Numerical Analysis of Effect of Jacked Pile on Performance of Buried Pipes

-

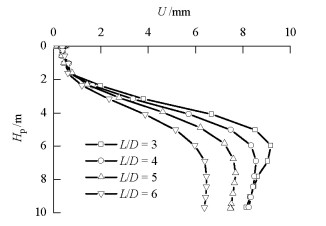

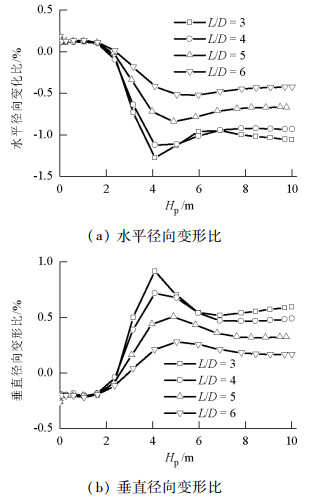

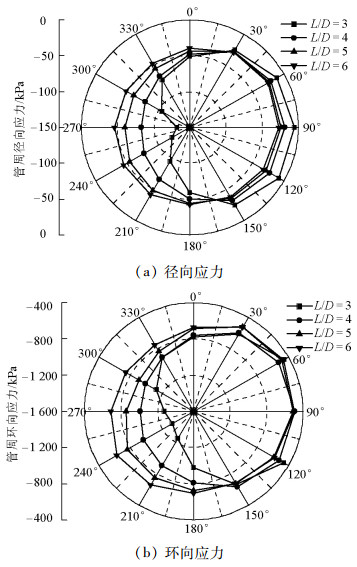

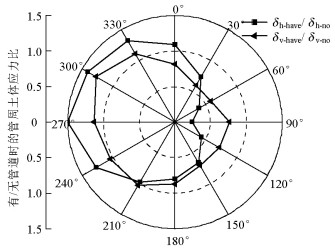

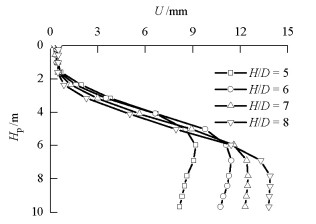

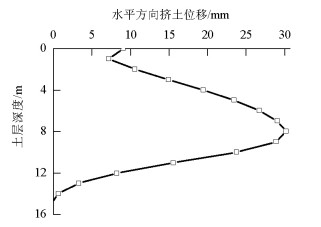

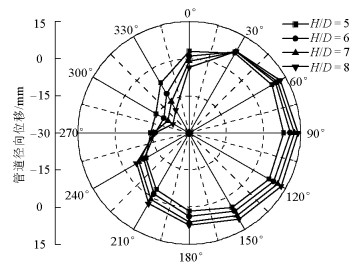

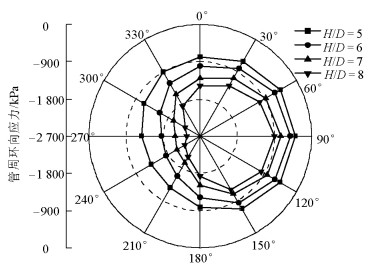

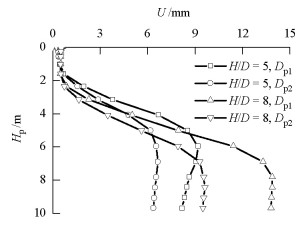

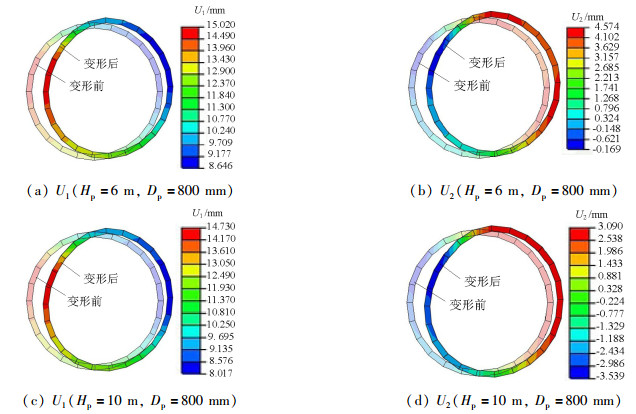

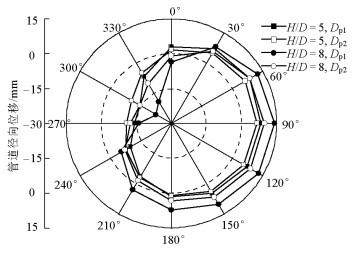

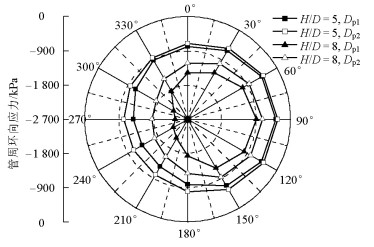

摘要: 为了分析静压沉桩过程对邻近埋地管道性能的影响,基于位移贯入法模拟静压沉桩的二维有限元数值方法,建立了桩-土、管-土接触面并在桩顶施加位移荷载实现动态压桩过程,并综合分析了压桩过程中沉桩深度、桩径大小、管道中心与桩体中心的水平距离以及管道的埋深等因素对管道变形与力学性能的影响.研究结果表明:同等条件下,增加管-桩水平距离,管道水平位移、径向变形和管周应力相应减小,近桩侧管周土体的最大水平应力约为不设置管道时的1.5倍;随着沉桩深度增大,初始使管道产生明显水平位移的临界沉桩深度约为管道上方1 m处,随后管道水平位移呈现先增大后略微减小,并最终趋于稳定的趋势,且当沉桩深度为2倍埋深时管道水平位移最大;管道埋深越大,管道受沉桩挤土效应的影响越明显;当埋深为5倍管径时,沉桩桩径减少25%时管道最大水平位移减少27.8%,表明减小桩径可显著降低沉桩对周边管道性能的影响.Abstract: To analyse the influence of the driving process of jacked piles on the performance of adjacent buried pipes via the planar finite element method numerical simulation based on the displacement penetration method and achieve the dynamic pile driving process by establishing the pile-soil and pipe-soil contact surfaces and applying the displacement load at the top of the pile, comprehensive analysis was carried out to investigate the effect of the pile penetration depth, pile diameter, horizontal centre distance between the pile and buried pipe, and buried depth, on the performance of buried pipes during pile driving. The calculation results showed that when keeping other parameters identical and first increasing the horizontal distance, caused a decrease in the horizontal displacement, radial deformation, and stresses of pipes. The maximum horizontal stress of the soil surrounding the pipes is 1.5 times that of the soil without pipes. Secondly, with the increase in the pile penetration depth, there exists a critical penetration depth, after reaching it, the horizontal displacement of pipes increases significantly, then somewhat decreases, and finally becomes steady. Moreover, the maximum horizontal displacement of pipes can be reached when the penetration depth is equal to 2 times the buried depth of the pipe. Thirdly, increasing the buried depth of the pipe results in remarkable change in the deformation and mechanical performance of the pipes. For a buried depth of 5 times the diameter of pipe, the maximum horizontal displacement of the pipes reduced by 27.8% when the pile diameter decreased by 25%. This implied that reducing the diameter of jacked piles can considerably weaken its effect on buried pipes.

-

Key words:

- buried pipes /

- jacked pile /

- finite element method /

- displacement penetration method

-

表 1 砂土模型参数

Table 1. Model parameters for sand

土体 密度/

(g·cm-3)弹性模

量E/MPa相对密

实度%泊松

比μ内摩擦

角β/(°)塑流应

力比K膨胀角

ψ/(°)桩土摩擦

因数f1管土摩擦

因数f2屈服强度

σc/kPa砂土 1.750 15 50 0.4 22.5 0.87 21.24 0.1 0.4 54.1 表 2 埋地管道力学与变形分析的数值计算方案

Table 2. Plan for analysing mechanical performance and deformation of buried pipes via numerical calculation

模拟组数 影响因素 L/D Hp/m H/D 桩径Dp/mm 9 3, 4, 5, 6 0~10 5, 6, 7, 8 600, 800 -

COREY R, HAN J, KHATRI D K, et al. Laboratory study on geosynthetic protection of buried steel-reinforced HDPE pipes from static loading[J]. Journal of Geotechnical and Geoenvironmental engineering, 2015, 140:9-18. doi: 10.1061/%28ASCE%29GT.1943-5606.0001113 HWANG J H, LIANG N, CHEN C H. Ground respond during pile driving[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2001, 127(11):939-949. doi: 10.1061/(ASCE)1090-0241(2001)127:11(939) CHOW Y K, THE C I. A theoretical study of pile heave[J]. Geotechnique, 1990, 40(1):1-14. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=1c4830dd973ffa4edfbc34fef314c545 罗战友, 夏建中, 龚晓南, 等.压桩过程中静压桩挤土位移的动态模拟和实测对比研究[J].岩石力学与工程学报, 2008, 27(8):1709-1714. doi: 10.3321/j.issn:1000-6915.2008.08.023LUO Zhanyou, XIA Jianzhong, GONG Xiaonan, et al. Comparative study of dynamic simulation for compacting displacement of jacked pile and in-situ test[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(8):1709-1714. doi: 10.3321/j.issn:1000-6915.2008.08.023 龚晓南, 李向红.静力压桩挤土效应中的若干力学问题[J].工程力学, 2000, 17(4):7-12. doi: 10.3969/j.issn.1000-4750.2000.04.002GONG Xiaonan, LI Xianghong. Several mechanical problems in compacting effects of static piling in soft clay ground[J]. Engineering Mechanics, 2000, 17(4):7-12. doi: 10.3969/j.issn.1000-4750.2000.04.002 徐建平, 周健, 许朝阳.沉桩挤土效应的数值模拟[J].工业建筑, 2000, 30(7):1-6. doi: 10.3321/j.issn:1000-8993.2000.07.001XU Jianping, ZHOU Jian, XU Zhaoyang. Numerical simulation of effect of pushing against soil of driven piles[J]. Industrial Construction, 2000, 30(7):1-6. doi: 10.3321/j.issn:1000-8993.2000.07.001 CAO L F, THE C I, CHANG M F. Undrainded cavity expansion in modified cam clay Ⅰ:theoretical analysis[J]. Geotechnique, 2001, 51(4):323-334. MABSOUT M E, TASSOULAS J L. A finite element model for the simulation of pile driving[J]. International Journal for Numerical Methods in Engineering, 1994, 37:257-278. doi: 10.1002/(ISSN)1097-0207 MABSOUT M E, TEESE L C, TASSOULAS J L. Study of pile driving by finite-element method[J]. Journal of Geotechnical Engineering, ASCE, 1995, 121:535-543. doi: 10.1061/(ASCE)0733-9410(1995)121:7(535) MABSOUT M E, SADEK S. A study of the effect of driving on pre-bored piles[J]. International Journal of Numerical and Analytical Methods in Geomechanics, 2003, 27(2):133-146. doi: 10.1002/(ISSN)1096-9853 罗战友.静压桩挤土效应及施工措施研究[D].杭州: 浙江大学, 2004. 张明义, 邓安福, 干腾君.静力压桩数值模拟的位移贯入法[J].岩土力学, 2003, 24(1):113-117. doi: 10.3969/j.issn.1000-7598.2003.01.020ZHANG Mingyi, DENG Anfu, GAN Tengjun. Displacement penetration method used for numerical simulation to jacked pile[J]. Rock and Soil Mechanics, 2003, 24(1):113-117. doi: 10.3969/j.issn.1000-7598.2003.01.020 雷华阳, 李肖, 陆培毅, 等.管桩挤土效应的现场试验和数值模拟[J].岩土力学, 2012, 33(4):1006-1012. doi: 10.3969/j.issn.1000-7598.2012.04.007LEI Huayang, LI Xiao, LU Peiyi, et al. Field test and numerical simulation of squeezing effect of pipe pile[J]. Rock and Soil Mechanics, 2012, 33(4):1006-1012. doi: 10.3969/j.issn.1000-7598.2012.04.007 佘艳华.机械冲击荷载对邻近埋地管道的影响及控制研究[D].绵阳: 中国工程物理研究院, 2012. 邓楚键, 何国杰, 郑颖人.基于M-C准则的D-P准则在岩土工程中的应用研究[J].岩土工程学报, 2006, 28(6):735-739. doi: 10.3321/j.issn:1000-4548.2006.06.011DENG Chujian, HE Guojie, ZHENG Yingren. Studies on D-P yield criteria based on M-C yield criterion and application in geotechnical engineerings[J]. Chinese Journal of Geotechnical Engineering, 2006, 28(6):735-739. doi: 10.3321/j.issn:1000-4548.2006.06.011 -

下载:

下载: