Combined Support of Segmental Lining and Compressible Layer of Coal Mine Shafts

-

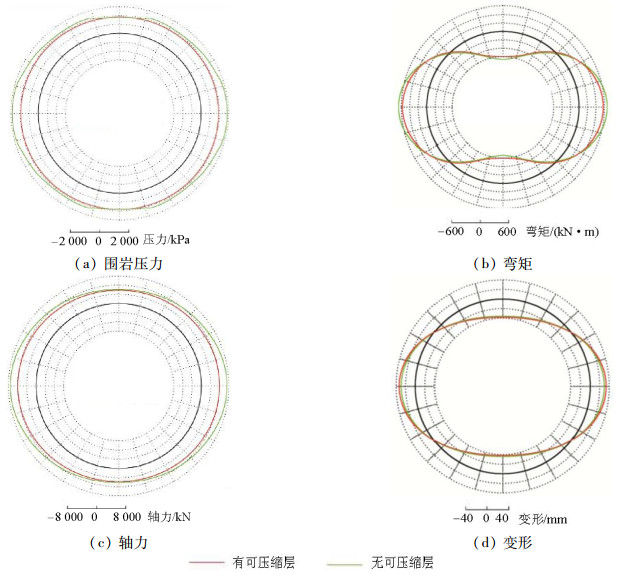

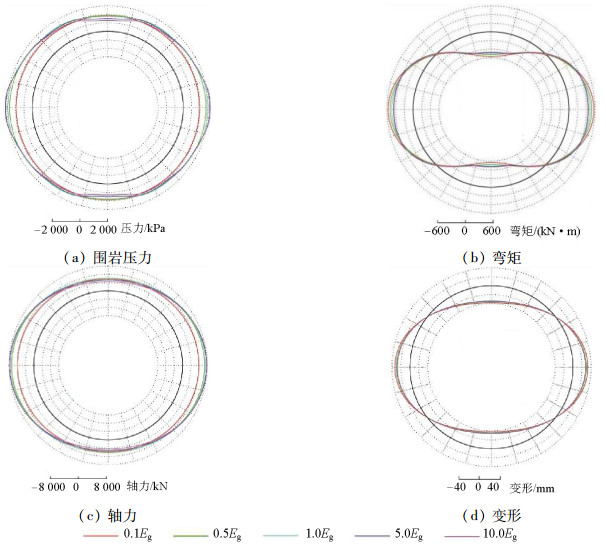

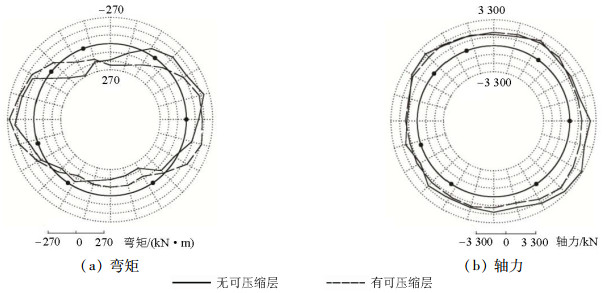

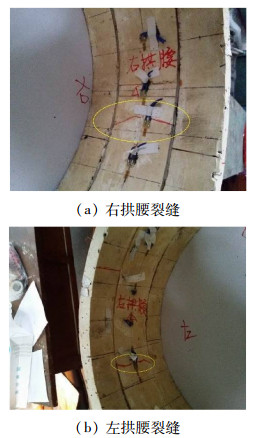

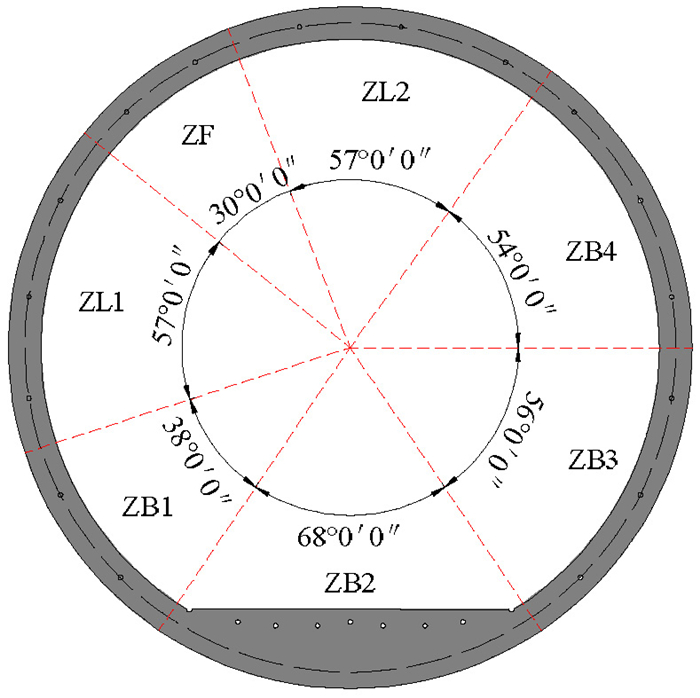

摘要: 为研究盾构斜井管片衬砌与可压缩层联合支护体系中可压缩层参数对管片衬砌力学性能的影响,以神华新街台格庙矿区主斜井工程为依托,建立考虑管片衬砌与可压缩层之间接触效应和管片整环刚度折减效应的数值计算模型,分析有无可压缩层、不同可压缩层刚度及厚度等因素下管片衬砌内力和变形的分布规律和变化情况;采用相似模型试验对上述问题进行了进一步研究,并对有无可压缩层时管片的极限承载力和破坏形式进行了探讨.研究结果表明:可压缩层刚度越大,管片所受围岩压力越大且分布越不均匀,同时使得管片弯矩减小,轴力增大,当可压缩层模量与围岩模量之比在0.1~0.5之间变化时更为明显;随着可压缩层厚度的增大,管片所受围岩压力依次按不均匀、均匀、不均匀的趋势变化,当可压缩层厚度与管片厚度之比为1.7时围岩压力最小,管片轴力则随可压缩层厚度的增大而减小;可压缩层存在与否对管片变形影响甚微,通过自身的挤密吸收围岩压力且促使应力重分布,从而减小并均匀化传递至管片上的荷载,使得管片内力随外荷载的增长更平缓,量值更小且分布更均匀,并使管片的极限承载力提高了40%;有无可压缩层时管片破坏均经历椭变、椭变加剧、裂缝出现和扩展、失稳破坏的过程,且有可压缩层时管片的破坏更严重.Abstract: In order to study the influence of the compressible layer parameters on the mechanical properties of the segmental lining in the combined support system of the inclined shaft constructed by shield, a numerical model considering the contact effect between the segmental lining and the compressible layer and the stiffness reduction of the segment ring was established based on the Main Inclined Shaft Project of Shenhua Xinjie Taigemiao Coal Mine Area, and the distribution characteristics and variation laws of the internal force and deformation of the segmental lining are analyzed under different factors such as the presence or absence, the stiffness and the thickness of compressible layer. Similar model tests were carried out to further investigate the above problems. The ultimate bearing capacity and the form of destruction are also discussed. The results show that the greater the compressible layer stiffness, the greater the and the more uneven distribution of the surrounding rock pressure on the segment, at the same time, the bending moment of the segment decreases and the axial force increases. It is more obvious when the ratio of compressible layer modulus to surrounding rock modulus varies from 0.1 to 0.5. With the increase of the compressible layer thickness, the surrounding rock pressure on the segment varies according to the trend of uneven to uniform and then again to uneven. When the ratio of the compressible layer thickness to the segment thickness is 1.7, the pressure of the surrounding rock is the smallest. The axial force decreases with the increase of compressible layer thickness. The existence of compressible layer has little effect on the deformation of segmental lining. The model test results further show that the compressible layer can absorb the surrounding rock pressure and cause stress redistribution through its own compaction, so as to reduce and homogenize the load transferred to the segment, so that the internal force of the segment grows more smoothly with the external load smaller and more evenly distributed; and increased the ultimate bearing capacity of the segments by 40%. In the presence or absence of the compressible layer, the failure of the segment has experienced the processes of elliptic, elliptical exacerbation, the occurrence and expansion of the crack and instability.Moreover, the damage of the segment is more serious when the compressible layer is present. The research results of this paper can provide some reference for the design and construction of similar projects.

-

Key words:

- coal mine shaft /

- segmental lining /

- compressible layer /

- yieldable support /

- shield construction /

- model test

-

表 1 地层及结构物理力学参数

Table 1. Parameters of seepage property for sandstone

名称 变形模量/GPa 天然重度/(kN·m-3) 粘聚力c/MPa 内摩擦角φ/(°) 泊松比 围岩 1.50 1.85 0.125 23.5 0.40 管片衬砌 34.50 — — — 0.20 碎石可压缩层 0.15~15.00 — — — 0.40 表 2 有无可压缩层时管片衬砌内力和变形对比

Table 2. Comparison of internal force and deformation of segment lining in the presence or absence of compressible layer

工况 围岩压力/kPa 弯矩/(kN·m) 轴力/kN 变形/mm 最大 最小 最大 最小 最大 最小 最大 最小 无可压缩层 1 912 1 216 624 -654 7 423 4 098 32.1 25.2 有可压缩层 1 278 1 227 564 -566 5 268 3 877 32.6 25.3 变化率/% -33.2 0.9 -9.6 -13.4 -28.8 -5.4 1.6 0.4 表 3 不同可压缩层刚度时管片衬砌内力和变形对比

Table 3. Comparison of internal force and deformation of segment lining with different compressible layer stiffness

Ec/ Eg 围岩压力/kPa Rp/% 弯矩/(kN·m) 轴力/kN 变形/mm 最大 最小 最大 最小 最大 最小 最大 最小 0.1 1 278 1 227 4.2 564 -566 5 268 3 877 32.6 25.3 0.5 1 803 1 267 35.0 522 -523 7 123 4 087 32.2 25.2 1.0 1 936 1 194 47.4 487 -504 7 492 3 986 32.1 25.2 5.0 2 106 996 71.5 445 -476 7 813 3 514 32.0 25.2 10.0 2 134 856 85.4 438 -466 7 887 3 002 31.9 25.3 表 4 不同可压缩层厚度时管片衬砌内力和变形对比

Table 4. Comparison of internal force and deformation of segment lining with different compressible layer thickness

Ec/ Eg 围岩压力/kPa Rp/% 弯矩/(kN·m) 轴力/kN 变形/mm 最大 最小 最大 最小 最大 最小 最大 最小 0.2 1 466 1 298 12.2 550 -548 5 929 4 162 32.4 25.2 0.4 1 278 1 227 4.2 564 -566 5 268 3 877 32.6 25.3 0.6 1 164 1 158 0.5 577 -576 4 855 3 610 32.7 25.3 0.8 1 105 1 080 2.2 581 -585 4 575 3 397 32.8 25.4 1.0 1 063 1 024 3.8 581 -592 4 374 3 232 32.9 25.4 表 5 材料物理力学参数

Table 5. Mechanical parameters of materials

项目 容重/(kg·m-3) 弹性模量/GPa 粘聚力/MPa 内摩擦角/(°) 原型 17.0~20.0 1.0~2.0 0.05~0.20 20~27 模型 19.0 0.7 0.01 22 表 6 环向接头对应槽缝深度

Table 6. Cutting depth of groove for circumferential joints

参数 原型弯曲刚度/(N·m·rad-1) 原型槽缝深度/m 模型槽缝深度/mm 正弯曲 3.0×107 0.155 8 负弯曲 2.0×107 0.180 9 -

何川.盾构/TBM施工煤矿长距离斜井的技术挑战与展望[J].隧道建设, 2014, 34(4):287-297. http://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201404001.htmHE Chuan. Challenges and prospective of construction of long-distance inclined shafts of coal mine by shield/TBM[J]. Tunnel Construction, 2014, 34(4):287-297. http://www.cnki.com.cn/Article/CJFDTOTAL-JSSD201404001.htm 何川, 齐春, 晏启祥, 等.盾构(TBM)施工煤矿长距离斜井关键问题研究现状与展望[C]//第七届中日盾构隧道技术交流会论文集.西安: 人民交通出版社, 2013: 227-235. 王建宇, 胡元芳, 刘志强.高地应力软弱围岩隧道挤压型变形和可让性支护原理[J].现代隧道技术, 2012, 49(3):9-17. doi: 10.3969/j.issn.1009-6582.2012.03.002WANG Jianyu, HU Yuanfang, LIU Zhiqiang. Tunneling in squeezing ground with yielding supports[J]. Modern Tunneling Technology, 2012, 49(3):9-17. doi: 10.3969/j.issn.1009-6582.2012.03.002 赵玉东.挤压型大变形地下硐室中支护型式的适宜性研究[D].成都: 西南交通大学, 2016. 袁亮.深井巷道围岩控制理论及淮南矿区工程实践[M].北京:煤炭工业出版社, 2006:27-29. RAMONI M, ANAGNOSTOU G. Tunnel boring machines under squeezing conditions[J]. Tunnelling and Underground Space Technology, 2010, 25(2):139-157. doi: 10.1016/j.tust.2009.10.003 CANTIENI L, ANAGNOSTOU G. The interaction between yielding supports and squeezing ground[J]. Tunnelling and Underground Space Technology, 2009, 24(3):309-322. doi: 10.1016/j.tust.2008.10.001 SWK C, BROWN S F. Reduced rutting in unbound granular pavement layers through improved grading design[J]. Transport, 1996, 117(1):40-49. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=23782f0efab71e8772a5ed31f9365637 WERKMEISTER S, DAWSON A R, WELLNER F, et al. Permanent deformation behavior of granular materials[J]. Road Materials and Pavement Design, 2005, 6(1):31-51. doi: 10.3166-rmpd.6.31-51/ BROWN S F, HYDE A F L. Significance of cyclic confining stress in repeated-load triaxial testing of granular material[C]//Transportation Research Record. Washington D. C.: TRB, 1975: 49-58. 田建勃, 韩晓雷, 于清桦, 等.碎石垫层强度与变形特性试验研究和有限元分析[J].岩土力学, 2014, 35(1):83-89, 97. http://d.old.wanfangdata.com.cn/Periodical/ytlx201401012TIAN Jianbo, HAN Xiaolei, YU Qinghua, et al. Experimental study and finite element analysis of strength and deformation characteristics of gravel cushion[J]. Rock and Soil Mechanics, 2014, 35(1):83-89, 97. http://d.old.wanfangdata.com.cn/Periodical/ytlx201401012 谷小阳.级配碎石复合式基层沥青路面力学性能研究[D].西安: 长安大学, 2015. 封坤.大断面水下盾构隧道管片衬砌结构的力学行为研究[D].成都: 西南交通大学, 2011. 封坤, 何川, 苏宗贤.南京长江隧道原型管片结构破坏试验研究[J].西南交通大学学报, 2011, 46(4):564-571. http://manu19.magtech.com.cn/Jweb_xnjd/CN/abstract/abstract11459.shtmlFENG Kun, HE Chuan, SU Zongxian. Prototype test on failure characteristics of segmental lining structure for Nanjing Yangtze River Tunnel[J]. Journal of Southwest Jiaotong University, 2011, 46(4):564-571. http://manu19.magtech.com.cn/Jweb_xnjd/CN/abstract/abstract11459.shtml 李晶晶. TBM(盾构)施工斜井围岩-支护相互作用机理研究[D].北京: 中国矿业大学, 2015. 何川, 周济民, 封坤, 等.基于接头非线性抗弯刚度的盾构隧道迭代算法的实现与应用[J].土木工程学报, 2012, 45(3):166-173. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201201447378HE Chuan, ZHOU Jimin, FENG Kun, et al. An iterative algorithm based on segment joint stiffness nonlinearity and application for shield tunnel structures[J]. China Civil Engineering Journal, 2012, 45(3):166-173. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201201447378 胡雄玉, 晏启祥, 何川, 等.管片衬砌配合碎石可压缩层的斜井支护结构型式及其应用[J].岩石力学与工程学报, 2016, 35(3):579-591. http://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201603015.htmHu Xiongyu, YAN Qixiang, HE Chuan, et al. A support structure of segment lining combined with compressible crushed stone and its applications in inclined shaft[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(3):579-591. http://www.cnki.com.cn/Article/CJFDTOTAL-YSLX201603015.htm 王士民, 于清洋, 彭博, 等.水下盾构隧道管片衬砌结构渐进性破坏机理模型试验研究[J].土木工程学报, 2016, 49(4):111-120. http://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201604013.htmWANG Shimin, YU Qingyang, PENG Bo, et al. A model test for the progressive failure mechanism of lining segment structure of underwater shield tunnels[J]. China Civil Engineering Journal, 2016, 49(4):111-120. http://www.cnki.com.cn/Article/CJFDTOTAL-TMGC201604013.htm -

下载:

下载: