Periodic and Collaborative Allocation of Berth-Yard-Gate Resources at Container Terminals

-

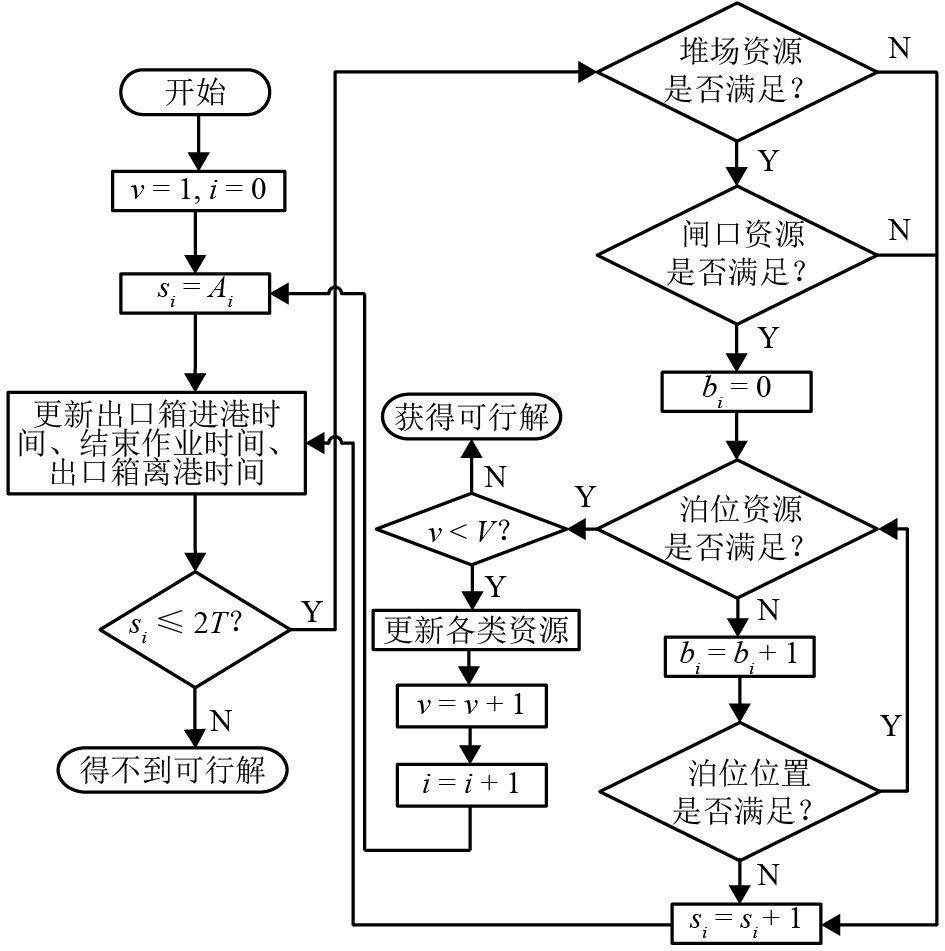

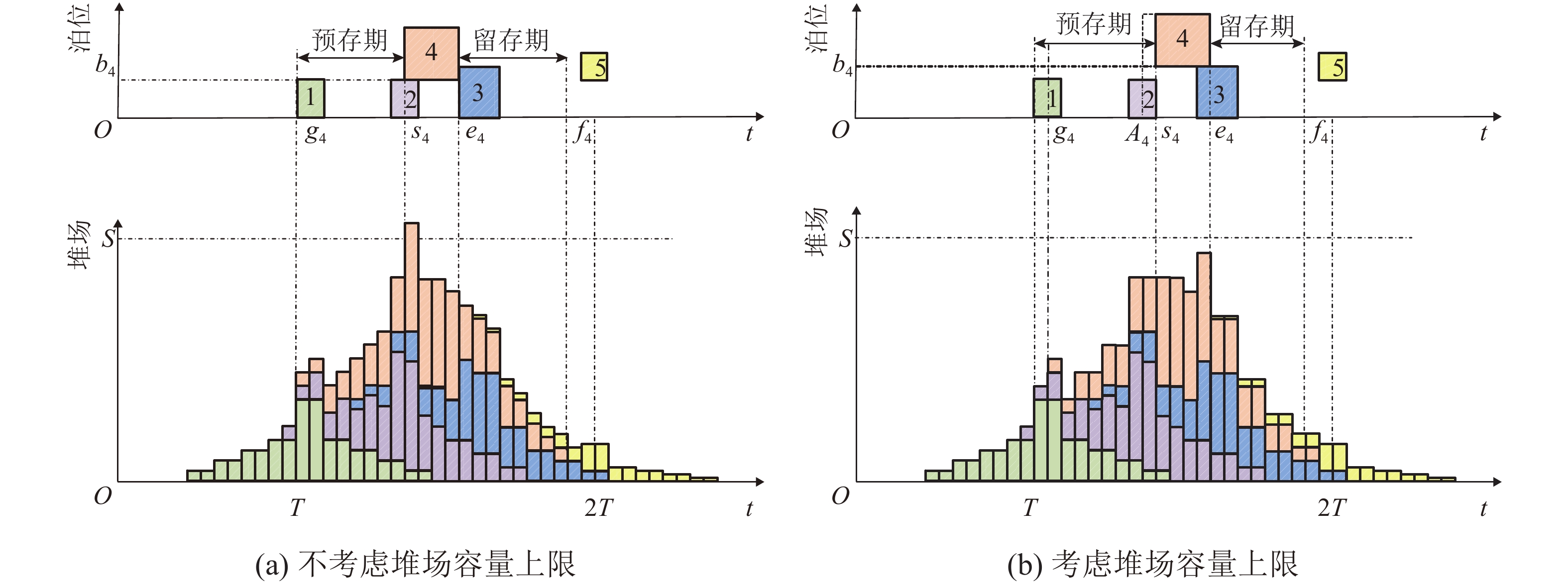

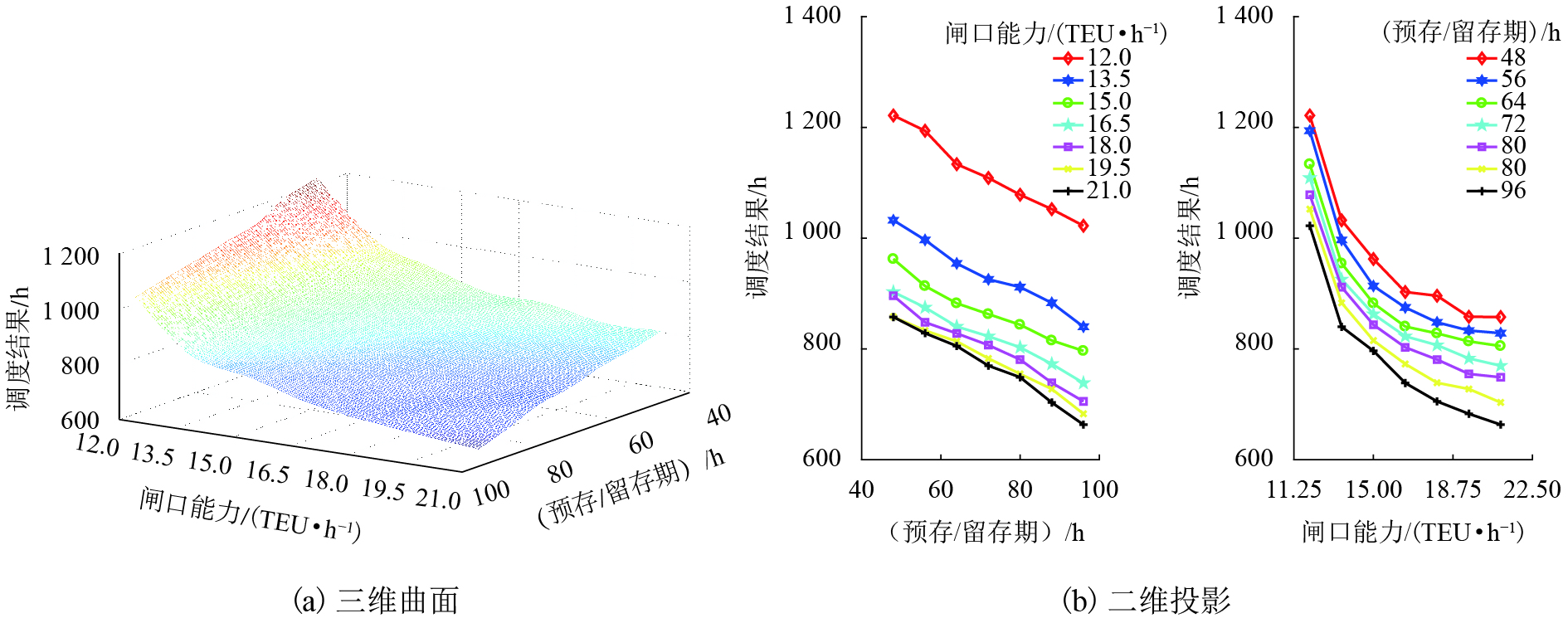

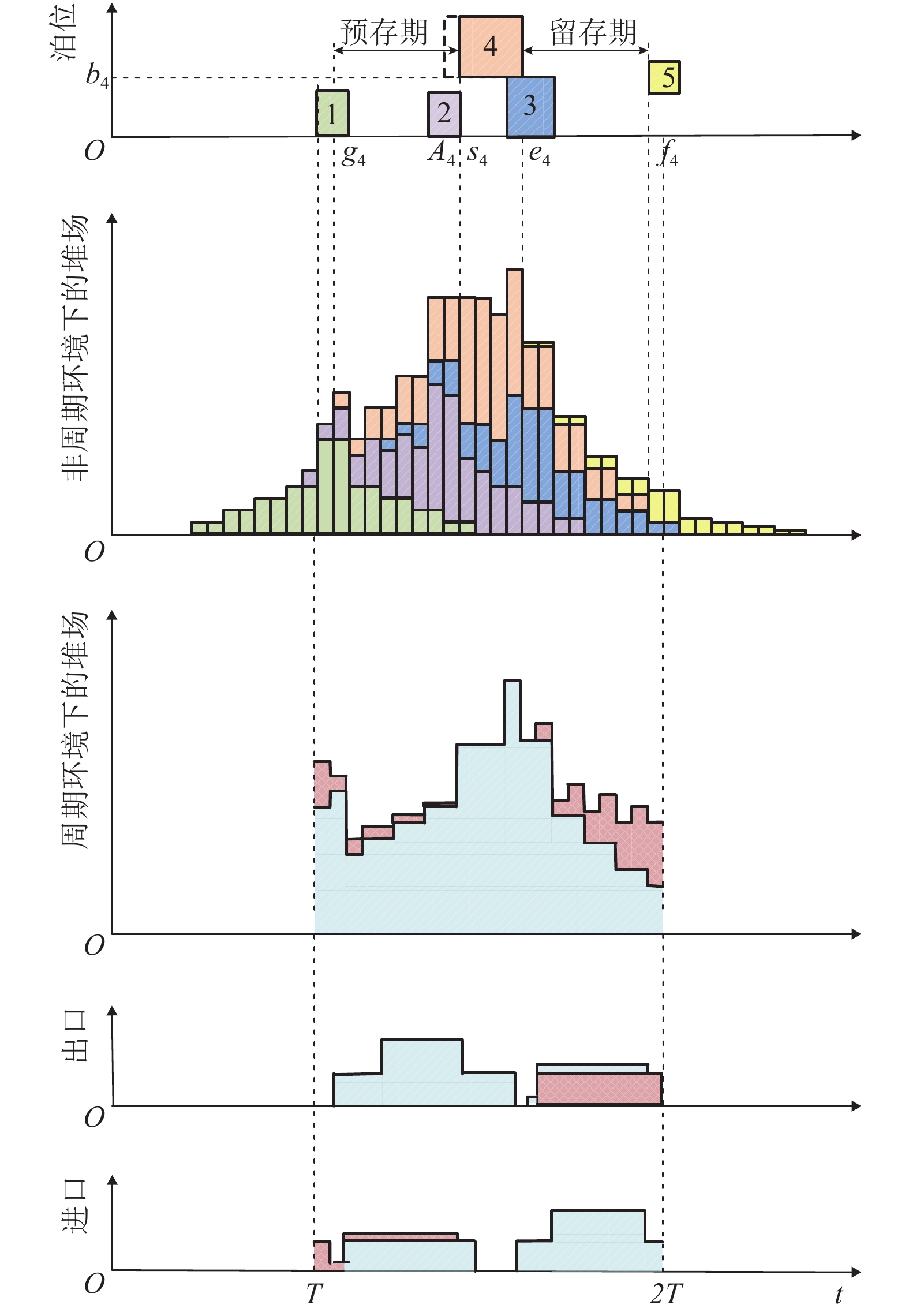

摘要: 为提高集装箱进出口码头在周期性环境下的作业效率,对集装箱码头泊位-堆场-闸口的周期协同分配问题进行了研究. 首先考虑泊位、堆场、闸口3类资源对船分配过程中的可用量约束、相关性约束和周期性约束,以最小化船舶总在港时间为目标函数,建立集成调度的混合整数规划模型;在此基础上设计自适应遗传算法进行求解,其上层对船舶优先级构成的编码空间展开进化搜索,下层利用启发式将优先级解码为多资源协同分配计划,并将其评价值返回至上层迭代. 数值实验显示,协同考虑泊位、堆场和闸口3类资源的集成调度,相较于传统的两阶段调度,周期计划下的船舶总在港时间缩短约20%.Abstract: In order to improve the efficiency of import/export container terminals in periodic environment, the periodical and collaborative allocation problem of key resources at container terminals, including berth, yard and gate is investigated. A mixed-integer linear programming model is first established for the integrated scheduling of three types of resources. This model takes into account the capacity restrictions, inter-relationships and periodicity requirements, and sets the objective of minimizing total dwelling time of all vessels. Furthermore, an adaptive genetic algorithm is proposed to find a solution. As for the algorithm, the upper level performs evolutionary search within the space consisting the encoded vessel priority lists, while the lower level decodes each vessel priority to generate a complete resource allocation plan by heuristics, and returns its evaluation for upper level iteration. Numeral experiments shows that with the collaborative allocation of berth-yard-gate resources, the dwelling time of vessels in the execution of periodic plan is shortened by 20% comparing to traditional two-stage method.

-

Key words:

- container terminal /

- resource allocation /

- periodicity /

- gate /

- genetic algorithm

-

表 1 船舶类型及其参数

Table 1. Parameters of different types of vessel

船舶类型 船长/(×10 m) 占比 装卸载箱总量/TEU (预存/留存期)/h 小型 U[10,20] 1/3 U[360,1 080] 72 中型 U[20,30] 1/3 U[960,1 920] 72 大型 U[30,40] 1/3 U[1 800,3 600] 72 表 2 不同问题规模下的可用资源配置

Table 2. Resource configurations under different problem scales

V/条 J/(×10 m) S/TEU ${G_{\rm{L}}}$/(TEU•h–1) ${G_{\rm{D}}}$/(TEU•h–1) 20 70 28 800 18 18 30 110 38 400 27 27 40 150 57 600 36 36 表 3 20船规模下数值实验

Table 3. Algorithm performance of 20 vessels

算例 Z Z1 Z2 g/% 1 202 142 229 -11.8 2 258 109 322 -19.8 3 194 96 288 -32.6 4 195 114 242 –19.4 5 224 119 327 –31.5 6 203 116 227 –10.6 7 202 121 262 –22.9 8 170 112 186 –8.6 9 215 128 254 –15.4 10 152 95 187 –22.8 平均值 201.5 115.2 253.4 –20.5 表 4 30船规模下数值实验

Table 4. Algorithm performance of 30 vessels

算例 Z Z1 Z2 g/% 1 318 197 412 –22.8 2 293 145 384 –23.7 3 268 154 380 –29.5 4 259 140 313 –17.3 5 302 172 381 –20.7 6 277 154 347 –20.2 7 262 146 325 –19.4 8 239 167 256 –6.6 9 330 157 436 –24.3 10 260 168 317 –18.0 平均值 280.8 160 355.1 –19.8 表 5 40船规模下数值实验

Table 5. Algorithm performance of 40 vessels

算例 Z Z1 Z2 g/% 1 387 251 445 –13.0 2 350 187 443 –21.0 3 349 184 460 –24.1 4 298 187 370 –19.5 5 382 208 505 –24.4 6 284 188 330 –13.9 7 362 201 434 –16.6 8 326 185 401 –18.7 9 402 222 544 –26.1 10 299 183 358 –16.5 平均值 343.9 199.6 429.0 –19.8 -

桂小娅,陆志强,韩笑乐. 集装箱码头连续型泊位与岸桥集成调度[J]. 上海交通大学学报,2013,47(2): 226-229.GUI Xiaoya, LU Zhiqiang, HAN Xiaole. Integrating optimization method for continuous berth and quay crane scheduling in container terminals[J]. Journal of Shanghai Jiaotong University, 2013, 47(2): 226-229. 秦进,倪玲霖,王承娜,等. 集装箱码头岸桥调度优化模型及算法[J]. 西南交通大学学报,2013,48(1): 184-192. doi: 10.3969/j.issn.0258-2724.2013.01.029QIN Jin, NI Linglin, WANG Chengna, et al. Optimization model and algorithm for quay crane scheduling in container terminals[J]. Journal of Southwest Jiaotong University, 2013, 48(1): 184-192. doi: 10.3969/j.issn.0258-2724.2013.01.029 LI Mingkun, YIP T L. Joint planning for yard storage space and home berths in container terminals[J]. International Journal of Production Research, 2013, 51(10): 3143-3155. doi: 10.1080/00207543.2012.760852 NG W C, MAK K L, LI Mingkun. Yard planning for vessel services with a cyclical calling pattern[J]. Engineering Optimization, 2010, 42(11): 1039-1054. doi: 10.1080/03052151003650092 ZHANG Chuqian, LIU Jiyin, WAN Y W, et al. Storage space allocation in container terminals[J]. Transportation Research Part B:Methodological, 2003, 37(10): 883-903. doi: 10.1016/S0191-2615(02)00089-9 CHEN Lu, LU Zhiqiang. The storage location assignment problem for outbound containers in a maritime terminal[J]. International Journal of Production Economics, 2012, 135(1): 73-80. doi: 10.1016/j.ijpe.2010.09.019 MOORTHY R, TEO C P. Berth management in container terminal:the template design problem[J]. OR spectrum, 2006, 28(4): 495-518. doi: 10.1007/s00291-006-0036-5 HENDRIKS M P M, LEFEBER E, UDDING J T. Simultaneous berth allocation and yard planning at tactical level[J]. OR Spectrum, 2013, 35(2): 441-456. doi: 10.1007/s00291-012-0305-4 CORDEAU J F, LAPORTE G, LEGATO P, et al. Models and tabu search heuristics for the berth-allocation problem[J]. Transportation Science, 2005, 39(4): 526-538. doi: 10.1287/trsc.1050.0120 LU Zhen, CHEW E P, LEE L H. An integrated model for berth template and yard template planning in transshipment hubs[J]. Transportation Science, 2011, 45(4): 483-504. doi: 10.1287/trsc.1100.0364 ROBENEK T, UMANG N, BIERLAIRE M, et al. A branch-and-price algorithm to solve the integrated berth allocation and yard assignment problem in bulk ports[J]. European Journal of Operational Research, 2014, 235(2): 399-411. doi: 10.1016/j.ejor.2013.08.015 JIN Jiangang, LEE D H, HU Hao. Tactical berth and yard template design at container transshipment terminals:a column generation based approach[J]. Transportation Research Part E: Logistics & Transportation Review, 2015, 73: 168-184. CHEN Gang, GOVINDAN K, YANG Zhongzhen. Managing truck arrivals with time windows to alleviate gate congestion at container terminals[J]. International Journal of Production Economics, 2013, 141(1): 179-188. doi: 10.1016/j.ijpe.2012.03.033 杨超,陆志强. 基于遗传算法的出口集装箱送箱时间窗优化[J]. 计算机应用研究,2013,30(6): 1643-1646. doi: 10.3969/j.issn.1001-3695.2013.06.010YANG Chao, LU Zhiqiang. Optimizing time windows for delivering export container using genetic algorithm[J]. Application Research of Computers, 2013, 30(6): 1643-1646. doi: 10.3969/j.issn.1001-3695.2013.06.010 YUN W Y, YONG S C. A simulation model for container-terminal operation analysis using an object-oriented approach[J]. International Journal of Production Economics, 1999, 59(1/2/3): 221-230. doi: 10.1016/S0925-5273(98)00213-8 LIU C, JULA H, IOANNOU P A. Design,simulation,and evaluation of automated container terminals[J]. IEEE Transactions on Intelligent Transportation Systems, 2002, 3(1): 12-26. doi: 10.1109/6979.994792 HENESEY L, WERNSTEDT F, DAVIDSSON P. Market-driven control in container terminal management[C]//The 2nd International Conference on Computer Applications and Information Technology in the Maritime Industries. Hamburg: [s.n.], 2003: 377-386 -

下载:

下载: