Modified Constitutive Model and Ductile Fracture Criterion for 5A06 Al-Alloy Sheets at Elevated Temperatures

-

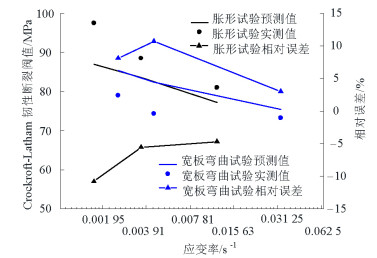

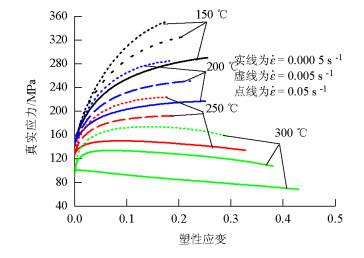

摘要: 为了获取材料在不同条件下成形性能指标,对5A06铝合金板材进行了热态单向拉伸试验,结合热态单向拉伸试验和韧性断裂试验结果,提出了一种修正Misiolek模型;利用修正模型的外插性能预测颈缩后板材流变应力,应用径向基函数神经网络算法建立了Cockroft-Latham韧性断裂阈值预测模型,并对该模型进行了预测精度评估.结果表明,流变应力对温度及应变速率敏感,对比径向基函数网络模型预测误差小于10.6%.Abstract: In order to obtain the formation characteristics of 5A06 aluminium alloy sheets, uniaxial tensile tests were conducted under different conditions. From hot tensile and fracture tests, a modified Misiolek equation was defined that extrapolated the flow stress from the diffuse necking of the metal sheet. By using a radial basis unction (RBF) artificial neural network, a Crockroft-Latham ductile fracture threshold prediction model was also developed. An evaluation of the network compared model results with experimental data. Results show that the material flow stress is very sensitive to temperature and strain rate, and the RBF artificial neural network can predict the ductile fracture threshold with a maximum error of less than 10.6%.

-

表 1 5A06-O铝合金板材化学成分

Table 1. Chemical composition of the 5A06 alloy

元素 Mg Si Fe Cu Mn Zn Ti Al wB/% 5.9 0.4 0.4 0.1 0.7 0.2 0.06 其余 表 2 不同条件下5A06铝合金Crockroft-Latham韧性断裂阈值

Table 2. Crockroft-Latham fracture threshold of the 5A06 Al alloy under various conditions

MPa 应变速率/s-1 温度/℃ 150 200 250 300 0.055 00 76.535 73.423 65.652 65.105 0.005 50 91.979 80.172 71.438 58.668 0.000 55 115.048 90.071 73.938 51.417 -

LANG Lihui, LIU Kangning, CAI Gaoshen, et al. A critical review on special forming processes and associated research for lightweight components based on sheet and tube materials[J]. Manufacturing Review, 2014, 1(9):1-20. 杨锋平, 罗金恒, 张华, 等.金属延性断裂准则精度的评价[J].塑性工程学报, 2011, 18(2):103-106. doi: 10.3969/j.issn.1007-2012.2011.02.021YANG Fengping, LUO Jinheng, ZHANG Hua, et al. Evaluation of ductile fracture criterions[J]. Journal of Plasticity Engineering, 2011, 18(2):103-106. doi: 10.3969/j.issn.1007-2012.2011.02.021 虞松, 陈军, 阮雪榆.韧性断裂准则的试验与理论研究[J].中国机械工程, 2006, 17(19):2049-2052. doi: 10.3321/j.issn:1004-132X.2006.19.018YU Song Y, CHEN Jun, RUAN Xueyu. Experimental and theoretical research on ductile fracture criterion[J]. China Mechanical Engineering, 2006, 17(19):2049-2052. doi: 10.3321/j.issn:1004-132X.2006.19.018 余心宏, 翟妮芝, 翟江波.应用韧性断裂准则预测板料的成形极限图[J].锻压技术, 2007, 32(5):44-47. doi: 10.3969/j.issn.1000-3940.2007.05.012YU Xinhong, ZHAI Nizhi, ZHAI Jiangbo. Prediction of sheet metal forming limit diagram by applying ductile fracture criterion[J]. Forging and Stamping Technology, 2007, 32(5):44-47 doi: 10.3969/j.issn.1000-3940.2007.05.012 COCKCROFT M G, LATHAM D J. Ductility and the workability of metals[J]. Journal Institute of Metals, 1968, 96(1):33-39. BROZZO P, DELUKA B, RENDINA R. A new method for the prediction of formability in metal sheets[C]//Proceedings of the Seventh Biennial Conference on Sheet Metal Forming and Formability.[S. l.]: International Deep Drawing Research Group, 1972: 18-26. OYANE M, SATO T, OKIMOTO K, et al. Criteria for ductile fracture and their applications[J]. Journal of Mechanical Working Technology, 1980, 4(1):65-81. doi: 10.1016/0378-3804(80)90006-6 叶拓, 王冠, 姚再起, 等.汽车用6xxx系铝合金薄壁件的韧性断裂行为[J].中国有色金属学报, 2014, 24(4):878-887. http://d.old.wanfangdata.com.cn/Periodical/zgysjsxb201404006YE Tuo, WANG Guan, YAO Zaiqi, et al. Ductile fracture behavior of 6xxx aluminum alloy thin-walled components of automobile[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(4):878. http://d.old.wanfangdata.com.cn/Periodical/zgysjsxb201404006 张红霞, 吴广贺, 闫志峰, 等. 5A06铝合金及其焊接接头的疲劳断裂行为[J].中国有色金属学报, 2013, 23(2):327-335. http://d.old.wanfangdata.com.cn/Periodical/zgysjsxb201302007ZHANG Hongxia, WU Guanghe, YAN Zhifeng, et al. Fatigue fracture behavior of 5A06 aluminum alloy and its welded joint[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2):327-335. http://d.old.wanfangdata.com.cn/Periodical/zgysjsxb201302007 LIN Yongcheng, CHEN Mingsong, ZHANG Jun. Modeling of flow stress of 42CrMo steel under hot compression[J]. Materials Science and Engineering:A, 2009, 499(1):88-92. http://www.sciencedirect.com/science/article/pii/S0921509308006230 YIN Fei, HUA Lin, MAO Huajie, et al. Constitutive modeling for flow behavior of GCr15 steel under hot compression experiments[J]. Materials and Design, 2013, 43:393-401. doi: 10.1016/j.matdes.2012.07.009 GUPTA A K, ANIRUBH V K, SINGH S K. Constitutive models to predict flow stress in austenitic stainless steel 316 at elevated temperatures[J]. Materials and Design, 2013, 43:410-418. doi: 10.1016/j.matdes.2012.07.008 PENG Xiaona, GUO Hongzhen, SHI Zhifeng, et al. Constitutive equations for high temperature flow stress of TC4-DT alloy incorporating strain, strain rate and temperature[J]. Materials & Design, 2013, 50(17):198-206. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=a263d63110dc7a6ee931987d1178fdf0 CHABOCHE J L. A review of some plasticity and viscoplasticity constitutive theories[J]. International Journal of Plasticity, 2008, 24(10):1642-1693. doi: 10.1016/j.ijplas.2008.03.009 GRONOSTAJSKI Z. The constitutive equations for FEM analysis[J]. Journal of Materials Processing Technology, 2000, 106(1):40-44. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=cfe67a71605bf2d771283a48c39a8b08 MISIOLEK Z, KOWALCZYK J, KASTNER P. Investigation of plastic flow stresses of Zn and its alloys[J]. Arch. Hutn, 1977, 22(1):71-88. FAGERHOLT E, DORUM C, BORVIK T, et al. Experimental and numerical investigation of fracture in a cast aluminum alloy[J]. International Journal of Solids and Structures, 2010, 47(24):3352-3365. doi: 10.1016/j.ijsolstr.2010.08.013 缪报通, 陈发来.径向基函数神经网络在散乱数据插值中的应用[J].中国科学技术大学学报, 2001, 31(2):135-142. doi: 10.3969/j.issn.0253-2778.2001.02.002MIAO Baotong, CHEN Falai. Applications of radius basis function neural networks in scattered data interpolation[J]. Journal of University of Science and Technology of China, 2001, 31(2):135-142. doi: 10.3969/j.issn.0253-2778.2001.02.002 王炜, 吴耿锋, 张博锋, 等.径向基函数(RBF)神经网络及其应用[J].地震, 2005, 25(2):19-25. http://d.old.wanfangdata.com.cn/Periodical/diz200502003WANG Wei, WU Gengfeng, ZHANG Bofeng, et al. Neural networks of radial basis function (RBF) and it's application to earthquake prediction[J]. Earthquake, 2005, 25(2):19-25. http://d.old.wanfangdata.com.cn/Periodical/diz200502003 张晓斌, 孙宇, 代珊.基于径向基神经网络杯形件拉深成形变压边力预测技术研究[J].机械科学与技术, 2007, 24(8):36-38. http://d.old.wanfangdata.com.cn/Periodical/jxsj200708011ZHANG Xiaobin, SUN Yu, DAI Shan. A study on the prediction technology of variable blank-holding force for deep drawing forming of cup shaped parts based on radial basis neural network[J]. Journal of Machine Design, 2007, 24(8):36-38. http://d.old.wanfangdata.com.cn/Periodical/jxsj200708011 -

下载:

下载: