Simulation and Macro-Mesoscopic Parameter Analysis for Direct Shear of Filled Rough Joints

-

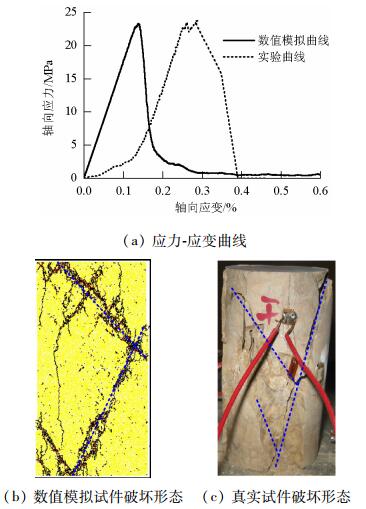

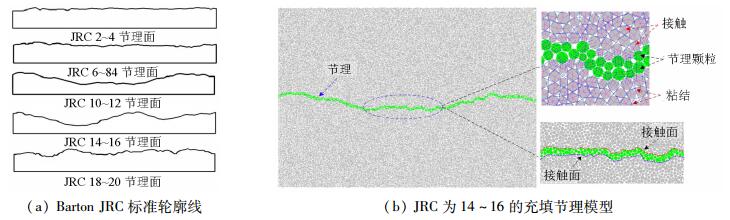

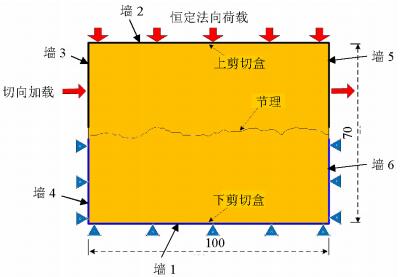

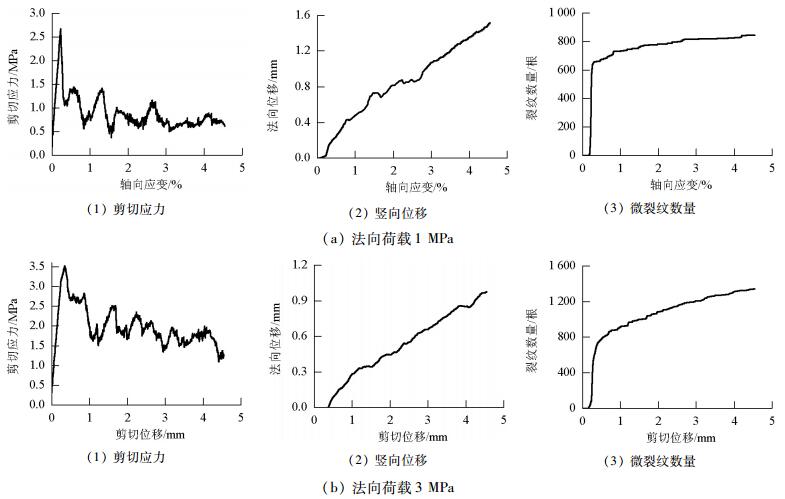

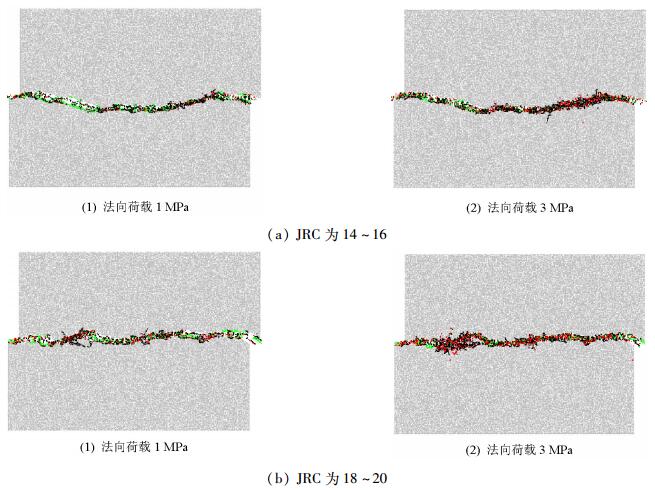

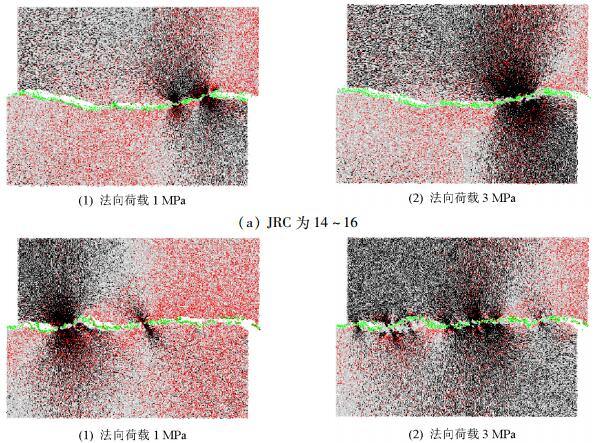

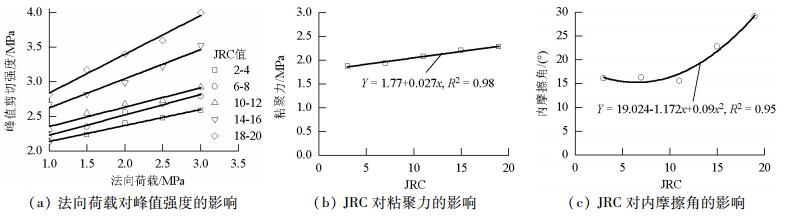

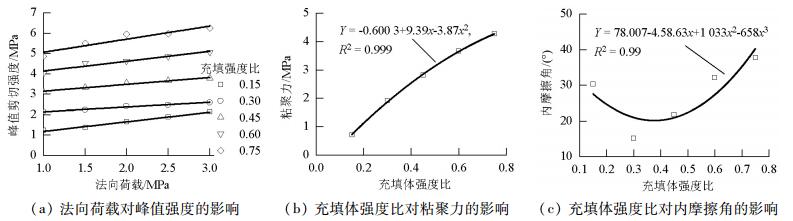

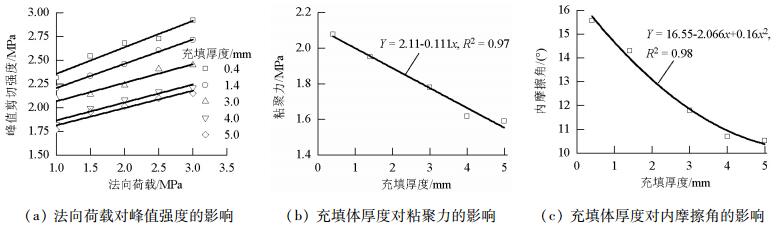

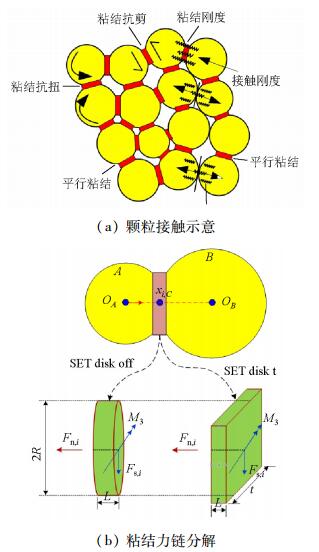

摘要: 利用颗粒流数值计算方法对岩石充填节理直剪作用下力学性质进行研究,从细观角度分析不同法向荷载下粗糙节理面的损伤情况;探讨充填节理粗糙程度、充填物强度参数、充填物与围岩接触面强度以及充填厚度对节理剪切强度的影响,结果表明:(1)随着法向荷载的增大,上下节理面接触状态及粘结力分布规律发生转变,充填节理面粘结破坏明显增加;(2)节理粗糙度系数(JRC)对峰值剪切应力的影响较大;随JRC的增加节理峰值剪切强度增大;节理面粘结力呈类线性增长,而内摩擦角随JRC的增大而呈明显的非线性变化;(3)随节理充填物粘结强度比的增加,峰值剪切应力增大;随充填物强度比的增加,节理面粘结力出现明显的增长,而内摩擦角呈现先下降后增加的趋势;(4)当法向荷载较小时,峰值剪切应力受接触面粘结强度比的影响较大;当法向荷载较大时,其对峰值剪切应力的影响程度明显降低.节理面粘结力和内摩擦角随接触面粘结的增加分别呈现出非线性增长和下降的趋势.(5)节理剪切力学形式随充填后的增加呈现降低的趋势,然而随着厚度的不断增加,所带来的剪切力学参数变化程度逐渐减小.Abstract: A joint model based on particle flow was built successfully and the mechanical properties of the fill joint were investigated in this study. The morphology of damage and the crack evolution mechanism of roughness of the jointed model were also analysed from the viewpoint of meso-mechanics. At the same time, the influence of the value of the JRC(joint roughness coefficient), fill strength, interface, and fill thickness on the mechanical behaviour have been analysed. The detailed results are as follows:(1) The normal stress has a significant influence on the peak shear stress, contact condition, and contact force of the joint. With higher stress, the bond break at the joint surface becomes apparent; (2) The joint peak shear stress increases with an increase in the JRC value, and the shear strength parameters for cohesion and friction angle exhibit linear and nonlinear increases with the increase in the JRC value, respectively; (3) The joint peak shear stress increases with the strength of filling material. However, the strength of filling material has a different influence on the cohesion and friction angle of the fill joint. Cohesion increases with an increase in material strength. The friction angle decreases as the fill strength ratio changes from 0.1 to 0.3, and increases when the fill strength ratio exceeds 0.3; (4) When the normal constant load is small, the interface has a significant influence on the peak shear stress, but when the normal constant load is large, the influence is weaker. Joint shear-strength parameters for cohesion increase with the increase in the strength of interface, but the friction angle shows the opposite trend with cohesion; (5) With increasing fill thickness, the mechanical parameters of the joint model exhibit an obvious downward trend. However, with a further increase in thickness, the decrement in the mechanical parameters is less pronounced.

-

Key words:

- JRC(joint roughness coefficient) /

- direct shear /

- filled joint /

- meso-mechanics /

- shear strength

-

表 1 颗粒细观参数

Table 1. Microscopic parameters for rock mass

接触模量/GPa 接触刚度比 粘结半径系数 粘结模量/GPa 粘结刚度比 粘结法向强度/MPa 粘结切向强度/MPa 30.5 2.4 1.0 25.0 2.4 30 30 表 2 各工况组内的影响因素及数值

Table 2. Factors influencing the simulation cases

类别 JRC 节理充填物和完整岩样的摩擦因数比 节理充填物与完整岩样粘结力之比 充填厚度/mm A-1 2~4 0.30 1.0 0.4 A-2 6~8 A-3 10~12 A-4 14~16 A-5 18~20 B-1 2~4 0.15 1.0 0.4 B-2 0.30 B-3 0.45 B-4 0.60 B-5 0.75 C-1 2-4 0.30 0.2 0.4 C-2 0.4 C-3 0.6 C-4 0.8 C-5 1.0 D-1 10-12 0.30 1.0 0.4 D-2 1.4 D-3 3.0 D-4 4.0 D-5 5.0 -

夏才初, 孙宗颀.工程岩体节理力学[M].同济大学出版社, 2002:1-2. YANG S Q, XU T, H E L, et al. Numerical study on failure behavior of brittle rock specimen containing pre-existing combined flaws under different confining pressure[J]. Archives of Civil and Mechanical Engineering, 2015, 15(4):1085-1097. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=7d4490be12a8d4e3eaacdf65752b7a02 蒋宇静, 王刚, 李博, 等.岩石节理剪切渗流耦合试验及分析[J].岩石力学与工程学报, 2007, 26(11):2253-2259. doi: 10.3321/j.issn:1000-6915.2007.11.011JIANG Yujing, WANG Gang, LI bo, et al. Experimental study and analysis of shear-flow coupling behaviors of rock joints[J]. Chinese Journal of Rock Mechanicss and Engineering, 2007, 26(11):2253-2259. doi: 10.3321/j.issn:1000-6915.2007.11.011 周喻, MISAR A, 吴顺川, 等.岩石节理直剪试验颗粒流宏细观分析[J].岩石力学与工程学报, 2012, 31(6):1245-1256. doi: 10.3969/j.issn.1000-6915.2012.06.021ZHOU Yu, MISRA A, WU Shunchuan, et al. Macro-and meso-analysis of rock joint direct shear test using particle flow theory[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(6):1245-1256. doi: 10.3969/j.issn.1000-6915.2012.06.021 唐雯钰, 林杭.不同锯齿高度对软弱结构面剪切特性的影响[J].中南大学学报:自然科学版, 2017, 48(5):1300-1307. http://d.old.wanfangdata.com.cn/Periodical/zngydxxb201705024TANG Wenyu, LIN Hang. Influence of dentate discontinuity height on shear properties of soft structure plane[J]. Journal of Central South University:Science and Technology, 2017, 48(5):1300-1307. http://d.old.wanfangdata.com.cn/Periodical/zngydxxb201705024 曹平, 范祥, 蒲成志, 等.节理剪切试验及其表面形貌特征变化分析[J].岩石力学与工程学报, 2011, 30(3):480-485. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb201103006CAO Ping, FAN Xiang, PU Chengzhi, et al. Shear test of joint and analysis of morohology characteristic evolution of joint surface[J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(3):480-485. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb201103006 GHAZVINIAN A, AZINFAR MJ, NOROZI P. Mechanical response of discontinuities of different joint wall contact strengths[J]. Arabian Journal of Geosciences, 2013, 6(11):4419-4426. doi: 10.1007/s12517-012-0683-6 陈必光, 宋二祥, 程晓辉.二维裂隙岩体渗流传热的离散裂隙网络模型数值计算方法[J].岩石力学与工程学报, 2014(1):43-51. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb201401005CHEN Biguang, SONG Erxiang, CHENG Xiaohui. A numerical method for discrete fracture network model for flow and heat transfer in two-dimensional fractured rocks[J]. Chinese Journal of Rock Mechanics and Engineering, 2014(1):43-51. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb201401005 杜守继, 职洪涛, 周枝华.岩石节理剪切过程中应力与渗流特性的数值模拟[J].岩石力学与工程学报, 2008, 27(12):2473-2481. doi: 10.3321/j.issn:1000-6915.2008.12.012DU Shouji, ZHI Hongtao, ZHOU Zhihua. Numerical simulation of stress and seepage properties of rock joint during shearing processes[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(12):2473-2481. doi: 10.3321/j.issn:1000-6915.2008.12.012 BAHAADDINI M, SHARROCK G, HEBBLEWHITE B K. Numerical investigation of the effect of joint geometrical parameters on the mechanical properties of a non-persistent jointed rock mass under uniaxial compression[J]. Computers and Geotechnics, 2013, 49(1):206-225. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=0a9ce63c3554260002523a841d831339 吴顺川, 周喻, 高斌.卸载岩爆试验及PFC3D数值模拟研究[J].岩石力学与工程学报, 2010, 29(S2):4082-4088. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb2010z2087WU Shunchuan, ZHOU Yu, GAO Bin. Study of unloading tests of rock burst and PFC3D numerical simulation[J]. Chinese Journal of Rock Mechanicss and Engineering, 2010, 29(S2):4082-4088. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb2010z2087 MANOUCHEHRIAN A, SHARIFZADEH M, MARJI M F, et al. A bonded particle model for analysis of the flaw orientation effect on crack propagation mechanism in brittle materials under compression[J]. Archives of Civil and Mechanical Engineering, 2014, 14(1):40-52. doi: 10.1016/j.acme.2013.05.008 黄达, 岑夺丰.单轴静-动相继压缩下单裂隙岩样力学响应及能量耗散机制颗粒流模拟[J].岩石力学与工程学报, 2013(9):1926-1936. doi: 10.3969/j.issn.1000-6915.2013.09.026HUANG Da, CEN Duofeng. Mechanical responses and energy dissipation mechanism of rock specimen with a single fissure under static and dynamic unaxial compression using particle flow code simulations[J]. Chinese Journal of Rock Mechanics and Engineering, 2013(9):1926-1936. doi: 10.3969/j.issn.1000-6915.2013.09.026 PARK J W, SONG J J. Numerical simulation of a direct shear test on a rock joint using a bonded-particle model[J]. International Journal of Rock Mechanics and Mining Sciences, 2009, 46(8):1315-1328. doi: 10.1016/j.ijrmms.2009.03.007 SARFARAZI V, GHAZVINIAN A, SCHUBERT W. Numerical simulation of the process of fracture of echelon rock joints[J]. Rock Mechanics and Rock Engineering, 2014, 47(4):1355-1371. doi: 10.1007/s00603-013-0450-3 Itasca Consulting Group. PFC2D (partical flow code in 2 dimensions) theory and background[M]. Minnesota:Itasca Consulting Group Inc, 2002:77-78. 黄飘.不同粗糙度结构面试件剪切试验特性研究[J].建筑监督检测与造价, 2015, 8(3):1-5. http://www.cnki.com.cn/Article/CJFDTOTAL-PJZJ201503001.htmHUANG Piao. Study on shear test properties of different structural plane roughness[J]. Supervision Test and Cost of Construction, 2015, 8(3):1-5. http://www.cnki.com.cn/Article/CJFDTOTAL-PJZJ201503001.htm -

下载:

下载: