Static Recrystallization Behavior of Nitrogen Alloyed HRB500E Steel

-

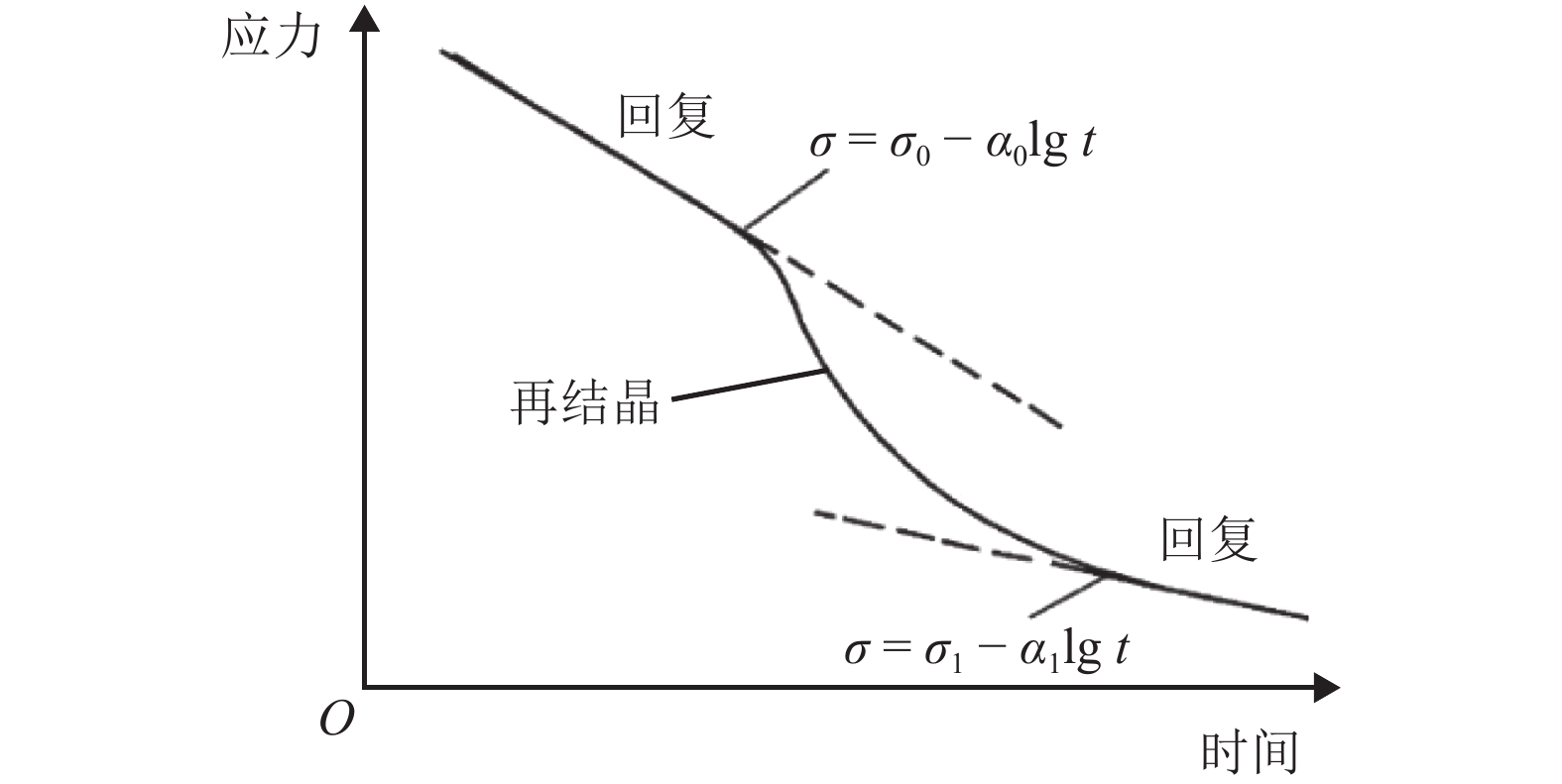

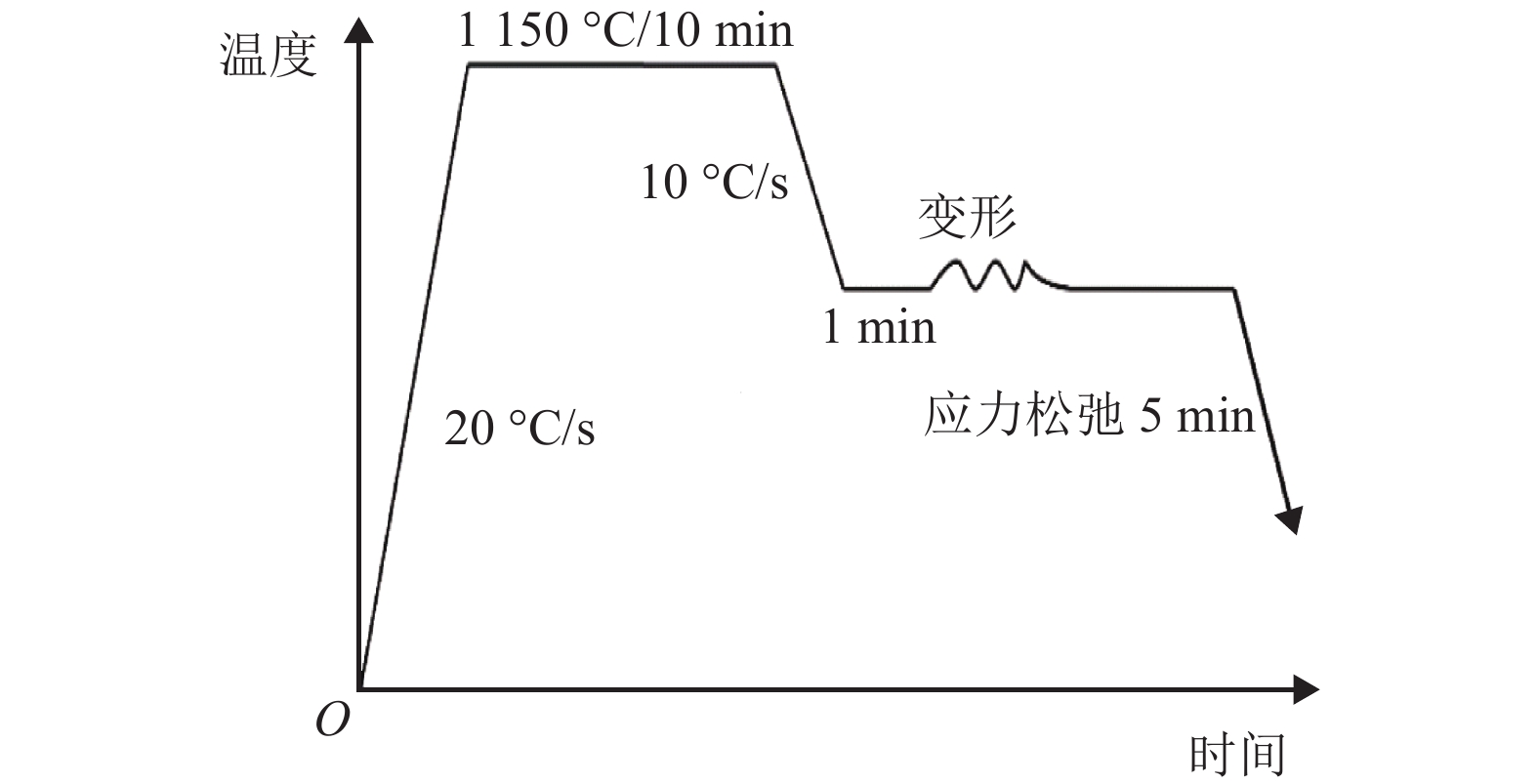

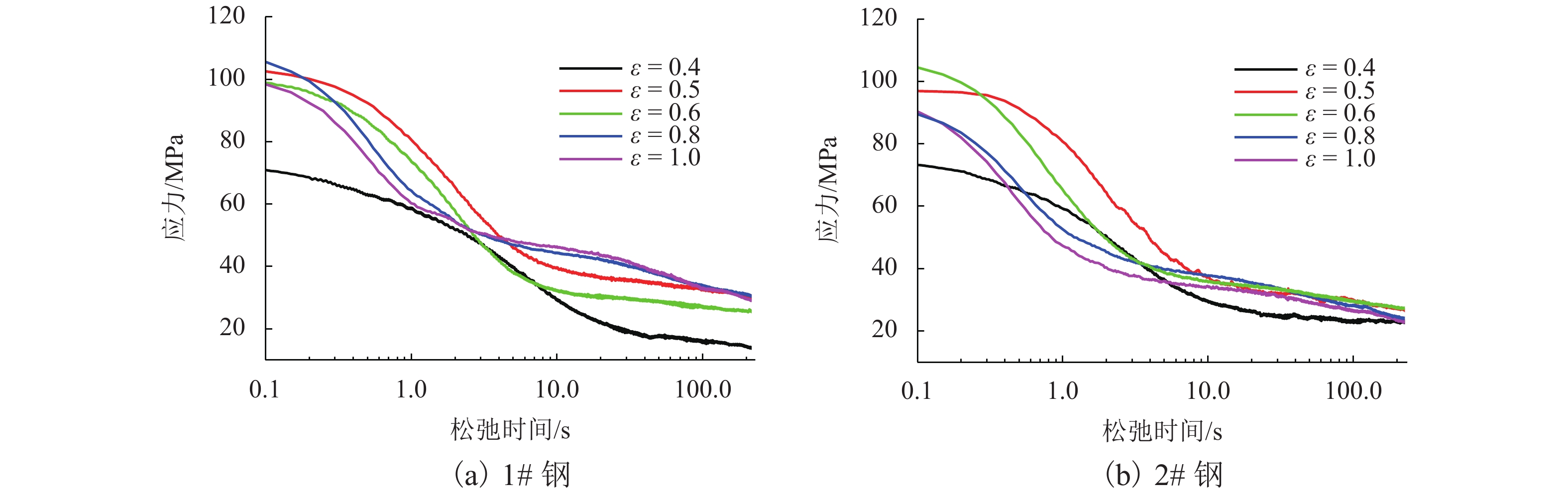

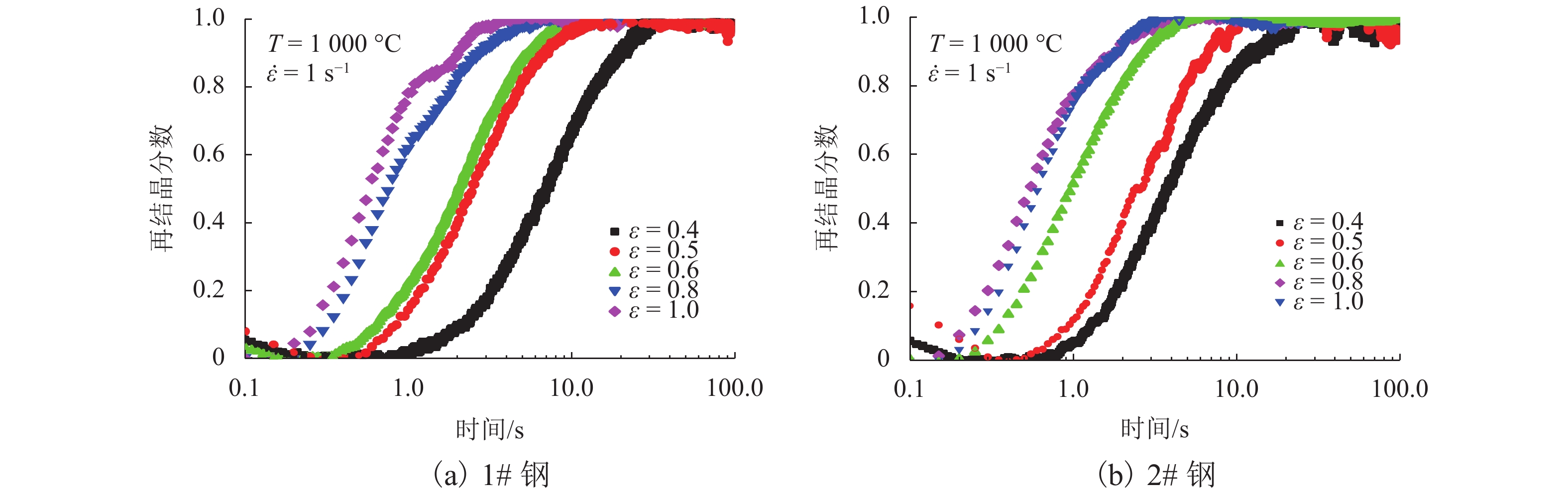

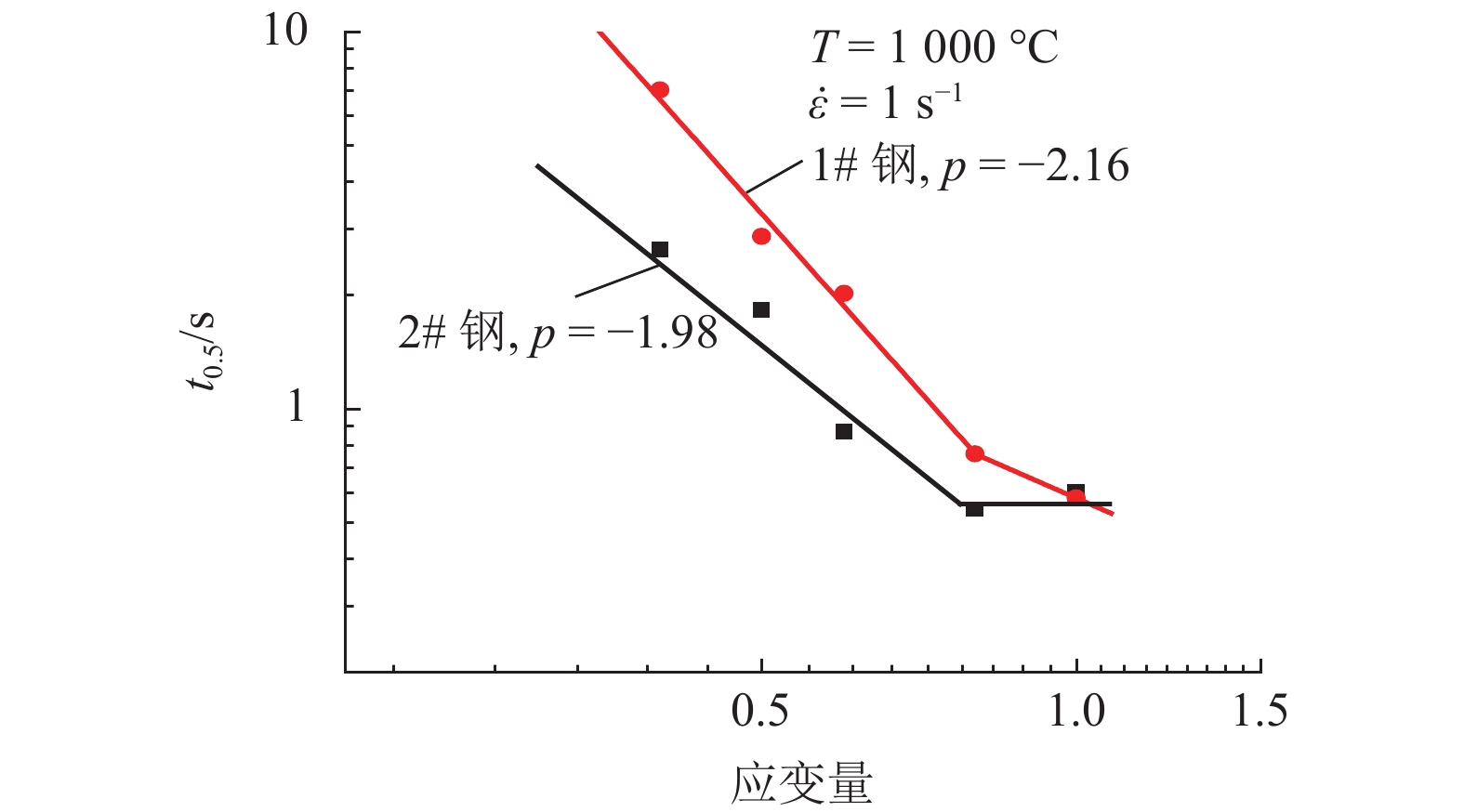

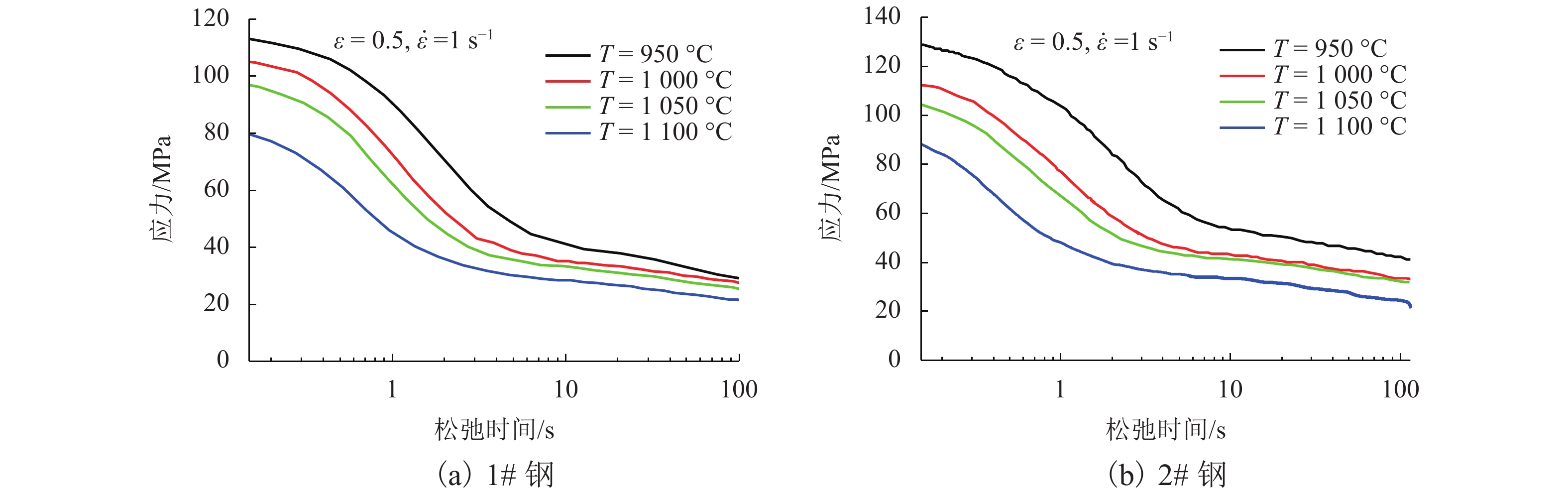

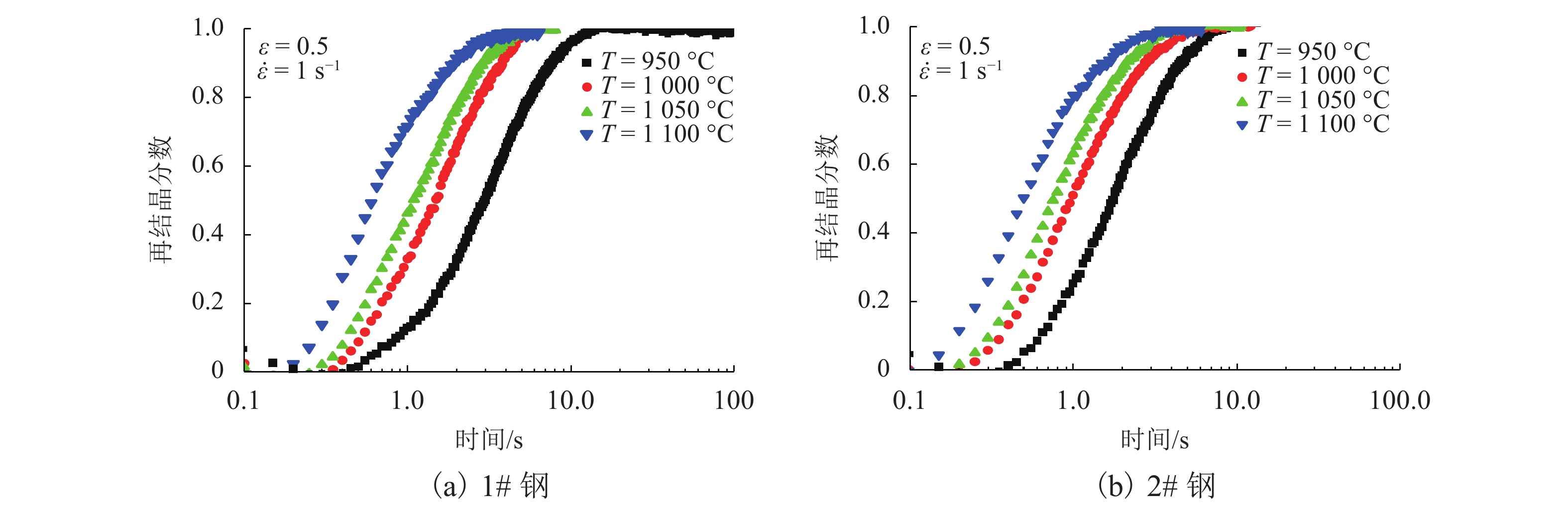

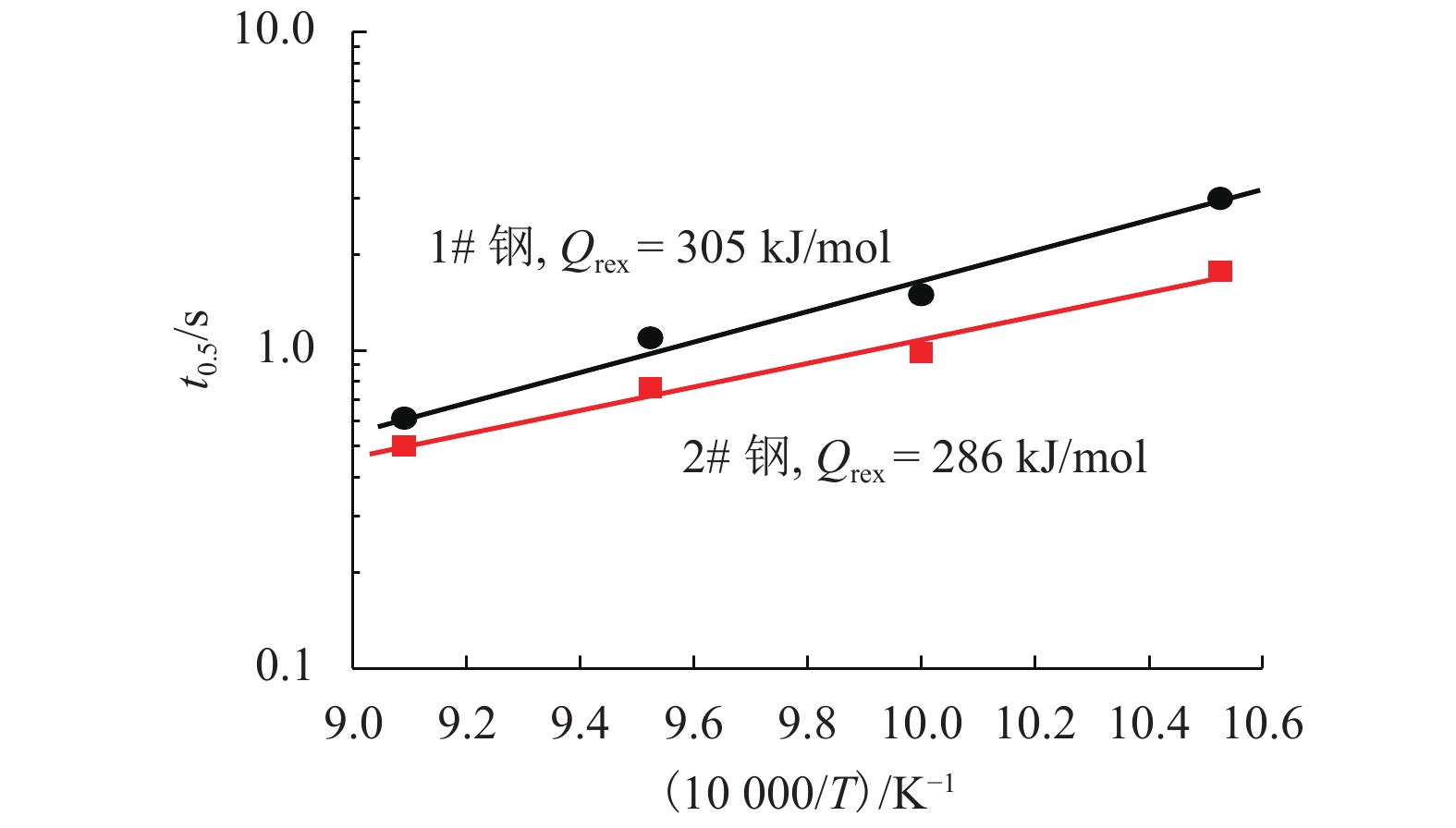

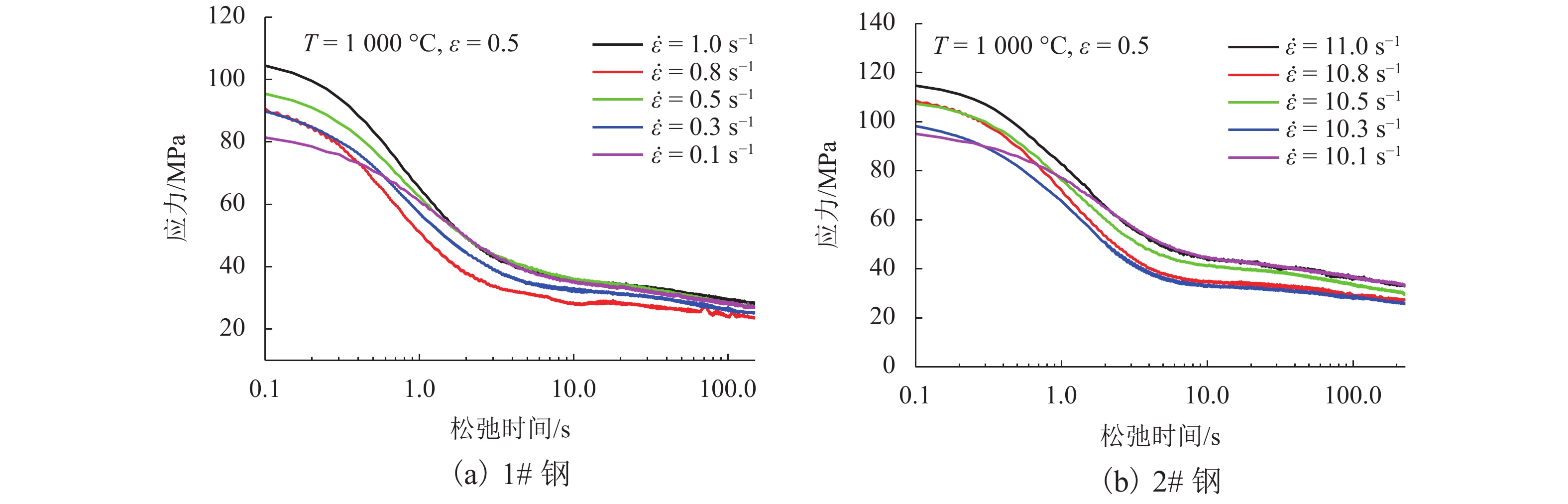

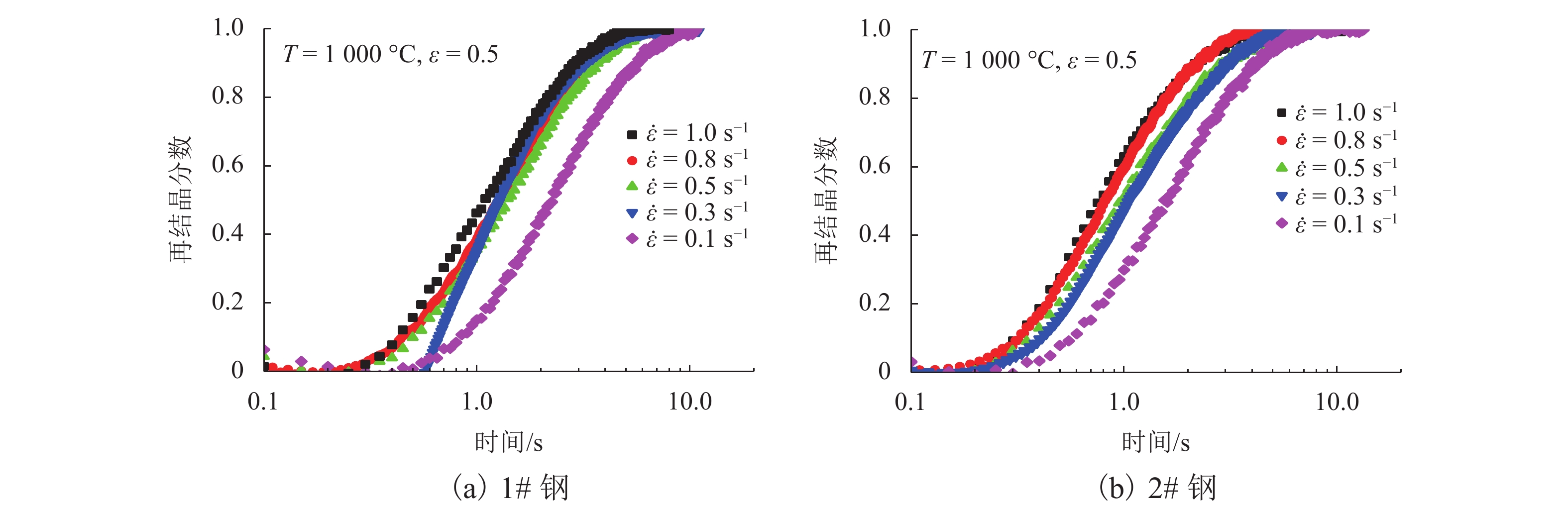

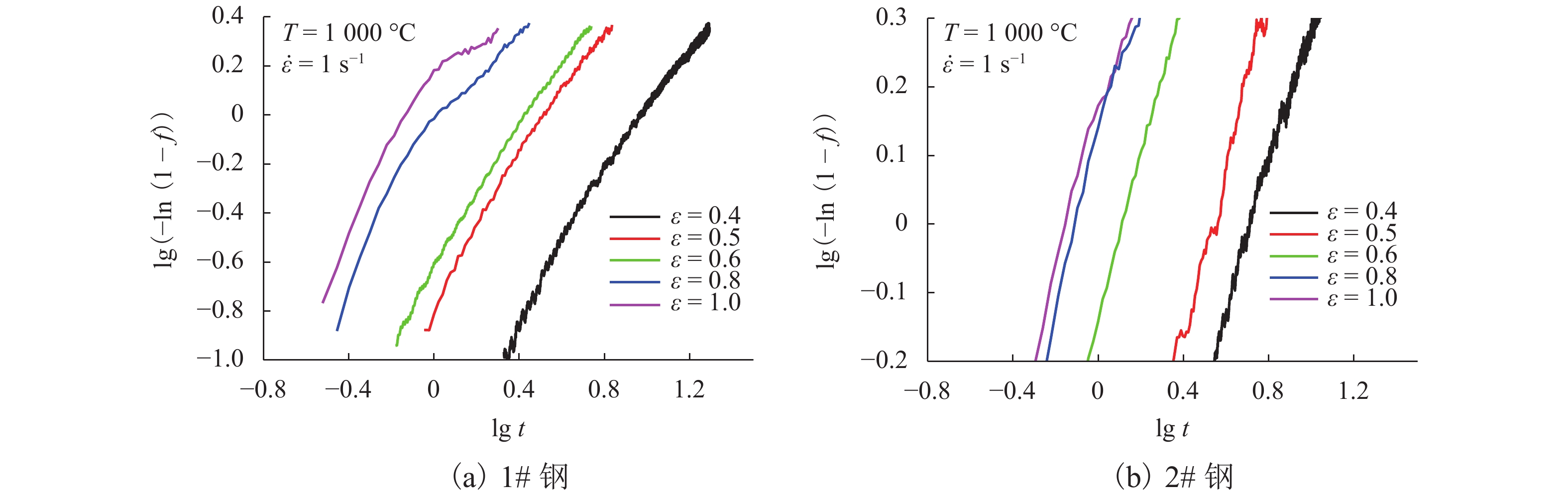

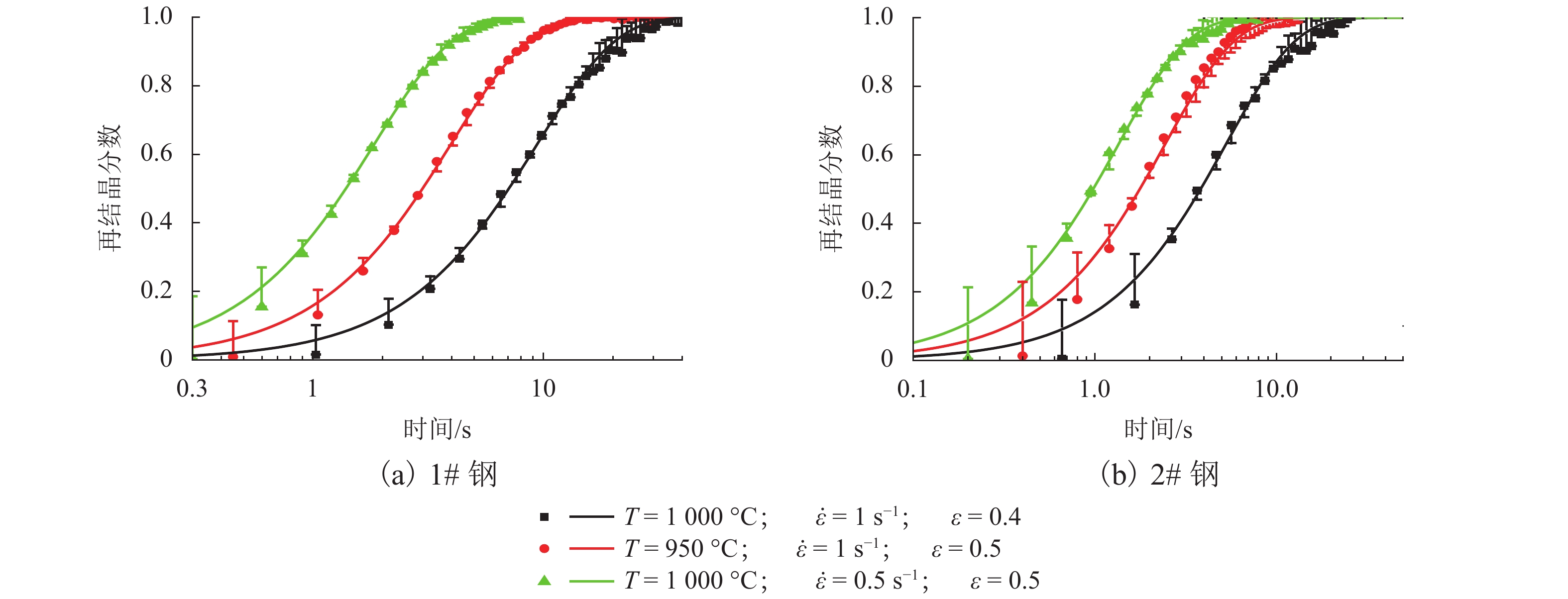

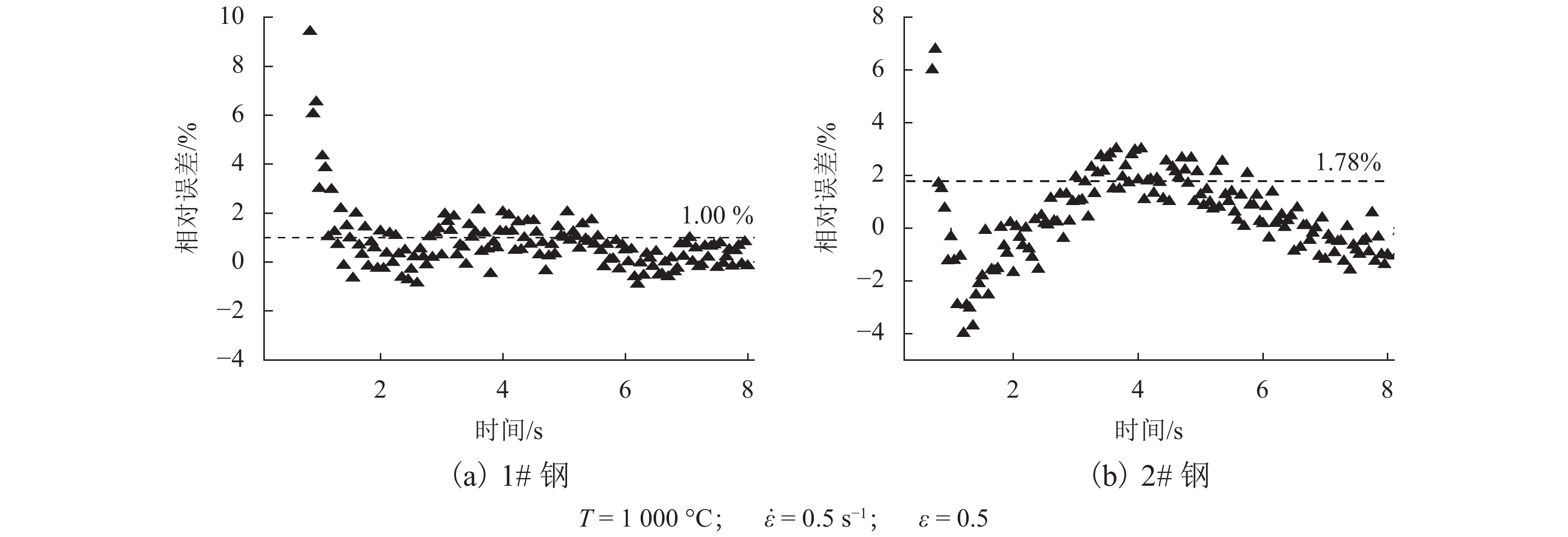

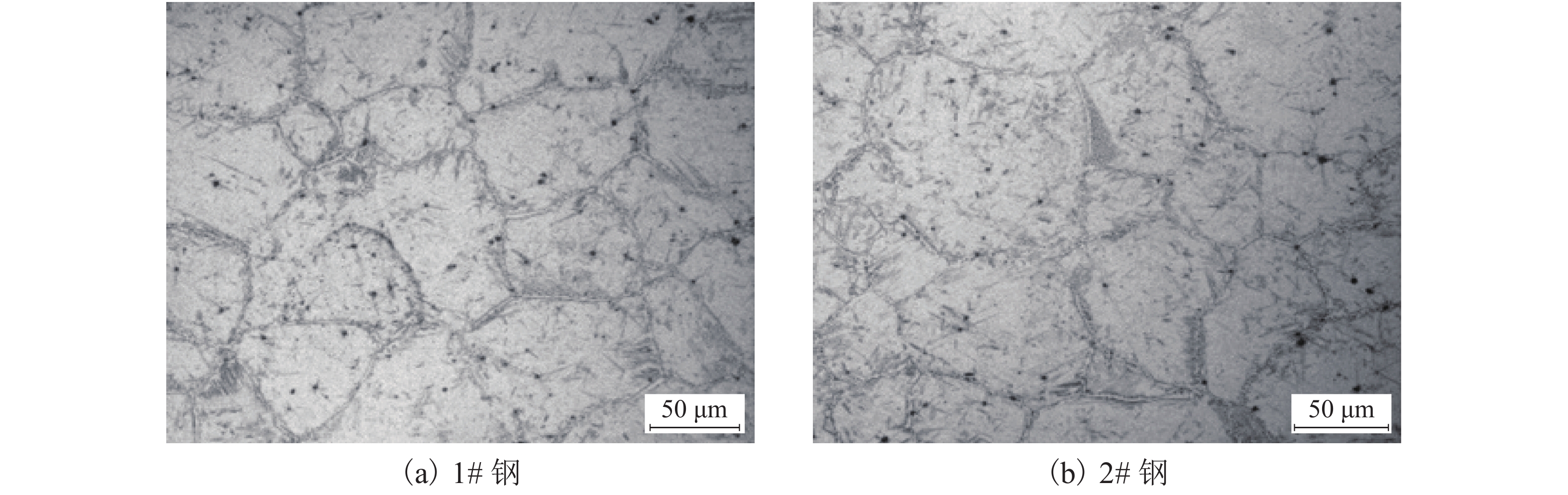

摘要: 为了对相关热轧工艺制度的确定提供必要的理论依据,采用应力松弛法研究了氮合金化HRB500E钢的静态再结晶行为,运用Gleeble-1500D热模拟试验机分析了不同的应变量、应变温度、应变速率对试验钢静态再结晶的影响,并与普通的钒微合金化HRB500E钢进行了对比. 依据试验结果,以Avrami 方程为基础,建立了两种试验钢的静态再结晶动力学模型,并进行了静态再结晶分数曲线与模型预测值的对比检验. 研究结果表明,控制两种试验钢的应变量在0.4~1.0区间递增,应变温度在950~1 100 ℃范围内递增,应变速率在0.1~1.0 s−1范围内递增时,其t0.5值(再结晶完成50%所需要的时间)均分别随之减少,再结晶速度加快;其中,应变量及应变温度对试验钢静态再结晶的影响较为显著,应变速率次之. 在应变条件相同的情况下,氮合金化HRB500E钢静态再结晶进程滞后于钒微合金化HRB500E钢. 检验结果表明,两种试验钢静态再结晶动力学模型预测结果与试验结果较吻合.Abstract: In order to provide necessary theoretical basis for hot rolling process, the static recrystallization behavior of nitrogen alloyed HRB500E steel was studied by using stress relaxation method. The effects of various strain capacity, strain temperature and strain rate on the static recrystallization of samples were analyzed with Gleeble-1500D thermal simulation machine. Besides, the results were compared with those of vanadium microalloyed HRB500E steel. Based on the experimental results and Avrami equation, the kinetic models of static recrystallization were established in terms of two kinds of experimental steels, and the static recrystallization fraction curve was compared with the predicted one of the model. The results show that when the strain is increased in the range of 0.4−1.0, the strain temperature in the range of 950−1 100 ℃, and the strain rate in the range of 0.1−1.0 s−1, t0.5 (time for 50% recrystallization) decreases and the recrystallization speed increases. In particular, the static recrystallization of the experimental steels is more notably affected by strain capacity and strain temperature than strain rate. Under the same strain conditions, the static recrystallization process of the nitrogen alloyed HRB500E steel lags behind that of the vanadium microalloyed HRB500E steel. The verification results show that the prediction results of the kinetic models were in good agreement with the experimental results.

-

Key words:

- nitrogen alloying /

- HRB500E /

- static recrystallization /

- kinetic model

-

表 1 试样铸坯实时参数及主要成分

Table 1. Main components and real-time parameters of samples in continous casting

样品 拉速/(m•min−1) 热度/℃ C/% Si/% Mn/% P/% S/% V/% N/% Ti/% 1# 2.8 24 0.210 0.350 1.490 0.028 0.032 0.078 0.011 0.005 2# 2.8 20 0.230 0.540 1.560 0.033 0.026 0.110 0.005 -

HWANG B, SHIM J H, LEE M G, et al. Technical developments and trends of earthquake resisting high-strength reinforcing steel bars[J]. Journal of the Korean Institute of Metals and Materials, 2016, 54(12): 862-874. CHENG M Y, HUNG S C, LEQUESNE R D, et al. Earthquake-resistant squat walls reinforced with high-strength steel[J]. Aci Structural Journal, 2016, 113(5): 1065-1076. SHI G, HU F, SHI Y. Recent research advances of high strength steel structures and codification of design specification in China[J]. International Journal of Steel Structures, 2014, 14(4): 873-887. doi: 10.1007/s13296-014-1218-7 DING H, LIU Y, GUO Y, et al. Seismic behavior study on concrete structures reinforced with high-strength steel bars[J]. Building Structure, 2015: 3-34. ALAEE P, LI B. High-strength concrete exterior beam-column joints with high-yield strength steel reinforcements[J]. Journal of Structural Engineering, 2017, 145(7): 305-321. CHEN W, SHI Z, ZHAO Y. Research of HRB500E high-strength earthquake-proof bars produced by VN alloy and MnSiN12 process[J]. Hot Working Technology, 2010, 39(4): 35-39. WINZER N, ROTT O, THIESSEN R, et al. Hydrogen diffusion and trapping in Ti-modified advanced high strength steels[J]. Materials & Design, 2016, 92: 450-461. CHEN W, CAO J, YANG Y, et al. Investigation on the strengthening and toughening mechanism of 500 MPa V-Nb microalloyed anti-seismic rebars[J]. Materials Science, 2015, 21(4): 536-542. CHEN W, SHI Z, ZHAO Y. Strengthening and toughening mechanism of HRB500 anti-seismic rebars with Nb microalloyed and controlled cooling process[J]. Journal of Central South University, 2011, 42(6): 1604-1610. XIANG Y, LAN L, ZHANG C, et al. Composition optimization and mechanical properties control for 500 MPa high strength ribbed bars[M]. [S.l.]: John Wiley & Sons, Inc., 2016: 967-972. ZHANG J, WANG F M, YANG Z B, et al. Microstructure,precipitation,and mechanical properties of V-N alloyed steel after different cooling processes[J]. Metallurgical & Materials Transactions A, 2016, 47(12): 6621-6631. JIAO Z, LIU C T. Ultrahigh-strength steels strengthened by nanoparticles[J]. Science Bulletin, 2017(15): 1043-1044. MIRZADEH H, CABRERA J M, PRADO J M, et al. Hot deformation behavior of a medium carbon microalloyed steel[J]. Materials Science & Engineering A, 2011, 528(10): 3876-3882. PENTTI K L, PERTTULA J. Characteristics of static and metadynamic recrystallization and strain accumulation in hot-deformed austenite as revealed by the stress relaxation method[J]. ISIJ International, 1996, 36(6): 729-736. doi: 10.2355/isijinternational.36.729 CHO S H, KANG K B, JONAS J J. Effect of manganese on recrystallisation kinetics of niobium microalloyed steel[J]. Materials Science & Technology, 2013, 18(4): 389-395. MEDINA S F, MANCILLA J E. Static recrystallization modelling of hot deformed steels containing severl alloying elements[J]. ISIJ International, 1996, 36(8): 1070-1076. doi: 10.2355/isijinternational.36.1070 ELWAZRI A M, WANJARA P, YUE S. Metadynamic and static recrystallization of hypereutectoid steel[J]. ISIJ International, 2003, 43(7): 1080-1088. doi: 10.2355/isijinternational.43.1080 周晓锋. 钒对20MnSi钢的热变形再结晶的影响[J]. 塑性工程学报,2007,14(1): 20-23. doi: 10.3969/j.issn.1007-2012.2007.01.005ZHOU Xiaofeng. Effect of vanadium on hot deformation recrystallization of 20MnSi steel[J]. Journal of Plasticity Engineering, 2007, 14(1): 20-23. doi: 10.3969/j.issn.1007-2012.2007.01.005 -

下载:

下载: