Optimized Design of New Coupling Mechanism for Electric Vehicles

-

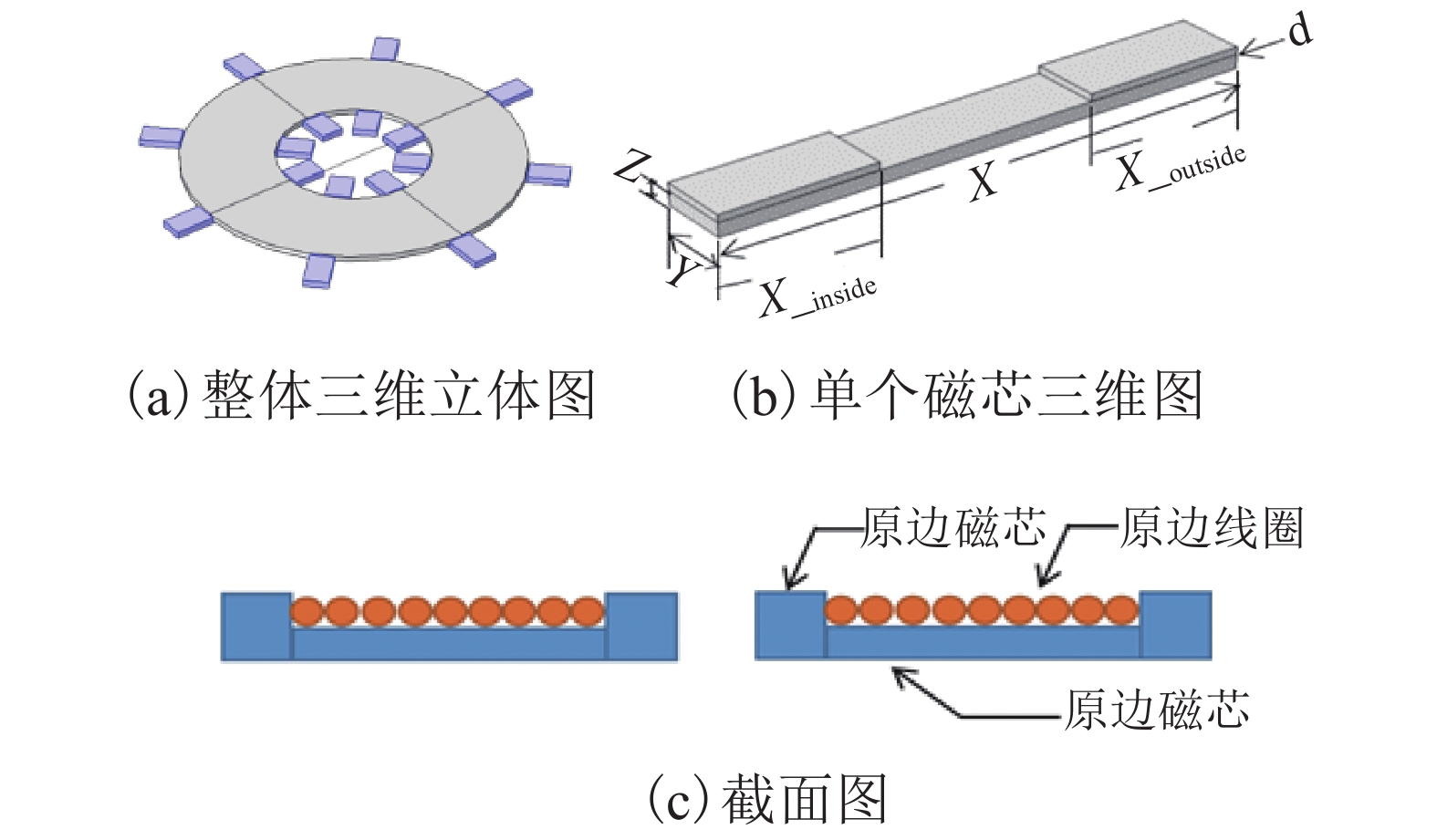

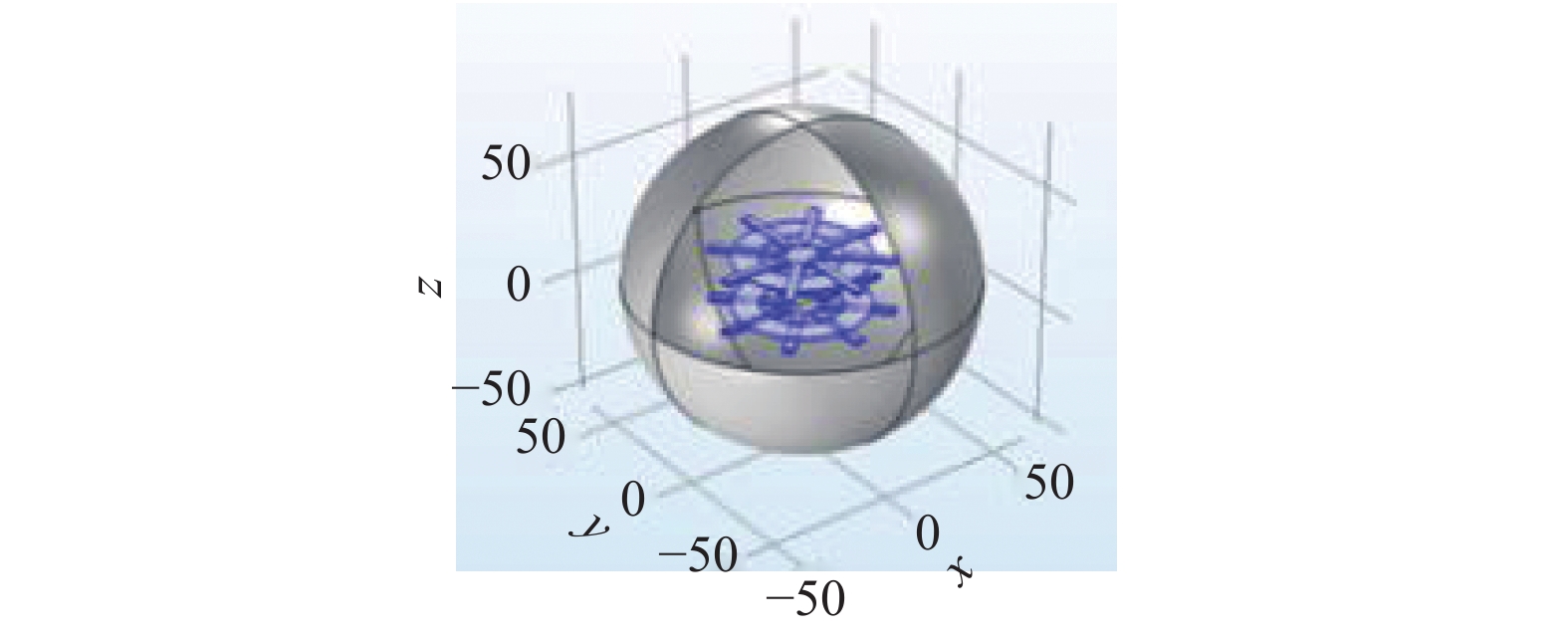

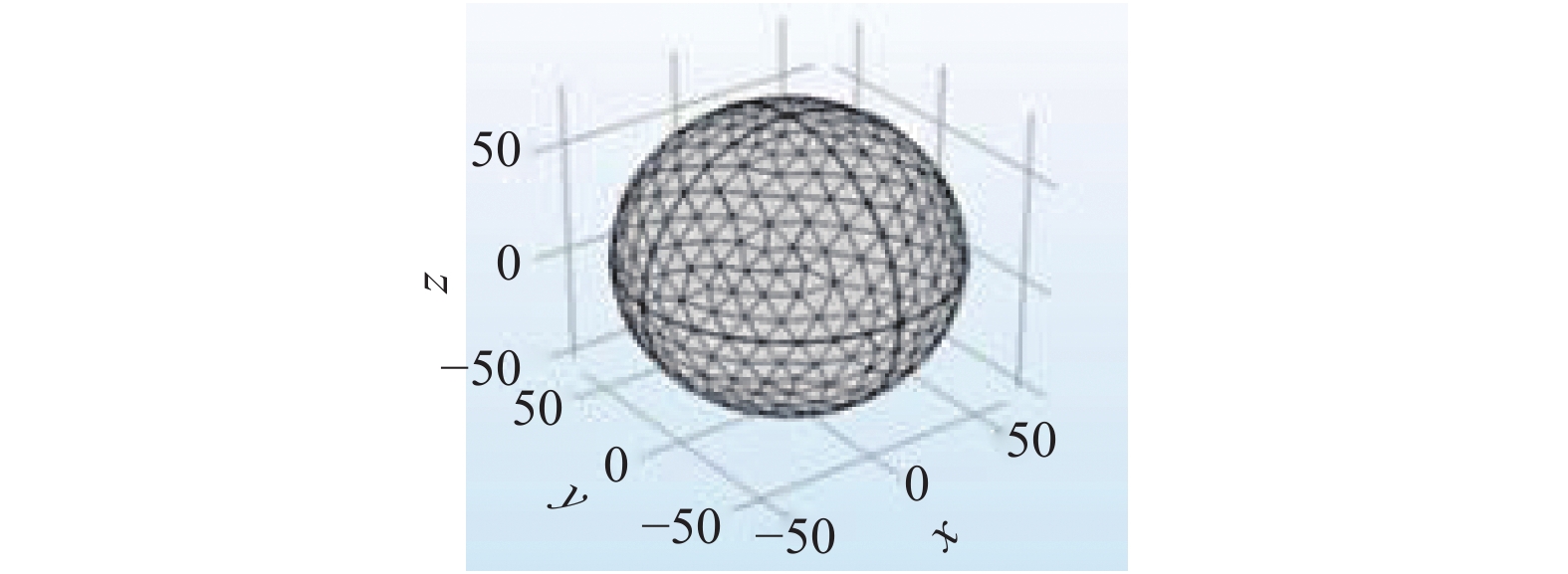

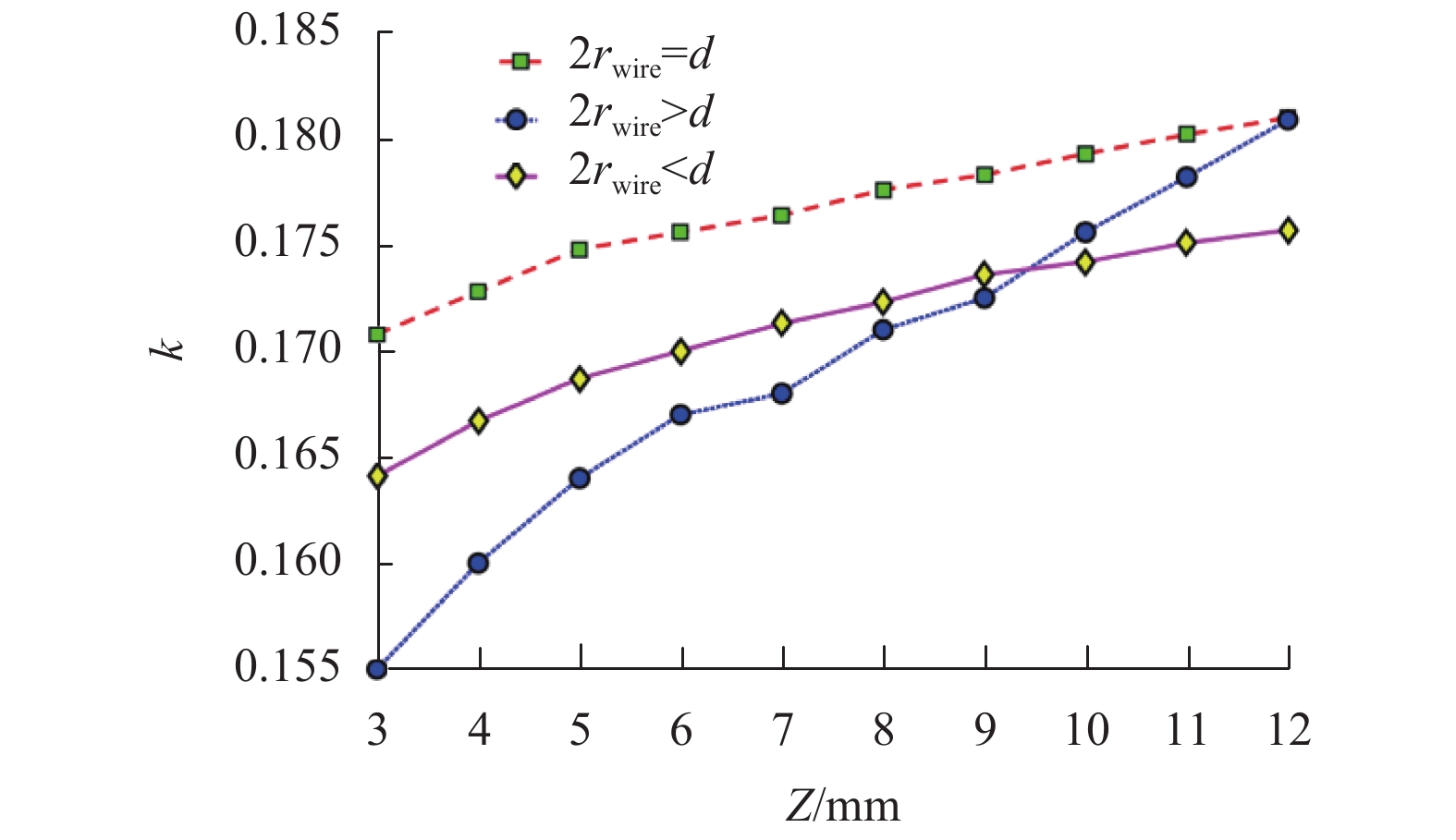

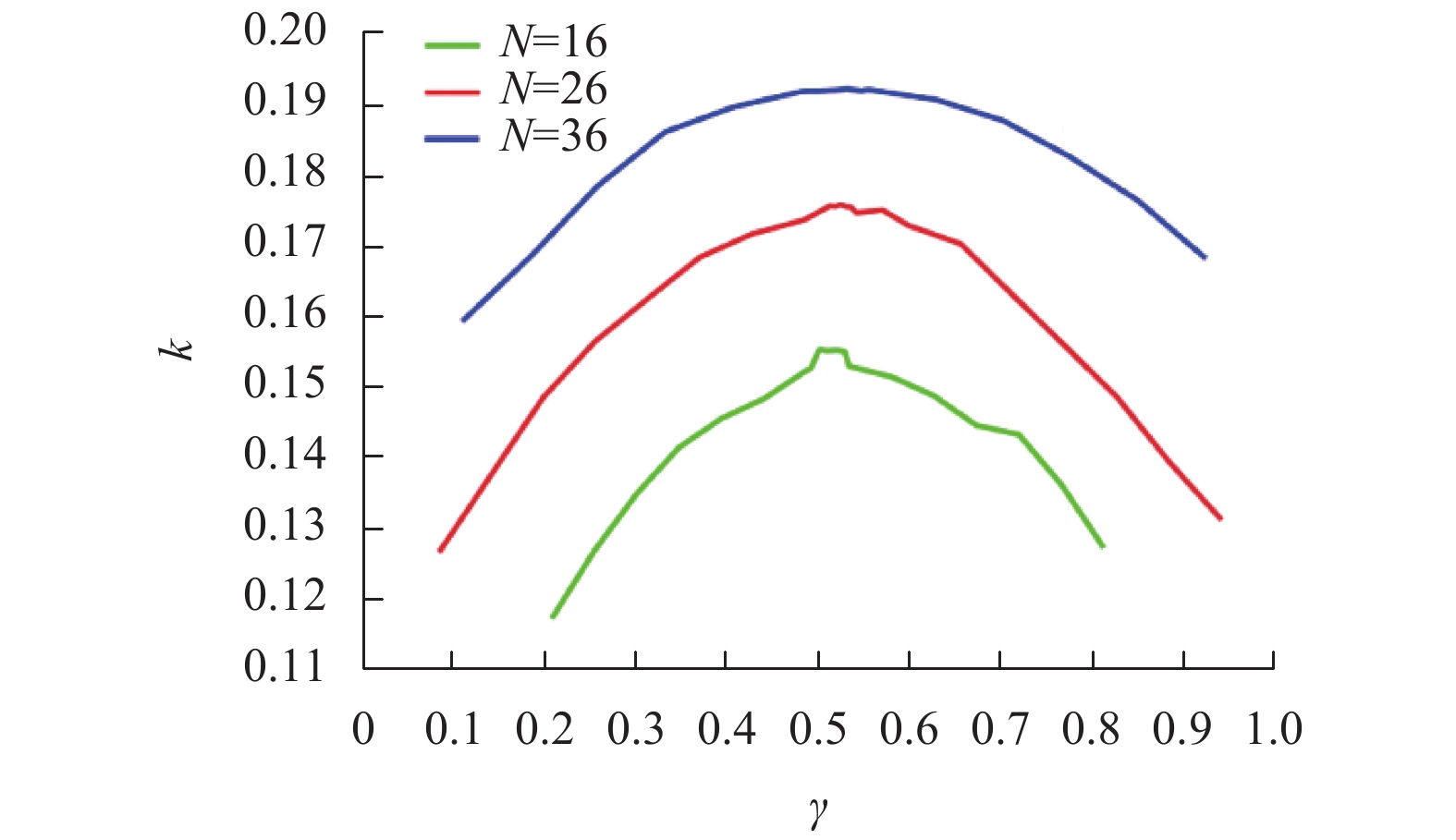

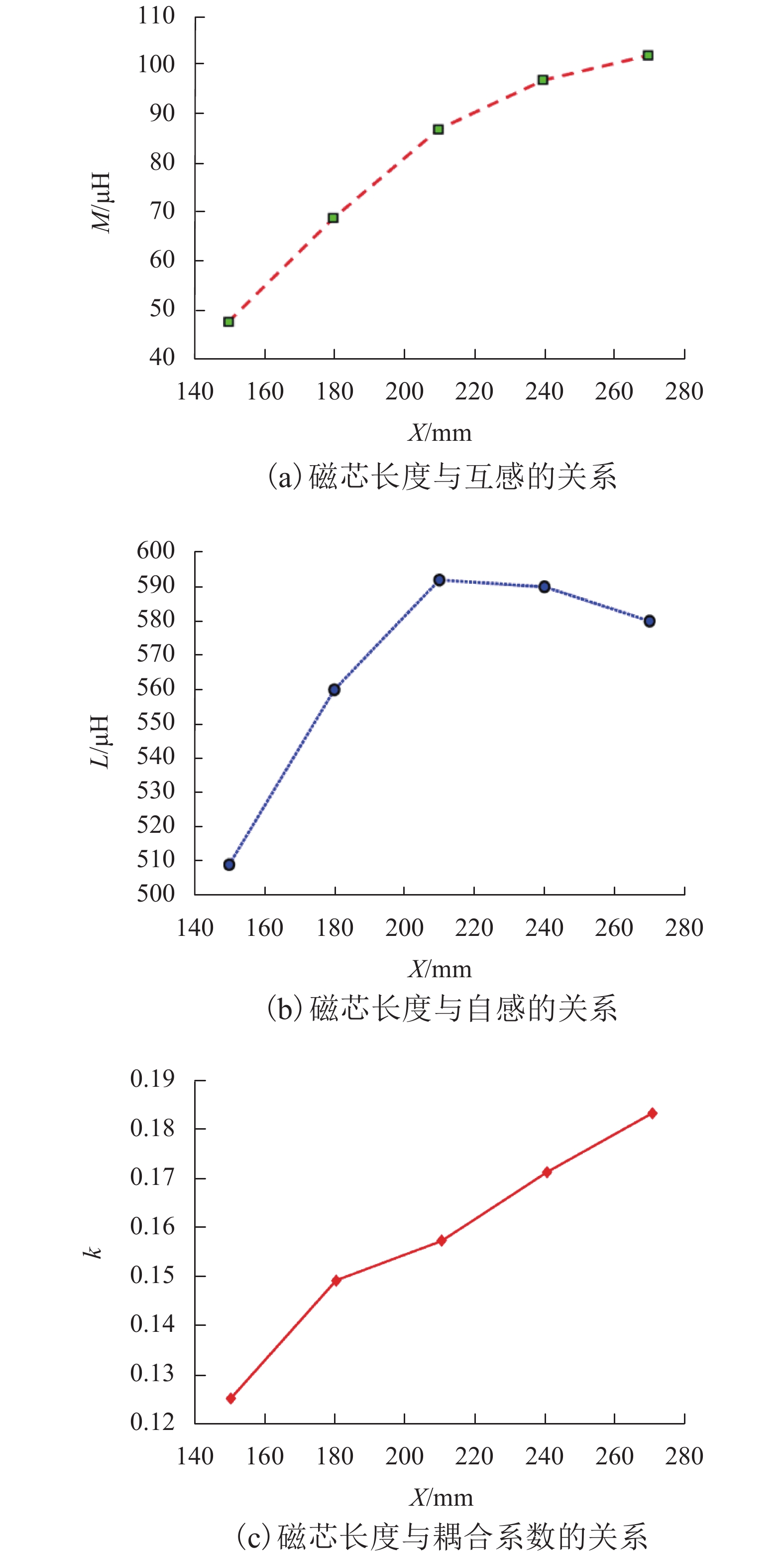

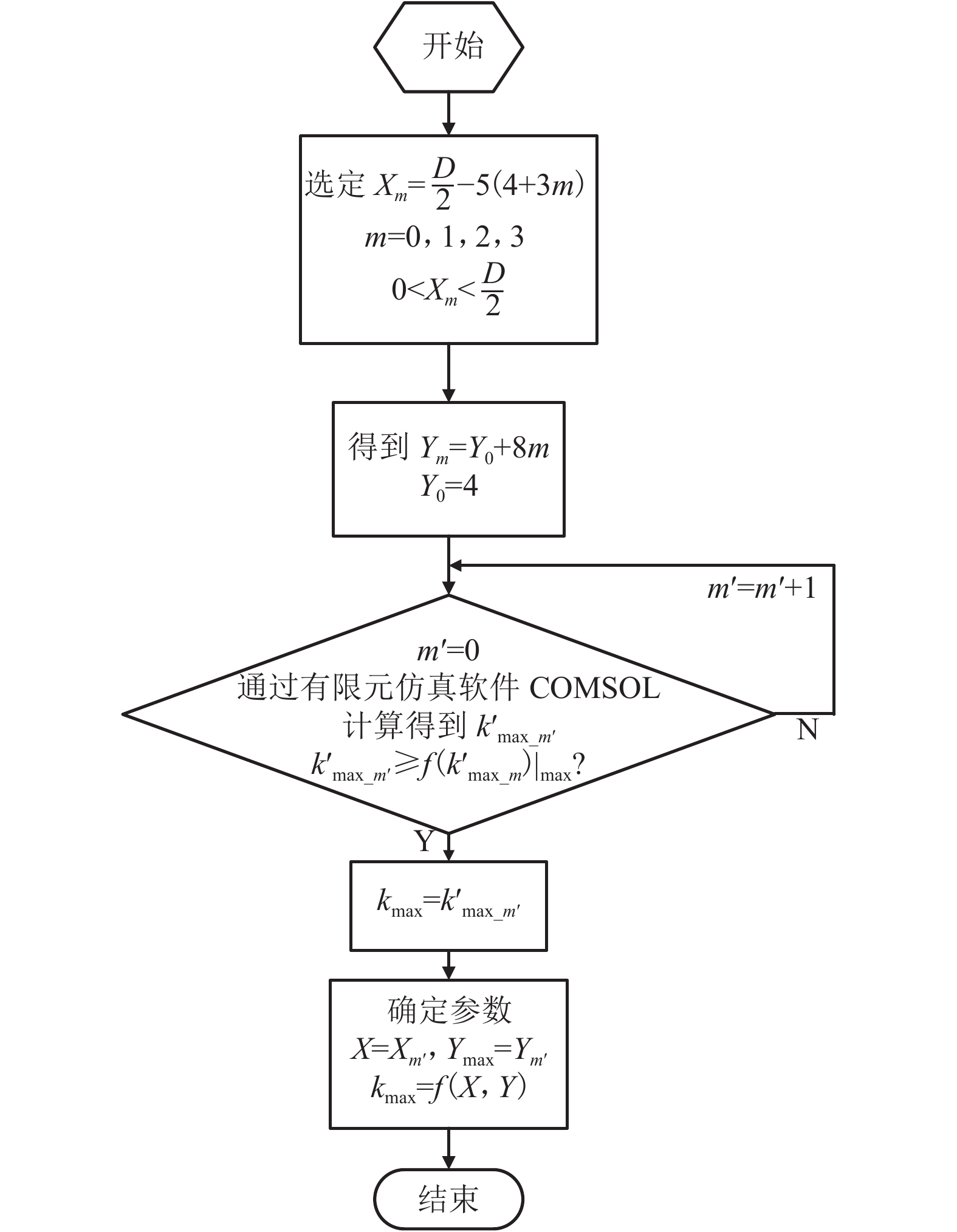

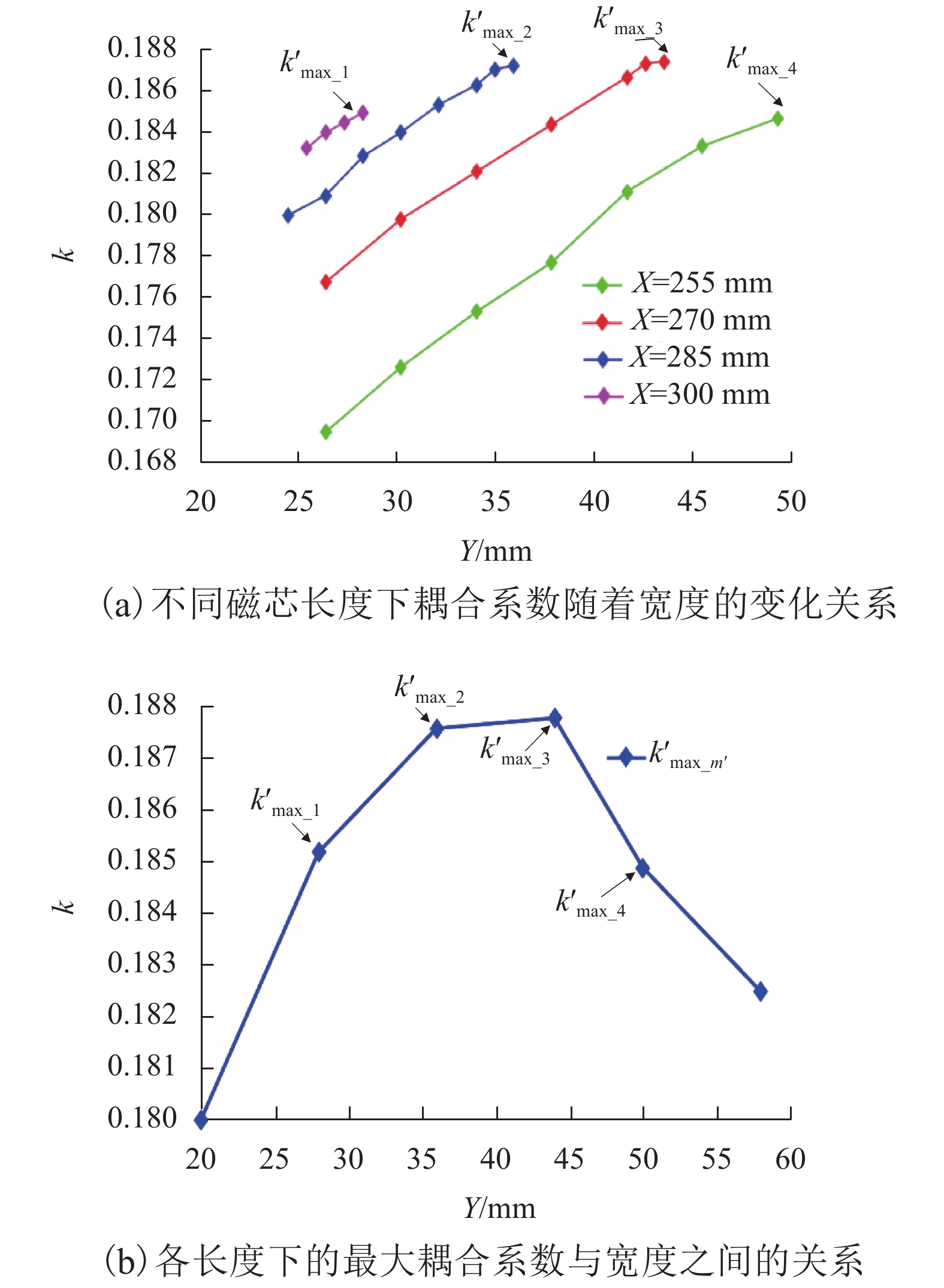

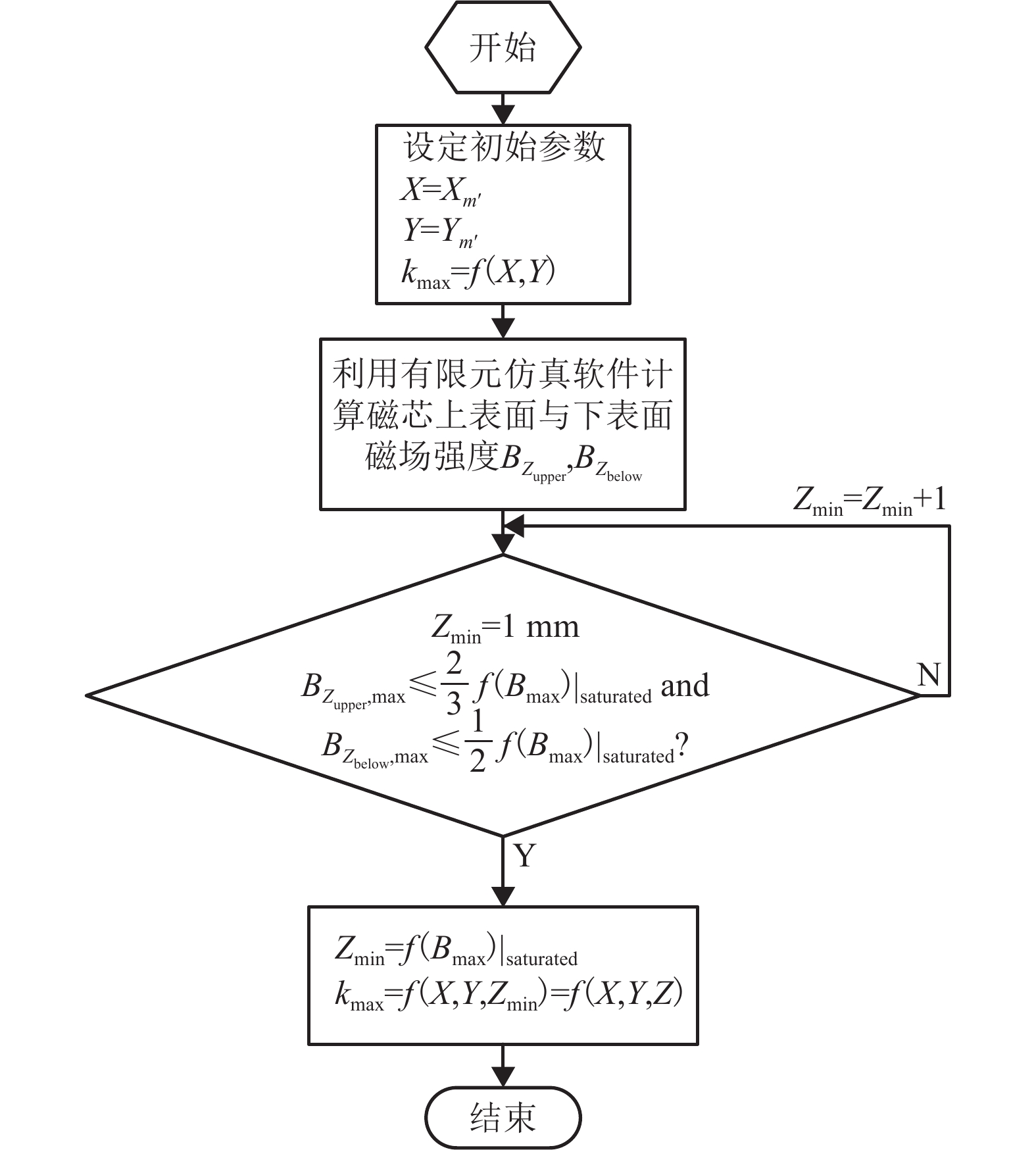

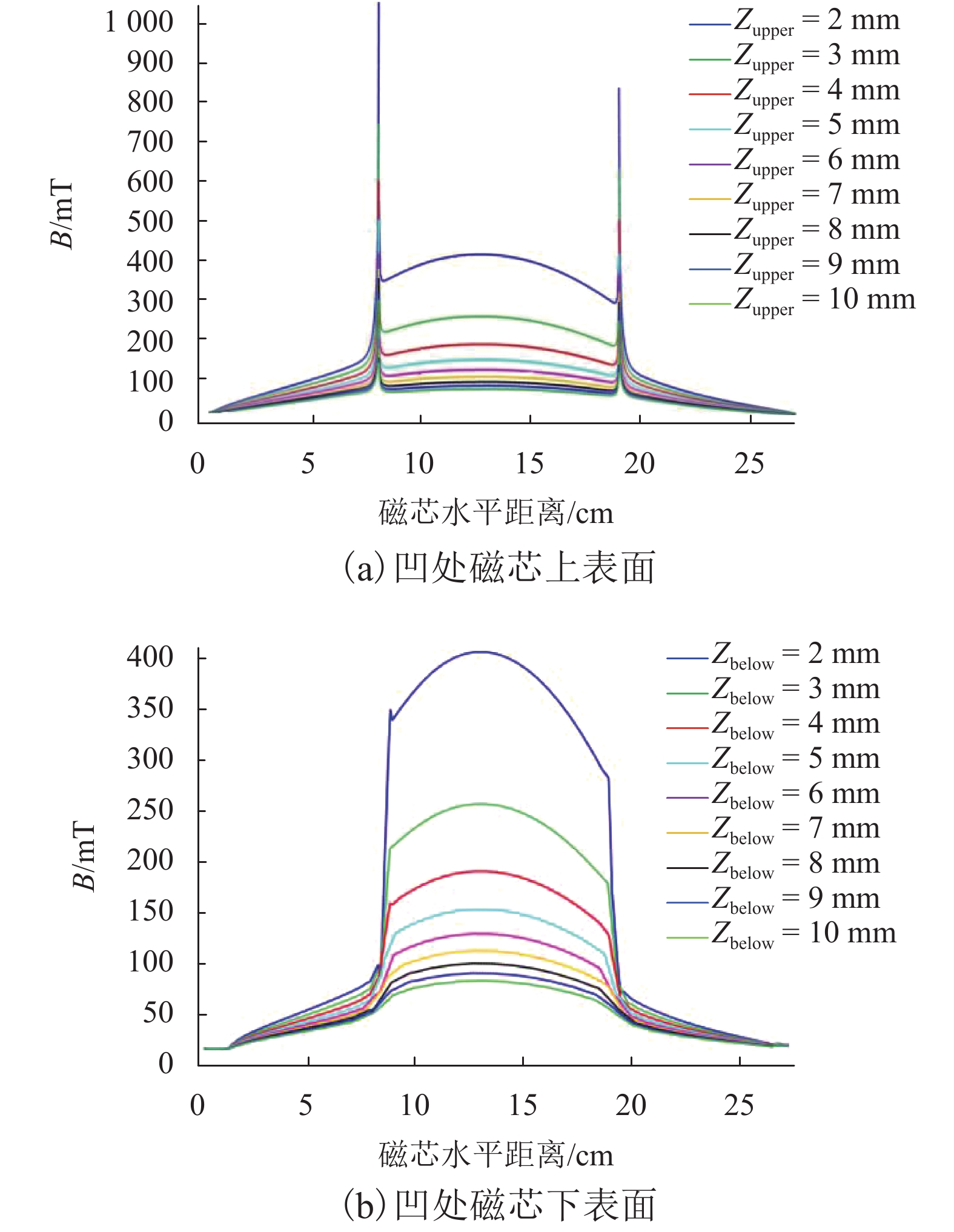

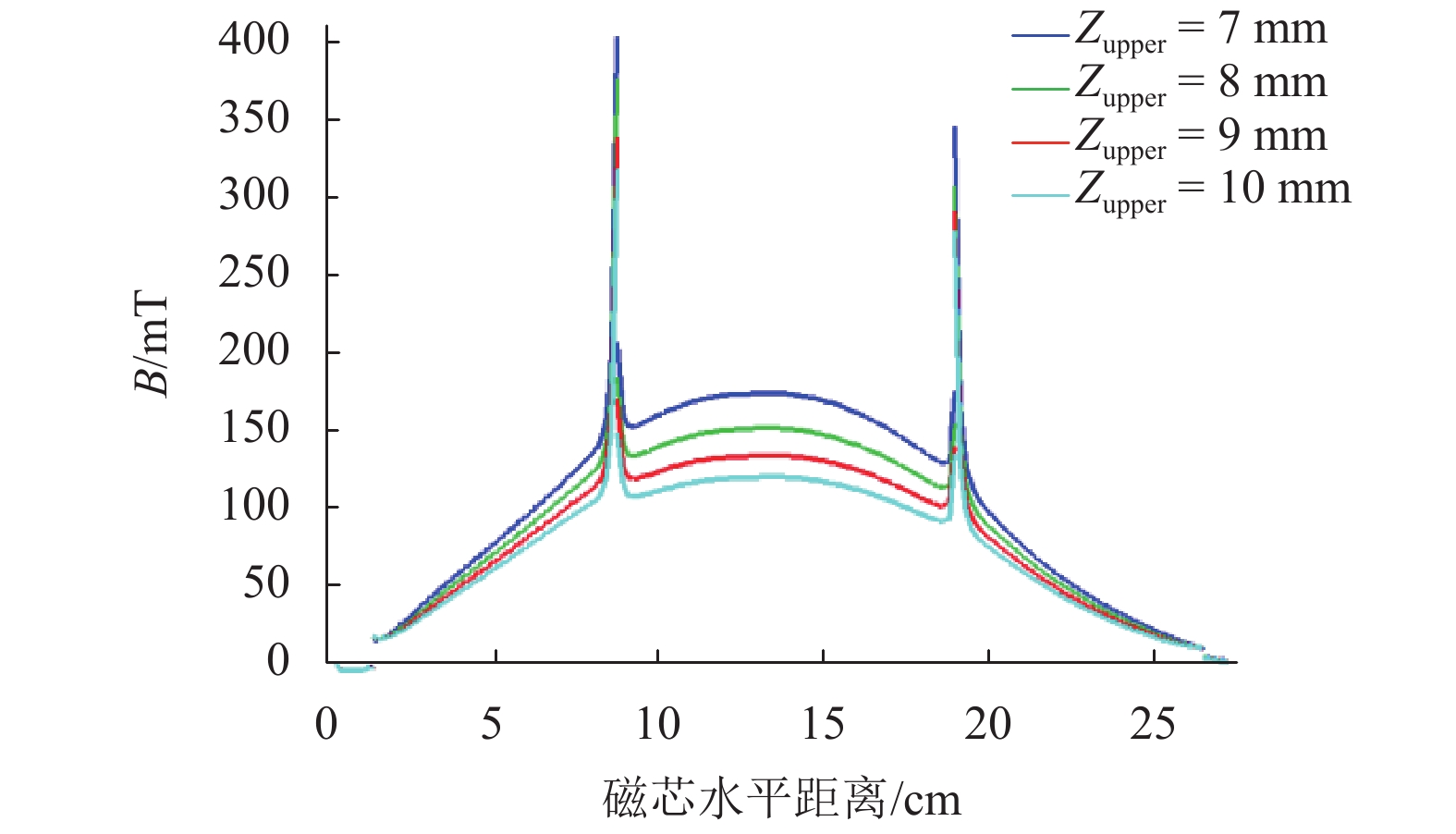

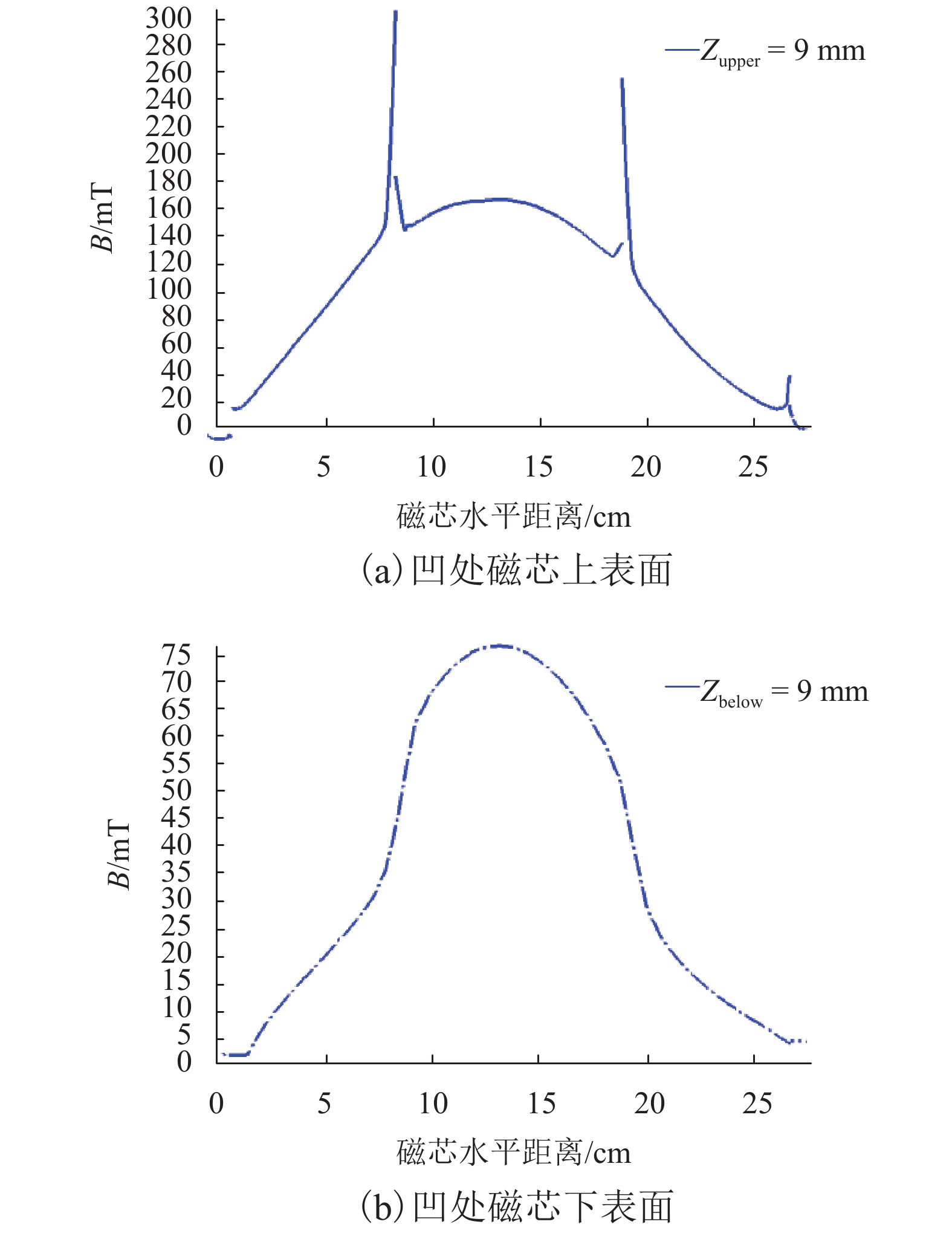

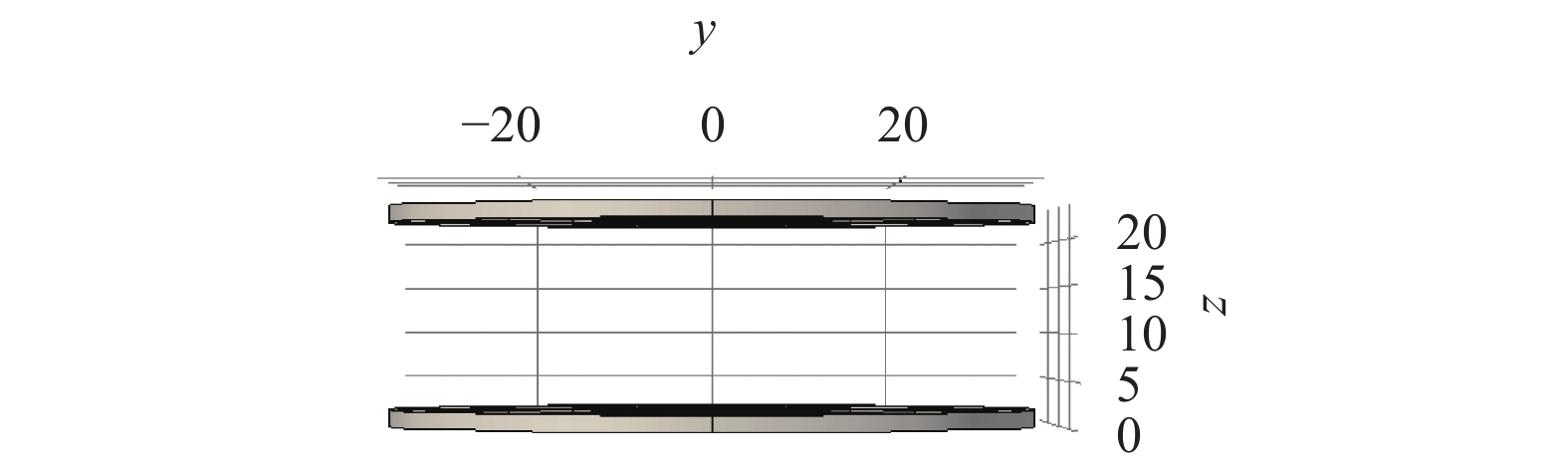

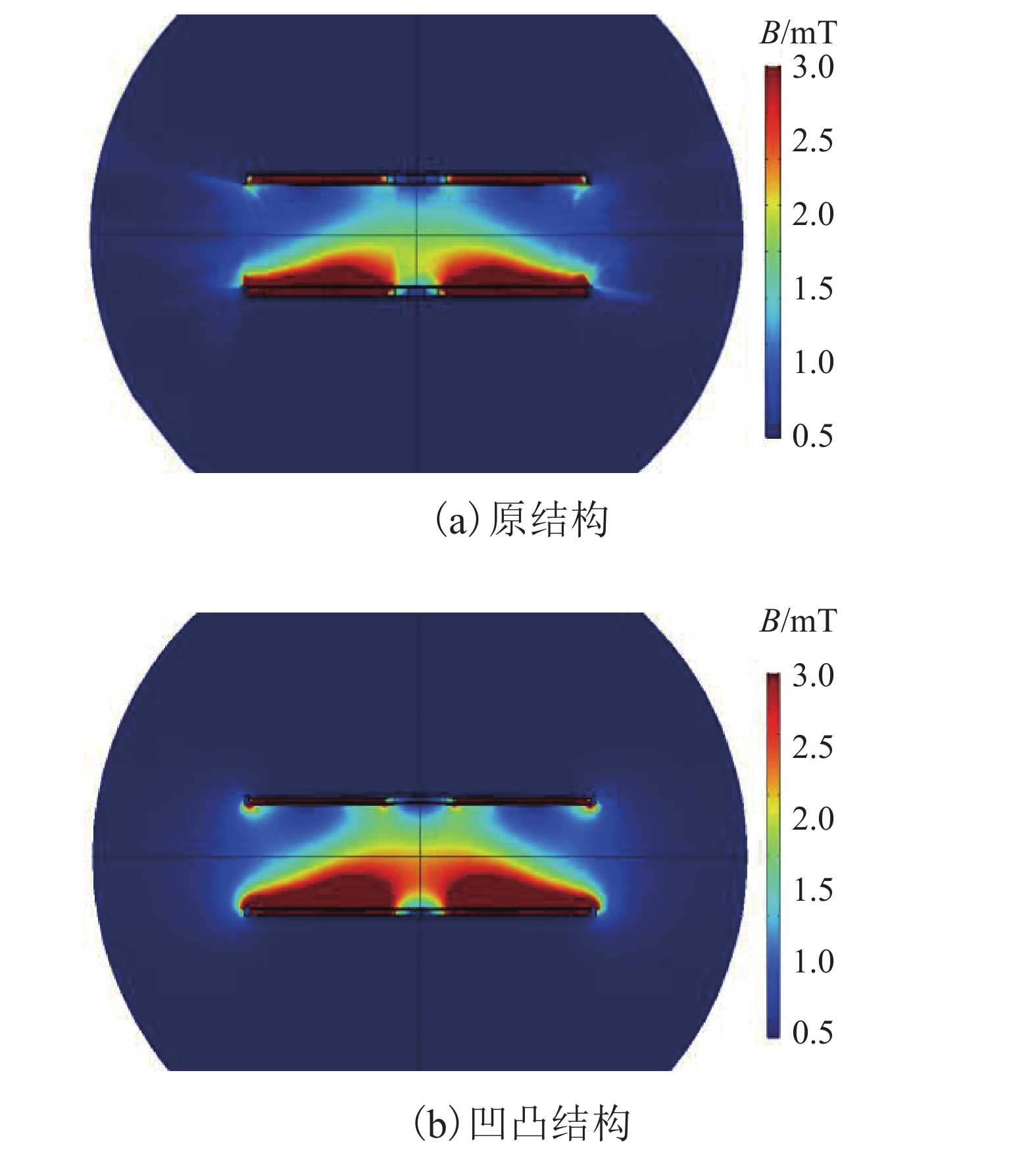

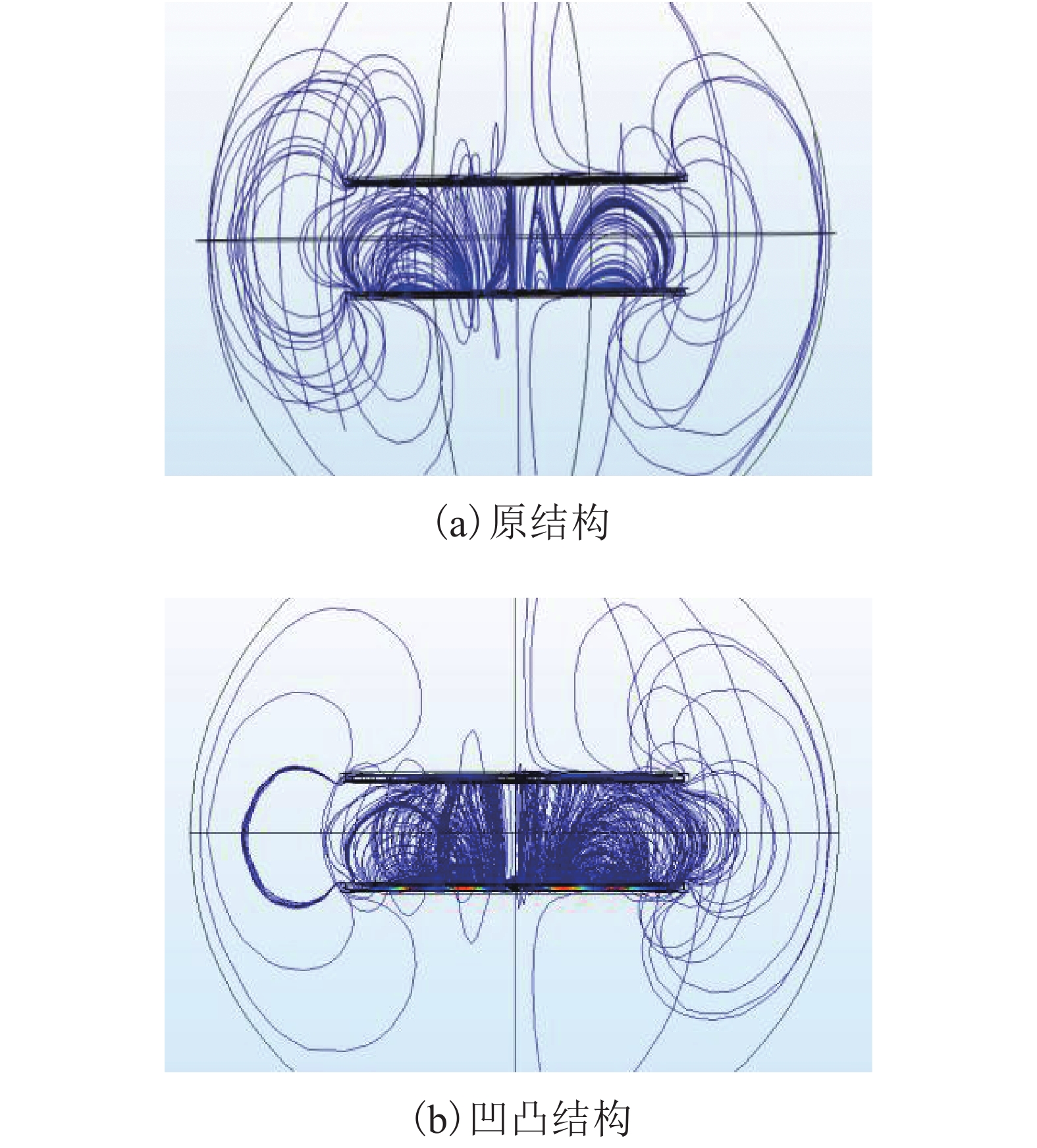

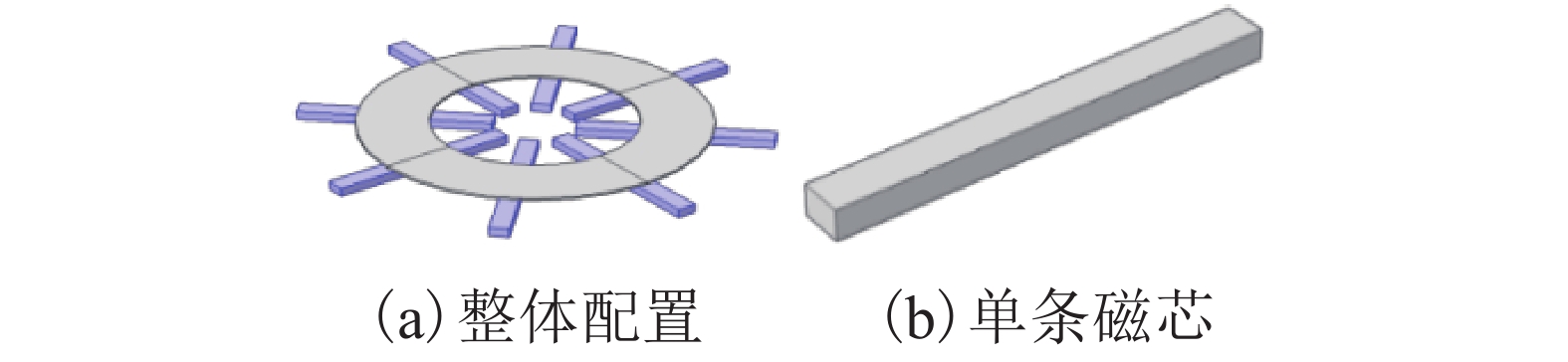

摘要: 针对电动汽车无线充电应用,提出了一种凹凸型磁耦合机构,在减小磁芯体积的情况下实现了更好的耦合特性,提高了系统功率传输能力. 基于有限元理论,利用COMSOL电磁场仿真软件,建立了凹凸型耦合机构的有限元仿真模型,针对线圈两端凸起磁芯高度、线圈两端凸起磁芯长度配比、磁芯长度、磁芯长度与宽度之间的约束关系以及磁芯厚度等主要结构参数从互感及耦合系数等角度分别进行了分析和优化设计,并讨论了磁芯变薄后的磁饱和特性. 通过仿真和实验测试结果验证了所设计耦合机构的可行性及在磁场分布及耦合特性方面的优势,使得系统的输出功率和效率相对原条状磁芯结构分别提高了37%和10%.Abstract: Aimed at the application of wireless charging in electric vehicles, a type of concave-convex magnetic coupling mechanism is proposed, which realizes better coupling characteristics and improves the system power transmission capacity. Based on the finite element theory and the COMSOL simulation software, a model of the concave-convex coupling mechanism was developed. According to the height of the convex magnetic core at both ends of the coil, the length ratio of the convex magnetic core at both ends of the coil, and the core length, the relationship between the length and the width of the core and the main structural parameters such as the thickness of the core was analysed and optimised from the perspective of mutual inductance and coupling coefficient, respectively. The magnetic saturation after thinning is also discussed. The feasibility of the coupled mechanism and the advantages of the magnetic field distribution and coupling characteristics were verified by the simulation and experimental results. The output power and efficiency of the system improved by 37% and 10%, respectively, compared with those of the original strip core structure.

-

Key words:

- electric vehicle /

- static charging /

- concavity and convexity /

- coupling

-

表 1 电磁耦合机构磁芯参数

Table 1. Electromagnetic coupling mechanism core parmeters

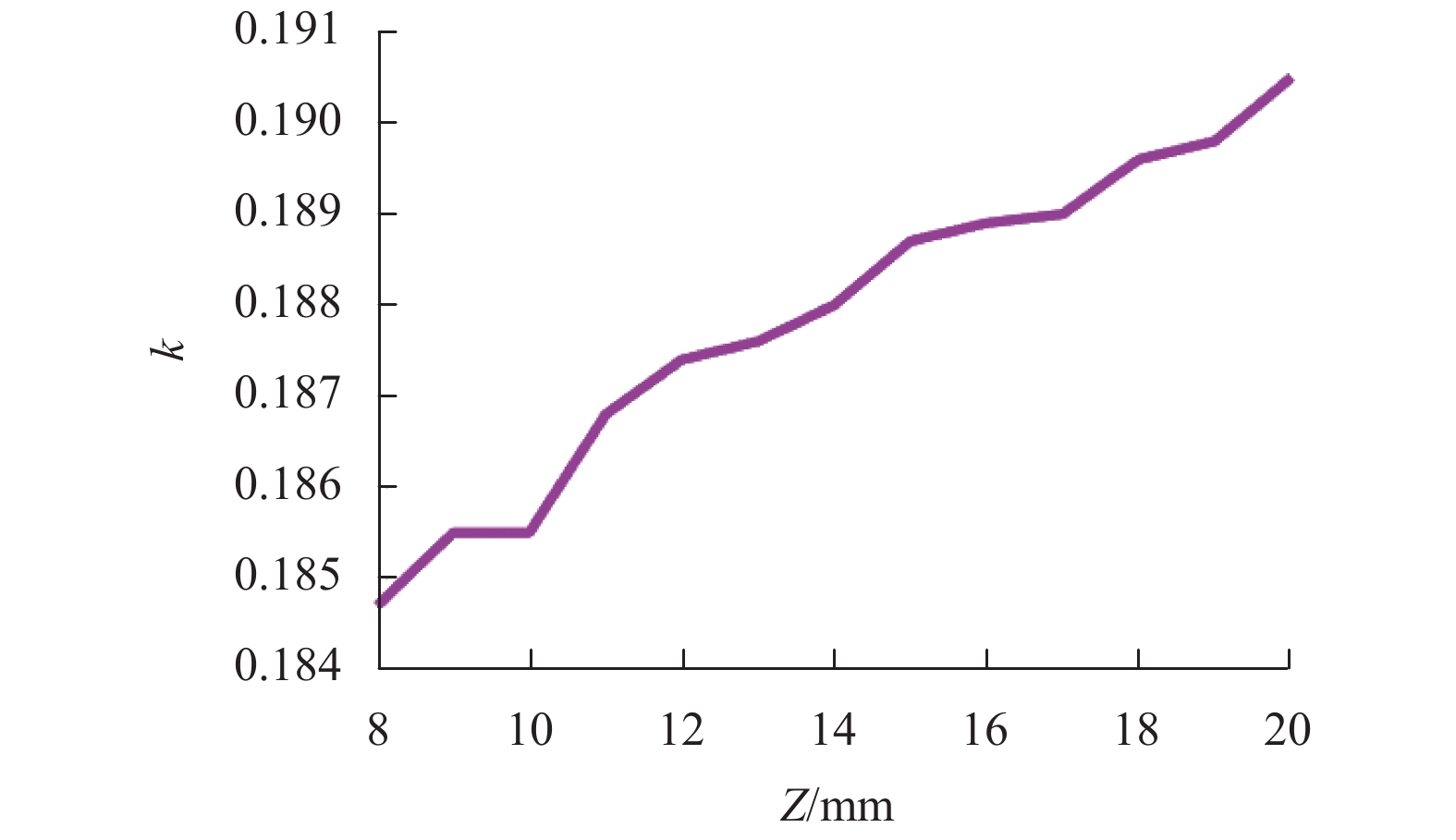

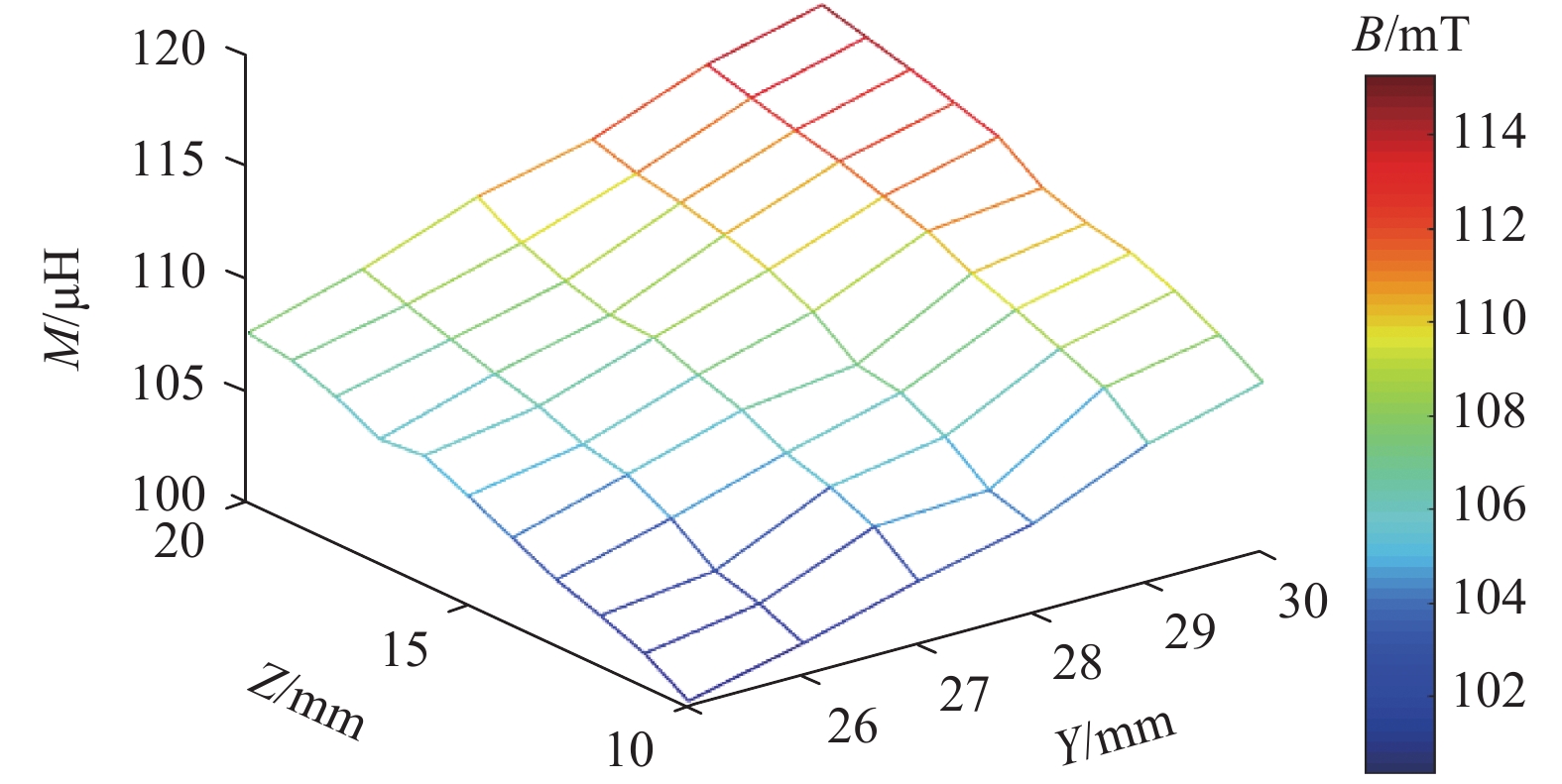

参数 原结构 新结构 参数 原结构 新结构 x/mm 279 270 f/kHz 20 20 y/mm 28 36 M/μH 96.10 115.95 z/mm 16 9 k 0.173 0.188 Vc/cm3 1 500 1 166 Rp/Ω 0.270 0.267 Ip/A 23 23 Rs/Ω 0.270 0.263 注:Vc为磁芯用量总体积;f为系统工作频率;Rp、Rs分别为原、副边线圈的阻值. -

BUDHIA M, COVIC G A, BOYS J T. Design and optimization of circular magnetic structures for lumped inductive power transfer systems[J]. IEEE Transactions on Power Electronics, 2011, 26(11): 3096-3108 HUANG C, JAMES J E, COVIC G A. Design considerations for variable coupling lumped coil systems[J]. IEEE Transactions on Power Electronics, 2015, 30(2): 680-689 NAGENDRA G R, CHEN L, COVIC G A, et al. Detection of EVs on IPT highways[J]. IEEE Journal of Emerging and Selected Topics in Power Electronics, 2014, 2(3): 584-597 BUDHIA M, BOYS J T, Covic G A, et al. Development of a single-sided flux magnetic coupler for electric vehicle IPT charging systems[J]. IEEE Transactions on Industrial Electronics, 2013, 60(1): 318-328 COVIC G A, BOYS J T. Inductive power transfer[J]. Proceedings of the IEEE, 2013, 101(6): 1276-1289 KISSIN M L G, BOYS J T, COVIC G A. Interphase mutual inductance in polyphase inductive power transfer systems[J]. IEEE Transactions on Industrial Electronics, 2009, 56(7): 2393-2400 ZAHEER A, HAO H, COVIC G A, et al. Investigation of multiple decoupled coil primary pad topologies in lumped IPT systems for interoperable electric vehicle charging[J]. IEEE Transactions on Power Electronics, 2015, 30(4): 1937-1955 COVIC G A, BOYS J T. Modern trends in inductive power transfer for transportation applications[J]. IEEE Journal of Emerging and Selected Topics in Power Electronics, 2013, 1(1): 28-41 ELLIOTT G, RAABE S, COVIC G A, et al. Multiphase pickups for large lateral tolerance contactless power-transfer systems[J]. IEEE Transactions on Industrial Electronics, 2010, 57(5): 1590-1598 RAABE S, COVIC G A. Practical design considerations for contactless power transfer quadrature pick-ups[J]. IEEE Transactions on Industrial Electronics, 2013, 60(1): 400-409 BUDHIA M, COVIC G, BOYS J. A new IPT magnetic coupler for electric vehicle charging systems[C]// IECON 2010-36th Annual Conference on IEEE Industrial Electronics Society. Glendale: [s.n.], 2010, 7500(1): 2487-2492 BUDHIA M, COVIC G A, BOYS J T, et al. Development and evaluation of single sided flux couplers for contactless electric vehicle charging[C]// 2011 IEEE Energy Conversion Congress and Exposition. [S.l.]: IEEE, 2011, 47(10): 614-621 TAKANASHI H, SATO Y, KANEKO Y, et al. A large air gap 3kW wireless power transfer system for electric vehicles[C]//2012 IEEE Energy Conversion Congress and Exposition (ECCE). Raleigh: [s.n.], 2012, 11(4): 269-274 NAGATSUKA Y, EHARA N, KANKEO Y, et al. Compact contactless power transfer system for electric vehicles[C]//International Power Electronics Conference (IPEC). Sapporo: [s.n.], 2010: 807-813 LEE J, SHEN H, LEE K. Design and implementation of weaving-type pad for contactless EV inductive charging system[J]. IET Power Electronics, 2014, 10(7): 2533-2542 JANG Y J, KO Y D, JEONG S. Optimal design of the wireless charging electric vehicle[C]//2012 IEEE International Electric Vehicle Conference. Greenville: IEEE, 2012: 1-5 PARK C, LEE S W, RIM C T. 5m-off-long-distance inductive power transfer system using optimum shaped dipole coils[C]//Proceedings of the 7th International Power Electronics and Motion Control Conference. Harbin: [s.n.], 2012, 2: 1137-1142 HU C, SUN Y, LV X, et al. Magnetic coupler design procedure for IPT system and its application to EVs' wireless charging[J]. International Journal of Applied Electromagnetics and Mechanics, 2015, 47(3): 861-873 -

下载:

下载: