Design and Analysis of New Type of Piston Pump

-

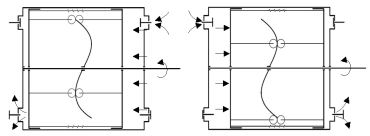

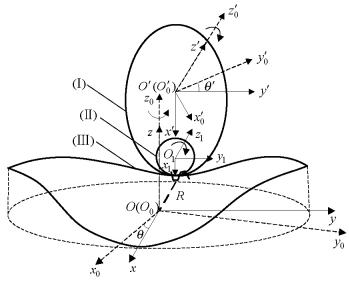

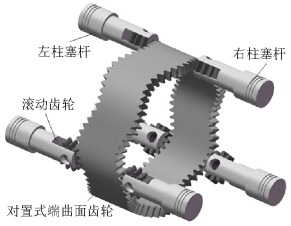

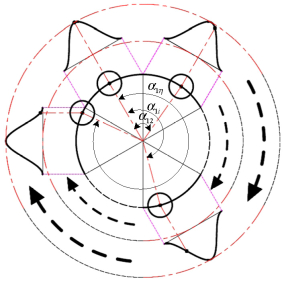

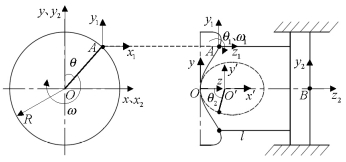

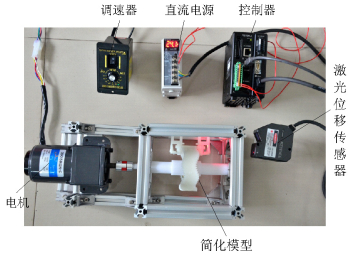

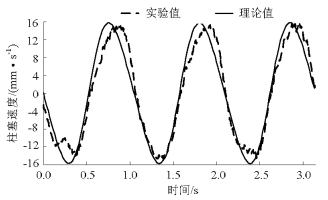

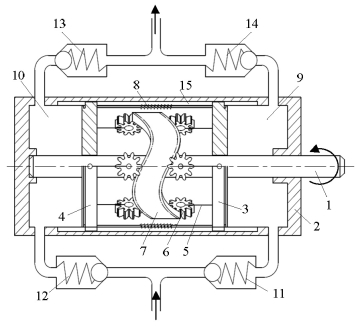

摘要: 为改善斜盘式柱塞泵的脉动性能,基于啮合理论和几何学的相关知识,提出了由双端曲面齿轮作为转子、双作用柱塞不间断排油的新型双作用柱塞泵.利用端曲面齿轮副传动原理,建立了双端曲面齿轮啮合坐标系和柱塞运动坐标系,结合柱塞泵的工作特性,进行了柱塞结构的设计,探讨了新型柱塞泵的柱塞分布情况;运用新型双作用柱塞泵的工作原理,推导出了柱塞位移、速度及相应的瞬时流量方程,并分析了柱塞数、偏心率和端曲面齿轮阶数对流量脉动率的影响因素.分析结果表明:相较于现有的斜盘式柱塞泵,新型双作用柱塞泵流量脉动率的变化趋势更为平稳,且流量脉动率随着柱塞数量的增多,偏心率的减小,端曲面齿轮阶数的增大而降低;通过试验,得出柱塞运动速度的最大误差为4.79 mm/s.Abstract: To improve the pulsating performance of a swashplate piston pump, a new type of double-acting piston pump is designed based on the meshing theory and the related knowledge of geometry. The pump is driven by the double curve-face gear and its pistons drain oil uninterruptedly. By using the transmission principle of the curve-face gear pair, the engagement coordinates of the double curve-face gear and piston motion analysis coordinates were established. The piston structure was designed according to the working characteristics of the piston pump, and the piston distribution of a new type piston pump is discussed. The equations of piston displacement, velocity, and instantaneous flow were deduced based on the working principle of the proposed double-acting piston pump, and the factors affecting the flow pulsation rate, such as the number of plungers, eccentricity, and the order of curve-face gear, were analysed. The analysis results show that compared with the existing swashplate piston pump, the variation in the flow pulsation rate of the proposed double-acting piston pump is more stable, and the flow pulsation rate decreases with increase in the number of plungers, decrease in the eccentricity, and increase in the order of the curve-face gear. The test-bed was used to test the plunger velocity, and the maximum error value is 4.79 mm/s.were in good agreement with the theoretical values; the error was less than 5%, which is within the allowable range of error.

-

Key words:

- swashplate piston pump /

- curve-face gear /

- theory /

- kinematic analysis /

- flow characteristics

-

表 1 柱塞布局

Table 1. Arrangement of pistons

参数 柱塞布局 柱塞机构 n1=1

n2=3

u=η=3

n1=2

n2=2

u=η=4

n1=1

n2=5

u=η=5

n1=2

n2=3

u=η=6

n1=1

n2=7

u=η=7

n1=2

n2=4

u=η=8

表 2 瞬时流量与柱塞速度的变化规律

Table 2. Variation of instantaneous flow and piston velocity

柱塞参数 柱塞速度 瞬时流量 n1=2

n2=3

u=6

η=3

n1=2

n2=3

u=6

η=4

n1=2

n2=3

u=6

η=5

n1=2

n2=3

u=6

η=6

n1=2

n2=3

u=6

η=7

n1=2

n2=3

u=6

η=8

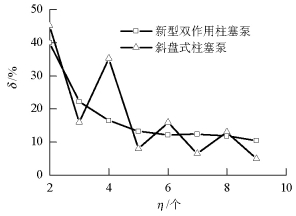

表 3 柱塞数对泵的流量脉动率的影响

Table 3. Influence of number of pistons on pump flow pulsation rates

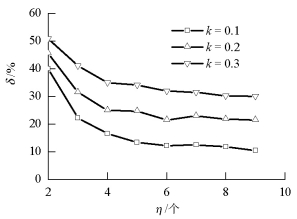

% 泵的类型 η/个 2 3 4 5 6 7 8 9 新型双作用柱塞泵 40.0 22.2 16.5 13.3 12.2 12.5 11.8 10.5 斜盘式柱塞泵 45.0 15.9 35.3 8.0 15.9 6.5 13.0 5.0 表 4 偏心率对流量脉动率的影响

Table 4. Influence of eccentricity on pump flow pulsation rates

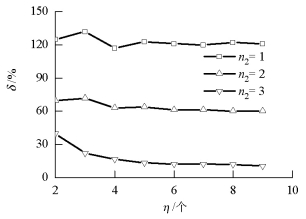

% k η/个 2 3 4 5 6 7 8 9 0.1 40.0 22.2 16.5 13.3 12.2 12.5 11.8 10.5 0.2 45.5 31.4 24.9 24.7 21.5 22.9 21.7 21.5 0.3 50.9 41.0 35.0 34.0 31.0 31.5 30.2 30.0 表 5 端曲面齿轮阶数对泵的流量脉动率的影响

Table 5. Relationship between piston pump flow pulsation rates and order of curve-face gear

% n2 η/个 2 3 4 5 6 7 8 9 1 125.0 132.0 117.0 123.0 121.0 120.0 122.0 121.0 2 69.5 71.6 63.0 63.7 61.1 61.4 60.2 60.0 3 40.0 22.2 16.5 13.3 12.2 12.5 11.8 10.5 -

张燃, 刘桓龙, 柯坚, 等.基于AMESim的斜盘式轴向柱塞泵脉动特性分析[J].机床与液压, 2012, 40(15):118-120. doi: 10.3969/j.issn.1001-3881.2012.15.033ZHANG Ran, LIU Henglong, KE Jian. Characteristics simulation of swashplate axial piston pump based on AEMSim[J]. Machine Tool & Hydraulics, 2012, 40(15):118-120. doi: 10.3969/j.issn.1001-3881.2012.15.033 张志鹏. 55 mL/r十一柱塞斜盘式轴向柱塞泵的设计研究[D].成都: 西南交通大学, 2012. KIM J H, JEON C S, HONG Y S. Constant pressure control of a swash plate type axial piston pump by varying both volumetric displacement and shaft speed[J]. International Journal of Precision Engineering & Manufacturing, 2015, 16(11):2395-2401. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=e765edfb982e616fc44928f62b5b4bbf JOHANSSON A, ÖVANDER J, PALMBERG J O. Experimental verification of cross-angle for noise reduction in hydraulic piston pumps[J]. Proceedings of the Institution of Mechanical Engineers Part I Journal of Systems & Control Engineering, 2007, 221(3):321-330. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=75d3f48b3a2e1e520c890f847d56e918 GUAN Changbin, JIAO Zongxia, HE Shouzhan. Theoretical study of flow ripple for an aviation axial-piston pump with damping holes in the valve plate[J]. Chinese Journal of Aeronautics, 2014, 27(1):169-181. doi: 10.1016/j.cja.2013.07.044 成焕波, 刘志峰, 谢萍, 等.基于能量损失的斜盘式柱塞泵最小留缸长度计算方法[J].农业机械学报, 2014, 45(9):333-339. http://d.old.wanfangdata.com.cn/Periodical/nyjxxb201409054CHENG Huanbo, LIU Zhifeng, Xie Ping, et al. Calculation method of minimum length retained in cylinder for swash-plate plunger pump based on energy loss[J]. Transactions of the Chinese Society for Agricultural Machinery, 2014, 45(9):333-339. http://d.old.wanfangdata.com.cn/Periodical/nyjxxb201409054 WU Xingying, GUANG Ouyang, TAN Di. The wear analysis for cam mechanism of diesel fuelinjection pump based on multibody dynamics theories[C]//International Conference on Electronic and Mechanical Engineering and Information Technology. [S. l.]: IEEE, 2011: 1278-1282. 杨华勇, 艾青林, 周华.轴向柱塞泵配流副润滑特性的研究进展[J].中国机械工程, 2004, 15(17):1587-1593. doi: 10.3321/j.issn:1004-132X.2004.17.023YANG Huayong, AI Qinglin, ZHOU Hua. Development of lubrication of port plate/cylinder block in axial piston pump[J]. China Mechanical Engineering, 2004, 15(17):1587-1593. doi: 10.3321/j.issn:1004-132X.2004.17.023 SUN Yi, JIANG Jihai, ZHOU Yu. Analysis and simulation of the property of oil film of the slipper in axial piston pump[C]//International Conference on Electronic and Mechanical Engineering and Information Technology. [S. l.]: IEEE, 2011: 1359-1362. 那成烈.轴向柱塞泵可压缩流体配流原理[M].北京:兵器工业出版社, 2003:87-119. 张力, 项辉宇, 赵罘, 等.斜盘式轴向柱塞泵摩擦副分析[J].机床与液压, 2007, 35(6):120-122. doi: 10.3969/j.issn.1001-3881.2007.06.041ZHANG Li, XIANG Huiyu, ZHAO Fu, et al. Frictional couple analysis on slanting axial piston pump[J]. Machine Tool & Hydraulics, 2007, 35(6):120-122. doi: 10.3969/j.issn.1001-3881.2007.06.041 曾祥荣, 李小宁.斜轴型轴向柱塞泵缸体组件的优化设计[J].哈尔滨工业大学学报, 1989(2):33-46. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000001298042ZENG Xiangrong, LI Xiaoning. An optimum design of the cylinder components of a tilting-head axial plunger pump[J]. Journal of Harbin Institute of Technology, 1989(2):33-46. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000001298042 刘恒龙, 柯坚, 王国志, 等.水压柱塞摩擦副的润滑特性研究[J].中国机械工程, 2007, 220(10):1559-1567. http://d.old.wanfangdata.com.cn/Periodical/zgjxgc200704015LIU Huanlong, KE Jian, WANG Guozhi, et al. Research on the lubrication characteristics of water hydraulic slipper friction pairs[J]. China Mechanical Engineers, 2007, 220(10):1559-1567. http://d.old.wanfangdata.com.cn/Periodical/zgjxgc200704015 BERGADA J M, HAYNES J M, WATTON J. Leakage and groove pressure of an axial piston pump slipper with multiple lands[J]. Tribology Transactions, 2008, 51(4):469-474. doi: 10.1080/10402000802044332 MANRING N D. Valve-plate design for an axial piston pump operating at low displacements[J]. Journal of Mechanical Design, 2003, 125(1):200-205. doi: 10.1115/1.1541632 龚海.正交非圆面齿轮副的传动设计与特性分析[D].重庆: 重庆大学, 2012. 林超, 王瑶, 蔡志钦.正交变传动比面齿轮副的强度计算与分析[J].四川大学学报, 2015, 47(1):200-206. http://d.old.wanfangdata.com.cn/Periodical/scdxxb-gckx201501029LIN Chao, WANG Yao, CAI Zhiqin. Calculation and analysis of strength for orthogonal variable transmission ratio face gear[J]. Journal of Sichuan University, 2015, 47(1):200-206. http://d.old.wanfangdata.com.cn/Periodical/scdxxb-gckx201501029 赵相路.双端曲面齿轮柱塞泵复合传动特性分析[D].重庆: 重庆大学, 2016. 林超, 赵相路, 吴小勇, 等.双端曲面齿轮式柱塞泵运动特性分析与实验[J].农业机械学报, 2016, 47(6):387-393. http://d.old.wanfangdata.com.cn/Periodical/nyjxxb201606051LIN Chao, ZHAO Xianglu, WU Xiaoyong, et al. Theory and test on kinematics characteristics of double curve-face gear piston pump[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(6):387-393. http://d.old.wanfangdata.com.cn/Periodical/nyjxxb201606051 YIN Jun, WANG Xinyu, WANG Lu, et al. Design and simulation of axial piston pump with constant flow[C]//IEEE International Conference on Industrial Informatics. Beijing: IEEE, 2012: 591-595. -

下载:

下载: