Failure Analysis on Surrounding Rock of Soft-Layered Rock Tunnel Using Coupled Continuum-Discrete Model

-

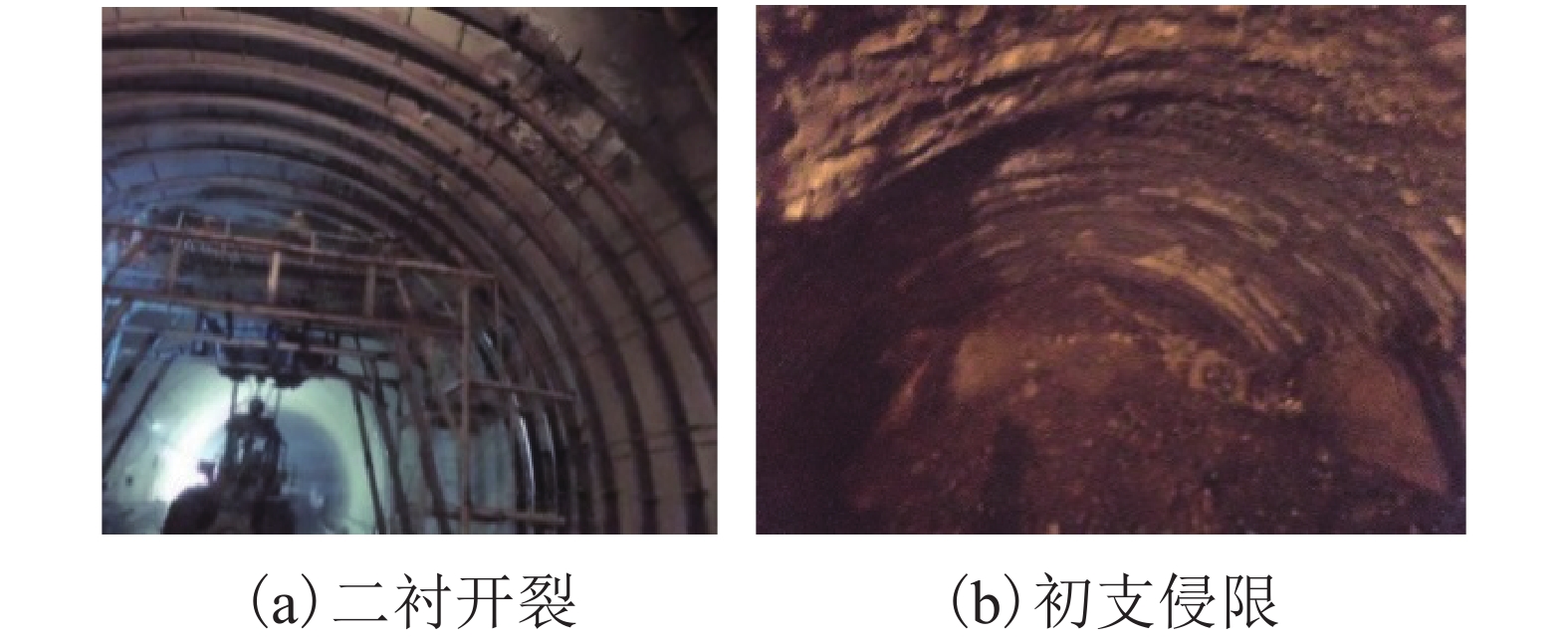

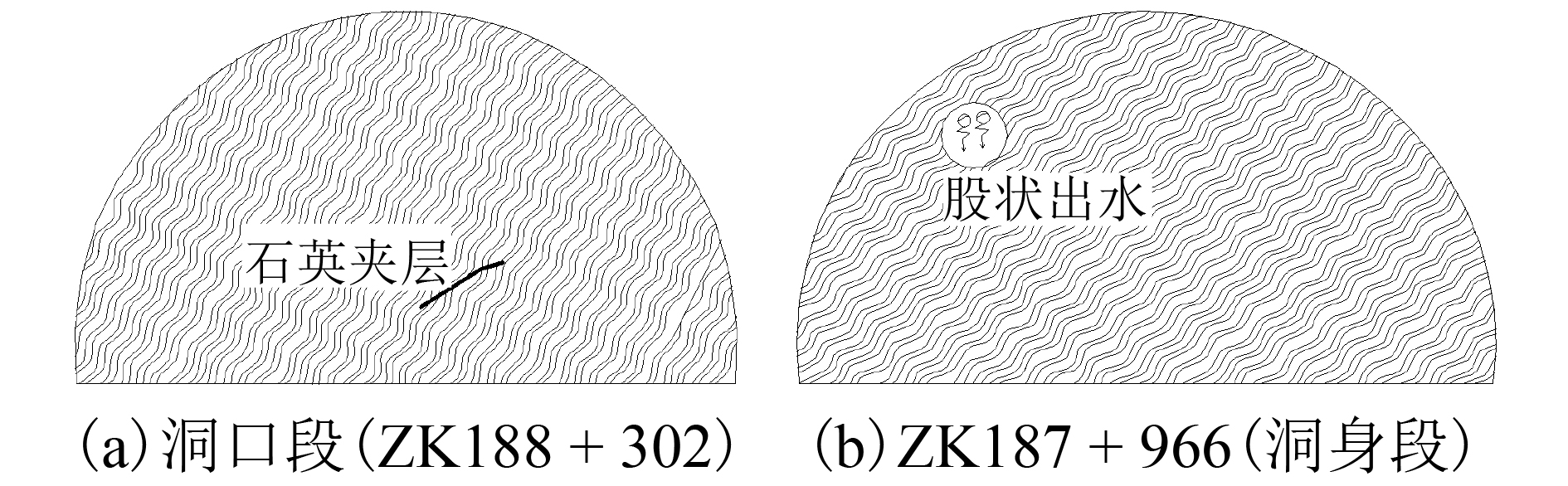

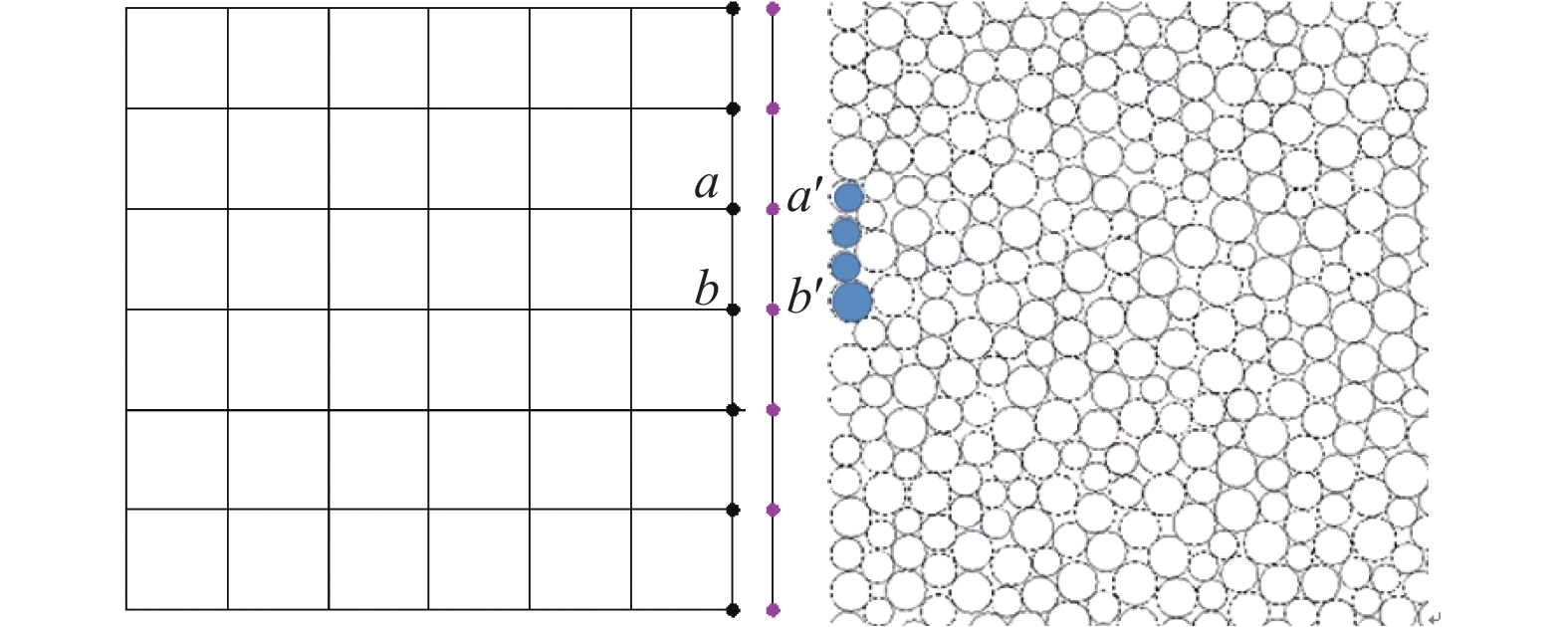

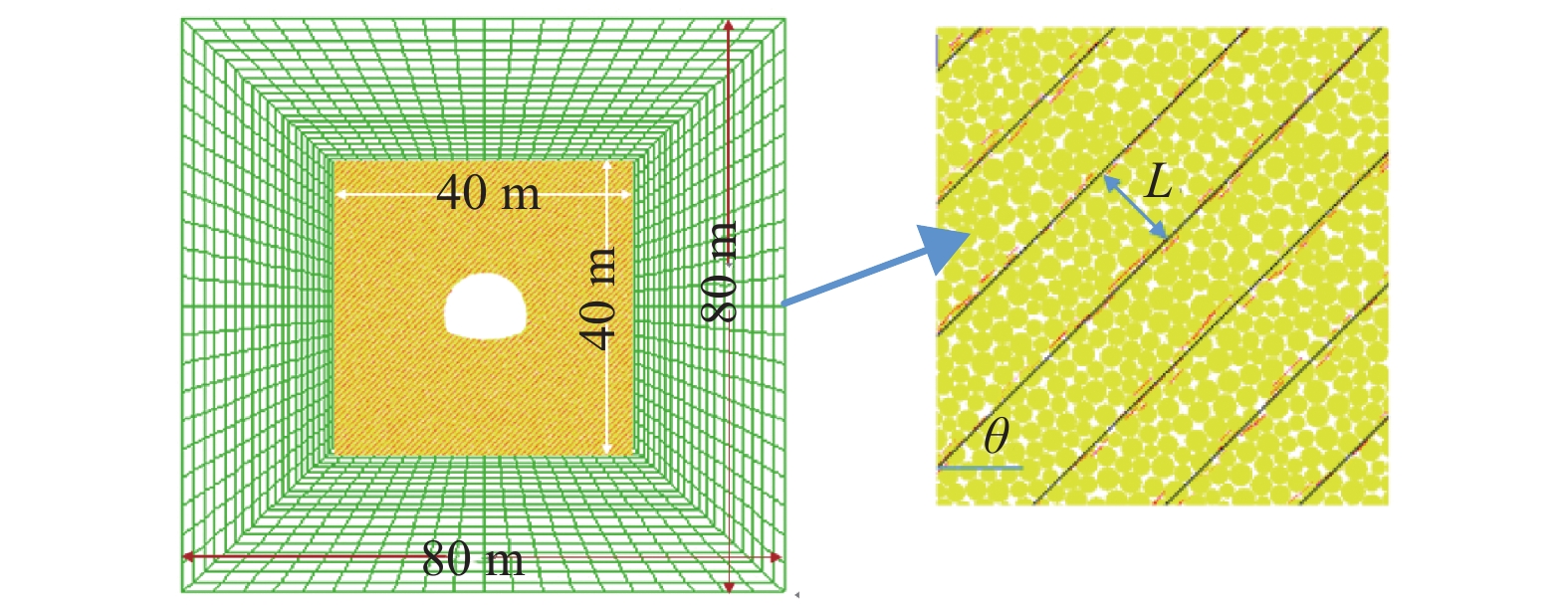

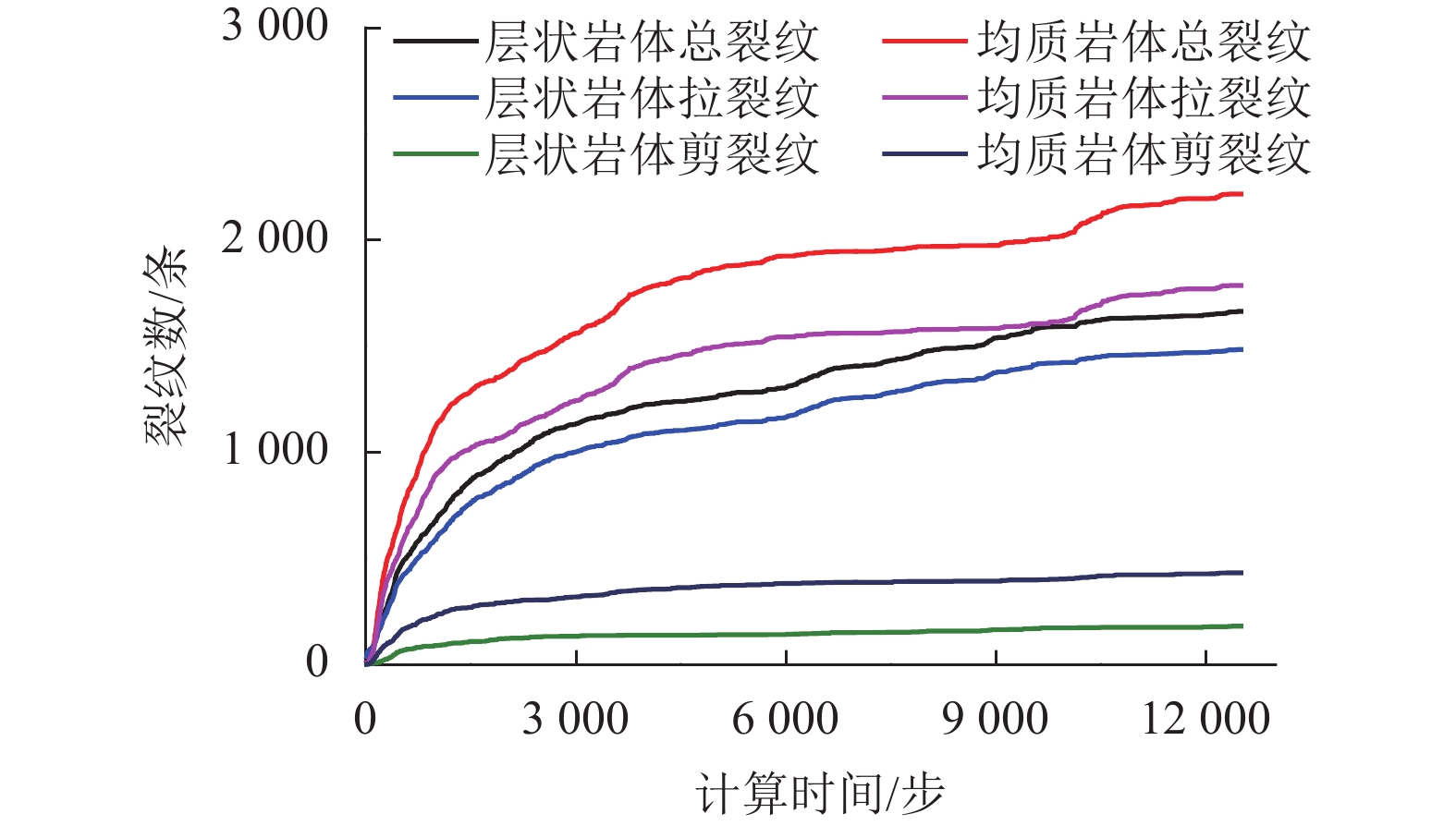

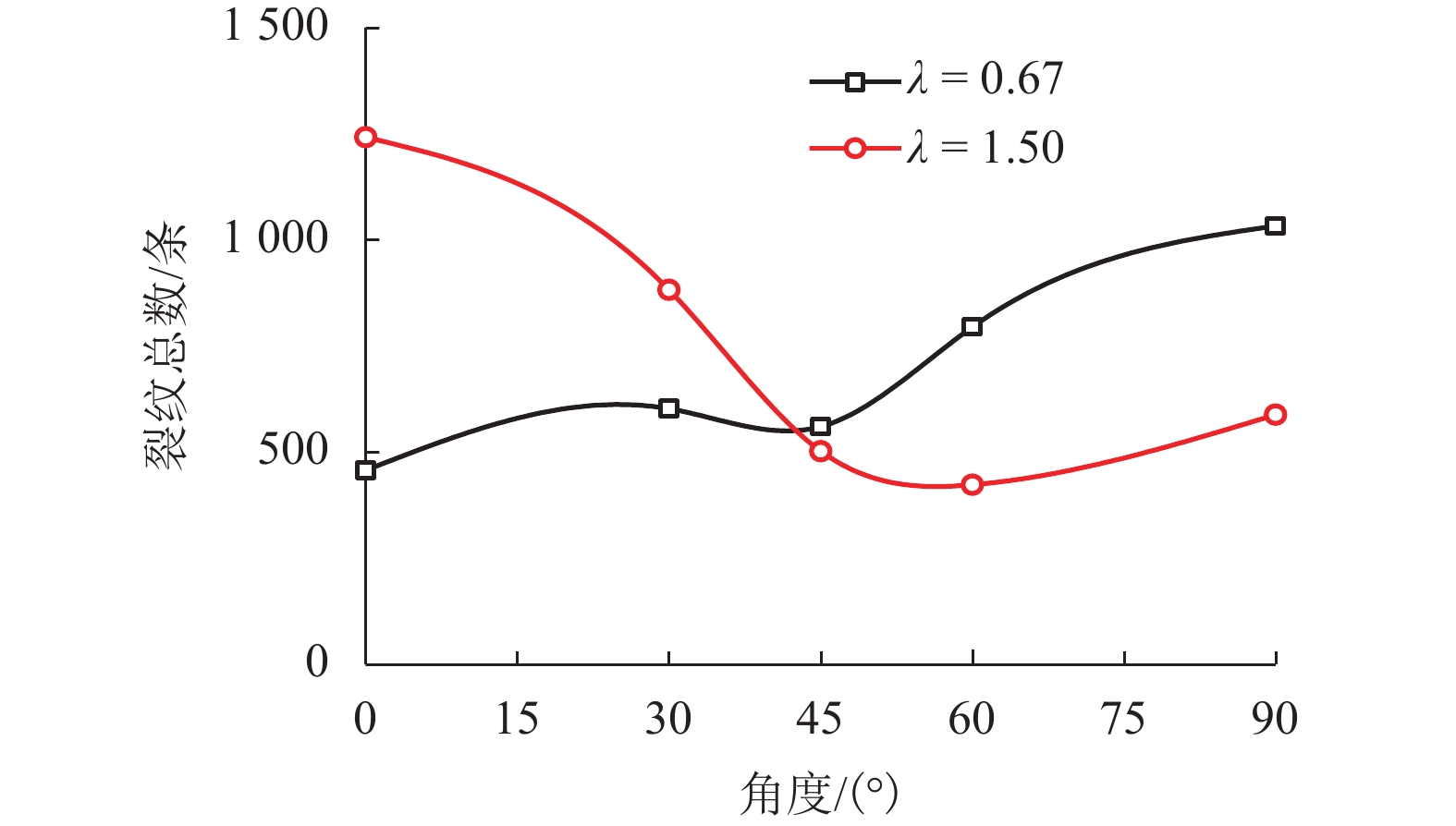

摘要: 为了研究层状岩体中隧道开挖后围岩的破坏机理,以汶马高速鹧鸪山隧道为例,基于离散元-有限差分耦合算法,建立了一种新的层状软岩隧道开挖模拟方法,采用该方法对不同地应力场、层理间距等因素影响下围岩的破坏模式进行了数值模拟. 研究结果表明:隧道开挖后,应力重分布导致强度较低的层理面首先发生滑移及张开破坏,岩体的滑移及张开使得应力场受到进一步扰动,导致层间岩体产生拉裂破坏;同种水平应力条件下,随着侧压力系数的减小,岩体产生的微裂纹不断增多. 当侧压力系数为1.00、0.80、0.67、0.57、0.50时,微裂纹总数分别为304、391、602、999、1 240;当层理间距为0.6 m时,层理对围岩破坏形态起控制作用;随着层理间距从0.6 m增加至1.2 m,层理对围岩破坏模式的控制作用减弱,围岩的破坏形态与均质围岩相似.Abstract: In order to study the failure mechanism of layered surrounding rock after tunnel excavation, taking the Zhegu mountain tunnel of Wenma highway as an example, a new numerical approach is put forward based on continuum-discrete coupling method. The failure patterns of surrounding rock under different geo-stress fields and bedding spacing are obtained through this method. The results show that: slipping and opening failure occurs on joint surface because of its low strength after stress redistribution during tunnel excavation. Then, stress field is disturbed furtherly and this disturbance leads to tensile failure of rock matrix; Micro-cracks in rock mass increases with the decrease of lateral pressure coefficient for the same stress level. When the lateral pressure coefficient is 1.00, 0.80, 0.67, 0.57, and 0.50, the total number of micro-cracks is 304, 391, 602, 999, and 1240, respectively. When the bedding spacing is 0.6 m, bedding has a controlling influence on the failure mode of surrounding rock, while this influence is weakened and the failure mode is similar to that of homogeneous surrounding rock with the increase of bedding spacing from 0.6 m to 1.2 m.

-

Key words:

- layered rock mass /

- soft rock /

- failure mechanics /

- coupled continuum-discrete analysis

-

表 1 BPM模型参数

Table 1. Parameters of BPM

参数 数值 参数 数值 颗粒最小半径/mm 0.18 平行黏结系数 1 最大最小颗粒半径比 1.66 平行黏结弹性模量/GPa 36 颗粒密度/(kg•m–3) 2 730 平行黏结法向-切向刚度比 3.3 颗粒间摩擦因数 0.5 平行黏结法向强度/MPa 65 ± 15 颗粒法向-切向刚度比 3.3 颗粒弹性体模量

/GPa38 平行黏结法向强度/MPa 120 ± 30 表 2 SMJ模型参数

Table 2. Parameters of SMJ

参数 数值 参数 数值 法向刚度

/(GPa•m–1)3 700 黏结模式 切向与法向

黏结切向刚度

/(GPa•m–1)860 黏结法向强度/MPa 3.5 摩擦因数 0.4 黏结黏聚力/MPa 20 剪胀角/(°) 0 黏结摩擦角/(°) 14 表 3 连续单元计算参数

Table 3. Parameters of FDM

密度ρ/(kg•m–3) 弹性模量E/GPa 泊松比ν 2 600 20 0.23 表 4 平行粘结模型参数

Table 4. Parameters of parallel bond

颗粒最小

半径/cm最大最小颗粒

半径比颗粒密度/

(kg•m–3)颗粒间摩

擦因数颗粒弹性

体模量/

GPa颗粒法向-

切向刚

度比平行黏结

系数平行黏结

弹性模量/

GPa平行黏结法

向-切向

刚度比平行黏结法

向强度/

MPa平行黏结法

向强度/

MPa6 1.66 2 600 0.5 20 2.5 1 20 2.5 12 ± 2 12 ± 2 表 5 光滑节理模型参数

Table 5. Parameters of smooth joint

法向刚度/(N•m–1) 切向刚度/(N•m–1) 摩擦因数 剪胀角/(°) 黏结模式 黏结法向强度/MPa 黏结黏聚力/MPa 黏结摩擦角/(°) 2 × 1013 2 × 1013 0.5 0 3 2 2 15 表 6 裂纹统计表

Table 6. Crack number

侧压力系数 裂纹总数/条 拉裂纹占比/% 剪裂纹占比/% 1.00 304 94.1 5.9 0.80 391 92.8 7.2 0.67 602 91.6 7.0 0.57 999 91.3 8.7 0.50 1 240 89.9 10.1 -

韩昌瑞,张波,白世伟,等. 深埋隧道层状岩体弹塑性本构模型研究[J]. 岩土力学,2008,29(9): 2404-2408HAN Changrui, ZHANG Bo, BAI Shiwei, et al. Research on elastoplastic constitutive model of layered surrounding rock mass of a deep buried tunnel[J]. Rock and Soil Mechanics, 2008, 29(9): 2404-2408 TIEN Y M, KUO M C, JUANG C. An experimental investigation of the failure mechanism of simulated transversely isotropic rocks[J]. International Journal of Rock Mechanics and Mining Science, 2006, 43(8): 1163-1181 LISJAK A, GARITTE B, GRASSELLI G, et al. The excavation of a circular tunnel in a bedded argillaceous rock (opalinus clay): short-term rock mass response and FDEM numerical analysis[J]. Tunnelling and Underground Space Technology, 2015, 45: 227-248 BLUMLING P, BERNIER F, LEBON P, et al. The excavation damaged zone in clay formations time-dependent behaviour and influence on performance assessment[J]. Phys. Chem. Earth Parts A/B/C, 2007, 32: 588-599 沙鹏,伍法权,李响,等. 高地应力条件下层状地层隧道围岩挤压变形与支护受力特征[J]. 岩土力学,2015,36(5): 1407-1414SA Peng, WU Faquan, LI Xiang, et al. Squeezing deformation in layered surrounding rock and force characteristics of support system of a tunnel under high in-situ stress[J]. Rock and Soil Mechanics, 2015, 36(5): 1407-1414 夏彬伟. 深埋隧道层状岩体破坏失稳机理实验研究[D]. 重庆: 重庆大学, 2009 周晓军,高杨,李泽龙,等. 地质顺层偏压隧道围岩压力及其分布特点的试验研究[J]. 现代隧道技术,2006,43(1): 12-21ZHOU Xiaojun, GAO Yang, LI Zelong, et al. Experimental study on the uneven rock pressure and its distribution applied on a tunnel embedded in geologically bedding strata[J]. Modern Tunnelling Technology, 2006, 43(1): 12-21 LABIOUSE V, VIECTOR T. Laboratory and in-situ simulation tests of the excavation damaged zone around galleries in Opalinus Clay[J]. Rock Mechanics and Rock Engineering, 2014, 47: 57-70 CORKUM A G. Behaviour of Opalinus Clay around deep underground excavations[D]. Edmonton: University of Alberta, 2006 POPP T, SALZER K, MINKLEY W. Influence of bedding planes to EDZ-evolution and the coupled HM properties of opalinus clay. phys. chem[J]. Earth, 2008, 33: 374-387 YOUNG S, KAISER P K, LOEW S. Influence of tectonic shears on tunnel-induced fracturing[J]. International journal of rock mechanics and mining science, 2010, 47: 894-907 JUNG-WOO C, HANNA K, SEOKWON J, et al. Deformation and strength anisotropy of Asan gneiss, Boryeong shale, and Yeoncheon schist[J]. International journal of Rock Mechanics and Mining Science, 2012, 50: 158-169 ZHOU Jian, JIAN Qiwei, ZHANG Jiao, et al. Coupled 3D discrete-continuum numerical modeling of pile penetration in sand[J]. Journal of Zhejiang University-Science A: Applied Physics & Engineering, 2012, 13(1): 44-55 孙新坡,何思明,刘恩龙,等. 基于离散元和有限差分耦合算法的崩塌体和结构碰撞预测分析[J]. 工程力学,2014,31(12): 32-39SUN Xinpo, HE Siming, LIU Enlong, et al. Prediction analysis for impact of collapse bodies on structures based on unified discrete element and finite difference numerical simulation[J]. Engineering mechanics, 2014, 31(12): 32-39 李永兵,周喻,吴顺川,等. 圆形巷道围岩变形破坏的连续–离散耦合分析[J]. 岩石力学与工程学报,2015,34(9): 1849-1858LI Yongbing, ZHOU Yu, WU Shunchuan, et al. Deformation and failure analysis on surrounding rock of circular tunnel using coupled continuum-discrete method[J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(9): 1849-1858 严琼,吴顺川,周喻,等. 基于连续-离散耦合的边坡稳定性分析研究[J]. 岩土力学,2015,36(增刊2): 47-56YAN Qiong, WU Shunchuan, ZHOU Yu, et al. Slope stability analysis based on technology of continuum-discrete coupling[J]. Rock and Soil Mechanics, 2015, 36(Sup.2): 47-56 -

下载:

下载: