Evolutionary Characteristics of Pore Structure of Fly Ash Shotcrete

-

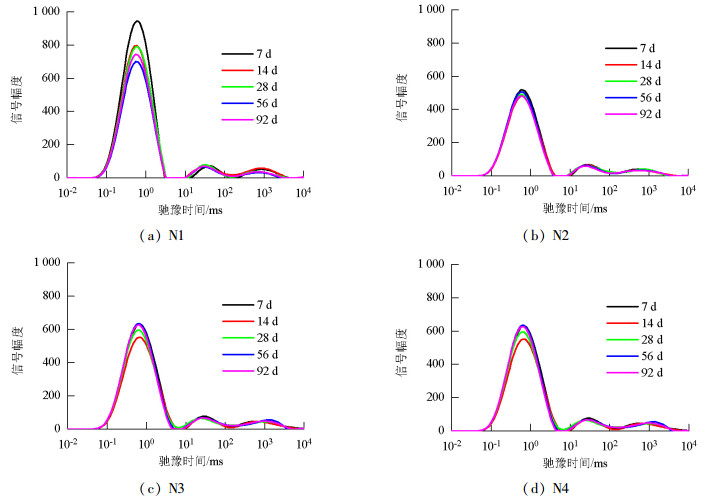

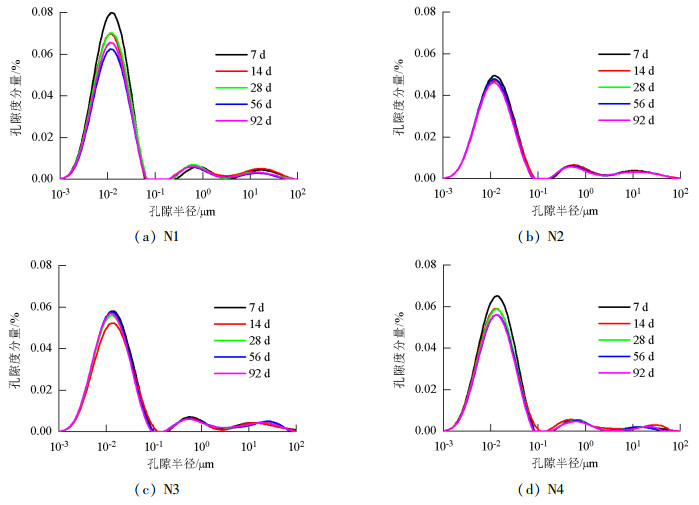

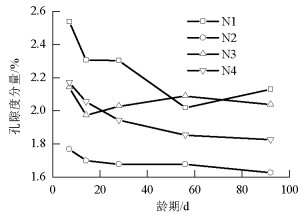

摘要: 为了寻找长期服役的喷射混凝土配合比,采用低场核磁共振技术,研究了不同粉煤灰掺量改性胶凝材喷射混凝土的微观孔隙结构,测定了不同掺量的粉煤灰喷射混凝土在不同养护龄期的微观孔隙结构分布特征及孔隙度.研究结果表明:掺有粉煤灰的喷射混凝土孔隙度随粉煤灰掺量的增加而增大,随龄期的延长总体呈现先减小后趋于平稳的趋势;粉煤灰掺量为10%时孔隙度最小,掺量为0时孔隙度最大;在7 d龄期后,不同粉煤灰掺量的喷射混凝土内部孔隙半径主要在1~80 nm的范围内,该半径范围内的孔隙含量占总孔隙含量的80%,最可几孔半径在12 nm.Abstract: To study the mixture ratio of pore structure in fly ash shotcrete during operation, low-field magnetic resonance imaging technology was adopted. The micro-pore structure of the modified cementitious shotcrete with different fly ash content was investigated. The micro-pore size distribution characteristics and porosity of shotcrete with different fly ash content, at different curing phases were measured. The results show that the porosity of the fly ash shotcrete increases with an increase in the fly ash content; however, with increase in the curing age, the porosity generally decreases first, and subsequently tends to be stable. The results also indicate that the value of porosity is minimum and maximum when the amount of fly ash is 10% and 0, respectively. After the 7-day healing period, the inner pore radius of shotcrete varies from 1 to 80 nm for different proportions of fly ash. In such a radius range, the value of micro-pore is 80% of the total fissure value. The most probable pore radius is approximately 12 nm.

-

Key words:

- shotcrete /

- low-field magnetic resonance imaging /

- fly ash /

- pore size distribution /

- porosity

-

表 1 喷射试验及配合比

Table 1. Site experiment of shotcrete and mixing proportions

编号 配比

类型粉煤

灰掺量/%实际喷射用量/(kg·m3) 水泥 粉煤灰 硅粉 细骨料 粗骨料 水 N1 JZ 0 414 / 36 864 796 190 N2 F10 10 369 45 36 864 796 190 N3 F20 20 324 90 36 864 796 190 N4 F30 30 279 135 36 864 796 190 表 2 水泥物理力学性能

Table 2. Physical and mechanical performance of cement

烧失量/% 凝结

时间/min抗折

强度/MPa抗压

强度/MPa初凝 终凝 3 d 28 d 3 d 28 d 4.77 184 240 6.2 8.6 30.6 50.8 表 3 粉煤灰物理性能

Table 3. Physical performance of fly ash

需水

量比含水

率/%45 μm筛余

率/%28 d活性

指数/%0.88 0.5 5.5 89.4 -

李红辉.大掺量粉煤灰高性能混凝土研究[D].北京: 北京建筑工程学院, 2008. 阿茹罕, 阎培渝.不同粉煤灰掺量混凝土的碳化特性[J].硅酸盐学报, 2011, 39(1):7-12. http://d.old.wanfangdata.com.cn/Conference/7468254Aruhan, YAN Peiyu. Carbonation characteristics of concrete with different fly-ash contents[J]. Journal of the Chinese Ceramic Society, 2011, 39(1):7-12. http://d.old.wanfangdata.com.cn/Conference/7468254 李观书.粉煤灰混凝土抗硫酸盐侵蚀性能[J].硅酸盐学报, 2012, 40(1):39-48. http://d.old.wanfangdata.com.cn/Thesis/D171981LI Guanshu. Sulfate resistance of fly ash concrete[J]. Journal of the Chinese Ceramic Society, 2012, 40(1):39-48. http://d.old.wanfangdata.com.cn/Thesis/D171981 杜明泽, 康天合, 尹博, 等.粉煤灰充填材料早龄期物理力学特性及其水化过程分析[J].岩石力学与工程学报, 2016, 35(4):826-836. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=XWC201510230000014197DU Mingze, KANG Tianhe, YIN Bo, et al. Physic-mechanical properties of fly ash filling material at early age and its hydration process[J]. Chinese Journal of Rock Mechanics and Engineering, 2016, 35(4):826-836. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=XWC201510230000014197 CHOUSIDIS N, RAKANTA E, IOANNOU I, et al. Mechanical properties and durability performance of reinforced concrete containing fly ash[J]. Construction & Building Materials, 2015, 101:810-817. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=f1bb06f1071db0bfbf9d703acfee3db1 马昆林, 谢友均, 刘运华.粉煤灰对混凝土孔隙率及强度的影响[J].粉煤灰综合利用, 2007(5):3-5. doi: 10.3969/j.issn.1005-8249.2007.05.001MA Kunlin, XIE Youjun, LIU Yunhua. Influence of fly ash to concrete porosity and strength[J]. Fly Ash Comprehensive Utilization, 2007(5):3-5. doi: 10.3969/j.issn.1005-8249.2007.05.001 鲁彩凤, 袁迎曙, 蒋建华.粉煤灰混凝土孔隙结构对气体扩散能力的影响[J].中国矿业大学学报, 2011, 40(4):523-529. doi: 10.1007-s11745-009-3347-x/LU Caifeng, YUAN Yingshu, JIANG Jianhua. Effect of pore structure on gas diffusion in fly ash concrete[J]. Journal of China University of Mining & Technology, 2011, 40(4):523-529. doi: 10.1007-s11745-009-3347-x/ 陆安群, 邓敏, 莫立武.粉煤灰水泥压实体早期水化和孔隙结构的演变[J].混凝土, 2012, 11:24-27. http://d.old.wanfangdata.com.cn/Periodical/hnt201211008LU Anqun, DENG Min, MO Liwu. Hydration and pore structure evolution of fly ash cement compacts at early age[J]. Concrete, 2012, 11:24-27. http://d.old.wanfangdata.com.cn/Periodical/hnt201211008 POON C S, LAM L, WONG Y L. Effects of fly ash and silica fume on interfacial porosity of concrete[J]. Journal of Materials in Civil Engineering, 1999, 11(3):197-205. doi: 10.1061/(ASCE)0899-1561(1999)11:3(197) POON C S, LAM L, WONG Y L. A study on high strength concrete prepared with large volumes of low calcium fly ash[J]. Cement and Concrete Research, 2000, 30(3):447-455. doi: 10.1016/S0008-8846(99)00271-9 THEERAWAT S, PRINYA C, CHAI J. Influence of fly ash fineness and shape on the porosity and permeability of blended cement pastes[J]. International Journal of Minerals, Metallurgy and Materials, 2010, 17(6):683-690. doi: 10.1007/s12613-010-0374-9 李杰林.基于核磁共振技术的寒区岩石冻融损伤机理试验研究[D].长沙: 中南大学, 2012. 王萧萧, 申向东, 王海龙, 等.盐蚀-冻融循环作用下天然浮石混凝土的抗冻性[J].硅酸盐学报, 2014, 42(11):1414-1421. http://d.old.wanfangdata.com.cn/Periodical/gsyxb201411011WANG Xiaoxiao, SHEN Xiangdong, WANG Hailong, et al. Frost-resistance of natural pumice concrete due to salt corrosion and freeze-thaw circulation[J]. Journal of the Chinese Ceramic Society, 2014, 42(11):1414-1421. http://d.old.wanfangdata.com.cn/Periodical/gsyxb201411011 RME V, PEL L, HAZRATI K, et al. Pore water distribution in mortar during drying as determined by NMR[J]. Materials and Structures, 2001, 34(10):599-604. doi: 10.1007/BF02482126 MULLER A C A, SCRIVENER K L, GAJEWI A M, et al. Densification of C-S-H measured by 1H NMR relaxometry[J]. Journal of Physical Chemistry C, 2013, 117(1):403-412. doi: 10.1021/jp3102964 董树国, 张国杰, 侯黎阳, 等.核磁共振数据分析混凝土孔隙率与抗盐冻关系[J].电子显微学报, 2015, 34(5):428-432. doi: 10.3969/j.issn.1000-6281.2015.05.012DONG Shuguo, ZHANG Guojie, HOU Liyang, et al. Analysis of the relationship between the porosity and the salt freezing resistance of concrete by NMR date[J]. Journal of Chinese Electron Microscopy Society, 2015, 34(5):428-432. doi: 10.3969/j.issn.1000-6281.2015.05.012 SHARMA S, CASANOVA F, WACHE W, et al. Analysis of historical porous building materials by the NMR-MOUSE[J]. Magnetic Resonance Imaging, 2003, 21(3/4):249. doi: 10.1016-S0730-725X(03)00132-2/ TZIOTZIOU M, KARAKOSTA E, KARATASIOS I, et al. Application of 1H NMR to hydration and porosity studies of lime-pozzolan mixtures[J]. Microporous & Mesoporous Materials, 2011, 139(1/2/3):16-24. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=c1d4b42d856fb169b9f5d5c7e6fae44e -

下载:

下载: