Characterization of Vertical and Horizontal Propagations of Double Cracks in Asphalt Pavements under Moving Loads

-

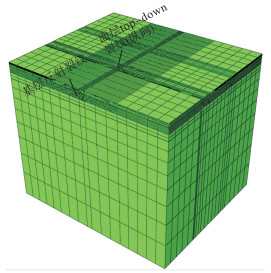

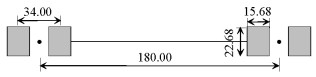

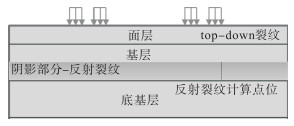

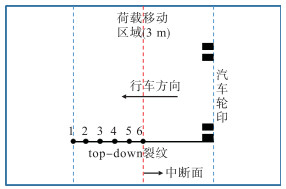

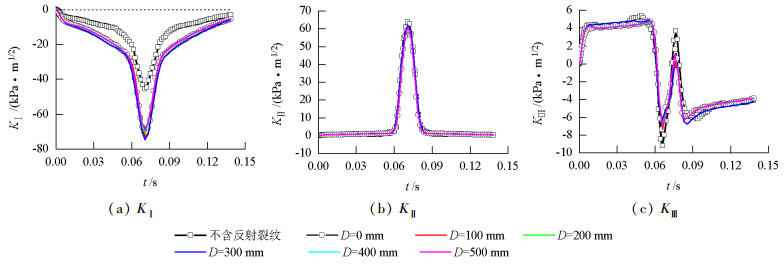

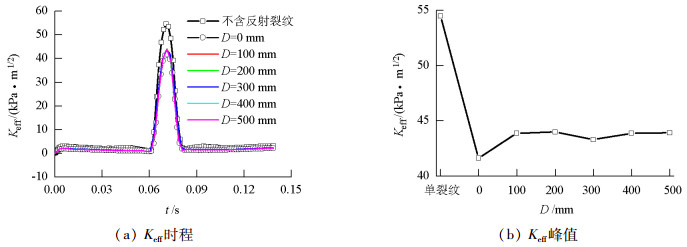

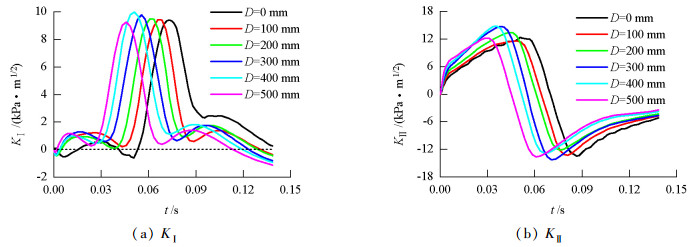

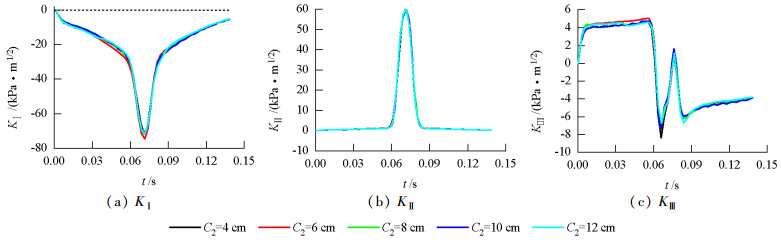

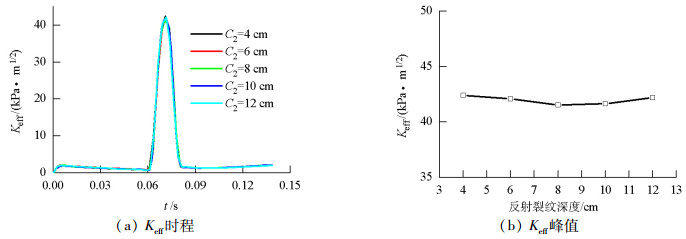

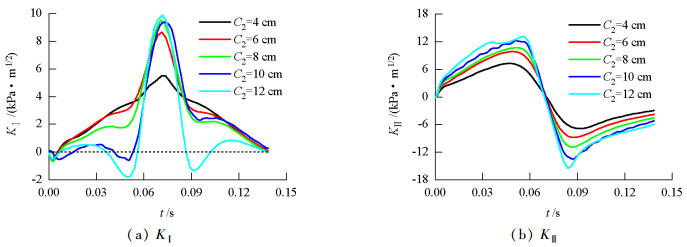

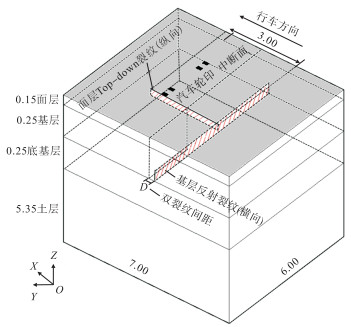

摘要: 为了研究移动荷载作用下沥青路面的复合开裂的变化规律,基于断裂力学及有限元数值模拟方法,考虑沥青面层材料的粘弹性,分别研究了移动荷载作用下不同双裂纹间距、不同反射裂纹深度对面层top-down(纵向)、基层反射(横向)裂纹应力强度因子的影响,探讨了其开裂扩展特性,评估了不同移动荷载状态下面层top-down裂纹的断裂疲劳寿命.结果表明:移动荷载作用下,面层top-down裂纹以Ⅱ型扩展为主,在单裂纹及双裂纹间距为0时,分别对应其扩展最严重与最轻微情形,但双裂纹间距及反射裂纹深度对其扩展影响较小;对于基层反射裂纹,当双裂纹间距为400 mm时,最易发生Ⅰ、Ⅱ型开裂扩展,随着反射裂纹深度的增加,扩展程度也逐渐增大;不同移动荷载状态下的top-down复合型裂纹断裂疲劳寿命长短顺序为:高速最长,次之静态、低速制动最短,制动情形下的疲劳寿命仅为高速情形下的20.4%.Abstract: The purpose of this research is to analyse the evolution of vertical and horizontal propagations of double cracks in asphalt pavements under moving loads using fracture mechanics and finite-element numerical simulations. In this regard, the effects of cracking space and reflective cracking depth on surface top-down cracking and base layer reflective cracking were studied by considering the viscoelastic behaviour of the surface material. Subsequently, crack propagation was characterized and the fatigue lives due to surface top-down cracking under different moving load levels were evaluated. The results indicated that surface top-down cracking mainly occurred in the type Ⅱ mode. Moreover, the cases of single crack and zero crack spacing corresponded to the conditions of most critical and noncritical propagations, respectively. However, crack spacing and the depth of reflective cracking did not have a significant influence on its propagation. For base layer reflective cracking, the most severe type Ⅰ and Ⅱ propagations occurred within a 400 mm cracking space, and the crack propagation level grew with increasing depth. The fatigue lives due to top-down mixed mode cracking under different moving load levels ranked in descending order as high speed, static state, low speed, and braking state. The fatigue life in the braking state was only 20.4% of that in the high-speed state.

-

表 1 路面结构各层参数

Table 1. Material parameters of different pavement layers

材料 层位 动态模量/MPa 泊松比 密度/

(kg·m-3)沥青混凝土 面层 — 0.25 2 400 水泥稳定碎石 基层 15 000 0.20 2 200 水泥稳定碎石 底基层 13 000 0.20 2 100 土基 土基 100 0.35 1 800 表 2 面层Prony级数模型参数

Table 2. Prony parameters of the surface material

参数 瞬态弹性模量E0=18 GPa 松弛时间/s 0.2 2.0 20.0 2×102 2×103 2×104 2×105 2×106 弹性模量/MPa 628.4 1 005.5 5 020.3 6 655.9 2 806.9 719.0 735.5 327.7 注:表中材料参数为-5 ℃条件下的取值. 表 3 不同计算点位Keff峰值

Table 3. Keff maxima of different calculation points

计算点位 1 2 3 4 5 6 Keff峰值/(kPa·m1/2) 4.646 45.978 45.903 46.061 46.222 54.497 表 4 不同裂纹间距下反射裂纹Keff峰值

Table 4. Keff maxima for different crack spacings

裂纹间距/mm 0 100 200 300 400 500 Keff/(kPa·m-0.5) 18.075 17.371 16.534 18.202 18.723 17.102 表 5 不同C2下反射裂纹Keff峰值

Table 5. Keff maxima of a reflective crack under different C2

C2/cm 4 6 8 10 12 Keff/(kPa·m0.5) 10.454 13.199 14.851 18.075 19.003 表 6 不同荷载状态下Keff-max拟合多项式

Table 6. Keff-max fitting polynomials for different loads

荷载种类 Keff-max拟合多项式 R2 低速(36 km/h) Keff-max=-735.524C3+90.596 06C2-0.763 560 4C+0.357 484 348 0.999 高速(108 km/h) Keff-max=-60.440 5C3-19.949 936 4C2+4.113 761 16C+0.263 089 809 2 0.980 制动(-5 km/h) Keff-max=-420.575C3+48.547 26C2-0.450 745 24C+0.513 707 757 1 0.989 静载 Keff-max=-856.497 5C3+102.035 361C2-0.809 021 737C+0.351 227 799 4 0.997 表 7 不同荷载状态下top-down裂纹疲劳寿命

Table 7. Top-down crack fatigue life under different loading conditions

荷载种类 低速(36 km/h) 高速(108 km/h) 制动(-5 km/h) 静载 N/次 1.228×108 2.011×108 4.110×107 1.246×108 -

张永平, 陆永林, 张洪亮, 等.基于弹性理论的沥青路面top-down开裂机理研究[J].公路交通科技, 2014, 31(4):16-21. doi: 10.3969/j.issn.1002-0268.2014.04.003ZHANG Yongping, LU Yonglin, ZHANG Hongliang, et al. Study on top-down cracking mechanism in asphalt pavement based on theory of elasticity[J]. Journal of Highway and Transportation Research and Development, 2014, 31(4):16-21. doi: 10.3969/j.issn.1002-0268.2014.04.003 毛成, 邱延峻, 李云鹏.沥青路面表面裂纹扩展模拟及影响因素分析[J].西南交通大学学报, 2004, 39(4):437-441. doi: 10.3969/j.issn.0258-2724.2004.04.005MAO Cheng, QIU Yanjun, LI Yunpeng. Simulation of surface crack propagation in asphalt pavements and analysis of its influential factors[J]. Journal of Southwest Jiaotong University, 2004, 39(4):437-441. doi: 10.3969/j.issn.0258-2724.2004.04.005 徐华.半刚性基层沥青混凝土路面反射裂缝扩展和疲劳寿命研究[D].南宁: 广西大学, 2012. http://cdmd.cnki.com.cn/Article/CDMD-10593-1012497001.htm 苗雨, 万云冬, 张邵敏.含反射裂纹沥青路面的动力响应分析[J].岩土力学, 2009, 30(8):2511-2516. doi: 10.3969/j.issn.1000-7598.2009.08.055MIAO Yu, WAN Yundong, ZHANG Shaomin. Dynamic response analysis of asphalt pavement with reflective crack[J]. Rock and Soil Mechanics, 2009, 30(8):2511-2516. doi: 10.3969/j.issn.1000-7598.2009.08.055 黄志义, 王金昌, 朱向荣.动荷载下含反射裂缝沥青路面结构黏弹性分析[J].浙江大学学报:工学版, 2007, 41(1):114-119. http://d.old.wanfangdata.com.cn/Periodical/zjdxxb-gx200701021HUANG Zhiyi, WANG Jinchang, ZHU Xiangrong. Viscoelastic analysis of asphalt pavement with reflective cracks and subjected to dynamic loading[J]. Journal of Zhejiang University:Engineering Science, 2007, 41(1):114-119. http://d.old.wanfangdata.com.cn/Periodical/zjdxxb-gx200701021 梁俊龙, 高江平, 苌亮.基于动态模量的含多裂缝沥青路面开裂分析[J].广西大学学报:自然科学版, 2016, 41(1):246-252. http://d.old.wanfangdata.com.cn/Periodical/gxdxxb201601031LIANG Junlong, GAO Jiangping, CHANG Liang. Cracking analysis of asphalt pavement with multi-crack based on dynamic modulus[J]. Journal of Guangxi University:Nat. Sci. Ed., 2016, 41(1):246-252. http://d.old.wanfangdata.com.cn/Periodical/gxdxxb201601031 PEREZ S A, BALAY J M, TAMAGNy P, et al. Accelerated pavement testing and modeling of reflective cracking in pavements[J]. Engineering Failure Analysis, 2007, 14(8):1526-1537. doi: 10.1016/j.engfailanal.2006.12.010 黄兵, 艾长发, 阳恩慧, 等.考虑层间状态的沥青面层动应变疲劳数值分析[J].西南交通大学学报, 2014, 49(4):682-686. doi: 10.3969/j.issn.0258-2724.2014.04.019HUANG Bin, AI Changfa, YANG Enhui, et al. Numerical analysis of dynamic strain and fatigue characteristics of asphalt layer considering interlayer condition[J]. Journal of Southwest Jiaotong University, 2014, 49(4):682-686. doi: 10.3969/j.issn.0258-2724.2014.04.019 肖川.典型沥青路面动力行为及其结构组合优化研究[D].成都: 西南交通大学, 2014. http://cdmd.cnki.com.cn/Article/CDMD-10613-1015348694.htm 彭彬.沥青路面低温开裂数值模拟与参数分析[D].南京: 东南大学, 2009. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=Y1492811 中交公路规划设计院. JTG D50-2006公路沥青路面设计规范[S].北京: 人民交通出版社, 2006. 孙家驷, 高建平.道路设计资料集4[M].北京:人民交通出版社, 2003:63-64. RICHARD H.A, FULLAND M, BUCHHOLZ F G, et al. 3D fracture criteria for structures with cracks[J]. Steel Research, 2003, 74(8):491-497. doi: 10.1002/srin.2003.74.issue-8 赵延庆, 王抒红, 周长红, 等.沥青路面top-down裂缝的断裂力学分析[J].同济大学学报:自然科学版, 2010, 38(2):218-222. http://d.old.wanfangdata.com.cn/Periodical/tjdxxb201002012ZHAO Yanqing, WANG Shuhong, ZHOU Changhong, et al. Analysis of top-down cracking of asphalt pavements based on fracture mechanics approach[J]. Journal of Tongji University:Natural Science, 2010, 38(2):218-222. http://d.old.wanfangdata.com.cn/Periodical/tjdxxb201002012 朱莉.三维复合型脆性断裂行为的数值计算与实验研究[D].哈尔滨: 哈尔滨工程大学, 2012. http://cdmd.cnki.com.cn/Article/CDMD-10217-1014134013.htm -

下载:

下载: