Risk Transfer Mechanism and Control in Logistics of Fresh Agriculture Product Supply Chain

-

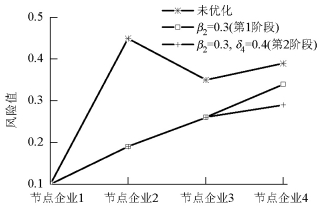

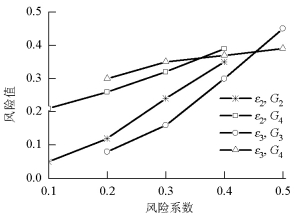

摘要: 为更好反映物流作业时间偏差产生的损耗风险传递情况,基于物流服务时间约束条件下,对物流延误造成的超期风险在生鲜农产品供应链中的传递问题进行了分析.首先,借鉴传染病学的疾病传播原理,将传染源、传播载体、受染者3个传染要素引入到物流风险传递识别中,获取物流超期风险五个要素,物流作业标准、管理能力、环境保障、物流延期和空间风险传递;其次,构建了生鲜农产品供应链物流风险的传递模型,采用数值分析迭代法,得到风险传递下供应链整体超期风险值;最后,研究了控制自身风险、空间传递和物流延迟等参数对供应链超期风险值的影响并通过算例进行分析.研究结果表明:在链式供应链沿单一物流方向传递情况下,风险值测算能够有利于发现控制风险传递的关键节点,对关键节点的风险要素优化后能有效减少供应链风险值;节点2和节点4被识别为供应链超期风险产生的关键节点,风险值为0.45和0.39.对占比较高的环境保障、空间传递因素进行优化后,使得供应链超期风险值从原有的0.39减少为0.29.Abstract: In order to better reflect the transmission of financial risk caused by the time deviation of a logistics operation, the transmission problem of overdue risk caused by logistics delays in the supply chain of fresh agricultural products was analysed, based on the condition of time constraints of a logistics service. First, by applying the principles of disease transmission of lemology, the three infectious elements, which are infection source, transmission carrier, and infected person, were introduced into the identification of logistics risk transmission, and five risk factors were established. These included logistics operation standards, management ability, environmental protection, logistics extension, and spatial risk transmission. Then, the numerical analysis of an iterative method was used to calculate the value of the supply chain overdue risk based on the risk transfer model of logistics of a fresh agricultural products supply chain. In addition, the factors that influence the overdue risk value of a supply chain, which is affected by controlling risks, were studied including internal nodes, spatial transfer, and logistics delay. These were analysed using an example. The analysis showed that calculating the risk node is beneficial to finding the key node for controlling risk transmission, and after optimizing the risk elements of key nodes it can be used to reduce the risk value effectively for the circumstance when the supply chain follows a single logistics direction. In the example analysis, nodes 2 and 4 were recognized as the key nodes for generating the supply chain overdue risk and their risk values were calculated as 0.45 and 0.39, respectively. After the factors were optimized the overdue risk value of the supply chain was reduced from 0.39 to 0.29.

-

Key words:

- logistics engineering /

- risks management /

- supply chains /

- fresh agricultural product /

- transfer

-

表 1 FAPSC各节点企业的风险相关系数

Table 1. Risk coefficient in node enterprise of FAPSC

变量 节点1 节点2 节点3 节点4 Xi~N(μ, σ2) N(2, 0.3) N(3, 0.5) N(2, 0.6) N(2, 0.5) Yi~N(μ, σ2) N(3, 0.5) N(2, 0.3) N(2, 0.3) N(3, 0.4) Zi~N(μ, σ2) N(1, 0.2) N(3, 0.5) N(3, 0.5) N(3, 0.4) αi 0.2 0.3 0.4 0.4 βi 0.3 0.5 0.4 0.4 γi 0.2 0.1 0.1 0.2 δi 0 0.4 0.2 0.5 εi 0.3 0.4 0.4 0.4 ΔTi 2 2 3 3 表 2 FAPSC各节点企业未改善前数据

Table 2. Previous data under unimproved condition in node enterprise of FAPSC

数值名称 节点1 (i=1) 节点2 (i=2) 节点3 (i=3) 节点4 (i=4) 供应链 Xi 2.05 2.91 1.87 2.14 Yi 2.78 2.65 2.06 1.94 Zi 1.13 2.34 2.56 2.77 Hi 0 2.56 1.94 2.33 Gi 1.47 4.04 3.41 4.80 4.80 非标准化风险占比/% 0.28 0.22 0.22 0.18 0.18 作业条件风险占比/% 0.57 0.32 0.24 0.16 0.16 组织管理能力风险占比/% 0.15 0.06 0.08 0.11 0.11 传递风险占比/% 0 0.15 0.23 0.35 0.35 物流延期风险占比/% 0 0.25 0.23 0.20 0.20 风险值 0.10 0.45 0.35 0.39 0.39 表 3 FAPSC风险控制第1阶段优化

Table 3. Optimized result in first stage for risk control of FAPSC

数值名称 节点1 (i=1) 节点2 (i=2) 节点3 (i=3) 节点4 (i=4) 供应链 Gi — 3.51 3.31 4.6 4.6 非标准化风险占比/% — 0.25 0.23 0.18 0.18 作业条件风险占比/% — 0.23 0.25 0.16 0.16 组织管理能力风险占比/% — 0.07 0.08 0.11 0.11 传递风险占比/% — 0.16 0.23 0.35 0.35 物流延期风险占比/% 0.29 0.21 0.20 0.20 风险值 — 0.19 0.26 0.34 0.34 表 4 FAPSC风险控制第2阶段优化

Table 4. Optimized result in second stage for risk control of FAPSC

数值名称 节点1 (i=1) 节点2 (i=2) 节点3 (i=3) 节点4 (i=4) 供应链 Gi — — — 4.1 4.1 非标准化风险占比/% — — — 0.21 0.21 作业条件风险占比/% — — — 0.19 0.19 组织管理能力风险占比/% — — — 0.13 0.13 传递风险占比/% — — — 0.23 0.23 物流延期风险占比/% 0.24 0.24 风险值 — — — 0.29 0.29 -

KANCHANASUNTORN K, TECHANITISAWAD A. An approximate periodic model for fixed-life perishable products in a two-echelon inventory-distribution system[J]. International Journal of Production Economics, 2007, 100(1):101-115. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=afcde8ad57a82d373281401e9e9a2819 彭建真.我国生鲜农产品流通损耗率是发达国家的5倍[EB/OL].[2017-6-22] http://www.sohu.com/a/151102725_170950. 徐娟, 章德宾.生鲜农产品供应链突发事件风险的评估模型[J].统计与决策, 2012(12):41-43. http://d.old.wanfangdata.com.cn/Periodical/tjyjc201212013 王雪峰, 邱幼珍, 杨芳.国内农产品流通风险研究综述[J].物流技术, 2015, 34(23):1-5. http://d.old.wanfangdata.com.cn/Periodical/wljs201512001 但斌, 陈军.基于价值损耗的生鲜农产品供应链协调[J].中国管理科学, 2008, 16(5):42-49. http://d.old.wanfangdata.com.cn/Periodical/zgglkx200805007 王婧, 陈旭.考虑流通损耗的生鲜农产品零售商期权订货策略[J].系统工程理论与实践, 2012, 32(7):1408-1414. doi: 10.3969/j.issn.1000-6788.2012.07.003 颜波.物联网环境下的农产品供应链风险评估与控制[J].管理工程学报, 2014, 28(3):196-202. doi: 10.3969/j.issn.1004-6062.2014.03.025 ASSELT E D V, MEUWISSEN M P M, ASSELDONK M A P M V, et al. Selection of critical factors for identifying emerging food safety risks in dynamic food production chains[J]. Food Control, 2010, 21(6):919-926. doi: 10.1016/j.foodcont.2009.12.010 丁秋雷, 胡祥培, 姜洋.物流配送受扰延迟问题的干扰管理两阶段决策方法[J].运筹与管理, 2012, 21(6):84-93. doi: 10.3969/j.issn.1007-3221.2012.06.015 AMORIM P, ALEM D, ALMADA Lobob. Risk management in production planning of perishable goods[J]. Industrial & Engineering Chemistry Research, 2013, 52(49):17538-17553. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=37a2ada887ccef88ee14ba4cf02314ba 王元明, 赵道致, 徐大海.基于风险传递的项目型供应链风险控制研究[J].软科学, 2008, 22(12):1-4. http://d.old.wanfangdata.com.cn/Periodical/rkx200812001 刘家国.需求拉动型供应链突发风险传递模型[J].运筹与管理, 2011, 20(5):14-19. doi: 10.3969/j.issn.1007-3221.2011.05.003 刘志学, 张艳, 郑长征.供应链提前期风险空间传递机理与控制策略[J].管理评论, 2012, 24(6):151-159. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201203370574 王世雄, 潘旭伟.供应链突发风险传染机理与控制策略研究[M].北京:经济科学出版社, 2013:42-43. 付焯, 严余松.物流视角下生鲜农产品供应链风险源识别[J].商业经济研究, 2017(8):92-94. http://d.old.wanfangdata.com.cn/Periodical/sysd201716031 IONUT F, CIPRIAN A T. Handbook of probability[M]. Hoboken:Wiley Press, 2014:256-265. -

下载:

下载: