Numerical Analysis on Seismic Performance of Load Bearing 3D Walls

-

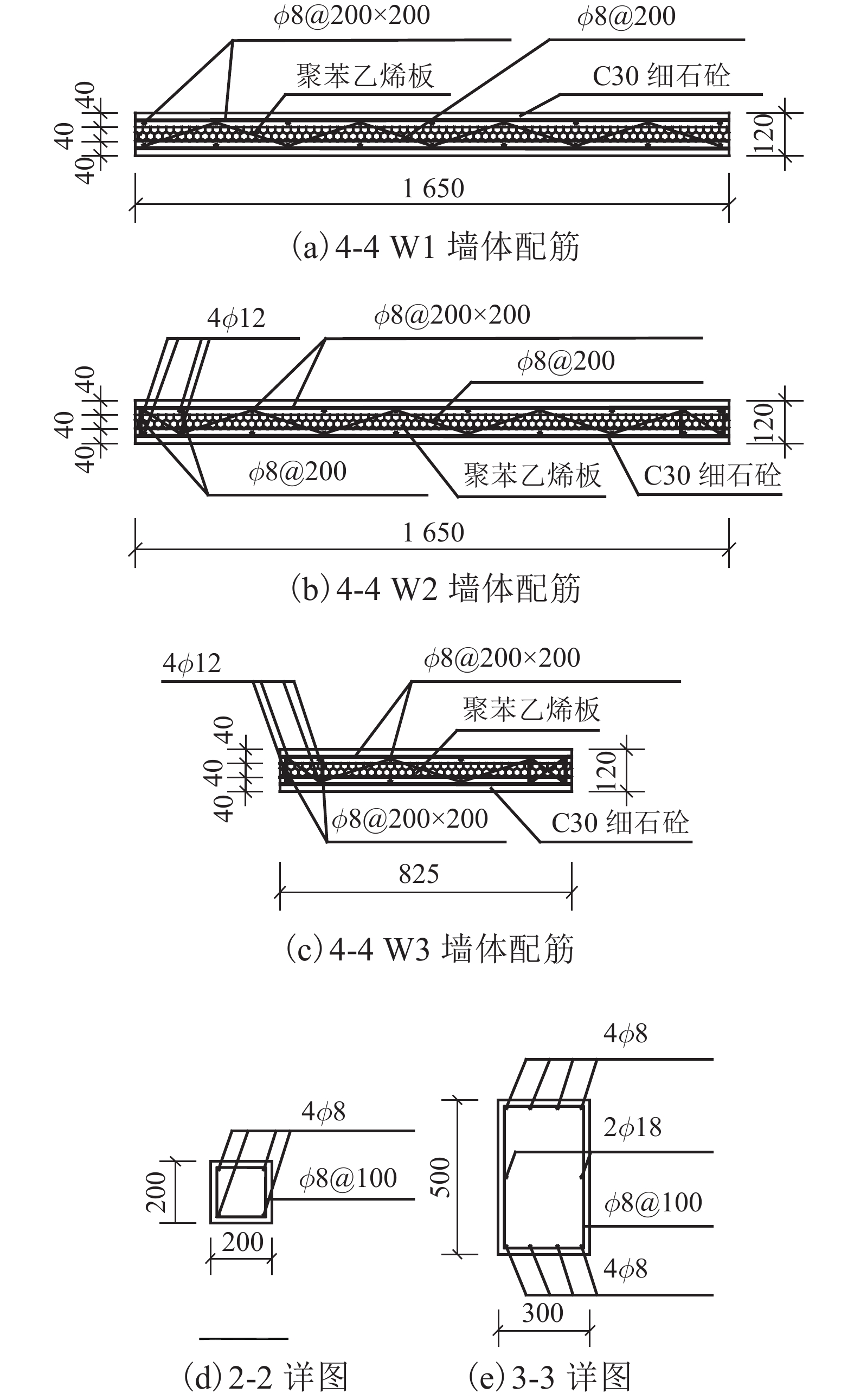

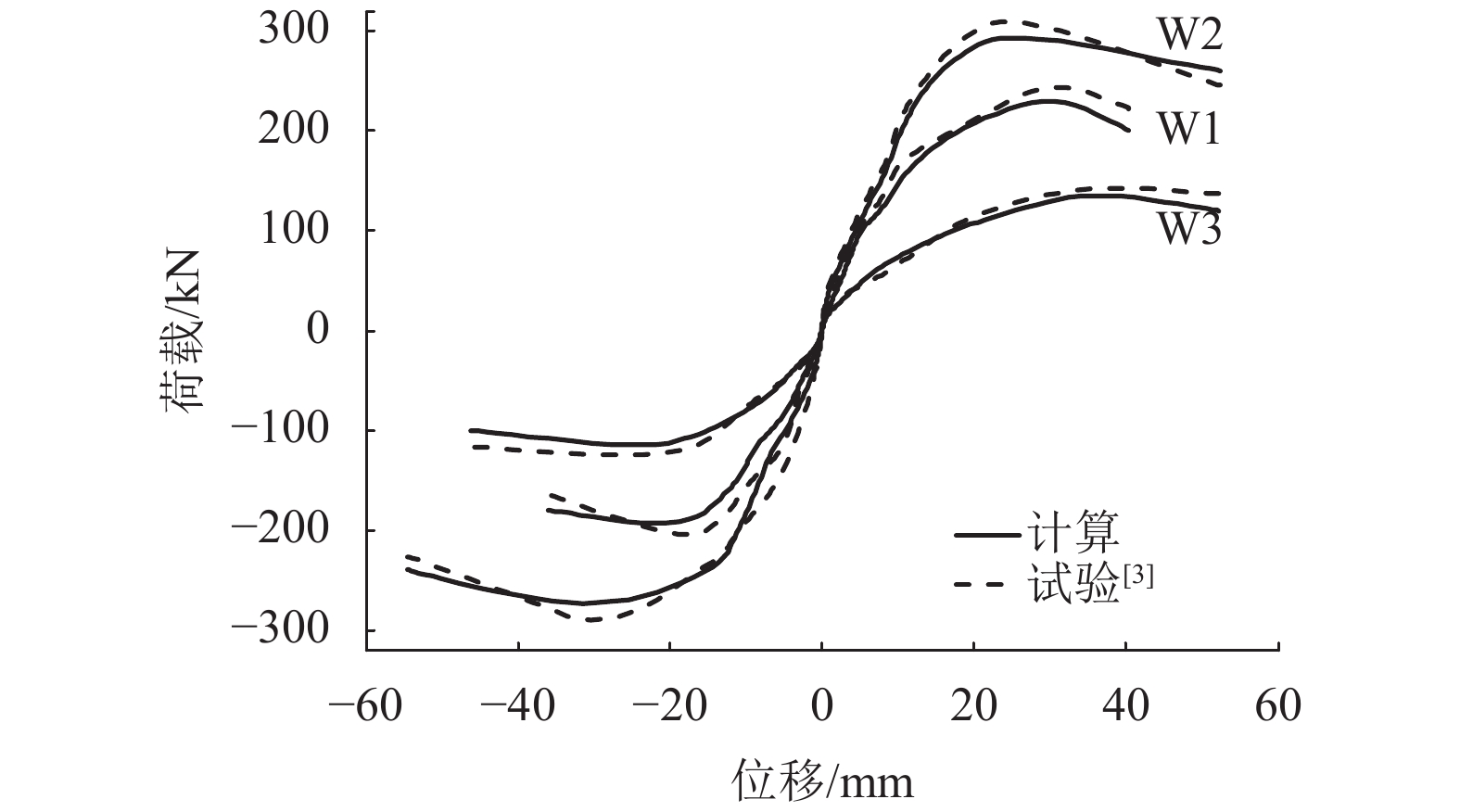

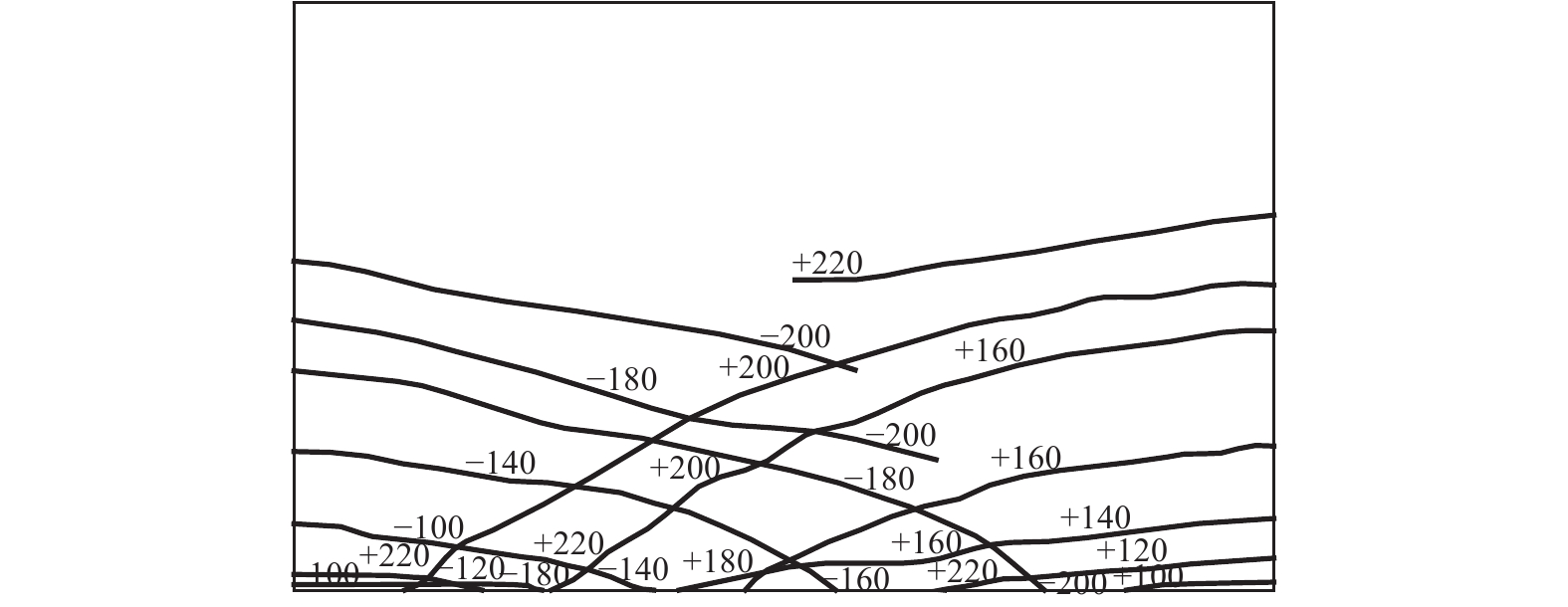

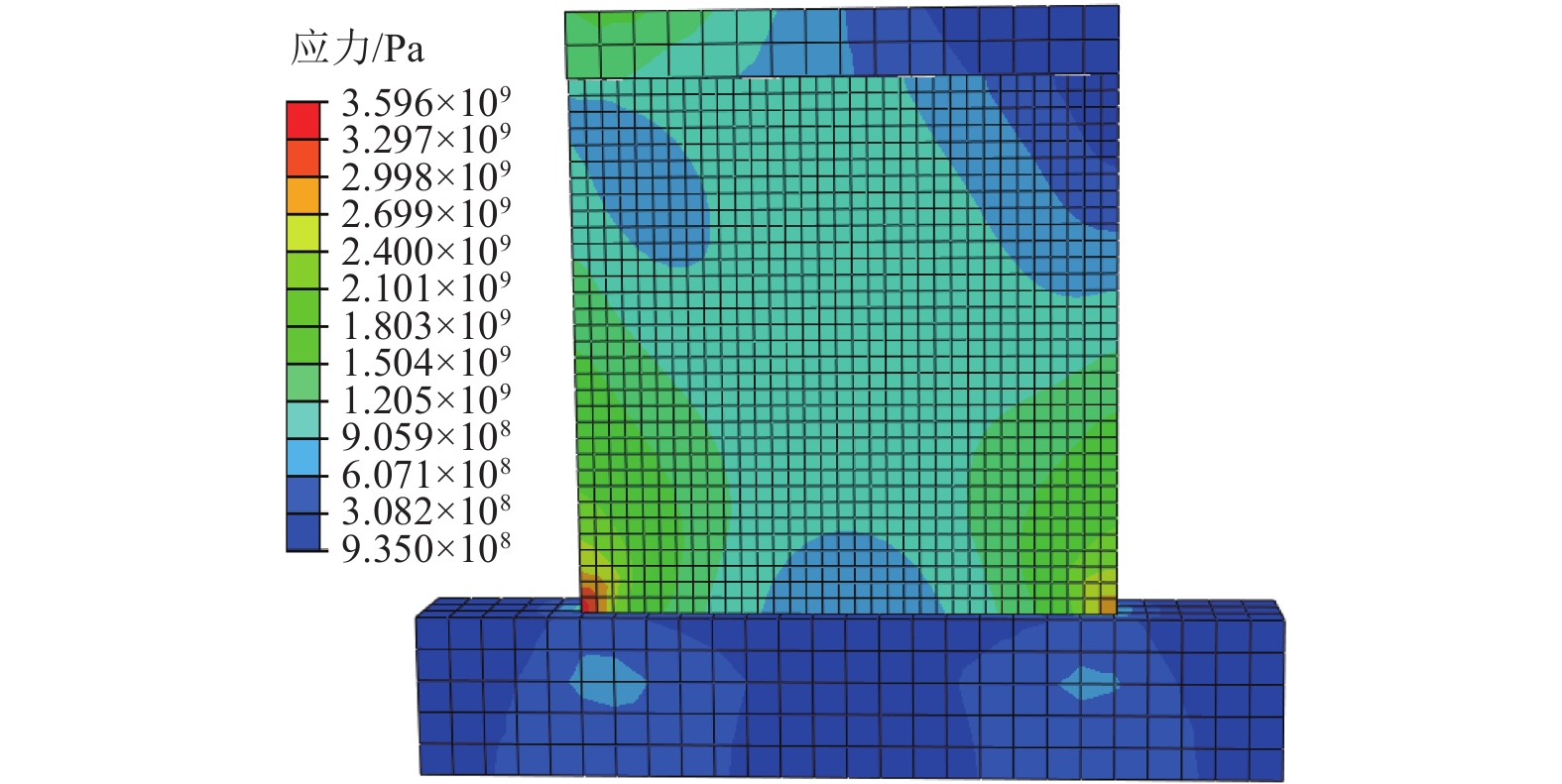

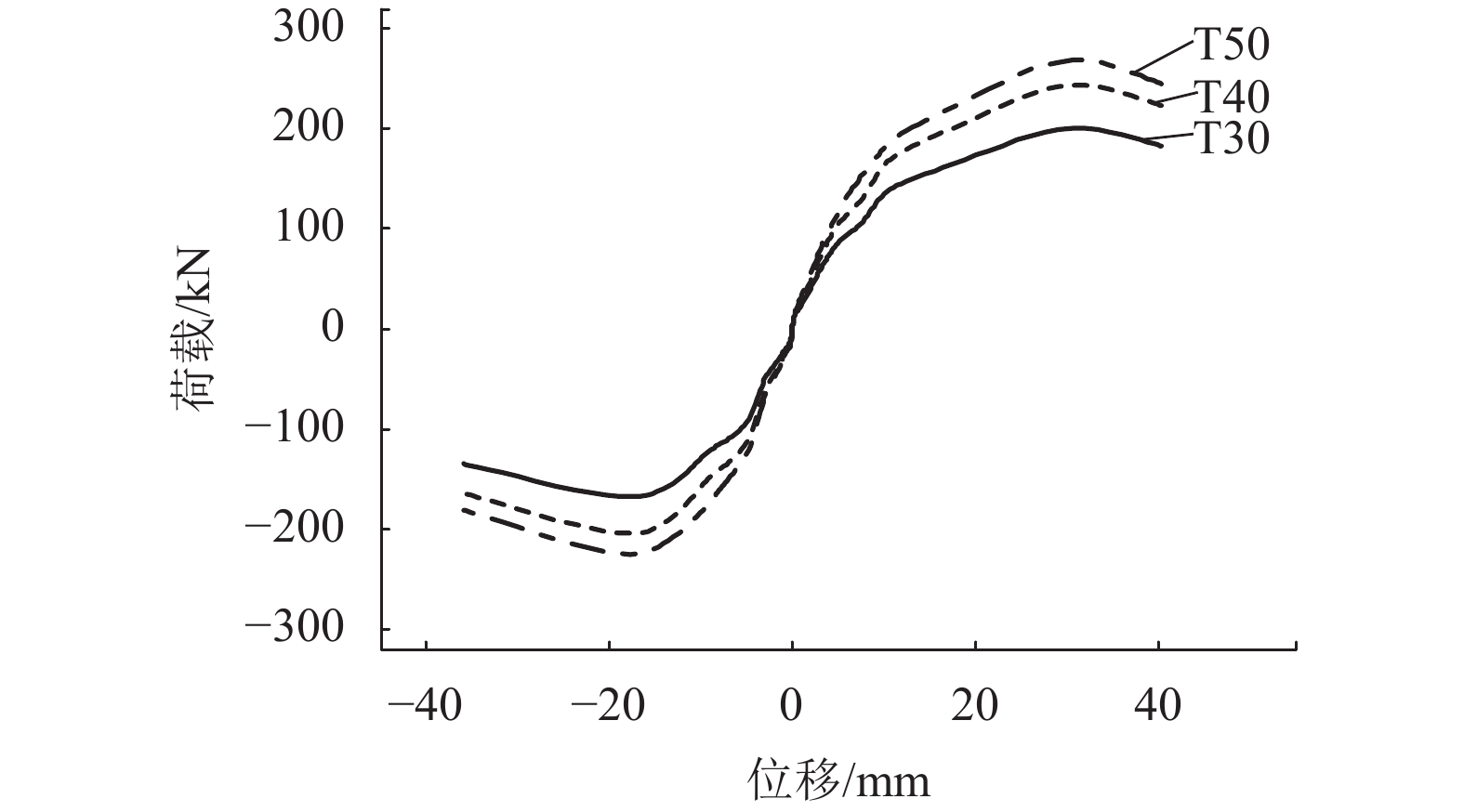

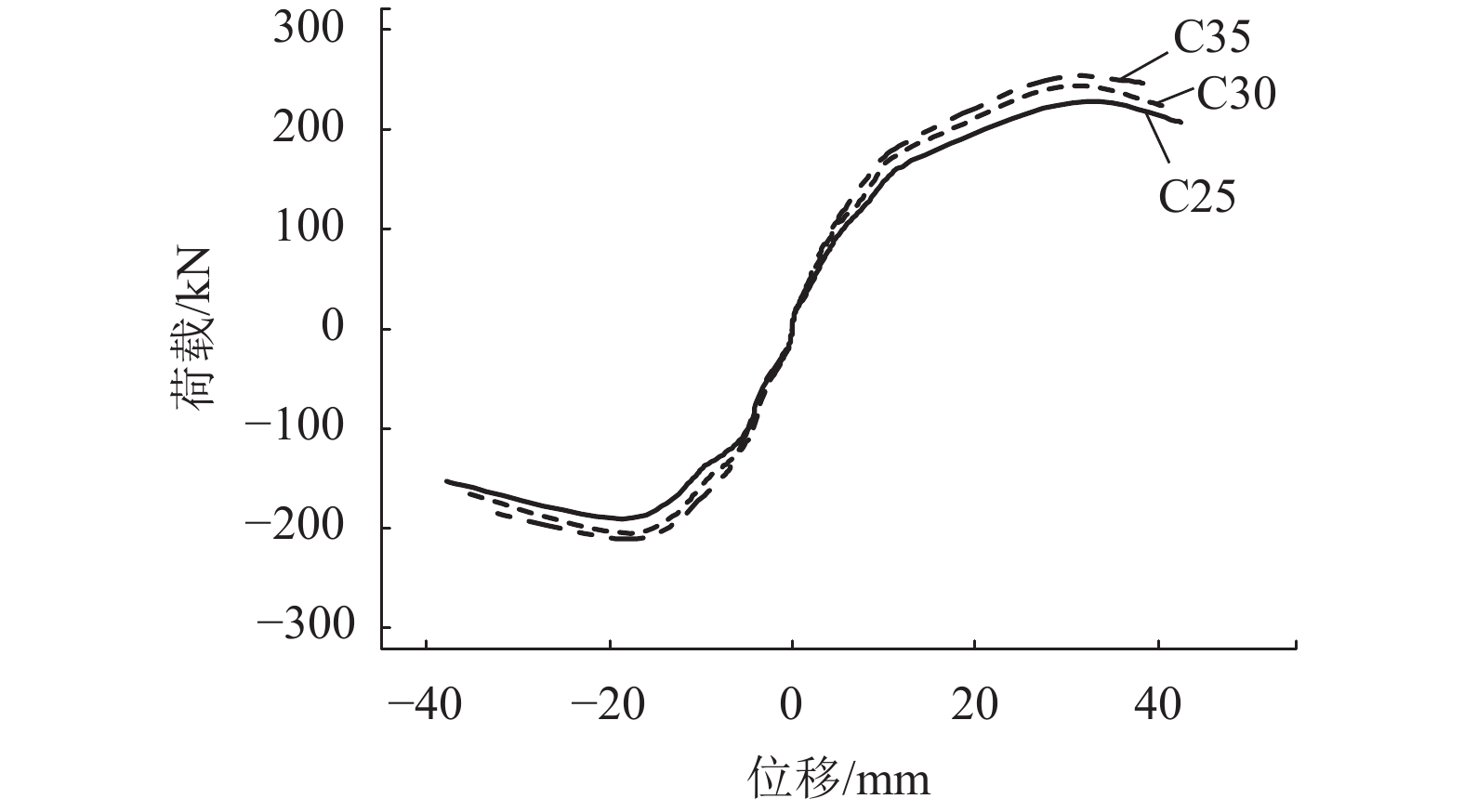

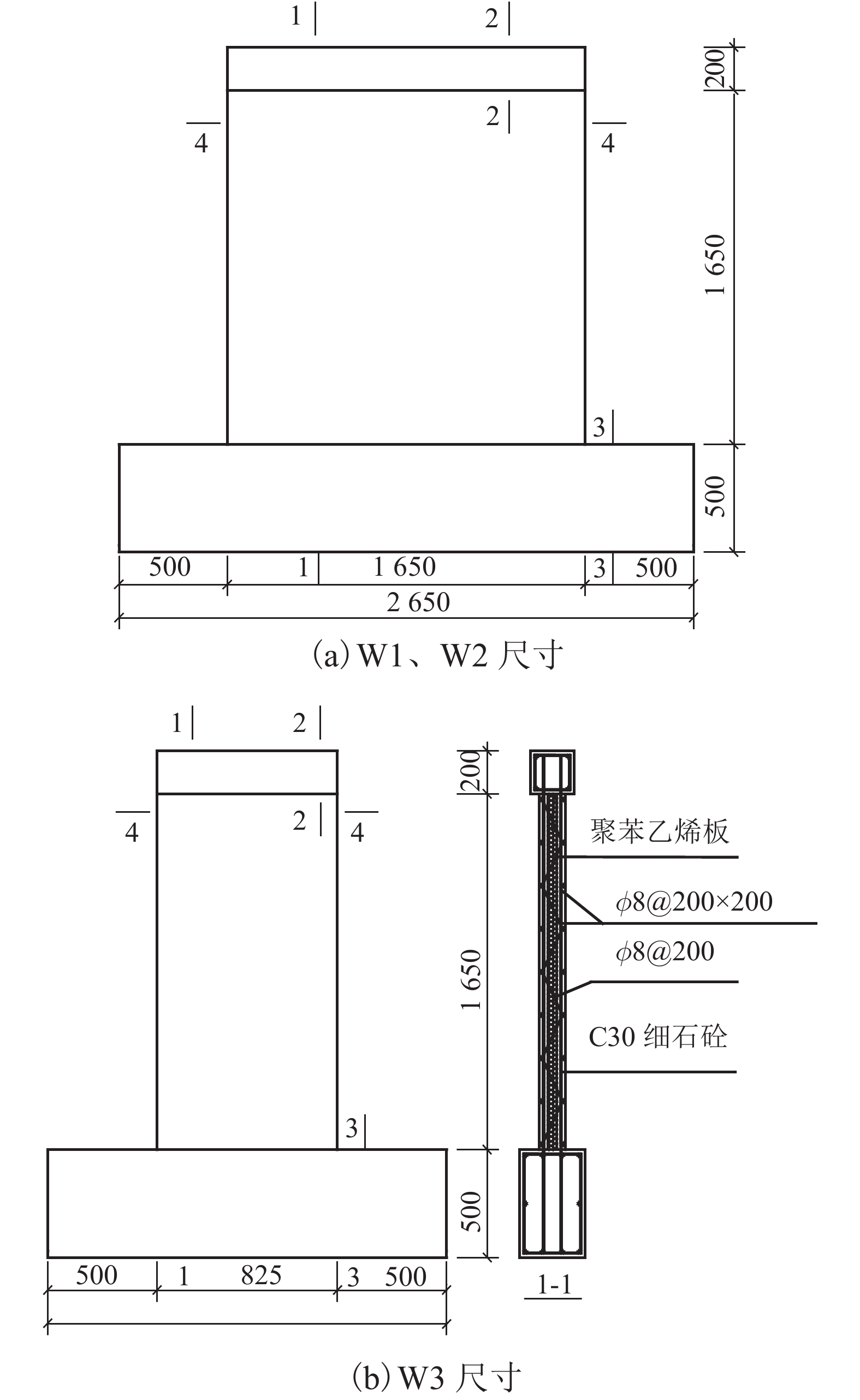

摘要: 为研究承重型3D板墙体的抗震性能,同时考虑单纯采用拟静力等抗震性能试验存在试验周期较长、成本较高等问题,采用有限元分析方法对承重型3D板墙体的抗震性能进行模拟计算,并将计算结果与试验结果进行对比,在验证数值模型准确合理的基础上,进一步分析高宽比、混凝土层厚度及强度对其抗震性能的影响,以此节约试验时间和成本. 研究结果表明:随着高宽比的增大,构件趋于弯曲破坏,有利于增加构件的延性及耗能能力. 增加混凝土层厚度对墙体极限承载力具有一定的提高作用,当单侧混凝土层厚度由30 mm增加至40、50 mm时,墙体极限承载能力由208 kN增加至253、279 kN;墙体的极限承载能力随着混凝土层强度的提高略有提升,当混凝土层强度由C25增加至C30、C35时,构件的极限承载力由236 kN增加至253、260 kN.Abstract: To investigate the seismic performance of load bearing 3D walls under low cyclic reversed loads, numerical analysis for load-displacement curves of load bearing 3D walls under low cyclic reversed loads are performed by using the solid model based on ABAQUS software. The simulation results agree well with the test results in literature. The influences of the height-width ratio, concrete thickness and concrete strength on the seismic performance of load bearing 3D walls under low cyclic reversed loads are analyzed. The analytical results indicate that height-width ratio is the major influence factors on the seismic performance of the walls. The flexural failure is more likely to observe in the wall with large aspect ratios, which increases the ductility and energy dissipation capacity of structure. When concrete layer thickness increased from 30 mm to 40 mm and 50 mm, the wall’s ultimate load-bearing capacity increased from 208 kN to 253 kN and 279 kN. Similarly, when the concrete layer strength increased from C25 to C30 and C35, the ultimate strength of the element accordingly increased from 236 kN to 253 kN and 260 kN.

-

Key words:

- load bearing 3D wall /

- seismic performance /

- numerical simulation /

- influencing factor

-

表 1 混凝土材料属性的设置参数

Table 1. Material attribute of concrete

强度

/MPa密度

/(kg•m–3)杨氏模量

/(kN•mm–2)泊松比 膨胀角

/(°)偏心率 fb0/fc0 32 2 400 30 0.2 35 0.1 1.16 表 2 受压时混凝土损伤塑性参数

Table 2. Parameters of concrete damaged plasticity model when concrete in compression

屈服应力/MPa 非弹性应变/ × 10–6 损伤因子 16.543 0 0 18.054 280.476 0.175 19.077 393.373 0.215 19.707 519.316 0.253 20.034 655.372 0.290 20.130 799.061 0.325 19.645 110.899 0.392 ⋮ ⋮ ⋮ 29.423 14 216.000 0.918 28.814 14 508.100 0.920 表 3 受拉时混凝土损伤塑性参数

Table 3. Parameters of concrete damaged plasticity model when concrete in tension

屈服应力/MPa 非弹性应变/ × 10–6 损伤因子 2.010 0 0 1.882 510.000 0.257 1.597 88.900 0.388 1.359 125.257 0.485 1.233 148.403 0.534 1.129 170.833 0.575 1.003 203.447 0.624 ⋮ ⋮ ⋮ 0.325 917.409 0.892 0.320 936.506 0.894 表 4 钢筋材料属性基本参数

Table 4. Material attribute of steel

钢筋规格 屈服强度/MPa 极限强度/MPa Φ8 420 540 Φ12 395 460 表 5 混凝土应力计算结果与试验对比

Table 5. Comparison of concrete stress between ABAQUS calculation and test result

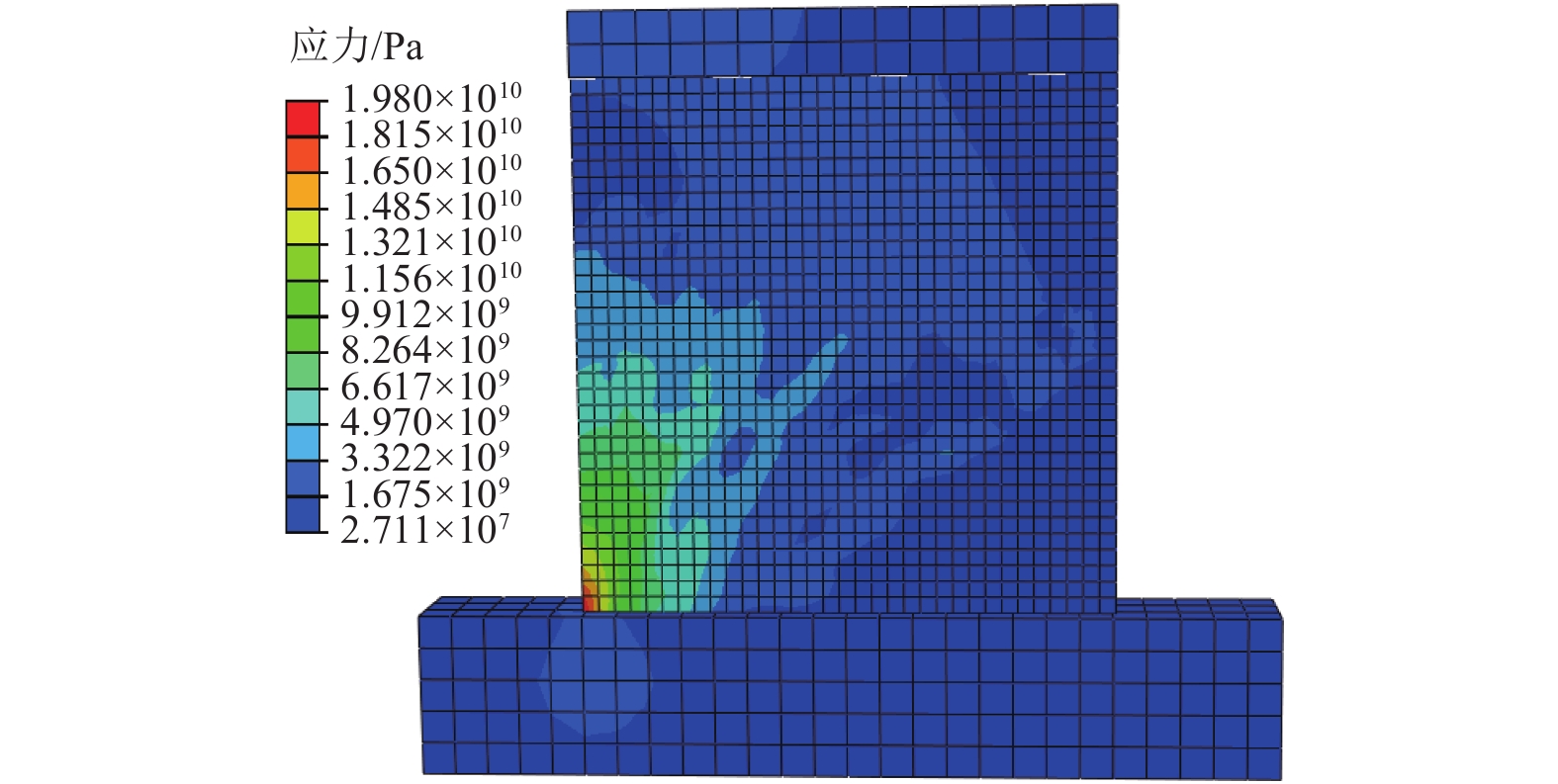

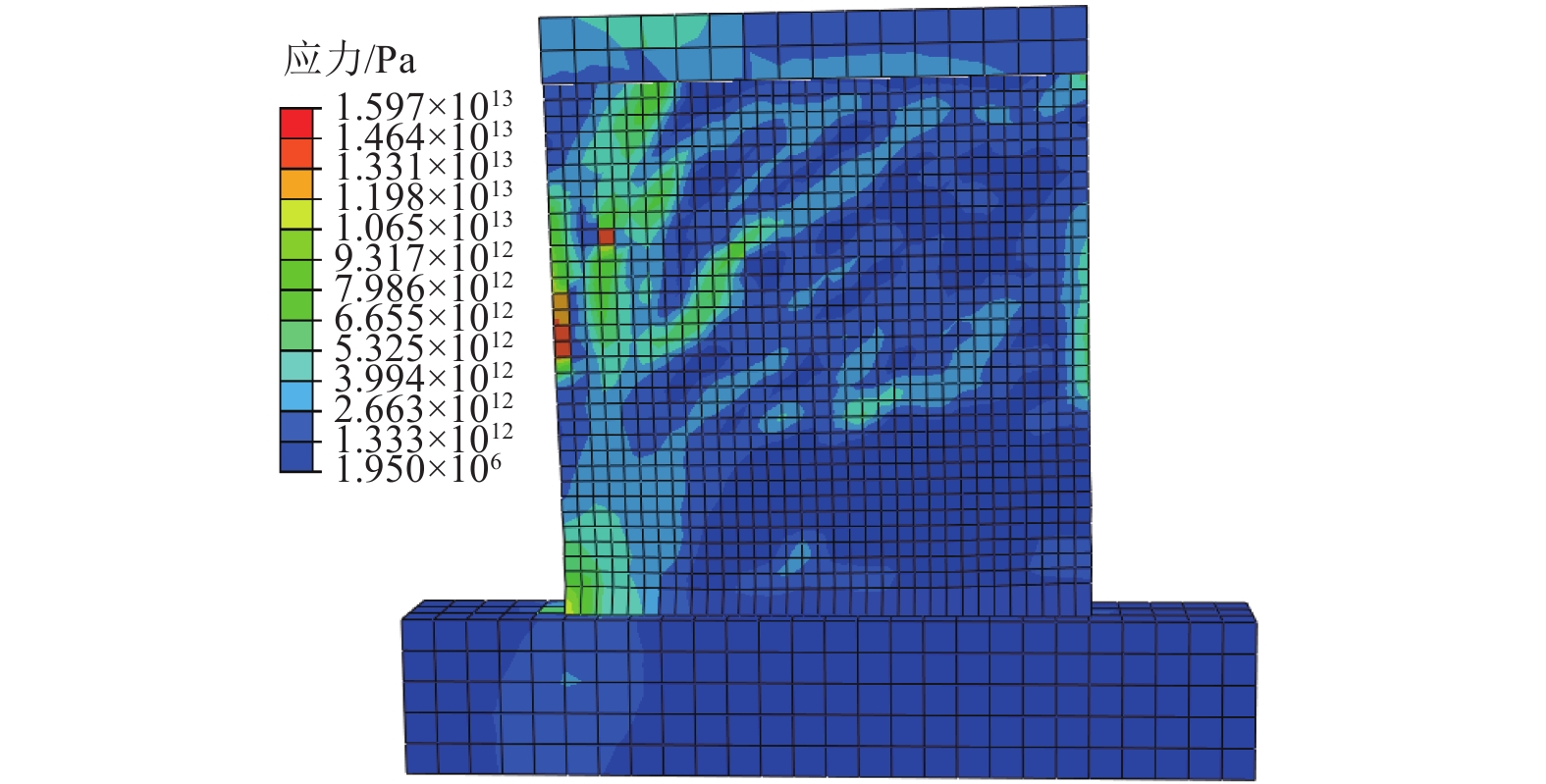

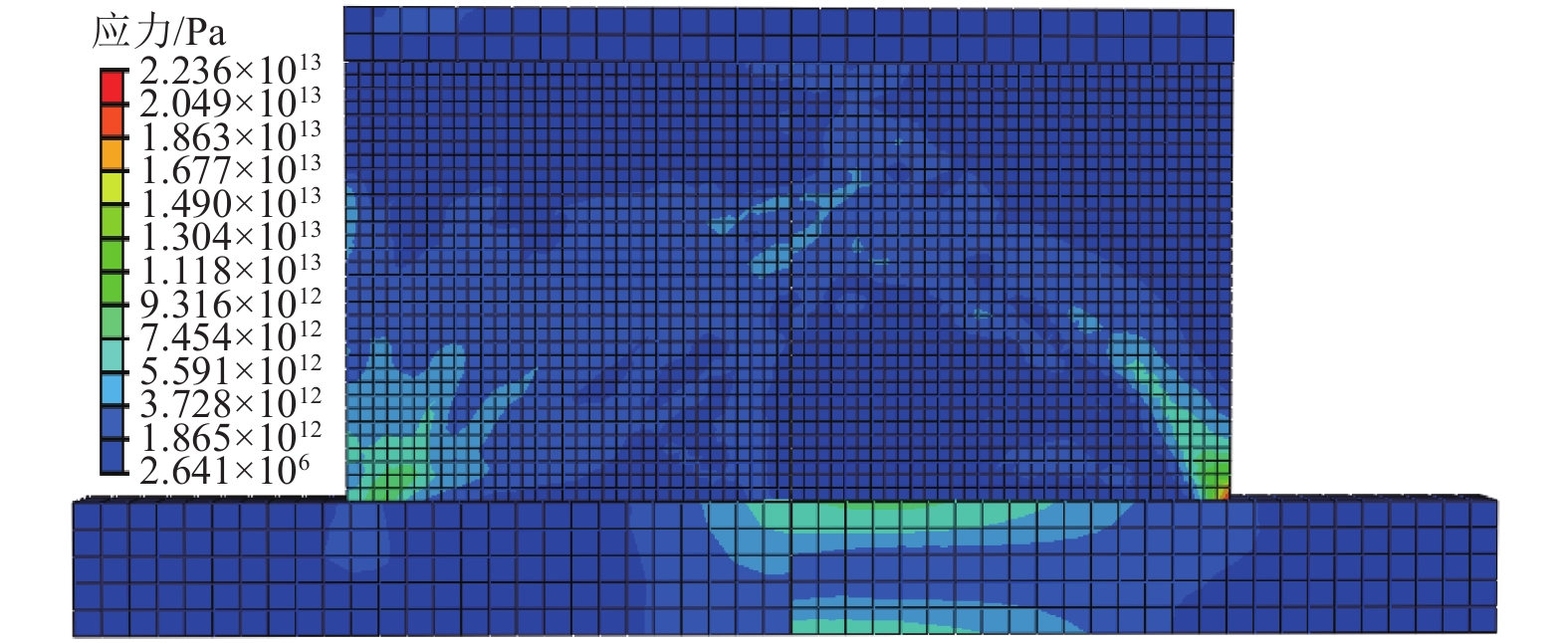

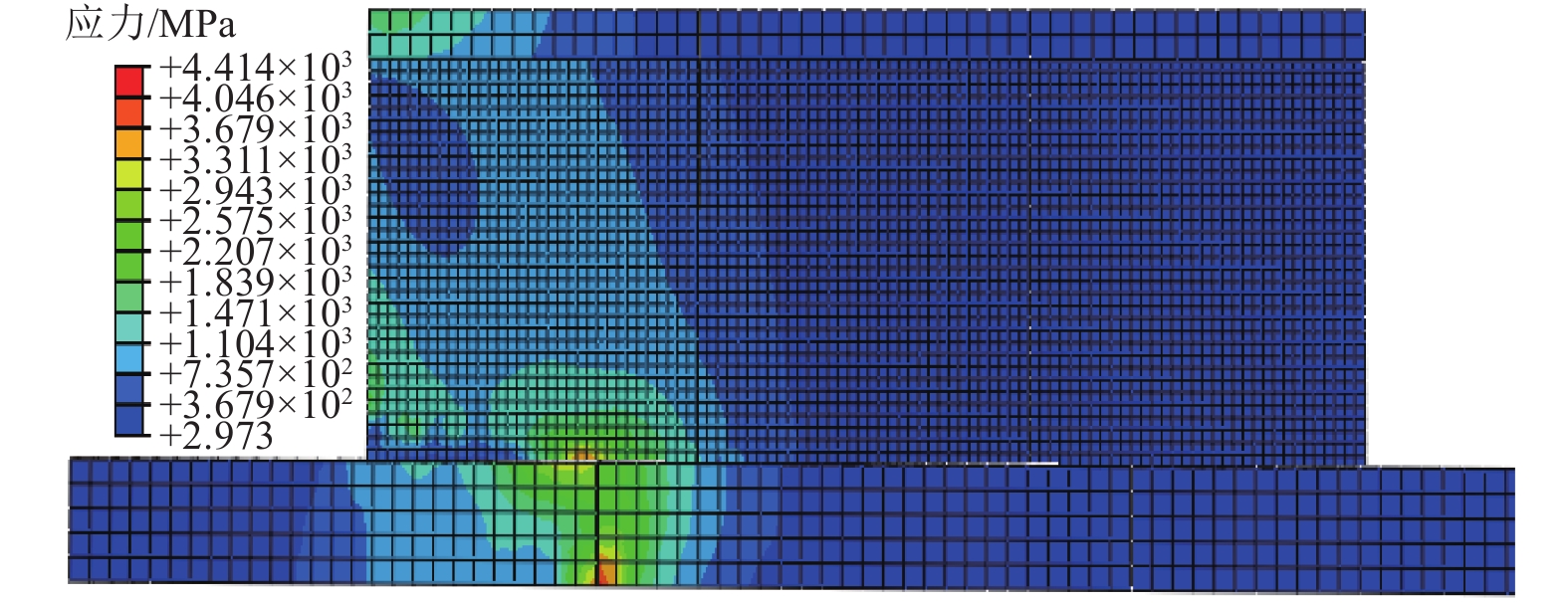

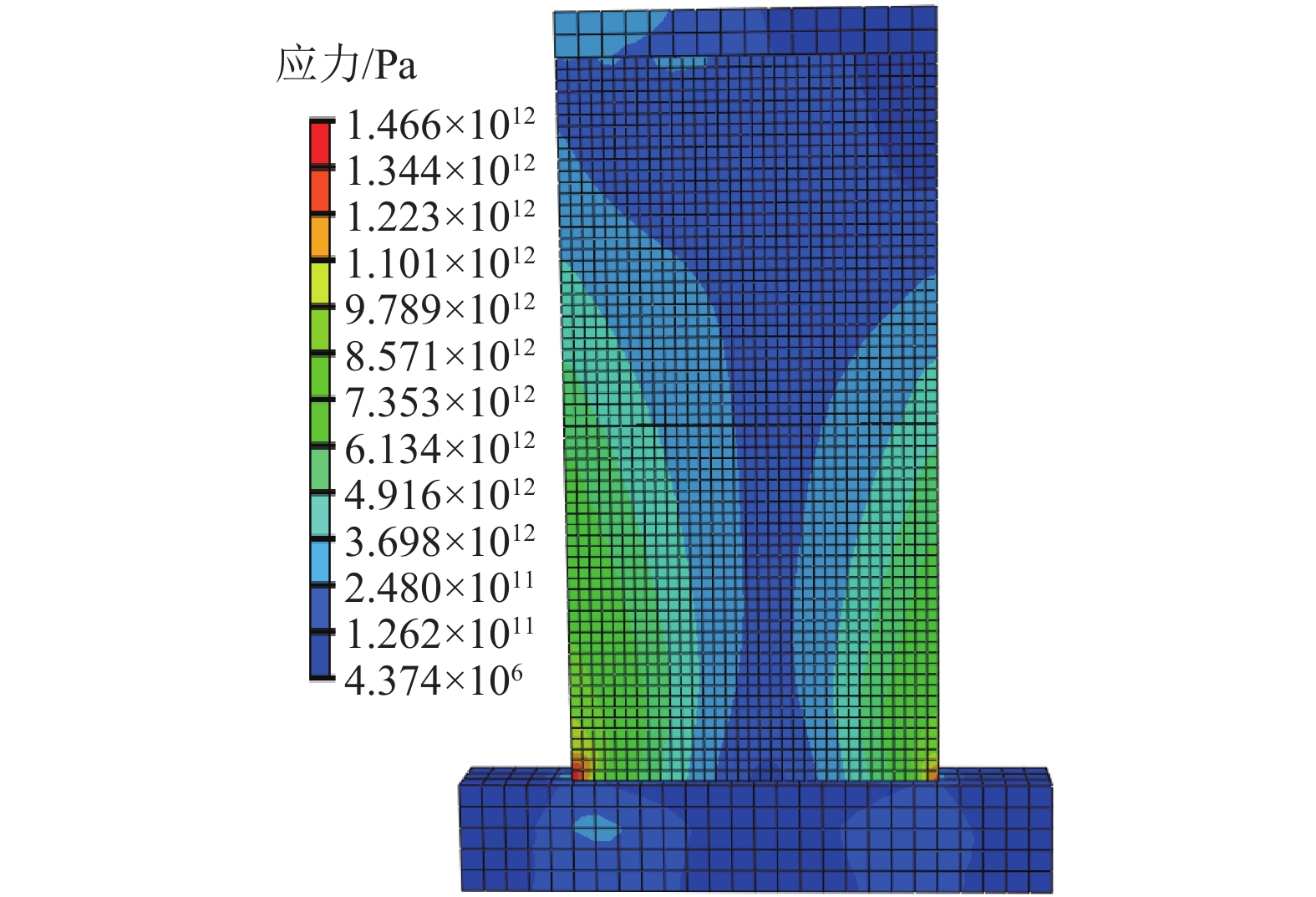

加载阶段 试验结果 计算结果 弹性阶段 未产生裂缝,整体完好. 整体应力较小,墙体底部两端应力稍大 屈服阶段 裂缝逐渐增多,混凝土少许脱落,裂缝呈“菱形”

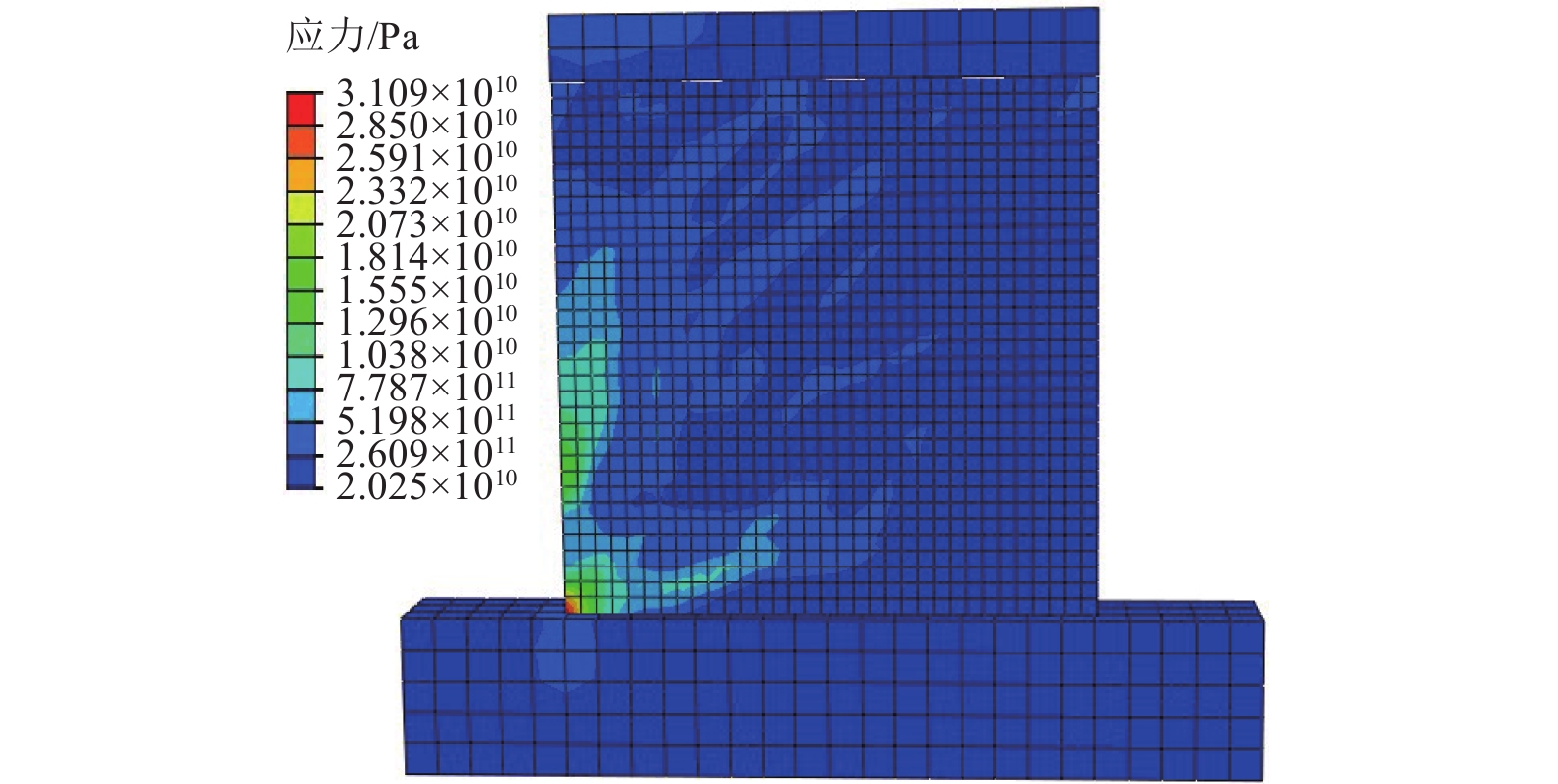

分布.应力急剧增大,沿对角线方向由下往上逐渐减小,并向上发展扩散. 极限阶段 墙体变形迅速增加,塑性变形明显. 混凝土应力达到最大. 破坏阶段 墙体底部受压区的混凝土产生酥裂,受拉区混凝土

明显开裂,并与基础梁脱离,导致变形急剧增大,

试件宣告破坏.混凝土应力随之下降,墙体变形急剧增大,计算不能收敛,试件宣告破坏. -

黄群艺,熊峰,徐锦祥,等. 承重型预制复合墙板抗震节能农居技术研究[J]. 自然灾害学报,2014,23(增刊): 142-145HUANG Qunyi, XIONG Feng, XU jinxiang, et al. Research on new type precast composite concrete structure in rural buildings[J]. Journal of Natural Disasters, 2014, 23(Sup.): 142-145 黄群艺. 新型3D板抗震节能农居结构研究[D]. 成都: 四川大学建筑与环境学院, 2013 黄群艺,熊峰,周宁,等. 新型3D板墙体抗震性能试验研究[J]. 四川大学学报: 工程科学版,2014,46(3): 15-22HUANG Qunyi, XIONG Feng, ZHOU Ning, et al. Experimental research on seismic performance of new type 3D-walls[J]. Journal of Sichuan University: Engineering Science Edition, 2014, 46(3): 15-22 BENAYOUNE A, ABDUL A, SAMAD A. Response of pre-cast reinforced composite sandwich panels to axial loading[J]. Construction and Building Materials, 2007, 21(1): 677-685 MOHAMAD N, HASSAN N. The structural performance of precast lightweight foam concrete sandwich panel with single and double shear truss connectors subjected to axial load[J]. Advanced Materials Research, 2013, 634/635/636/637/638: 2746-2751 BENAYOUNE A, SAMAD A, TRIKHA D, et al. Structural behavior of eccentrically loaded precast sandwich panels[J]. Construction and Building Materials, 2006, 20(1): 713-724 MOHAMAD N, MAHDI H M. Testing of precast lightweight foamed concrete sandwich panel with single and double symmetrical shear truss connectors under eccentric loading[J]. Advanced Materials Research, 2011, 335-336: 1107-1116 BUSH T N, STINE G L. Flexural behavior of composite precast concrete sandwich panels with continuous truss connectors[J]. Pci Journal, 1994, 39(2): 112-121 BENAYOUNE A, SAMAD A, TRIKHA D, et al. Flexural behavior of pre-cast concrete sandwich composite panel-Experimental and theoretical investigations[J]. Construction and Building Materials, 2008, 22(3): 1580-1592 SALMON D, EINEA A, MAHER K, et al. Full scale testing of precast concrete sandwich panels[J]. ACI Structural Journal, 1997, 94(4): 354-362 KABIR M Z. Structural performance of 3D sandwich panels under shear and flexural loading[J]. Scientia Iranica [J], 2005, 12(4): 402-408 KABIR M. Structural performance of 3D sandwich panels under shear and flexural loading[J]. Scientia Iranica [J], 2005, 12(4): 402-408 中华人民共和国国家标准. GB50010—2010 混凝土结构设计规范[S]. 北京: 中国建筑工业出版社, 2010 刘展. ABAQUS6.6基础教程与实例详解[M]. 北京: 中国水利水电出版社, 2008: 221-224 张劲,王庆扬,胡守营,等. ABAQUS混凝土损伤塑性模型参数验证[J]. 建筑结构,2008,38(8): 127-130ZHANG Jin, WANG Qinyang, HU Shouying et al. Parameters verification of concrete damaged plastic model of ABAQUS[J]. Building Structure, 2008, 38(8): 127-130 -

下载:

下载: