Physical and Mechanical Properties of Mud Pumping Soils in Railway Subgrade Bed

-

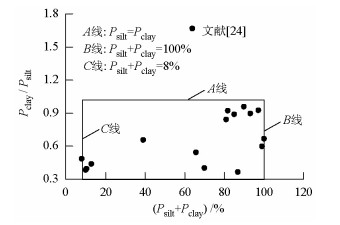

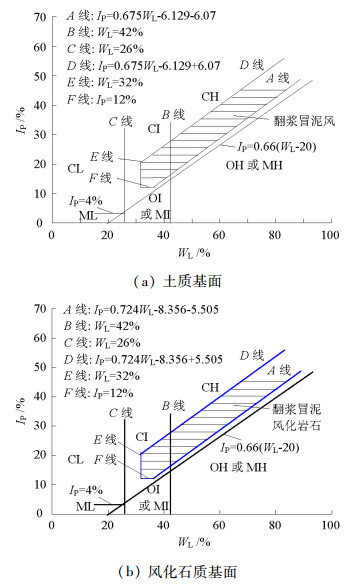

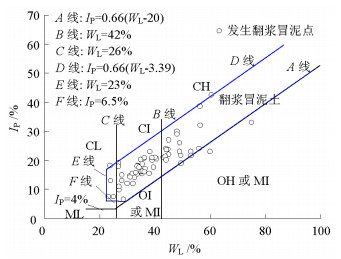

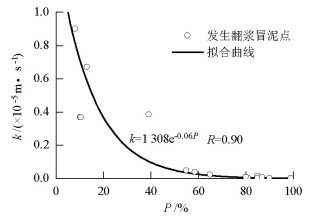

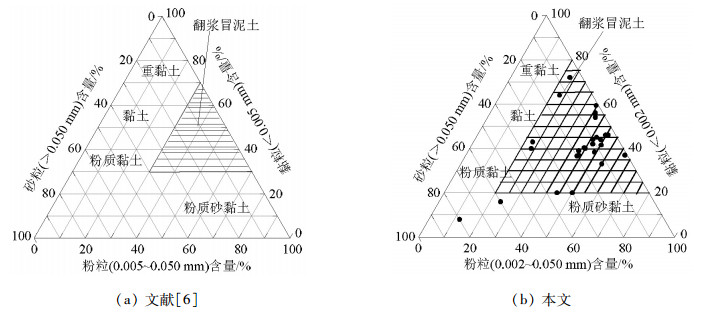

摘要: 随着列车提速和轴重大幅增加,基床出现翻浆冒泥病害的几率加大.为了进一步研究翻浆冒泥发生机理和探究其发生条件,系统研究了60多组翻浆冒泥实例,分析了翻浆冒泥土的颗粒组成、可塑性指标、渗透性及矿物成分等物理力学性质.研究结果表明:翻浆冒泥土中,绝大部分黏粒含量大于20%、粉粒含量大于20%,黏粒含量大于30%和粉粒含量大于40%的土所占数量最多;翻浆冒泥土中粉粒的含量一般要高于黏粒含量;翻浆冒泥土(主要包括砂黏土、粉质黏土、黏土和部分低液限粉质黏土)液限大于23%,塑性指数大于6.5;翻浆冒泥土渗透系数小于1.0×10-5 m/s;翻浆冒泥土的渗透系数与细颗粒含量之间存在较好的负指数关系.Abstract: Substantial increase in train speed and axle load may result in an increase in the probability of occurrence of the mud pumping problem in subgrade bed. In this study, to further study the mechanisms and occurrence conditions of the mud pumping problem, more than 60 mud pumping samples reported in published literature were studied systematically. Further, the physical and mechanical properties of mud pumping soils, such as particle composition, plasticity index, permeability, and mineral composition were analysed and summarized. The results indicate the following:For the most mud pumping soils, clay and silt particle content is greater than 20%; soils with clay content greater than 30% and silt content greater than 40% account for the largest proportion of the samples. In mud pumping soils, the silt content is generally greater than the clay content. The liquid limit is more than 23%, and plasticity index greater than 6.5, i.e., sandy clay, silty clay, clay and part of low liquid limit silty clay. Generally, the permeability coefficient of mud pumping soils is less than 1.0×10-5 m/s. The permeability coefficient and fine particle content show good negative exponential correlation.

-

Key words:

- mud pumping /

- particle composition /

- liquid limit /

- plasticity index /

- permeability coefficient

-

表 1 主要重载国家重载列车轴重和车长

Table 1. Typical heavy haul railway freight trains including axle loads and length worldwide

国家 轴重/t 列车长(车辆数)/辆 美国与加拿大 33.0 130~140 澳大利亚 35.0~40.0 200~240 南非 26.0~30.0 200~216 巴西 27.5~32.5 330 瑞典 30.0 68 中国 25.0~27.0 210 表 2 翻浆冒泥土的物理性质

Table 2. Physical properties of mud pumping soils

序号 土名 颗粒组成及矿物成分 液限

WL/%塑性指数Ip 含水率w/% 渗透系数k/

(×10-6cm·s-1)自由膨胀率Fs/% 饱和度

Sr/%密度ρ/

(g·cm-3)土粒相对密度 孔隙比e 参考文献 1 非有机质黏土 P0.420=93.7%,

P0.074=77.0%43.0 21.0 13.0 — 2.81 [25] 2 粉质黏土 细颗粒含量P=10.0% 49.0 26.0 2.74 [13] 3

4砂土 P(砂=80.0%, 粉粒和黏粒=20.0%) 45.0

40.027.0

21.0[26] 5

6

7黏土 48.0

45.0

48.030.0

22.0

29.0[27] 8 超固结海洋钙质黏土 P0.063=95.0% 44.0 24.0 [28] 9 黄色粉质低液限黏土 P(粉粒=60.0~70.0%,

黏粒=20.0%~26.0%,

砂粒=12.0%)25.4 9.1 [29] 10 棕色粉质低液限黏土 28.4 9.5 11 黏土 P(粉粒=62.0%,

黏粒=37.0%)44.2 23.6 3.40 12 火山灰黏土 P(粉粒=50.6%,

黏粒=46.7%)49.4 21.7 2.71 [30] 13 膨胀土 P(砂粒=8.3%~24.6%,

粉粒=42.6%~63.8%,

黏粒=23.2%~39.2%)56.3~60.5 38.6~42.5 81.6 [31] 14 膨胀土 伊利石为主,

少量高岭石,

微量蒙脱石P(砂粒=8.2%,

粉粒=49.8%,

黏粒=42.0%)[32] 15 P(砂粒=11.5%,

粉粒=54.0%,

黏粒=34.5%)36.5 20.0 22.5 39.0~70.0 82.0 1.86 0.65 16 P(砂粒=7.5%,

粉粒=47.5%,

黏粒=45.0%)40.6 20.5 21.1 35.0~80.0 80.2 1.98 0.79 17 P(砂粒=35.5%,

粉粒=44.3%,

黏粒=20.2%)31.0 14.6 24.6 49.0 83.0 1.89 0.80 18 39.0 20.0 19.4 30.0~50.0 74.4 1.87 0.79 19 35.3 15.3 19.4 49.0 87.7 2.03 0.61 20 38.0 15.5 22.9 49.0 71.6 1.86 0.87 21 43.8 21.3 23.0 7.7~77.0 72.7 1.87 0.88 22 中等膨胀性土 蒙脱石含量=24.36% 45.5 20.1 80.0 [33] 23 弱膨胀性土 蒙脱石含量=16.7% 49.5 19.0 51.0 24 黏土 P(粉粒>50.0%,

黏粒>20.0%)158.0 70.0 2.46 2.22 25 75.0 33.0 0.45 2.66 [34] 26 53.0 23.0 0.48 2.68 27 黏土 主要矿物成份为拜来石、伊利石, 高岭土占有一定的比例 44.1 20.1 29.0 [24] 28 黏土 土渗透性差, 亲水性强,

遇水易膨胀软化,

粉黏粒含量大于70.0%,

矿物成分以高岭石为主>12.0 >60.00 [6] 29 中膨胀性土 P(黏粒=87.0%) 60.0 23.0 75.0 2.62 [35] 30 黏土 P(黏粒>87.9%) 49.0 19.5 31 黏土 36.1 20.7 22.5 1.85 0.69 [36] 32 38.2 22.9 19.0 33 36.2 20.8 21.3 29.0 1.97 0.69 34 35.4 18.7 23.6 1.87 0.71 35 33.6 18.0 22.4 33.0 1.93 0.74 36 34.9 20.2 23.4 36.0 1.95 0.77 37 砂黏土 P(砾粒=43.6%,

砂粒=45.9%, 粉粒=7.6%, 黏粒=3.0%)26.9 19.1 21.5 368.00 17.0 100 0.49 [37] 39 P(砾粒=25.9%,

砂粒=49.5%, 粉粒=23.6%, 黏粒=15.5%)26.9 17.9 17.0 670.00 29.0 88.7 0.52 39 砂土 P(砾粒=11.4%, 砂粒=61.1%, 粉粒= 9.0%, 黏粒=4.0%) 28.6 6.5 20.1 386.00 100.0 0.53 40 黏土 P(砂粒=19.0%, 粉粒= 44.0%, 黏粒=37.0%) 39.5 17.6 1.31~3.60 76.2 0.73 41 砂土 P(砂粒=13.0%, 粉粒= 49.2%, 黏粒=44.0%) 31.0 14.2 84.0 0.80 42 粉黏土 P(砂粒=10.0%, 粉粒= 46.0%, 黏粒=44.0%) 36.2 16.0 1.50 85.1 0.63 43 28.0 15.0 15.3* 0.05 12.2 1.77* 44 砂土 P(砾粒=26.5%,

砂粒=55.4%, 粉粒= 7.3%, 黏粒=2.8%)23.7 18.2 13.5 368.00 22.0 100.0 0.32 45 P(砾粒=32.3%, 砂粒=59.7%, 粉粒= 5.4%, 黏粒=2.6%) 25.71 14.9 900.00 25.0 74.0 0.54 46 黏土 P(砂粒=15.0%, 粉粒= 45.0%, 黏粒=40.0%) 43.8 21.3 15.80~76.30 72.2 0.88 47

48弱膨胀性土 28.0

24.013.0

13.00.05

0.0512.2

12.3[38] 49 4处黏土,

5处砂黏土32.6~34.3 14.1~17.6 [23] 50 中等膨胀性土 P(粉黏粒>95.0%) 28.0~52.6 14.0~27.1 0.95~10.50 42.0~65.0 [39] 51 黏土 主要是蒙脱石和伊利石, 以蒙脱石为主 31.8 15.4 [40] 52 44.7 23.7 53 39.0 20.8 54 35.0 16.1 55 33.5 15.2 56 33.0 15.7 57 35.4 16.2 58 33.7 18.2 59 粉质黏土 细粒含量<0.08 mm=95.0% 27.0 11.0 16.0* 33.00~139.00 1.78* [16] 60 砂土 P(砾粒=8%, 砂粒= 82.0%, 粉粒=10.0%) 27.8 46.5 1.45 [41] 61 粉质黏土 25.0 7.4 78.0 [42] 62 低液限粉质黏土 23.1~23.1 7.4 16.0~-29.6 1.88~1.90* [43] 63 粉质黏土 P(砂粒=15.6%, 粉粒= 78.4%, 黏粒=6.0%) 32.0 12.0 16.8 1.68 2.72 [44] 64 P(砂粒=1.6%, 粉粒= 97.4%, 黏粒=1.0%) 32.0 14.0 24.5 1.63 2.69 注:P为质量百分数,P0.420、P0.074、P0.063分别指颗粒粒径小于0.420、0.074 mm和0.063 mm的质量百分数; 黏粒指粒径小于0.002 mm的颗粒; 粉粒指粒径大于0.002 mm小于0.050 mm的颗粒; 砂粒指粒径大于0.050 mm小于2.000 mm的颗粒; 砾粒指粒径大于2.000 mm的颗粒; *表示最优含水率或最大干密度. -

SELIG E T, WATERS J M. Track geotechnology and substructure management[M]. London:Thomas Telford, 1994:8-1-8-50. 杨志浩.重载铁路翻浆冒泥病害机理研究[D].石家庄: 石家庄铁道大学, 2014. http://cdmd.cnki.com.cn/Article/CDMD-10107-1015424499.htm FELDMAN F, NISSEN D. Alternative testing method for the measurement of ballast fouling: percentage void Contamination[C]//Cost Efficient Railways Through Engineering (CORE 2002).Wollongong: [s.n.], 2002: 10-13. https://trid.trb.org/view/1317346 INDRARATNA B, SU L, RUJIKIATKAMJORN C. A new parameter for classification and evaluation of railway ballast fouling[J]. Canadian Geotechnical Journal, 2011, 48(2):322-326. doi: 10.1139/T10-066 徐旸, 高亮, 井国庆, 等.脏污对道床剪切性能影响及评估指标的离散元分析[J].工程力学, 2015, 32(8):96-102. http://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201508015.htmXU Yang, GAO Liang, JING Guoqing, et al. Shear behavior analysis of fouled railroad ballast by DEM and its evaluation index[J]. Engineering Mechanics, 2015, 32(8):96-102. http://www.cnki.com.cn/Article/CJFDTOTAL-GCLX201508015.htm 杨若芳, 杨灿文.防治翻浆冒泥新技术[M].北京:中国铁道出版社, 1989:1-14. China Railway Corporation. The annual report of railway subgrade detection in 2013[R]. Beijing: China Railway Publishing House, 2013. VAN W A. Rigid pavement pumping: (1) subbase erosion and (2) economic modeling: informational report[R/OL]. [2016-09-20]. http://dx.doi.org/10.5703/1288284314094. ALOBAIDI I, HOARE D J. Factors affecting the pumping of fines at the subgrade subbase interface of highway pavements:a laboratory study[J]. Geosynthetics International, 1994, 1(2):221-259. doi: 10.1680/gein.1.0010 ALOBAIDI I, HOARE D J. The development pore water pressure at the subgrade-subbase interface of a highway pavement and its effect on pumping of fines[J]. Geotexitiles and Geomembranes, 1996, 14(2):111-135. doi: 10.1016/0266-1144(96)84940-5 ALOBAIDI I, HOARE D J. The role of geotextile reinforcement in the control of pumping at the subgrade-subbase interface of highway pavements[J]. Geosynthetics International, 1998, 5(6):619-636. doi: 10.1680/gein.5.0138 ALOBAIDI I, HOARE D J. Qualitative criteria for anti-pumping geocomposites[J]. Geotextiles and Geomembranes, 1998, 16(4):221-245. doi: 10.1016/S0266-1144(98)00012-0 ALOBAIDI I, HOARE D J. Mechanisms of pumping at the subgrade-subbase interface of highway pavements[J]. Geosynthetics International, 1999, 6(4):241-259. doi: 10.1680/gein.6.0152 TAKATOSHI I. Measure for the stabilization of railway earth structure[R]. Tokyo: Japan Railway Technical Service, 1997. ENG SEW A. Low cost monitoring system to diagnose problematic rail bed: case study at a mud pumping site[D]. Cambridge: Massachusetts Institute of Technology, 2007. DUONG T V, CUI Y J, TANG A M, et al. Investigating the mud pumping and interlayer creation phenomena in railway sub-structure[J]. Engineering Geology, 2014, 171:45-58. doi: 10.1016/j.enggeo.2013.12.016 DUONG T V, CUI Y J, TANG A M, et al. Physical model for studying the migration of fine particles in the railway substructure[J]. Geotechnical Testing Journal, 2014, 37(5):1-12. 聂如松, 冷伍明, 杨奇.既有重载铁路路基检测试验与状态评估[J].铁道工程学报, 2014, 31(11):20-24. doi: 10.3969/j.issn.1006-2106.2014.11.005NIE Rusong, LENG Wuming, YANG Qi. Detection test and condition assessment on existing heavy hual railway subgrade[J]. Journal of Railway Engineering Society, 2014, 31(11):20-24. doi: 10.3969/j.issn.1006-2106.2014.11.005 聂如松, 冷伍明, 杨奇.铁路路基质量检测试验对比分析[J].铁道学报, 2015, 37(1):91-96. doi: 10.3969/j.issn.1001-8360.2015.01.014NIE Rusong, LENG Wuming, YANG Qi. Comparison and analysis on railway subgrade quality detection tests[J]. Journal of the China Railway Society, 2015, 37(1):91-96. doi: 10.3969/j.issn.1001-8360.2015.01.014 NIE Rusong, LENG Wuming, SU Yu, et al. Causes and mechanism of mud pumping in ballast track subgrade[C]//The 4th International Conference on Railway Engineering: the Infrastructure Construction and Maintenance of High-speed Railway and Ubran Rail Transit in Complex Environment (ICRE2016). Beijing: [s.n.], 2016: 30-31. LI D, HYSLIP J, SUSSMANN T, et al. Railway geotechnics[M].[S.l.]:CRC Press, 2016:108-124. 韩自力, 张千里.既有线提速路基动应力分析[J].中国铁道科学, 2005, 26(5):1-5. doi: 10.3321/j.issn:1001-4632.2005.05.001HAN Zili, ZHANG Qianli. Dynamic stress analysis on speed-increase subgrade of existing railway[J]. China Railway Science, 2005, 26(5):1-5. doi: 10.3321/j.issn:1001-4632.2005.05.001 乔连军.京通线K245~K462路基翻浆冒泥的整治[J].铁道建筑, 2006(10):75-76. doi: 10.3969/j.issn.1003-1995.2006.10.029 杨荣兴.浙赣线红门工点翻浆冒泥的整治[J].路基工程, 1996(6):53-56. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199600349227YANG Rongxing. Remediation of the mud pumping Red Gate Worksite[J]. Subgrade Engineering, 1996(6):53-56. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199600349227 VOOTTIPRUEX P, ROONGTHANEE J. Prevention of mud pumping in railway embankment a case study from Baeng Pra-pitsanuloke, Thailand[J]. The Journal of KMITB, 2003, 13(1):20-25. BOOMINTAHAN S, SRINIVASAN G R. Laboratory studies on mud pumping into ballast under repetitive rail loading[J]. Indian Geotechnical Journal, 1988, 18(1):31-47. RAYMOND G P. Geotextileapplication for a branch line upgrading[J]. Geotextiles and Geomembranes, 1986, 3(2):91-104. http://www.sciencedirect.com/science/article/pii/0266114486900026 AYRES D J. Geotextiles or geomembranes in track? British railways' experience[J]. Geotextiles and Geomembranes, 1986, 3(2):129-142. http://www.sciencedirect.com/science/article/pii/026611448690004X 谷宪明.季冻区道路冻胀翻浆机理及防治研究[D].长春: 吉林大学, 2007. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=kxycf201606121 MURAMOTO K, SEKINE E, NAKAMURA T, et al. Roadbed degradation mechanism under ballastless track and its countermeasures[J]. Quarterly Report of Rtri, 2006, 47(4):222-227. doi: 10.2219/rtriqr.47.222 倪宏革, 张令诺, 周庆坡.兖石铁路基床翻浆冒泥产生机理与整治对策分析[J].铁道建筑, 2007(2):61-63. doi: 10.3969/j.issn.1003-1995.2007.02.022 葛如生.阳安线基床病害整治[D].成都: 西南交通大学, 2003. http://cdmd.cnki.com.cn/Article/CDMD-10613-2004020478.htm 钟涛, 梁维新.成都东站峰前场基床翻浆冒泥原因的试验分析[J].路基工程, 1995(5):39-41. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199500331572ZHONG Tao, LIANG Weixin. Mud pumping analysis of roadbed in front of Chengdu East Railway Station[J]. Subgrade Engineering, 1995(5):39-41. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199500331572 山田干雄, 小野一良, 孙明漳.关于产生翻浆冒泥机理的初步研究[J].路基工程, 1988(3):70-75. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000002086579 吴新民.南昆铁路膨胀土路基翻浆冒泥病害分析与改良土试验研究[D].成都: 西南交通大学, 2007. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y1131160 易波.电阻率层析成像技术在阳安铁路翻浆冒泥探测中的应用[J].路基工程, 2013(6):150-155. doi: 10.3969/j.issn.1003-8825.2013.06.035YI Bo. Appliaction of resistivity tomography in detection of mud pumping along Yangpingguan-Ankang Railway[J]. Subgrade Engineering, 2013(6):150-155. doi: 10.3969/j.issn.1003-8825.2013.06.035 赵满庆.裂隙土基床病害整治研究[D].成都: 西南交通大学, 2002. http://cdmd.cnki.com.cn/Article/CDMD-10613-2003060289.htm 傅鹤林, 刘宝琛.路基基床翻浆冒泥病害整治的固化材料的室内试验研究[C]//中国土木工程学会第九届土力学及岩土工程学术会议论文集(下册).北京: 中国土木工程学会, 2003: 1303-1306. http://www.wanfangdata.com.cn/details/detail.do?_type=conference&id=4502316 段铭钰.铁路路基翻浆冒泥的原因及整治措施[J].铁道技术监督, 2010(6):23-25. doi: 10.3969/j.issn.1006-9178.2010.06.010 杨新安, 周青.铁路路基病害与动力触探试验研究[J].中国矿业大学学报, 2002, 31(4):31-35. http://d.old.wanfangdata.com.cn/Periodical/zgkydxxb200204007YANG Xinan, ZHOU Qing. Shanghai-Nanjing railway embankment settlement and dynamic penetration test[J]. Journal of China University of Mining & Technology, 2002, 31(4):31-35. http://d.old.wanfangdata.com.cn/Periodical/zgkydxxb200204007 HAYASHI S, SHAHU J T. Mud pumping problem in tunnels on erosive soil deposits[J]. Geotechnique, 2000, 50(4):393-408. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=914b0f79090c33cba762731784fdeaf7 崔新壮.交通荷载作用下黄河三角洲低液限粉土地基累积沉降规律研究[J].土木工程学报, 2012, 45(1):154-162. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201200025965CUI Xinzhuang. Traffic-induced settlement of subgrade of low liquid limit silt in Yellow River Delta[J]. China Civil Engineering Journal, 2012, 45(1):154-162. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK201200025965 尹成斐.朔黄铁路神池南站咽喉路基病害检测与分析[J].现代城市轨道交通, 2013(3):65-70. doi: 10.3969/j.issn.1672-7533.2013.03.019YIN Chengfei. Inspection and analysis on subgrade defects over station throat at Shenchi South of Shuohuang Railway[J]. Modern Ubran Transit, 2013(3):65-70. doi: 10.3969/j.issn.1672-7533.2013.03.019 冷伍明, 聂如松, 赵春彦, 等.重载铁路桥梁和路基检测与强化技术研究: 重载铁路路基静动力性能与检测技术研究(分报告之八)[R].长沙: 中南大学, 2011. 周锡九.铁路路基基床病害及其产生机理分析[J].北方交通大学学报, 1994, 18(1):24-28. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199400153669ZHOU Xijiu. Analysis of classification and mechanism of railway bed[J]. Journal of Northern Jiaotong University, 1994, 18(1):24-28. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK199400153669 伊东孝之.整治路基翻浆冒泥的措施[J].屈野威译, 周柔琴校.铁道建筑, 1980(4): 30-32. 张云根.高速铁路基床填料物理力学特性试验分析[D].成都: 西南交通大学, 2006. http://cdmd.cnki.com.cn/Article/CDMD-10613-2008178900.htm -

下载:

下载: