Fatigue Testing of CRTS Ⅲ Ballastless Slab Track Structures under Transverse Bending

-

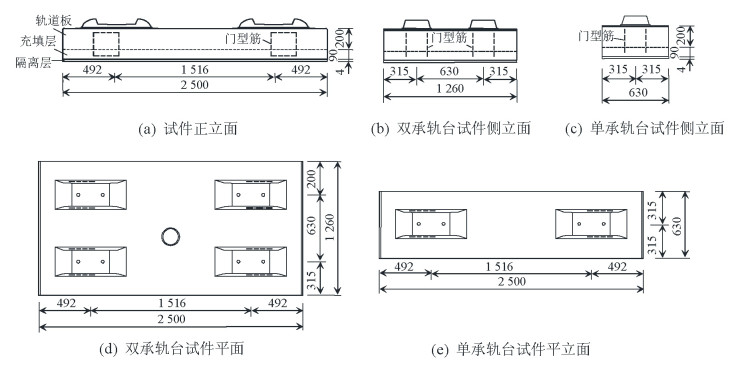

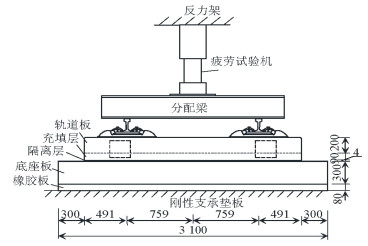

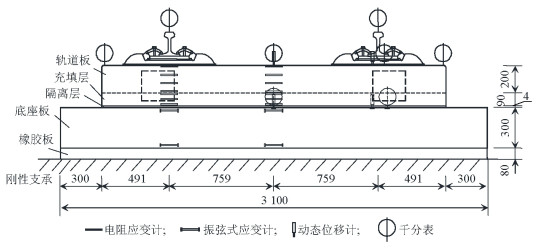

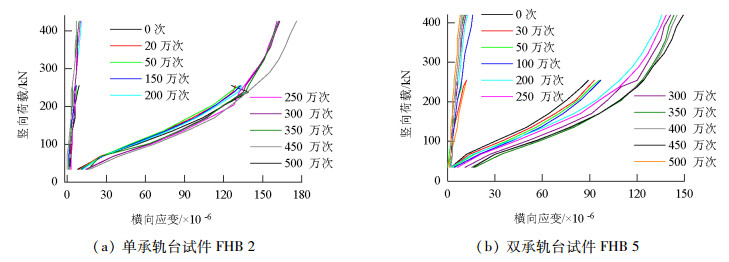

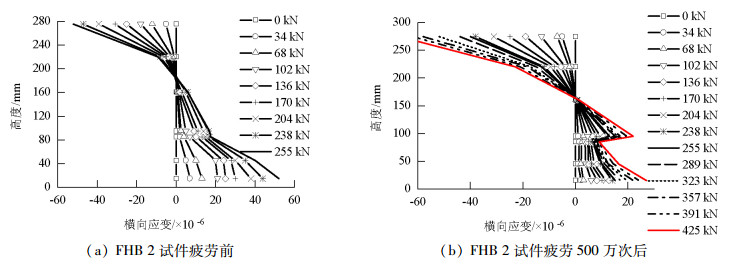

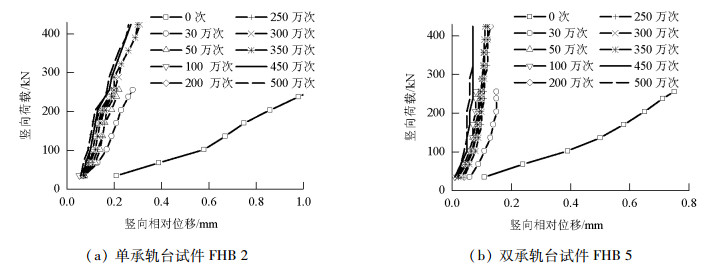

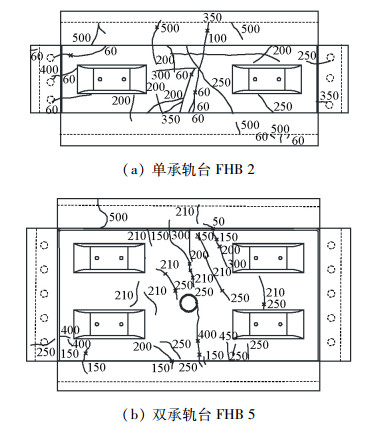

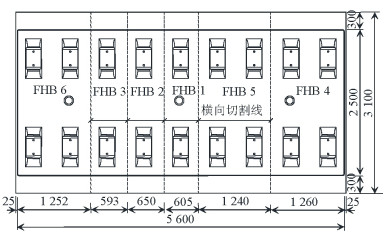

摘要: 为了研究列车疲劳荷载作用下CRTSⅢ型板式无砟轨道结构横向受力性能,采用实际工程施工现场的材料及施工工艺,利用足尺模型,切割制作6个单承轨台或双承轨台的板式无砟轨道试件,进行橡胶板模拟路基上板式无砟轨道结构的横向弯曲疲劳试验,得出列车疲劳荷载引起的横向弯矩作用下板式轨道试件的应力、变形分布规律及疲劳损伤的发展形态.试验结果表明,在15.0~255.0 kN和42.5~425.0 kN疲劳荷载作用下,模拟路基上单承轨台和双承轨台的试件板中位置轨道板上表面先出现纵向裂缝,随后轨道板横向预应力筋锚固端出现由锚头向轨道板上表面的劈裂裂缝,累计疲劳500万次后,三点弯曲模式下轨道板-充填层复合板试件的自密实混凝土开裂荷载和层间滑移荷载分别减小20%~30%和25%以上,疲劳损伤、层间离缝对轨道板与充填层的协同工作性能有不利影响.Abstract: To investigate the transverse mechanical performance of CRTS Ⅲ slab ballastless track structures under the cyclic action of train loads, a full-scale CRTS Ⅲ slab track structure was fabricated using the same materials and technology as that employed in practical on-site construction applications. Six slab track specimens with one or two sleepers were fabricated from the full-scale slab track structure. Fatigue tests under transverse bending were conducted on these slab track specimens supported on rubber plate-simulated subgrades. The characteristics of stress distribution, deformation distribution, and nature of development of fatigue damage on slab tracks subjected to transverse bending were determined from the fatigue tests. The fatigue test results indicated that longitudinal cracks first appear on the top surface of the track slab in the middle of the slab track specimens with one or two sleepers under fatigue cycles of 15.0-255.0 kN and 42.5-425.0 kN, respectively. Several splitting cracks subsequently developed from the transverse prestressing tendon to the top surface of the track slab on the profile of anchorage end. After cumulative 5 million fatigue cycles, the loads for a composite plate with a track slab-infilling layer under the three-point bending mode corresponding to self-compacting concrete (SCC) cracking and interlayer bond-slip reduced by 20%-30% and more than 25%, respectively. It can be concluded that fatigue damage and interlayer delamination have adverse effects on the cooperative working performance of the track slab and the SCC infilling layer.

-

Key words:

- ballastless track /

- track slab /

- self-compacting concrete /

- cooperative working /

- fatigue test /

- damage

-

表 1 轨道板与SCC复合板试件设计

Table 1. Design of composite plate specimens of the track slab and SCC

编号 长×宽×厚/mm×mm×mm 轨道板普通钢筋 轨道板预应力筋 充填层钢筋 门型筋 底座板钢筋 试验模式 备注 FHB 1 2 500×605×290 4ϕR8 2ϕH10 5ϕR10 8ϕR12 4ϕR10 疲劳+静载 拉毛 FHB 2 2 500×650×290 4ϕR8 3ϕH10 4ϕR10 8ϕR12 4ϕR10 疲劳+静载 拉毛 FHB 3 2 500×593×290 4ϕR8 3ϕH10 4ϕR10 8ϕR12 3ϕR10 静载 拉毛 FHB 4 2 500×1 218×290 7ϕR8 5ϕH10 9ϕR10 16ϕR12 7ϕR10 疲劳+静载 拉毛 FHB 5 2 500×1 240×290 8ϕR8 6ϕH10 8ϕR10 16ϕR12 7ϕR10 疲劳+静载 拉毛+凿毛 FHB 6 2 500×1 200×290 8ϕR8 5ϕH10 9ϕR10 16ϕR12 7ϕR10 静载 拉毛 注:备注栏为轨道板板底的处理工艺, 拉毛时灌砂法测定板底粗糙度R=1.371 mm, 拉毛+凿毛时R=2.196 mm. 表 2 复合板疲劳后横向三点弯曲试验结果

Table 2. Transverse three-point bending test results of the composite plates after fatigue

试件编号 Pts, cr/kN Pfl, cr/kN Pslip/kN Pu/kN Pslip/Pu FHB1 100 180 100 238 0.42 FHB2 100 140 60 300 0.20 FHB3 80 200 160 290 0.55 FHB4 200 400 240 440 0.55 FHB5 180 460 240 610 0.39 FHB6 200 360 320 530 0.60 注: Pslip为滑移荷载,复合板横向端部的千分表读数发生变化, 出现层间滑移时的荷载;Pu为极限荷载,复合板达到极限承载能力时的荷载;Pts, cr、Pfl, cr分别为轨道板和充填层开裂荷载,结构层侧面新增第1条肉眼可见裂缝时对应的荷载. -

王宇航, 王继军. CRTS Ⅲ型板式无砟轨道结构的多尺度有限元模型[J].铁道科学与工程学报, 2015(3):468-474. doi: 10.3969/j.issn.1672-7029.2015.03.003WANG Yuhang, WANG Jijun. Multi-scale finite element model for CRTS Ⅲ type slab ballastless track structures[J]. Journal of Railway Science and Engineering, 2015(3):468-474. doi: 10.3969/j.issn.1672-7029.2015.03.003 王明昃, 尹镪, 朱胜阳, 等.冲击荷载作用下CRTSⅢ型板式轨道-路基系统动力特性研究[J].中国科学:技术科学, 2014(7):722-728. http://www.cnki.com.cn/Article/CJFDTotal-JEXK201407010.htmWANG Mingze, YIN Qiang, ZHU Shengyang. et al. Dynamic analysis of CRTSⅢ slab track-subgrade system under impact load[J]. Scientia Sinica:Technologica, 2014(7):722-728. http://www.cnki.com.cn/Article/CJFDTotal-JEXK201407010.htm 高亮, 赵磊, 曲村, 等.路基上CRTSⅢ型板式无砟轨道设计方案比较分析[J].同济大学学报:自然科学版, 2013, 41(6):848-855. http://d.old.wanfangdata.com.cn/Periodical/tjdxxb201306008GAO Liang, ZHAO Lei, QU Cun, et al. Analysis on design scheme of CRTS Ⅲ slab track structure on roadbed[J]. Journal of Tongji University:Natural Science, 2013, 41(6):848-855. http://d.old.wanfangdata.com.cn/Periodical/tjdxxb201306008 ZENG Zhiping, HE Xianfeng, Meng Xiaobai, et al. Experimental study on mechanical characteristics of CRTSⅢ slab ballastless track under train load[C]//Proceedings of the 2015 International Conference on Architectural, Civil and Hydraulics Engineering. Paris: Atlantis Press, 2016: 503-507. 孙璐, 段雨芬, 杨薪.高速铁路CRTSⅢ型板式无砟轨道结构受力特性研究[J].铁道工程学报, 2013, 30(11):32-39. doi: 10.3969/j.issn.1006-2106.2013.11.007SUN Lu, DUAN Yufen, YANG Xin. Static response analysis of CRTS Ⅲ ballastless track structure[J]. Journal of Railway Engineering Society, 2013, 30(11):32-39. doi: 10.3969/j.issn.1006-2106.2013.11.007 杨俊斌, 赵坪锐, 刘永孝, 等.列车荷载对CRTS Ⅰ型板式轨道疲劳损伤的影响研究[J].铁道标准设计, 2013(10):19-23. http://d.old.wanfangdata.com.cn/Periodical/tdbzsj201310005YANG Junbin, ZHAO Pingrui, LIU Yongxiao, et al. Influence of train load on fatigue damage to CRTS-Ⅰslab track[J]. Railway Standard Design, 2013(10):19-23. http://d.old.wanfangdata.com.cn/Periodical/tdbzsj201310005 POVEDA E, YU R C, LANCHA J C, et al. A numerical study on the fatigue life design of concrete slabs for railway tracks[J]. Engineering Structures, 2015, 100:455-467. doi: 10.1016/j.engstruct.2015.06.037 李思云, 杨荣山. CRTS-Ⅰ型板式无砟轨道疲劳寿命研究[J].铁道标准设计, 2016(3):34-37. http://www.cnki.com.cn/Article/CJFDTOTAL-TDBS201603008.htmLI Siyun, YANG Rongshan. Research on fatigue life of CRTS-Ⅰ slab ballastless track[J]. Railway Standard Design, 2016(3):34-37. http://www.cnki.com.cn/Article/CJFDTOTAL-TDBS201603008.htm 王青, 卫军, 董荣珍, 等. CRTSⅡ型板式无砟轨道结构的疲劳力学性能分析[J].铁道工程学报, 2014, 31(5):41-47. doi: 10.3969/j.issn.1006-2106.2014.05.008WANG Qing, WEI Jun, DONG Rongzhen, et al. Fatigue behavior analysis of CRTSⅡ slab ballastless track structure[J]. Journal of Railway Engineering Society, 2014, 31(5):41-47. doi: 10.3969/j.issn.1006-2106.2014.05.008 何燕平. CRTSⅢ型板式无砟轨道疲劳特性研究[D].成都: 西南交通大学, 2011. 王安华. CRTSⅢ型板式无砟轨道耐久性研究[D].北京: 北京交通大学, 2012. BALL C G. Slab track laboratory test program[R].[S. l.]: Portland Cement Association, 2004. CHAPELEAU X, SEDRAN T, COTTINEAU L M, et al. Study of ballastless track structure monitoring by distributed optical fiber sensors on a real-scale mockup in laboratory[J]. Engineering Structures, 2013, 56:1751-1757. doi: 10.1016/j.engstruct.2013.07.005 TARIFA M, ZHANG X, RUIZ G, et al. Full-scale fatigue tests of precast reinforced concrete slabs for railway tracks[J]. Engineering Structures, 2015, 100:610-621. doi: 10.1016/j.engstruct.2015.06.016 冯什. CRTSⅠ型板式无砟轨道原型疲劳试验研究[D].成都: 西南交通大学, 2014. 田其义, 王军文, 石岩, 等. CRTSⅡ型板式无砟轨道轨道板力学性能试验研究[J].石家庄铁道大学学报, 2010, 23(4):36-40. http://d.old.wanfangdata.com.cn/Periodical/sjztdxyxb201004008TIAN Qiyi, WANG Junwen, Shi Yan, et al. Experimental study on mechanical properties of CRTSⅡballastless track slab[J]. Journal of Shijiazhuang Railway Institute, 2010, 23(4):36-40. http://d.old.wanfangdata.com.cn/Periodical/sjztdxyxb201004008 -

下载:

下载: