Shear Behavior of Mortar Layer in Continuous Slab Track with Different Arrangement Schemes of Embedded Steel Bars

-

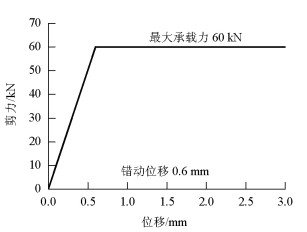

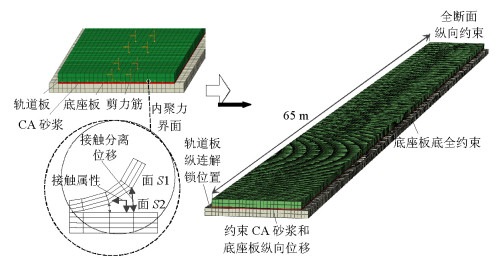

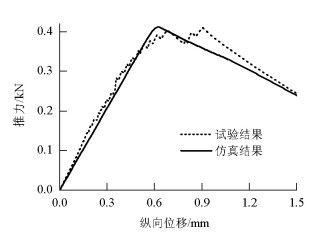

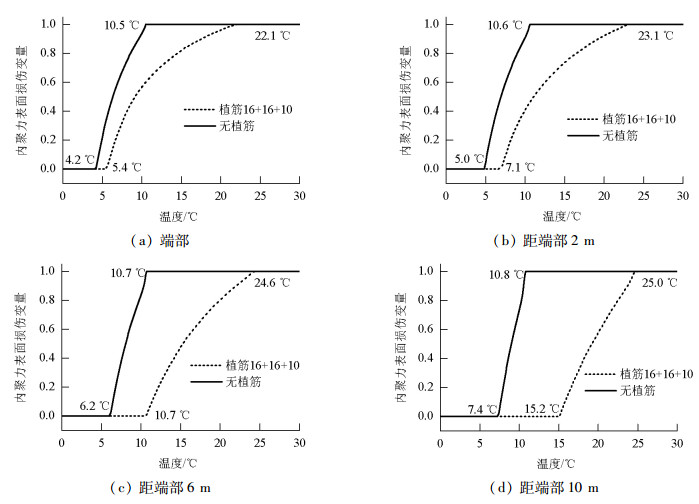

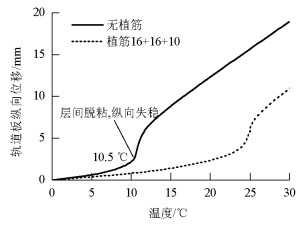

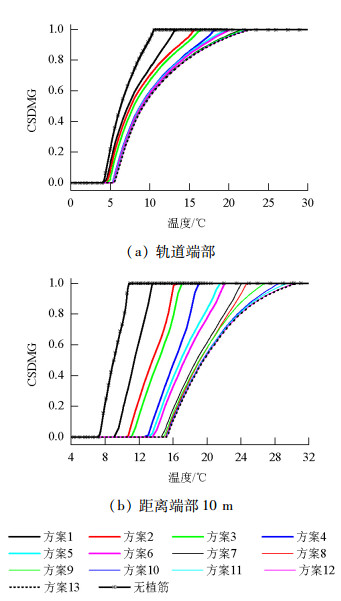

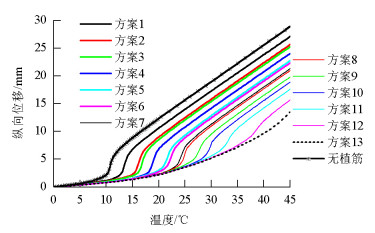

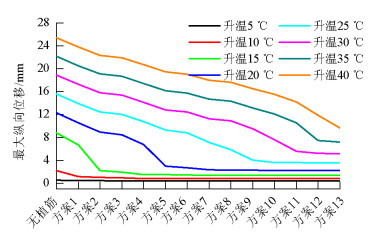

摘要: 为研究不同温度条件下的合理植筋方案,采用基于表面的内聚力模型模拟轨道板与砂浆层界面剪切破坏过程中层间黏结-脱黏-接触的复杂相互作用关系,考虑剪力筋的非线性约束特性,建立了纵连板式轨道三维有限元模型,并结合既有的推板试验结果对模型合理性进行验证,细致分析不同植筋方案下轨道板与砂浆层间的抗剪性能.研究结果表明:植筋可以明显提高轨道层间抗剪性能;层间开裂时对应的轨道温升幅度可由无植筋时的10.5℃提高到30℃;温升幅度小于20℃时,采用16+8+8植筋方案,温升幅度在20~30℃之间,采用16+16+16+10+8植筋方案,超过30℃时,需辅助其他限位措施.

-

关键词:

- 铁路轨道 /

- 植筋 /

- 抗剪强度 /

- 温度 /

- 基于表面的内聚力模型

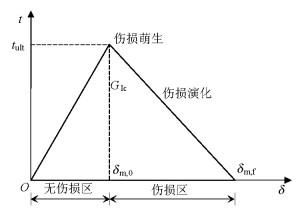

Abstract: In order to study the reasonable arrangement scheme of embedded steel bars under different temperatures, a three-dimensional finite element model of continuous slab track was established. In the model, a surface based cohesive zone model (SCZM) was introduced and utilized to simulate the complex interaction between track slab and mortar layer in the process of shear failure, which was bonding-debonding-contact. Nonlinear constraint characteristic of shearing steel bars were also considered. Based on the model validated by the results of longitudinal shear test of slab track, shear behaviors of CA mortar layer were analyzed particularly. The results show that embedded steel bars can significantly improve interlayer shear performance of slab track. The increasing extent of temperature when interlayer is cracking increases from 10.5℃ to 30℃.It is suggested that the 16+8+8 arrangement scheme of embedded steel bars could be used when the temperature rise less than 20℃, and 16+16+16+10+8 is also proposed when the temperature rise at 20~30℃, Over 30℃, other measures should be used. -

表 1 轨道参数取值

Table 1. Track parameters

项目 弹性模量/GPa 泊松比 密度/(kg·m-3) 热膨胀系数/(×10-5℃-1) 宽度/m 厚度/m 轨道板 36.0 0.2 2 400 1.0 2.55 0.20 底座板 25.5 0.2 2 400 1.5 2.95 0.20 CA砂浆层 8.0 0.2 2 400 1.5 2.55 0.03 表 2 轨道板-CA砂浆层界面参数

Table 2. Interface parameters of track slab-CA mortar layer

项目 法向刚度/(N·m-3) 切向刚度/(N·m-3) 抗拉强度/Pa 剪切强度/Pa 界面断裂韧度/(J·m-2) 摩擦因数 轨道 2×1012 5×107 5.4×105 2.5×104 10~35 0.35 表 3 初步设计的植筋方案

Table 3. Preliminary designed arrangement schemes of embedded steel bars

根 植筋方案 轨道板序号对应的植筋根数 总根数 1 2 3 4 5 6 7 无植筋 × × × × × × × 0 1 8 × × × × × × 8 2 8 8 × × × × × 16 3 10 8 × × × × × 18 4 16 8 × × × × × 24 5 16 8 8 × × × × 32 6 16 10 8 × × × × 34 7 16 16 8 × × × × 40 8 16 16 10 × × × × 42 9 16 16 10 8 × × × 50 10 16 16 16 8 × × × 56 11 16 16 16 10 8 × × 66 12 16 16 16 16 10 8 × 82 13 16 16 16 16 16 10 8 98 表 4 计算所得植筋方案表

Table 4. Selected arrangement schemes of embedded steel bars

根 升温幅度/℃ 植筋方案 轨道板序号对应的植筋根数 总根数 1 2 3 4 5 6 7 5 4 16 8 × × × × × 24 10 4 16 8 × × × × × 24 15 5 16 8 8 × × × × 32 20 5 16 8 8 × × × × 32 25 9 16 16 10 8 × × × 50 30 11 16 16 16 10 8 × × 66 35 — — — — — — — — — -

王平, 徐浩, 陈嵘, 等.路基上CRTS Ⅱ型板式轨道裂纹影响分析[J].西南交通大学学报, 2012, 47(6):929-934. doi: 10.3969/j.issn.0258-2724.2012.06.004WANG Ping, XU Hao, CHEN Rong, et al. Effects analysis of cracking of CRTS Ⅱ slab track on subgrade[J]. Journal of Southwest Jiaotong University, 2012, 47(6):929-934. doi: 10.3969/j.issn.0258-2724.2012.06.004 GAUTIER P E. Slab track:review of existing systems and optimization potentials including very high speed[J]. Construction and Building Materials, 2015, 92:9-15. doi: 10.1016/j.conbuildmat.2015.03.102 谭社会.高温条件下CRTSⅡ型板式无砟轨道变形整治措施研究[J].铁道建筑, 2016(5):23-27. doi: 10.3969/j.issn.1003-1995.2016.05.06TAN Shehui. Study on deformation treatment measures for CRTS Ⅱ slab-type ballastless track in high temperature condition[J]. Railway Engineering, 2016(5):23-27. doi: 10.3969/j.issn.1003-1995.2016.05.06 廖红建, 朱庆女, 昝月稳, 等.基于探地雷达的高铁无砟轨道结构层病害检测[J].西南交通大学学报, 2016, 51(1):8-13. doi: 10.3969/j.issn.0258-2724.2016.01.002LIAO Hongjian, ZHU Qingnü, ZAN Yuewen, et al. Detection of ballastless track diseases in high-speed railway based on ground penetrating radar[J]. Journal of Southwest Jiaotong University, 2016, 51(1):8-13. doi: 10.3969/j.issn.0258-2724.2016.01.002 曹世豪, 杨荣山, 刘学毅, 等.无砟轨道层间裂纹内动水压力特性分析[J].西南交通大学学报, 2016, 51(1):36-42. doi: 10.3969/j.issn.0258-2724.2016.01.006CAO Shihao, YANG Rongshan, LIU Xueyi, et al. Analysis of water pressure in ballastless track crack[J]. Journal of Southwest Jiaotong University, 2016, 51(1):36-42. doi: 10.3969/j.issn.0258-2724.2016.01.006 苗雨. CRTSⅡ型板式无砟轨道高温胀板病害研究与整治[J].科技创新与应用, 2014(34):37-39. http://d.old.wanfangdata.com.cn/Periodical/qgsj201434023MIAO Yu. Study and treatment of upheaval of CRTS Ⅱ type ballastless track[J]. Technology Innovation and Application, 2014(34):37-39. http://d.old.wanfangdata.com.cn/Periodical/qgsj201434023 倪跃峰, 任娟娟, 赵华卫. CRTSⅡ型板式无砟轨道抬板维修时轨道板锚固方案研究[J].铁道建筑, 2016(2):132-135. doi: 10.3969/j.issn.1003-1995.2016.02.31NI Yuefeng, REN Juanjuan, ZHAO Huawei. Study on anchoring scheme of lifted track slab in repairing of CRTS Ⅱ slab type ballastless track[J]. Railway Engineering, 2016(2):132-135. doi: 10.3969/j.issn.1003-1995.2016.02.31 王继军.板式无砟轨道锚固销钉限位技术的试验研究[J].铁道建筑, 2010(6):122-125. doi: 10.3969/j.issn.1003-1995.2010.06.040WANG Jijun. Test research on anchoring technology of slab track[J]. Railway Engineering, 2010(6):122-125. doi: 10.3969/j.issn.1003-1995.2010.06.040 孙立. CRTSⅡ型板式无砟轨道结构温度变形控制措施研究[R].武汉: 中铁第四勘察设计院集团有限公司, 2015. 刘钰. CRTSⅡ型板式轨道早期温度场特征及其影响研究[D].成都: 西南交通大学, 2013. DAI G, SU M. Full-scale field experimental investigation on the interfacial shear capacity of continuous slab track structure[J]. Archives of Civil and Mechanical Engineering, 2016, 16(3):485-493. doi: 10.1016/j.acme.2016.03.005 RAMAMURTHI M, LEE J S, YANG S H, et al. Delamination characterization of bonded interface in polymer coated steel using surface based cohesive model[J]. International Journal of Precision Engineering and Manufacturing, 2013, 14(10):1755-1765. doi: 10.1007/s12541-013-0235-3 LIU G, BAO H, TANG K. Damage prediction in notched fiber-reinforced composite laminates[J]. Composite Interfaces, 2016, 24(3):279-290. doi: 10.1080/09276440.2016.1202632 ZHANG M, ZUO C, SUN B, et al. Thermal ageing degradation mechanisms on compressive behavior of 3-D braided composites in experimental and numerical study[J]. Composite Structure, 2016, 140:180-191. doi: 10.1016/j.compstruct.2016.01.029 LUO C, LUA J, DESJARDIN P E. Thermo-mechanical damage modeling of polymer matrix sandwich composites in fire[J]. Composites Part A Applied Science and Manufacturing, 2012, 43(5):814-821. doi: 10.1016/j.compositesa.2011.03.006 赵磊.高速铁路无砟轨道空间精细化分析方法及其应用研究[D].北京: 北京交通大学, 2015. 戴公连, 粟淼.剪切荷载下板式无砟轨道界面黏结破坏机理[J].华中科技大学学报:自然科学版, 2016, 44(1):16-21. http://d.old.wanfangdata.com.cn/Periodical/hzlgdxxb201601004DAI Gonglian, SU Miao. Mechanism of interfacial bond failure of slab ballastless track under shear loading[J]. Journal of Huazhong University of Science and Technology:Natural Science Edition, 2016, 44(1):16-21. http://d.old.wanfangdata.com.cn/Periodical/hzlgdxxb201601004 ZHU S, CAI C. Interface damage and its effect on vibrations of slab track under temperature and vehicle dynamic loads[J]. International Journal of Non-linear Mechanics, 2014, 58:222-232. doi: 10.1016/j.ijnonlinmec.2013.10.004 HARPER P W, HALLETT S R. Cohesive zone length in numerical simulations of composite delamination[J]. Engineering Fracture Mechanics, 2008, 75(16):4774-4792. doi: 10.1016/j.engfracmech.2008.06.004 王明昃, 蔡成标, 朱胜阳, 等.基于黏聚力模型的双块式无砟轨道混凝土层间黏结性能试验与分析[J].铁道学报, 2016, 38(11):88-94. doi: 10.3969/j.issn.1001-8360.2016.11.013WANG Mingze, CAI Chengbiao, ZHU Shengyang, et al. Experimental investigation on adhesive performance of concrete interface of double-block ballastless track based on cohesive zone model[J]. Journal of the China Railway Society, 2016, 38(11):88-94. doi: 10.3969/j.issn.1001-8360.2016.11.013 -

下载:

下载: