|

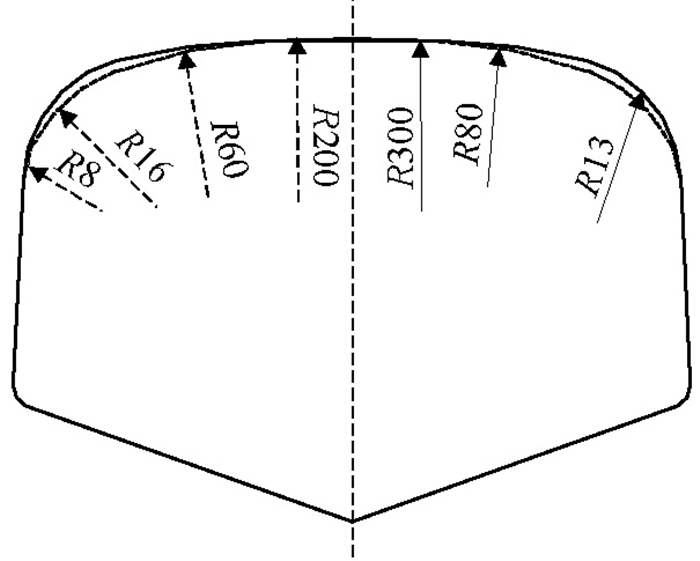

周清跃, 张银花, 田常海, 等. 60N钢轨的廓型设计及试验研究[J].中国铁道科学, 2014, 35(2):128-135. doi: 10.3969/j.issn.1001-4632.2014.02.21ZHOU Qingyue, ZHANG Yinhua, TIAN Changhai, et al. Profile design and test study of 60N rail[J]. China Railway Science, 2014, 35(2):128-135. doi: 10.3969/j.issn.1001-4632.2014.02.21

|

|

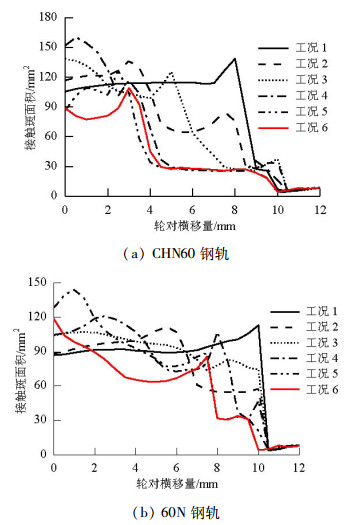

王健, 马晓川, 陈嘉胤, 等.高速铁路CHN60N钢轨与不同车轮踏面匹配性能研究[J].铁道学报, 2017, 39(12):94-101. doi: 10.3969/j.issn.1001-8360.2017.12.013WANG Jian, MA Xiaochuan, CHEN Jiayin, et al. Study of matching performance of CHN60N rail with different wheel treads in high-speed railway[J]. Journal of the China Railway Society, 2017, 39(12):94-101. doi: 10.3969/j.issn.1001-8360.2017.12.013

|

|

干锋, 戴焕云, 高浩, 等.铁道车辆不同踏面等效锥度和轮轨接触关系计算[J].铁道学报, 2013, 35(9):19-24. doi: 10.3969/j.issn.1001-8360.2013.09.004GAN Feng, DAI Huanyun, GAO Hao, et al. Calculation of equivalent conicity and wheel-rail contact relationship of different railway vehicle treads[J]. Journal of the China Railway Society, 2013, 35(9):19-24. doi: 10.3969/j.issn.1001-8360.2013.09.004

|

|

肖广文, 肖新标, 温泽峰, 等.高速客车轮对动力学性能的比较[J].铁道学报, 2008, 30(6):29-35. doi: 10.3321/j.issn:1001-8360.2008.06.006XIAO Guangwen, XIAO Xinbiao, WEN Zefeng, et al. Comparison of dynamic behaviors of wheelsets of high-speed passenger car[J]. Journal of the China Railway Society, 2008, 30(6):29-35. doi: 10.3321/j.issn:1001-8360.2008.06.006

|

|

罗仁, 曾京, 邬平波, 等.高速列车轮轨参数对车轮踏面磨耗的影响[J].交通运输工程学报, 2009, 9(6):47-63. doi: 10.3969/j.issn.1671-1637.2009.06.010LUO Ren, ZENG Jing, WU Pingbo, et al. Influence of wheel/rail parameters on wheel profile wear of high-speed train[J]. Journal of Traffic and Transportation Engineering, 2009, 9(6):47-63. doi: 10.3969/j.issn.1671-1637.2009.06.010

|

|

马晓川, 王平, 徐井芒, 等.基于高速铁路60N钢轨的车辆动力性能比较[J].中南大学学报:自然科学版, 2016, 47(11):3940-3947. http://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201611043.htmMA Xiaochuan, WANG Ping, XU Jingmang, et al. Comparison of vehicle dynamic characteristic with high-speed rail of 60N[J]. Journal of Central South University:Science and Technology, 2016, 47(11):3940-3947. http://www.cnki.com.cn/Article/CJFDTOTAL-ZNGD201611043.htm

|

|

崔大宾.高速车轮踏面设计方法研究[D].成都: 西南交通大学, 2013.

|

|

LI Z. Wheel-rail rolling contact and its application to wear simulation[D]. Delft: Delft University of Technology, 2002.

|

|

马晓川, 王平, 王健, 等.尖轨降低值超限对转辙器动力特性的影响研究[J].铁道学报, 2016, 38(3):99-105. http://d.old.wanfangdata.com.cn/Periodical/tdxb201603014MA Xiaochuan, WANG Ping, WANG Jian, et al. Study on impact of over-limit reduced value of switch rail on dynamic characteristics of switch[J]. Journal of the China Railway Society, 2016, 38(3):99-105. http://d.old.wanfangdata.com.cn/Periodical/tdxb201603014

|

|

XU J M, WANG P, WANG L, et al. Effects of profile wear on wheel-rail contact conditions and dynamic interaction of vehicle and turnout[J]. Advances in Mechanical Engineering, 2016, 8(1):1-14. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=Doaj000004705778

|

|

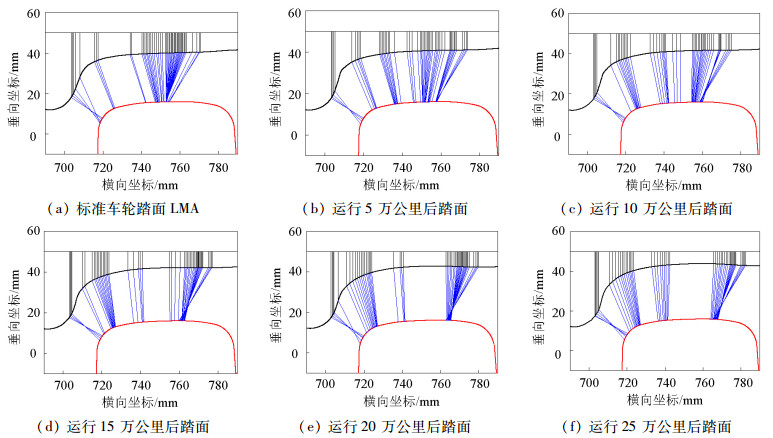

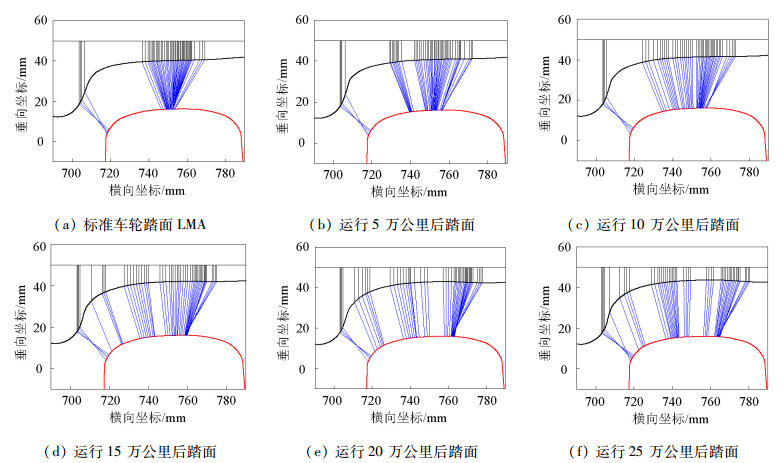

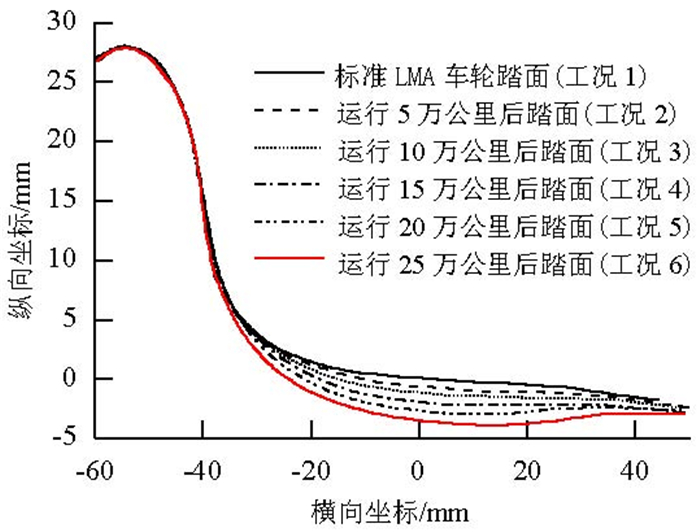

马晓川, 王平, 徐井芒, 等.基于LMA型面磨耗车轮与60N钢轨匹配的高铁车辆动力学性能分析[J].中国铁道科学, 2018, 39(1):93-99. doi: 10.3969/j.issn.1001-4632.2018.01.13MA Xiaochuan, WANG Ping, XU Jingmang, et al. Dynamic performance analysis of high speed vehicle based on LMA worn wheel matching with 60N rail[J]. China Railway Science, 2018, 39(1):93-99. doi: 10.3969/j.issn.1001-4632.2018.01.13

|

|

WANG P, MA XC, WANG J, et al. Optimization of rail profiles to improve vehicle running stability in switch panel of high-speed railway turnouts[J]. Mathematical Problems in Engineering, 2017, 2017:1-13. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=0be33171e2f8af1d0bc3bc8683427069

|

|

KALKER J J. A fast algorithm for the simplified theory of rolling contact[J]. Vehicle System Dynamics, 1982, 11(1):1-13. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=24e5e8be9f8a76e9727d651f0ad198d4

|

|

徐井芒.高速道岔曲尖轨磨耗仿真分析研究[D].成都: 西南交通大学, 2015.

|

|

EKBERG A, KABO E, ANDERSSON H. An engineering model for prediction of rolling contact fatigue of railway wheels[J]. Fatigue & Fracture of Engineering Materials & Structures, 2002, 25(10):899-909. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=9b1eb48e79dcdf576c72b2a0e4c1dc57

|

下载:

下载: