Construction Control System for Thousand-Meter-Scale Hybrid Girder Cable-Stayed Bridge Based on Double Target Control

-

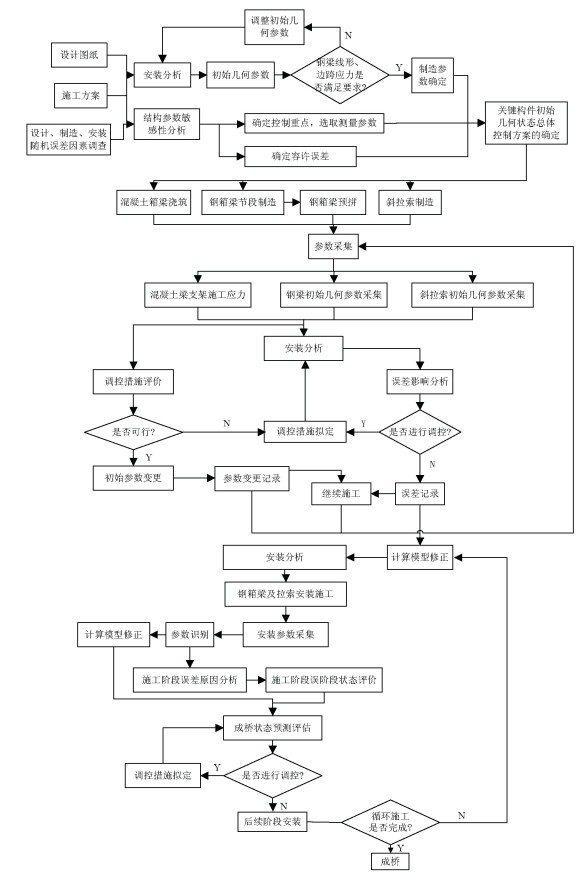

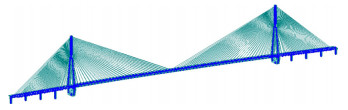

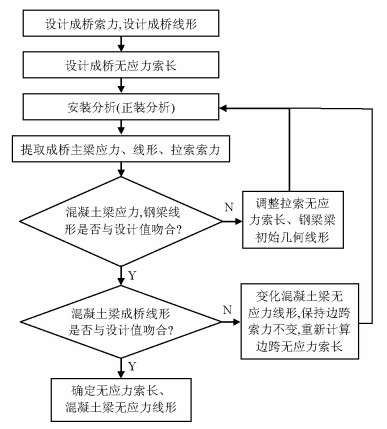

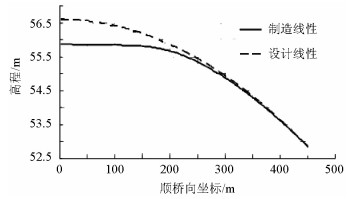

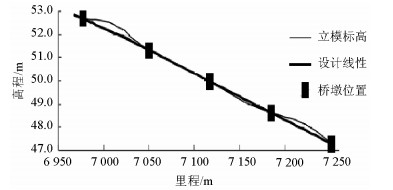

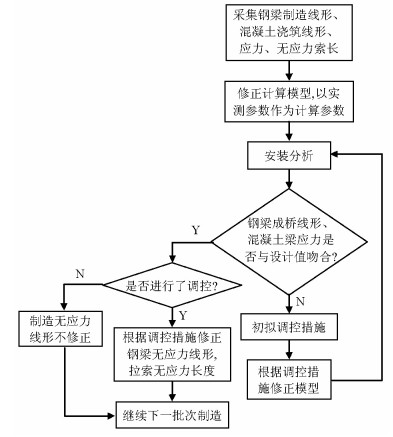

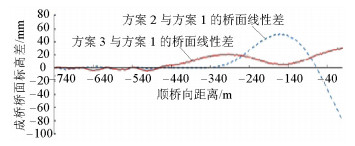

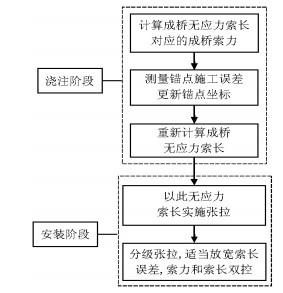

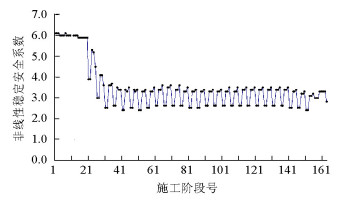

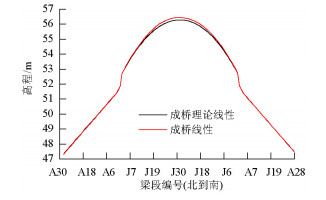

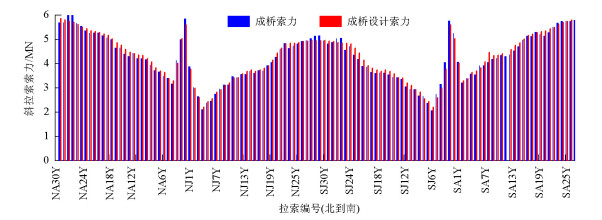

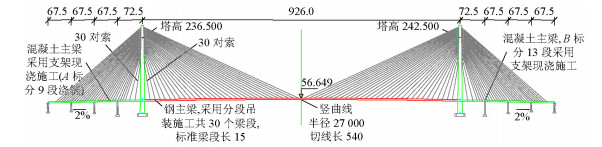

摘要: 为确保千米级混合梁斜拉桥施工监控的高效性、高精度以及安全性,以鄂东大桥为背景,通过理论分析、有限元数值计算,在充分考虑结构非线性效应,并结合现场实际及工程面临问题的基础上,开展了特大跨度混合梁斜拉桥施工监控理念、监控方法及监控内容研究,构建了适用于该复杂结构的监控体系.首先,根据千米级混合梁斜拉桥施工控制特点及面临的问题和挑战,基于几何控制理论,构建了双目标监控体系;其次,根据双目标控制系统关键问题,重点针对初始无应力状态量的确定、关键构件计算分析、制造浇筑及安装控制、施工期安全稳定等问题进行深入研究,得到了其计算分析及安装控制方法;最后,利用建立的监控体系,对鄂东桥进行了全过程控制.研究结果表明:采用的监控系统,制造阶段误差梁顶最大为16 mm,轴线误差2.7 mm,累计梁长误差10.8 mm;非线性稳定安全系数最小2.5,满足要求;边跨混凝土线形最大误差11 mm,中跨钢箱梁最大误差157 mm;塔偏相对误差为L/12 434,混凝土梁单根拉索索力最大误差为4.50%,钢梁索力最大为6.30%,全桥应力合理,监控各项指标均满足规范要求.Abstract: To ensure the construction control of thousand-meter-scale hybrid girder cable-stayed bridges for high efficiency, precision, and safety, taking the Edong Yangtze River Bridge as a case study, research on the construction monitoring concept, monitoring method, and monitored parameters of the super-long-span hybrid girder cable-stayed bridge was carried out, and the construction control system for this complicated structure was built. The research and the system were based on theoretical studies, finite element numerical calculations with full consideration of the structural nonlinear geometrical effects, and the issues faced at the construction site. First, according to the construction control characteristics, problems, and challenges of thousand-meter-scale hybrid girder cable-stayed bridges, the double target control system was built based on the geometry control method. Then, focusing on the key aspects of this control system, some important issues such as the determination of the initial unstressed state amount, calculations pertaining to key construction members, fabrication and cast-in-site control stage, erection stage, and safety control in the construction stage were extensively studied, and the calculation and installation control methods were obtained. Finally, the entire construction control procedure for the Edong Yangtze River Bridge was carried out using this control system. The results show that the maximum alignment error at the top of girder is 16 mm, the axis error is 2.7 mm, and the cumulative girder error is 10.8 mm during the manufacturing stage. The minimum value of the nonlinear stability safety factor is 2.5 and meets the specifications. Meanwhile, the maximum alignment error of concrete girder in the side span is 11 mm, and the maximum alignment error of the steel box girder in the middle span is 157 mm. The relative error of the pylon deviation is L/12434. Furthermore, the maximum cable force error of a single cable located in the concrete girder is 4.5%, and the maximum cable force error of a single cable located in the steel girder is 6.30%. All the analyses show that the stress condition in the entire structure is reasonable, and all the monitoring indexes meet the specifications.

-

表 1 梁段制造成果误差

Table 1. Errors of manufacturing process

mm 类别 梁顶制造线形 轴线制造 累计梁长 北岸(浠水侧) 15.0 2.7 10.8 南岸(黄石侧) 16.0 2.6 9.7 表 2 大悬臂阶段拉索“超张”、“放张”方案

Table 2. Over tension and loosening process of cables under the longest cantilevered construction stage

m 拉索编号 设计二张索长 调整后二张索长 二张超张量 放回设计索长时间 中跨21#索 362.423 362.380 0.043 25号索二张完成后 中跨22#索 376.813 376.768 0.045 26号索二张完成后 中跨23#索 391.256 391.172 0.084 27号索二张完成后 中跨24#索 405.874 405.758 0.116 28号索二张完成后 中跨25#索 420.480 420.317 0.163 28号索二张完成后 中跨26#索 435.118 434.949 0.169 29号索二张完成后 中跨27#索 449.742 449.513 0.229 29号索二张完成后 中跨28#索 464.409 464.150 0.259 30号索二张完成后 中跨29#索 479.140 478.872 0.268 30号索二张完成后 表 3 临时配重施加方案

Table 3. Temporary balance weight application method

施加时间 施加位置及大小 卸除情况 中跨25#索2张完, 26#段吊装前 21、22#索处各施加500 kN — 中跨26#索2张完, 27#段吊装前 23#索处施加500 kN — 中跨27#索2张完, 28#段吊装前 24#索处施加900kN, 25#索处施加500 kN — 中跨28#索2张完, 29#段吊装前 在25#索处再施加800 kN 拆除21、22#索处500 kN 中跨29#索2张完, 30#段吊装前 26#索处施加800 kN 拆除23#索处500 kN 中跨30#索2张完 — 拆除24、25、26#索处压重 表 4 监控实施效果汇总

Table 4. Summary of construction control error

项目 成桥误差 容许误差 钢梁线形/mm 157.0 235.0 混凝土梁线形/mm 11.0 31.0 轴线/mm 19.7.0 51.0 混凝土梁索力/% 4.50 5.00 钢梁索力/% 6.30 8.00 混凝土箱梁应力/MPa 1.2 1.5 塔偏/mm 18.9 30.0 注:表中为误差绝对值; 索力误差指单根拉索误差. -

陈开利, 余天庆, 习刚.混合梁斜拉桥的发展与展望[J].桥梁建设, 2005(2):1-4. doi: 10.3969/j.issn.1003-4722.2005.02.001CHEN Kaili, YU Tianqing, XI Gang. Development and prospective of hybrid girder cable-stayed bridge[J]. Bridge Construction, 2005(2):1-4. doi: 10.3969/j.issn.1003-4722.2005.02.001 徐国平, 张喜刚, 刘玉擎, 等.混合梁斜拉桥[M].北京:人民交通出版社, 2013:216-233. 詹建辉, 彭晓彬.大跨度组合梁斜拉桥结构设计方案研究[J].桥梁建设, 2016, 46(4):85-91. http://d.old.wanfangdata.com.cn/Periodical/qljs201604016ZHAN Jianhui, PENG Xiaobin. Study of structural design scheme for long span composite girder cable-stayed bridge[J]. Bridge Construction, 2016, 46(4):85-91. http://d.old.wanfangdata.com.cn/Periodical/qljs201604016 赵雷, 孙才志, 杨兴旺.鄂东长江大桥施工过程非线性稳定性分析[J].西南交通大学学报, 2012, 47(5):741-747. doi: 10.3969/j.issn.0258-2724.2012.05.003ZHAO Lei, SUN Caizhi, YANG Xingwang. Stability analysis of Edong Yangtze River Bridge during construction[J]. Journal of Southwest Jiaotong University, 2012, 47(5):741-747. doi: 10.3969/j.issn.0258-2724.2012.05.003 谢明志, 卜一之, 魏然, 等.千米级混合梁斜拉桥无应力索长及几何线形控制[J].重庆交通大学学报:自然科学版, 2013, 32(3):374-378. http://d.old.wanfangdata.com.cn/Periodical/cqjtxyxb201303002XIE Mingzhi, BU Yizhi, WEI Ran, et al. Unstressed cable length and geometric linear control of hybrid girder cable-stayed bridge with 1000 m sale span[J]. Journal of Chongqing Jiaotong University:Natural Science, 2013, 32(3):374-378. http://d.old.wanfangdata.com.cn/Periodical/cqjtxyxb201303002 宋亚洲, 李昌辉, 蔡瑞瑞.钢-混凝土混合梁斜拉桥参数敏感性分析与控制[J].施工技术, 2013, 42(23):14-16, 29. doi: 10.7672/sgjs2013230014SONG Yazhou, LI Changhui, CAI Ruirui. Parameter sensitivity analysis and control of steel-concrete girder for cable-stayed bridge[J]. Construction Technology, 2013, 42(23):14-16, 29. doi: 10.7672/sgjs2013230014 谢明志, 卜一之, 张克跃, 等.特大跨度混合梁斜拉桥几何控制法参数敏感性[J].长安大学学报:自然科学版, 2014, 34(3):66-73. http://d.old.wanfangdata.com.cn/Periodical/xagljtdx201403011XIE Mingzhi, BU Yizhi, ZHANG Keyue, et al. Sensitivity of parameters of super long-span hybrid girder cable-stayed bridge based on geometry control method[J]. Journal of Chang'an University:Natural Science Edition, 2014, 34(3):66-73. http://d.old.wanfangdata.com.cn/Periodical/xagljtdx201403011 石雪飞, 项海帆.斜拉桥施工控制方法的分类分析[J].同济大学学报, 2001, 29(1):55-59. doi: 10.3321/j.issn:0253-374X.2001.01.012SHI Xuefei, XIANG Haifan. Analysis of construction control systems of cable-stayed bridge[J]. Journal of Tongji University, 2001, 29(1):55-59. doi: 10.3321/j.issn:0253-374X.2001.01.012 MANABE Y, HIRAHARA N, MUKASA N, et al. Accuracy control on the construction of Tatara Bridge[C]//Cable-Stayed Bridges-Past, Present and Future: Proceedings of IABSE Conference.Malmö: IABSE, 1999: 332-335. https://structurae.net/literature/conference-paper/accuracy-control-on-the-construction-of-tatara-bridge 秦顺全.无应力状态控制法——斜拉桥安装计算的应用[J].桥梁建设, 2008(2):13-16. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=qljs200802004QIN Shunquan. Application of unstressed state control method to calculation for erection of cable-stayed bridge[J]. Bridge Construction, 2008(2):13-16. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=qljs200802004 李乔, 卜一之, 张清华.基于几何控制的全过程自适应施工控制系统研究[J].土木工程学报, 2009, 42(7):69-77. doi: 10.3321/j.issn:1000-131X.2009.07.011LI Qiao, BU Yizhi, ZHANG Qinghua. Whole-procedure adaptive construction control system based on geometry control method[J]. China Civil Engineering Journal, 2009, 42(7):69-77. doi: 10.3321/j.issn:1000-131X.2009.07.011 张家元, 丁望星, 朱世峰.荆岳长江公路大桥索塔锚固钢锚梁结构体系分析[J].桥梁建设, 2015, 45(2):89-93. http://d.old.wanfangdata.com.cn/Periodical/qljs201502015ZHANG Jiayuan, DING Wangxing, ZHU Shifeng. Analysis of steel anchor beam structural system of anchorage in pylon of Jingyue Changjiang River highway bridge[J]. Bridge Construction, 2015, 45(2):89-93. http://d.old.wanfangdata.com.cn/Periodical/qljs201502015 赵雷, 贾少敏, 顾乡.分幅斜拉桥斜拉索无应力长度的简化计算方法[J].重庆交通大学学报:自然科学版, 2014, 33(6):5-8, 88. http://d.old.wanfangdata.com.cn/Periodical/cqjtxyxb201406002ZHAO Lei, JIA Shaomin, GU Xiang. Simplified calculation method of unstressed length of cable-stayed bridge with separate twin-decks[J]. Journal of Chongqing Jiaotong University:Natural Science, 2014, 33(6):5-8, 88. http://d.old.wanfangdata.com.cn/Periodical/cqjtxyxb201406002 张清华, 黄灿, 卜一之, 等.大跨度钢斜拉桥制造误差的传播及其效应特性[J].西南交通大学学报, 2015, 50(5):830-837. doi: 10.3969/j.issn.0258-2724.2015.05.010ZHANG Qinghua, HUANG Can, BU Yizhi, et al. Fabrication error propagation properties of key components of large-span cable-stayed bridges with steel box girde[J]. Journal of Southwest Jiaotong University, 2015, 50(5):830-837. doi: 10.3969/j.issn.0258-2724.2015.05.010 尹子安.钢桁梁斜拉桥施工控制[D].成都: 西南交通大学, 2017. http://cdmd.cnki.com.cn/Article/CDMD-10613-1017137375.htm 赵彦峰.悬拼施工的叠合梁斜拉桥线形控制与分析[D].成都: 西南交通大学, 2016. http://cdmd.cnki.com.cn/Article/CDMD-10613-1016155010.htm 李乔, 卜一之, 张清华, 等.大跨度斜拉桥施工全过程及几何控制概论与应用[M].成都:西南交通大学出版社, 2009:15-26. 赵灿晖, 卜一之.超大跨混合梁斜拉桥施工控制技术[R].成都: 西南交通大学, 2011. 王振海, 王泽华, 赵灿晖.千米级斜拉桥施工期应力调控措施研究[J].施工技术, 2012, 41(9):74-78. http://d.old.wanfangdata.com.cn/Periodical/sgjs201209021WANG Zhenhai, WANG Zehua, ZHAO Canhui. Study on stress redeployment of cable-stayed bridge with 1000 m scale span during construction[J]. Construction Technology, 2012, 41(9):74-78. http://d.old.wanfangdata.com.cn/Periodical/sgjs201209021 -

下载:

下载: