.980 6 534 1.088 5 496 0.916 4 731 0.788 4 138 0.689 7 383 1.230 A11 0.419 3 387 3 618 1.068 3 872 1.143 3 445 1.017 2 949 0.871 2 780 0.821 3 466 1.023 A12 1.151 6 021 5 919 0.983 6 600 1.096 5 529 0.918 4 758 0.790 4 141 0.688 7 527 1.250 文献[9] BZ2 0.292 2 990 3 488 1.167 3 553 1.188 3 409 1.140 2 780 0.930 2 804 0.938 3 411 1.141 BZ3 0.402 3 820 3 892 1.019 4 007 1.049 3 761 0.985 3 055 0.800 3 032 0.794 4 046 1.059 BZ4 0.515 4 180 4 313 1.032 4 477 1.071 4 114 0.984 3 328 0.796 3 266 0.781 4 640 1.110 BZ5 0.566 4 460 4 484 1.005 4 684 1.050 4 277 0.959 3 460 0.776 3 370 0.756 4 970 1.114 CZ1 0.329 2 780 2 920 1.050 2 978 1.071 2 847 1.024 2 257 0.812 2 324 0.836 2 851 1.026 CZ2 0.658 3 678 3 891 1.058 4 057 1.103 3 672 0.998 3 005 0.817 2 862 0.778 4 222 1.148 CZ3 0.329 3 030 2 920 0.964 2 978 0.983 2 847 0.940 2 257 0.745 2 324 0.767 2 851 0.941 DZ1 0.592 4 290 4 325 1.008 4 521 1.054 4 121 0.961 3 334 0.777 3 235 0.754 4 802 1.119 DZ2 0.592 4 230 4 325 1.022 4 521 1.069 4 121 0.974 3 334 0.788 3 235 0.765 4 802 1.135 文献[10] TZ3-C50 0.682 3 029 2 751 0.908 2 935 0.969 2 590 0.855 1 973 0.651 1 989 0.657 3 212 1.061 TZ2-C50 0.407 2 265 2 308 1.019 2 381 1.051 2 181 0.963 1 782 0.787 1 726 0.762 2 360 1.042 TZ4-C50 0.804 3 274 2 921 0.892 3 169 0.968 2 763 0.844 2 270 0.693 2 100 0.641 3 604 1.101 TZ3-C40 0.764 2 768 2 628 0.949 2 812 1.016 2 494 0.901 1 869 0.675 1 885 0.681 3 090 1.116 TZ3-C60 0.621 2 914 2 862 0.982 3 046 1.045 2 684 0.921 2 067 0.709 2 083 0.715 3 323 1.140 平均值 1.027 1.090 0.988 0.802 0.759 1.127 标准差 0.062 0.068 0.047 0.068 0.064 0.077 -

梁坦, 王宏业, 吴善能, 等. 混凝土结构加固设计规范: GB50367—2013[S]. 北京:中国建筑工业出版社, 2014 潘毅,杨成,林拥军,等. 基于BP神经网络的FRP加固混凝土柱承载力预测[J]. 西南交通大学学报,2008,43(6): 736-739PAN Yi, YANG Cheng, LIN Yongjun, et al. BP neural network-based prediction of load-bearing capacity of concrete column reinforced by FRP[J]. Journal of Southwest Jiaotong University, 2008, 43(6): 736-739 蒲黔辉,勾红叶,张君华. 城市立交桥牛腿开裂及加固的模型试验[J]. 西南交通大学学报,2008,43(5): 648-653PU Qianhui, GOU Hongye, ZHANG Junhu. Model test of corbel cracking and reinforcement of urban overpass[J]. Journal of Southwest Jiaotong University, 2008, 43(5): 648-653 单成林. 粘贴钢板加固RC梁受弯裂缝宽度计算方法[J]. 西南交通大学学报,2010,45(4): 508-513SHAN Chenglin. Calculation method of bending crack width in RC beams strengthened by bonding steel plate[J]. Journal of Southwest Jiaotong University, 2010, 45(4): 508-513 CHAI Y H, PRIESTLEY M J N, SEIBLE F. Seismic retrofit of circular bridge columns for enhanced flexural performance[J]. ACI Structural Journal, 1991, 88(5): 572-584 PRIESTLEY M J N, SEIBLE F, XIAO Y, et al. Steel jacket retrofitting of reinforced concrete bridge columns for enhanced shear strength-part 1:theoretical considerations and test design[J]. Structural Journal, 1994, 91(4): 394-405 XIAO Y, WU H. Retrofit of reinforced concrete columns using partially stiffened steel jackets[J]. Journal of Structural Engineering, 2003, 129(6): 725-732 蔡健,徐进. 圆形钢套管加固混凝土中长柱轴压承载力研究[J]. 铁道科学与工程学报,2005,2(4): 62-67CAI Jian, XU Jin. Research on bearing capacity of reinforced concrete column strengthened by circular steel jacketing subjected to axial loads[J]. Journal of Railway Science And Engineering, 2005, 2(4): 62-67 徐进,蔡健. 圆形钢套管加固方形混凝土柱轴心受压性能[J]. 东南大学学报(自然科学版),2006,36(4): 580-584XU Jin, CAI Jian. Behaviour of square reinforced concrete column strengthened by circular steel jacket under axial loading[J]. Journal of Southeast University (Natural Science Edition), 2006, 36(4): 580-584 卢亦焱,龚田牛,张学朋,等. 外套钢管自密实混凝土加固钢筋混凝土圆形截面短柱轴压性能试验研究[J]. 建筑结构学报,2013,34(6): 121-128LU Yiyan, GONG Tianniu, ZHANG Xuepeng, et al. Experimental research on behavior of circular RC column strengthened with self-compacting concrete filled circular steel jacket under axial loading[J]. Journal of Building Structures, 2013, 34(6): 121-128 卢亦焱,梁鸿骏,李杉,等. 方钢管自密实混凝土加固钢筋混凝土方形截面短柱轴压性能试验研究[J]. 建筑结构学报,2015,36(7): 43-50LU Yiyan, LIANG Hongjun, LI Shan, et al. Experimental study on behavior of square RC columns strengthened with self-compacting concrete filled square steel tubes under axial load[J]. Journal of Building Structures, 2015, 36(7): 43-50 AJDUKIEWICZ A, KLISZCZEWICZ A. Influence of recycled aggregates on mechanical properties of HS/HPC[J]. Cement & Concrete Composites, 2002, 24(2): 269-279 YANG Y F, HAN L H. Experimental behaviour of recycled aggregate concrete filled steel tubular columns[J]. Journal of Constructional Steel Research, 2006, 62(12): 1310-1324 吴波,刘伟,刘琼祥,等. 薄壁钢管再生混合短柱轴压性能试验研究[J]. 建筑结构学报,2012,33(9): 22-28WU Bo, LIU Wei, LIU Qiongxiang, et al. Axial behavior of thin-walled steel stub columns filled with demolished concrete segment/lump[J]. Journal of Building Structures, 2012, 33(9): 22-28 XIAO J, HUANG J, YANG J, et al. Mechanical properties of confined recycled aggregate concrete under axial compression[J]. Construction & Building Materials, 2012, 26(1): 291-295 WANG Y, CHEN J, GENG Y. Testing and analysis of axially loaded normal-strength recycled aggregate concrete filled steel tubular stub columns[J]. Engineering Structures, 2015, 86(5): 192-212 汤关祚, 沈希明, 招炳泉, 等. 钢管混凝土结构设计与施工规程: JCJ 01-89[S]. 上海: 同济大学出版社, 1989 王玉银, 肖从真. 钢管混凝土结构设计与施工规程: CECS 28—2012[S]. 北京: 中国计划出版社, 2012 European Committee for Standardization. Design of steel and concrete structures. part11: general rules and rules for building: Eurocode 4(EC4)[S]. Brussels: European Committee for Standardization, 2004 马欣伯,张素梅,孙玉平. 日本AIJ关于圆钢管混凝土构件承载力设计方法介绍[J]. 工业建筑,2004,34(2): 69-74MA Xinbo, ZHANG Sumei, SUN Yuping. Introduction to AIJ method of load-carrying capacity of concrete-filled circular steel tubes[J]. Industrial Construction, 2004, 34(2): 69-74 ANSI/AISC. Specification for structural steel buildings: 360-05[S]. Chicago: American Institute of Steel Construction, 2005 -

下载:

下载: