Field Test on Controlled Grouting Technology for Soft Soil Subgrade of High-Speed Railway

-

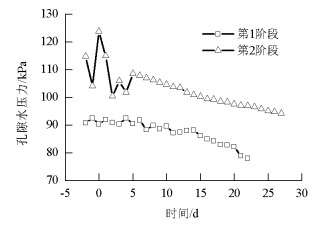

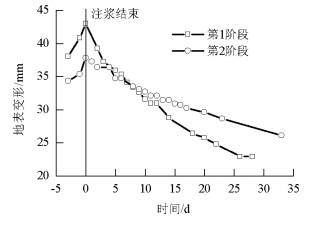

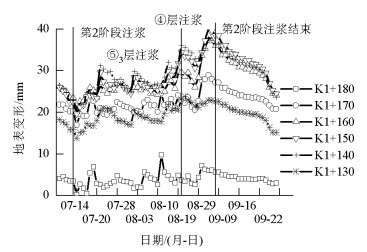

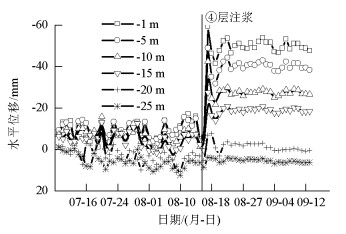

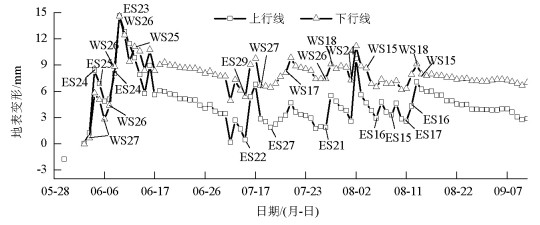

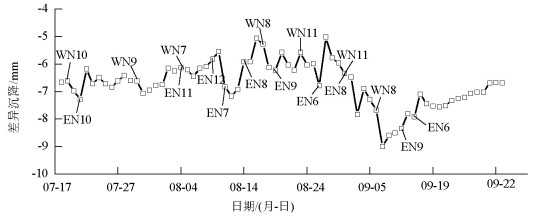

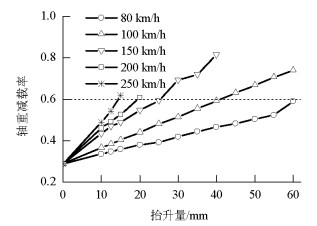

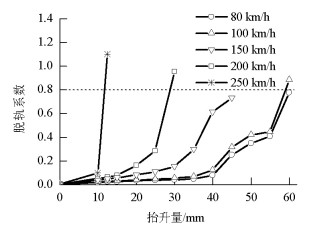

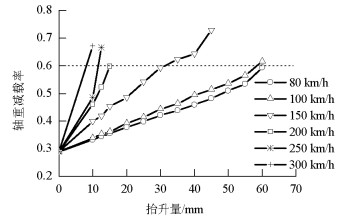

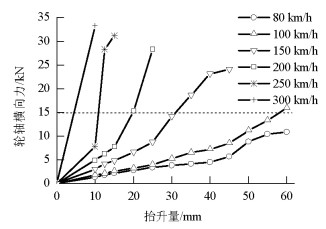

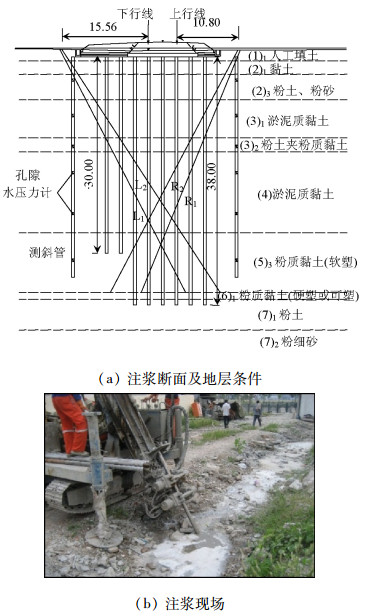

摘要: 为有效控制软土路基注浆对高速铁路轨面变形的影响,提出有控注浆的总体原则及其施工控制方法.依托长三角地区某运营高速铁路软土复合路基注浆抬升的现场试验,监测轨面变形、孔隙水压力和土体侧向位移,分析不同注浆施工控制措施对注浆抬升效果的影响;模拟分析在不同列车速度下轨面变形对列车运行安全的影响,以此为依据提出注浆引起轨面变形限值.研究结果表明:采用合理的注浆参数、层位和时间间隔和路基两侧交错注浆的控制措施,可控制轨面变形;列车运行速度越快,轨面变形越大,脱轨系数、轴重减载率和轮轴横向力也越大,列车速度大于200 km/h时,轨面整体变形与差异变形不得大于15 mm,列车速度达到300 km/h时,轨面差异变形应小于10 mm.Abstract: This study proposes the controlled grouting technology to effectively control the influence of soft soil subgrade grouting on the surface and rail surface deformation of operating high-speed railway. Field tests on grouting uplift for soft soil composite subgrade of high-speed railway, located at the Yangtze River delta, demonstrate potential feasibility and effect of this technology. The effect of different construction control measures on the grouting uplift was studied using data on surface deformation, pore water pressure, and lateral displacement of the soil. Simulations analyzed the influence of the rail deformation on the operational safety of the train at different train speeds. The deformation limit of the rail caused by grouting was determined. The results show that the concept of controlled grouting technology includes grouting, controlling standards, controlling measures, and monitoring. Reasonable grouting parameters, appropriate grouting layer, feasible time interval, and staggered grouting can effectively control the rail deformation. A higher train velocity implies greater deformation of the rail, which leads to a larger derailment factor, axle load shedding rate, and axle lateral force. Therefore, when the train speed is greater than 200 km/h, the overall and differential deformation of the rail surface should not exceed 15 mm; when the train speed reaches 300 km/h, the deformation of the rail surface should be less than 10 mm.

-

Key words:

- soft soil subgrade /

- controlled grouting /

- construction control /

- field test /

- train operation safety

-

表 1 注浆施工阶段及注浆参数

Table 1. Grouting phases and parameters

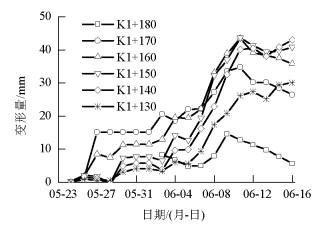

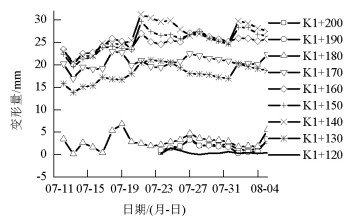

注浆阶段 时间/(月-日) 注浆速率/(m3·h-1) 注浆压力/MPa 注浆量/(m3·m-1) 第1次 05-25~06-16 1.0~2.0 0.2~0.5 0.60~0.81

1.00~1.20第2次 07-12~09-21 1.0~1.3 0.1~0.3 0.60~0.81

1.00~1.20表 2 注浆引起轨道整体抬升量限值

Table 2. Overall track uplift deformation limit

列车速度/(km·h-1) 80 100 150 200 250 抬升量限值/mm 55.0 35.0 20.0 15.0 12.5 表 3 注浆引起轨道差异抬升变形限值

Table 3. Track difference uplift deformation limit

列车速度/(km·h-1) 80 100 150 200 250 300 抬升量限值/mm 55 55 25 15 10 <10 -

王哲, 龚晓南, 程永辉, 等.劈裂注浆法在运营铁路软土地基处理中的应用[J].岩石力学与工程学报, 2005, 24(9):1619-1623. doi: 10.3321/j.issn:1000-6915.2005.09.025WANG Zhe, GONG Xiaonan, CHENG Yonghui, et al. Application of fracturing grouting method to treat soft foundation of operating railway[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(9):1619-1623. doi: 10.3321/j.issn:1000-6915.2005.09.025 白云.软土地基劈裂注浆加固的机理和应用[D].上海: 同济大学, 1988. ANDERSEN K H, RAWLINGS C G, LUNNE T A, et al. Estimation of hydraulic fracture pressure in clay[J]. Canadian Geotechnical Journal, 1994, 31(6):817-828. doi: 10.1139/t94-099 孙锋, 张顶立, 王臣, 等.劈裂注浆抬升既有管道效果分析及工程应用[J].岩土力学, 2010, 31(3):932-938. doi: 10.3969/j.issn.1000-7598.2010.03.045SUN Feng, ZHANG Dingli, WANG Chen, et al. Analysis of raising pipeline by fracture grouting and its application[J]. Rock and Soil Mechanics, 2010, 31(3):932-938. doi: 10.3969/j.issn.1000-7598.2010.03.045 EL-KELESH M, MOSSAAD M E, BASHA I M. Model of compaction grouting[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2001, 127:955-964. doi: 10.1061/(ASCE)1090-0241(2001)127:11(955) 李向红, 刘建航, 傅德明, 等. CCG注浆过程的数值模拟研究[J].岩石力学与工程学报, 2003(增刊1):2322-2327. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb2003z1042LI Xianghong, LIU Jianhang, FU Deming, et al. Numerical simulation study on compaction grouting[J]. Chinese Journal of Rock Mechanics and Engineering, 2003(Sup.1):2322-2327. http://d.old.wanfangdata.com.cn/Periodical/yslxygcxb2003z1042 邹金锋.扩孔问题的线性与非线性解析及其工程应用研究[D].长沙: 中南大学, 2007. 王广国, 杜明芳, 苗兴城.压密注浆机理研究及效果检验[J].岩石力学与工程学报, 2000, 19(5):670-673. doi: 10.3321/j.issn:1000-6915.2000.05.027WNG Guangguo, DU Mingfang, MIAO Xingcheng. Mechanism of compaction grouting and effect examination[J]. Journal of Rock Mechanics and Engineering, 2000, 19(5):670-673. doi: 10.3321/j.issn:1000-6915.2000.05.027 冯旭海.压密注浆作用机理与顶升效应关系的研究[D].北京: 煤炭科学研究总院, 2003. MARCHI M, GOTTARDI G, SOGA K. Fracturing pressure in clay[J]. Journal of Geotechnical and Geoenvironmental Engineering, 2014, 140(2):04013008. doi: 10.1061/(ASCE)GT.1943-5606.0001019 中华人民共和国铁道部. TG/GW 115-2012高速铁路无砟轨道线路维修规则(试行)[S].北京: 中国铁道出版社, 2012. 中华人民共和国铁道部.铁路线路修理规则[M].北京:中国铁道出版社, 2006:19-56. -

下载:

下载: