|

DONZELLA G, FACCOLI M, MAZZÙ A, et al. Progressive damage assessment in the near-surface layer of railway wheel-rail couple under cyclic contact[J]. Wear, 2011, 271: 408-416

|

|

WANG W J, GUO H M, DU X, et al. Investigation on the damage mechanism and prevention of heavy-haul railway rail[J]. Engineering Failure Analysis, 2013, 35: 206-218

|

|

刘启跃,张波,周仲荣,等. 滚动轮波形磨损实验研究[J]. 摩擦学学报,2003,23(2): 132-135LIU Qiyue, ZHANG Bo, ZHOU Zhongrong, et al. Experimental study on rolling wheel corrugation[J]. Tribology, 2003, 23(2): 132-135

|

|

邓铁松. 两种轴箱悬挂布置直线电机地铁车辆的轮轨磨耗及动力学性能对比[D]. 成都: 西南交通大学, 2014

|

|

大野薰. 增粘材料喷射装置(喷砂器)[J]. 国外内燃机车,2007(2): 11-14

|

|

JIN X S, ZHANG W H, ZENG J, et al. Adhesion experiment on a wheel-rail system and its numerical analysis[J]. Proceedings of the Institution of Mechanical Engineers,Part J:Journal of Engineering Tribology, 2004, 218(1): 293-303

|

|

ZHANG W H, CHEN J Z, WU X J, et al. Wheel/rail adhesion and analysis by using full scale roller rig[J]. Wear, 2002, 253: 82-88

|

|

KUMER S. 北美机车在撒砂和不撒砂情况下的轮轨磨损与粘着[J]. 国外内燃机车, 1987(10): 10-18

|

|

LIU Q Y, ZHANG B, ZHOU Z R. An experimental study of rail corrugation[J]. Wear, 2003, 255(7): 1121-1126

|

|

WANG W J, ZHONG W, LIU Q Y, et al. Investigation on rolling wear and fatigue properties of railway rail[J]. Proceedings of the Institution of Mechanical Engineers,Part J:Journal of Engineering Tribology, 2009, 223(7): 1033-1039

|

|

JIN Y, ISHIDA M, NAMURA A. Experimental simulation and prediction of wear of wheel flange and rail gauge corner[J]. Wear, 2011, 271(1/2): 259-267

|

|

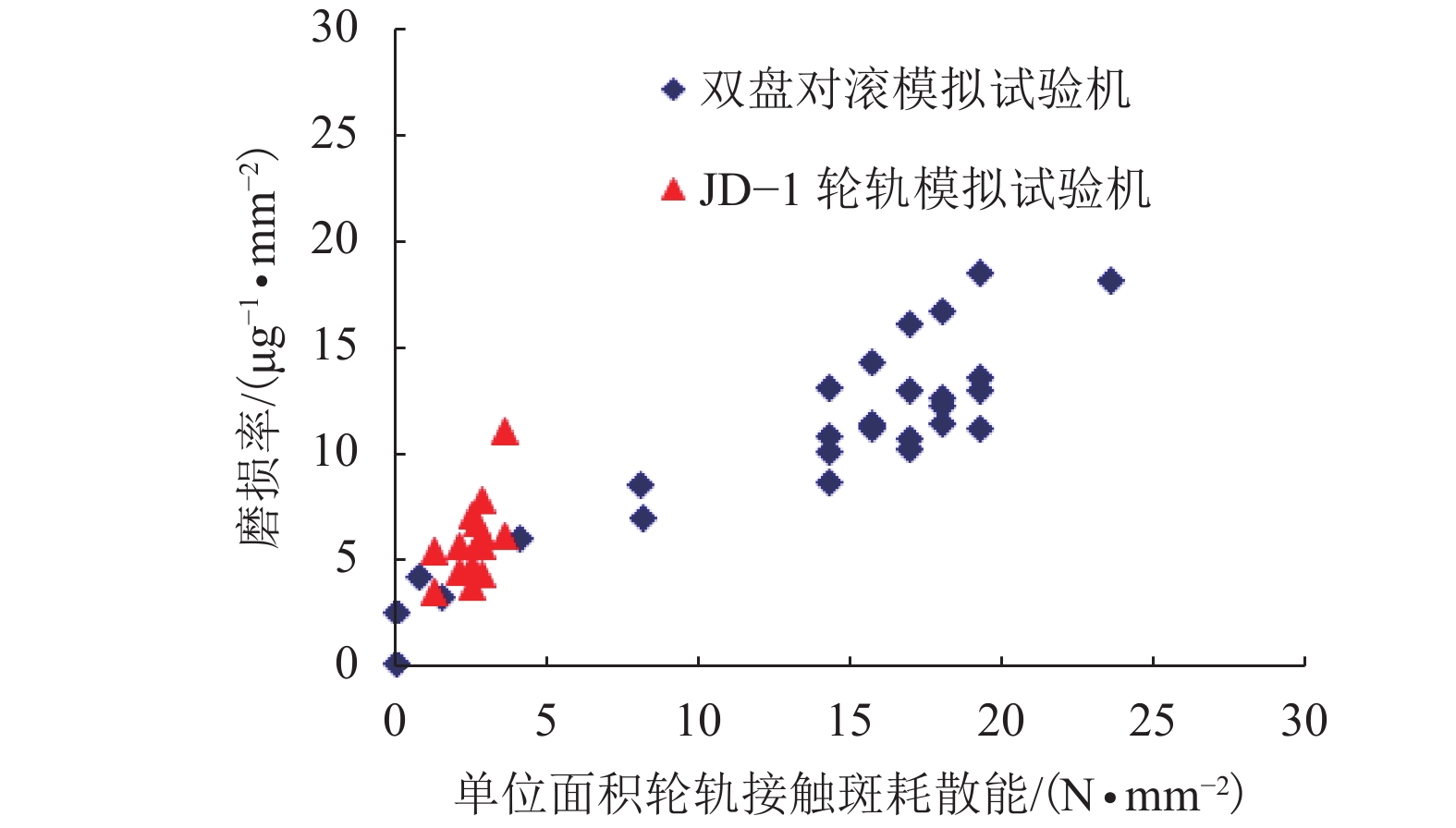

FLETCHER D I, BEYNON J H. Development of a machine for closely controlled rolling contact fatigue and wear testing[J]. Journal of Testing and Evaluation, 2000, 28(4): 267-275

|

|

DING H H, FU Z K, WANG W J, et al. Investigation on the effect of rotational speed on rolling wear and damage behaviors of wheel/rail materials[J]. Wear, 2015, 330/331: 563-570

|

|

BOLTON P J, CLAYTON P. Rolling-sliding wear damage in rail and type steels[J]. Wear, 1984, 93(2): 145-165

|

|

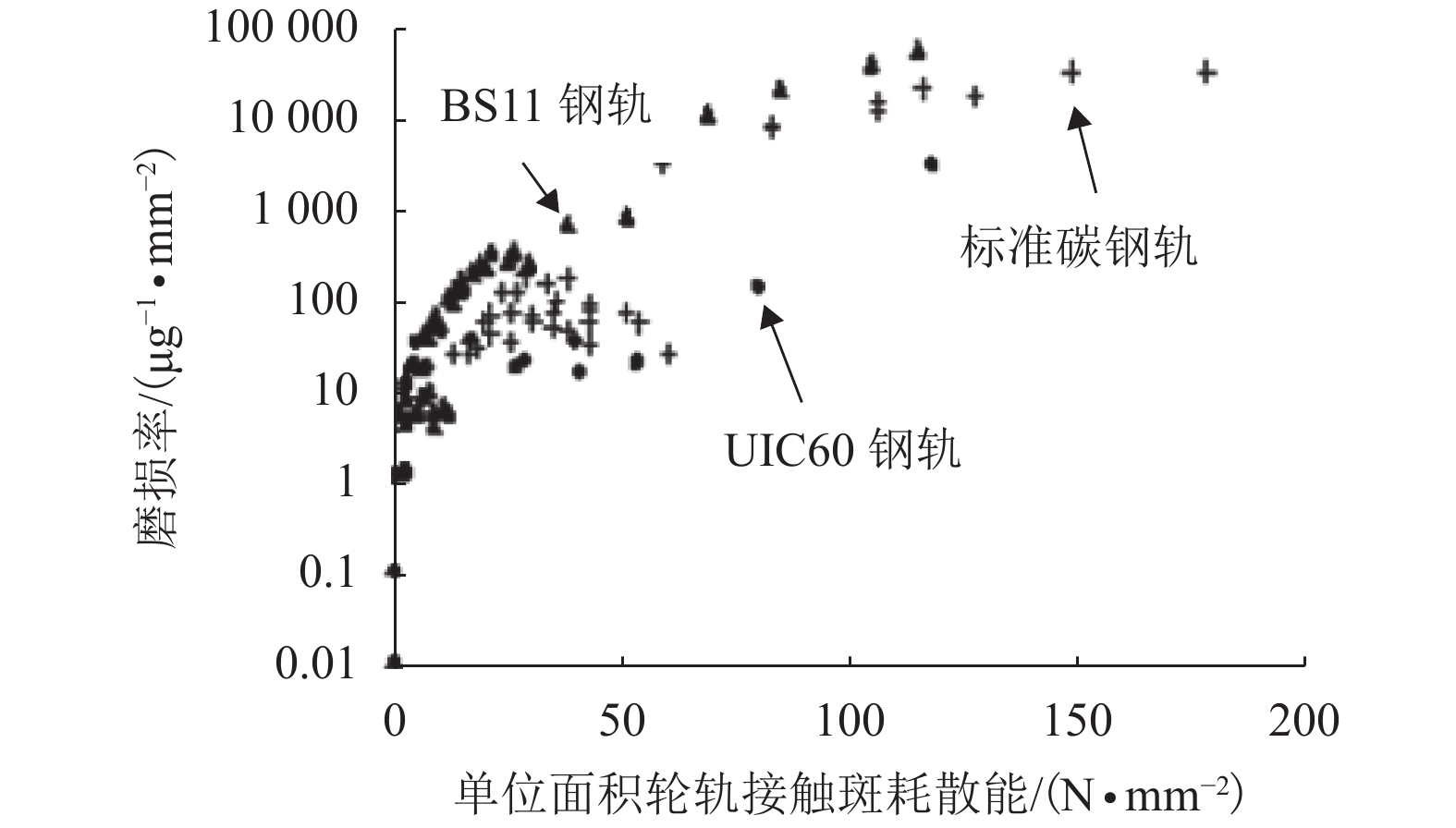

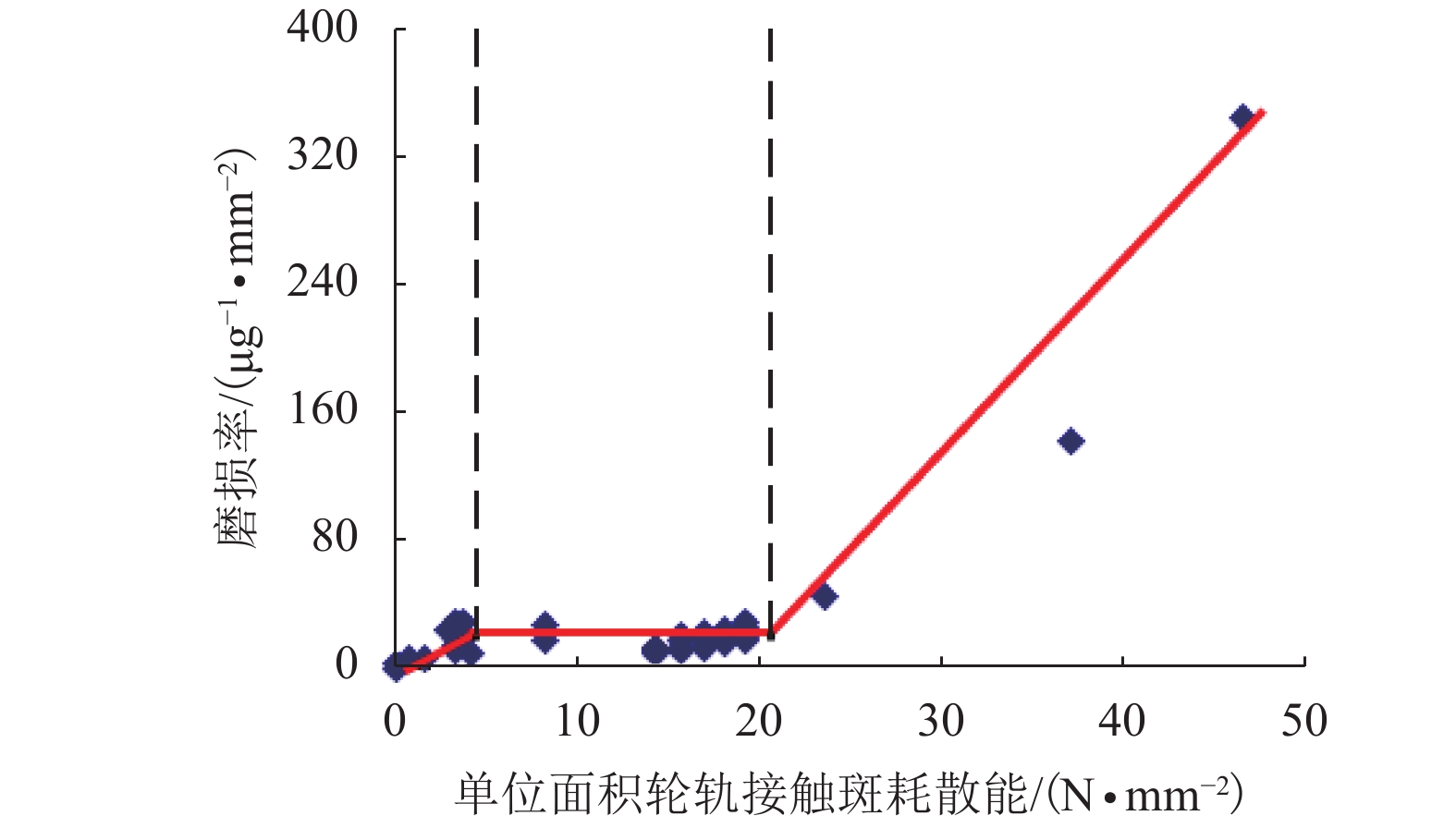

LEWIS R, OLOFSSON U. Mapping rail wear regimes and transitions[J]. Wear, 2004, 257(7): 721-729

|

|

LEWIS R, DWYER-JOYCE R S. Wear mechanisms and transitions in railway wheel steels[J]. Proceedings of the Institution of Mechanical Engineers,Part J:Journal of Engineering Tribology, 2004, 218(6): 467-478

|

|

LEWIS R, DWYER-JOYCE R S, OLOFSSON U, et al. Mapping railway wheel material wear mechanisms and transitions[J]. Proceedings of the Institution of Mechanical Engineers,Part F:Journal of Rail and Rapid Transit, 2010, 224(3): 125-137

|

|

BRAGHIN F, LEWIS R, DWYER-JOYCE R S, et al. A mathematical model to predict railway wheel profile evolution due to wear[J]. Wear, 2006, 261(11): 1253-1264

|

|

POMBOA J, AMBRÓSIO J, PEREIRA M, et al. Development of a wear prediction tool for steel railway wheels using three alternative wear functions[J]. Wear, 2011, 271(1): 238-245

|

|

WANG W J, LEWIS R, YANG B, et al. Wear and damage transitions of wheel and rail materials under various contact conditions[J]. Wear, 2016, 362/363: 146-152

|

|

HARDWICK C, LEWIS R, EADIE D T. Wheel and rail wear understanding the effects of water and grease[J]. Wear, 2014, 314(1): 198-204

|

下载:

下载: