Mechanical Performance of Novel Prefabricated Composite Girder with Top Flange of Ultra Hight Performance Concrete Waffle Deck Panel

-

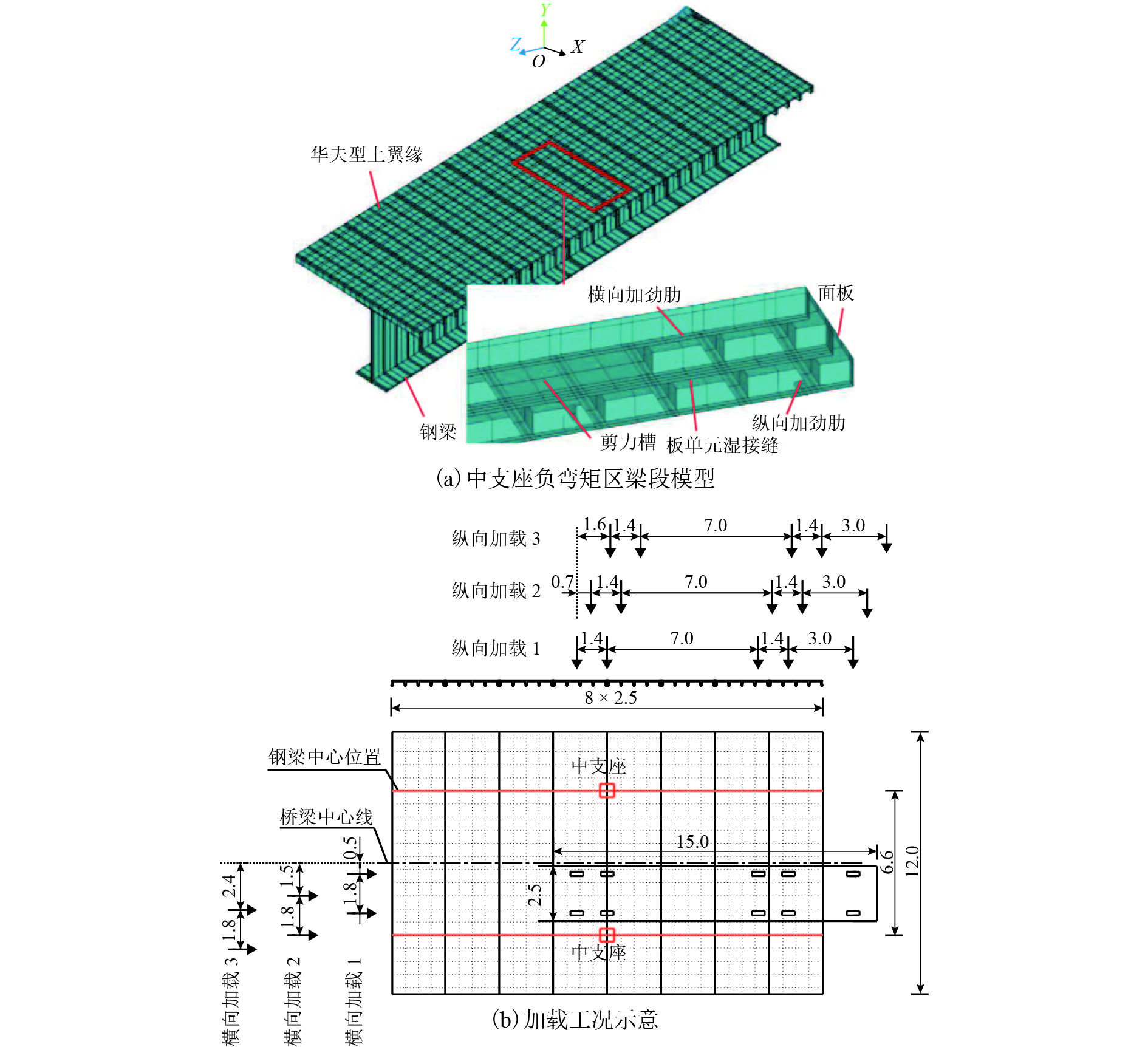

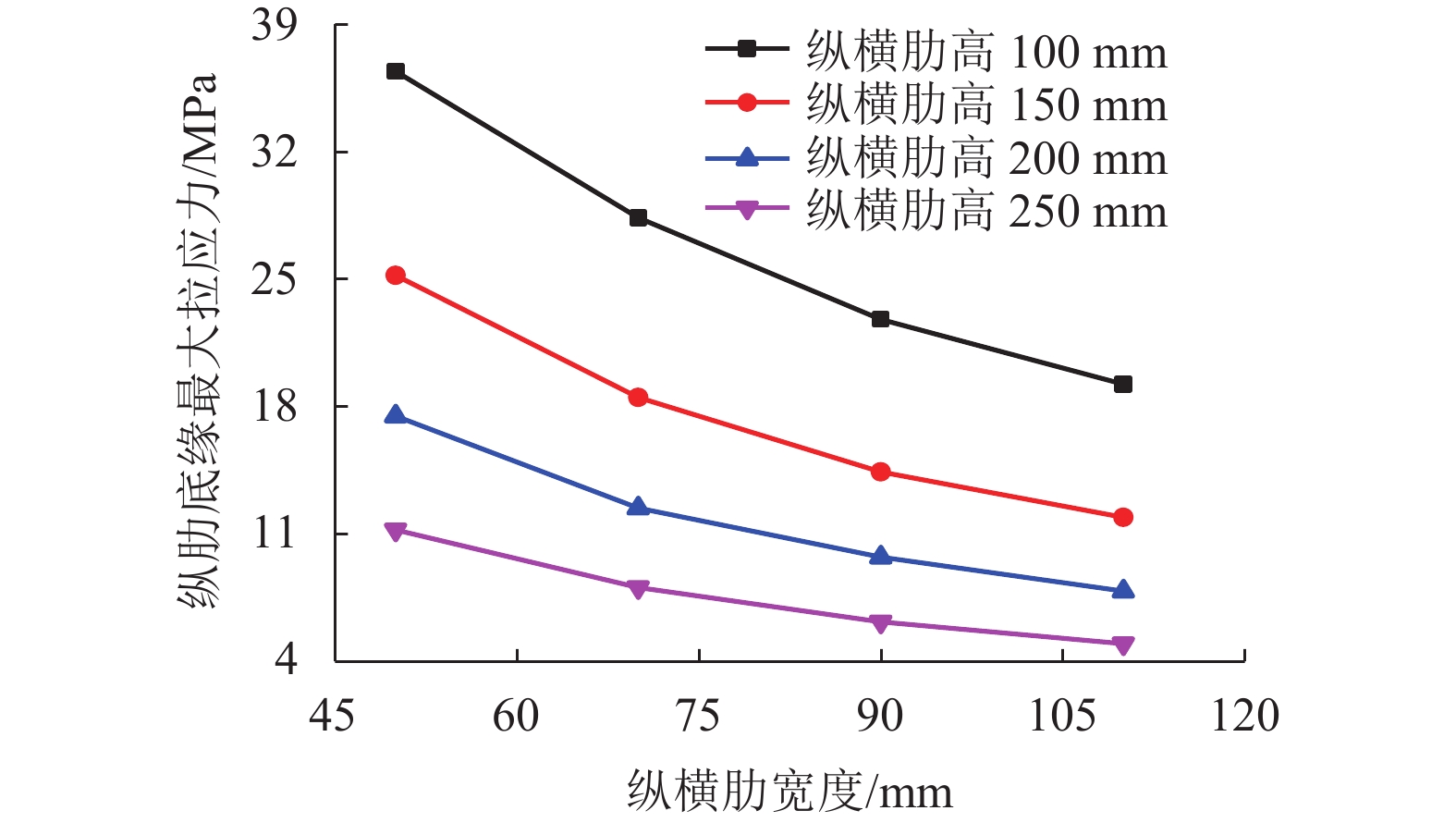

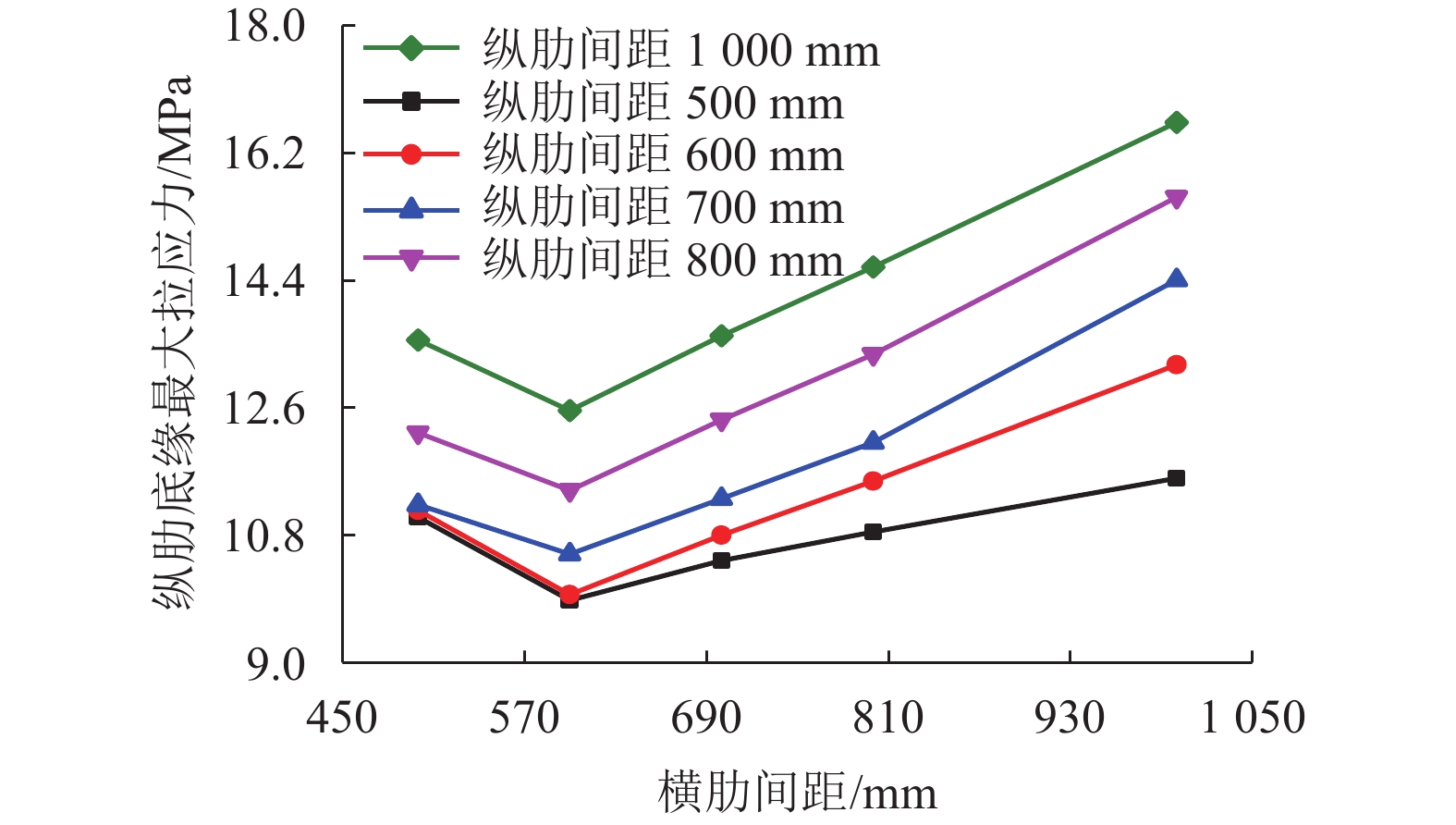

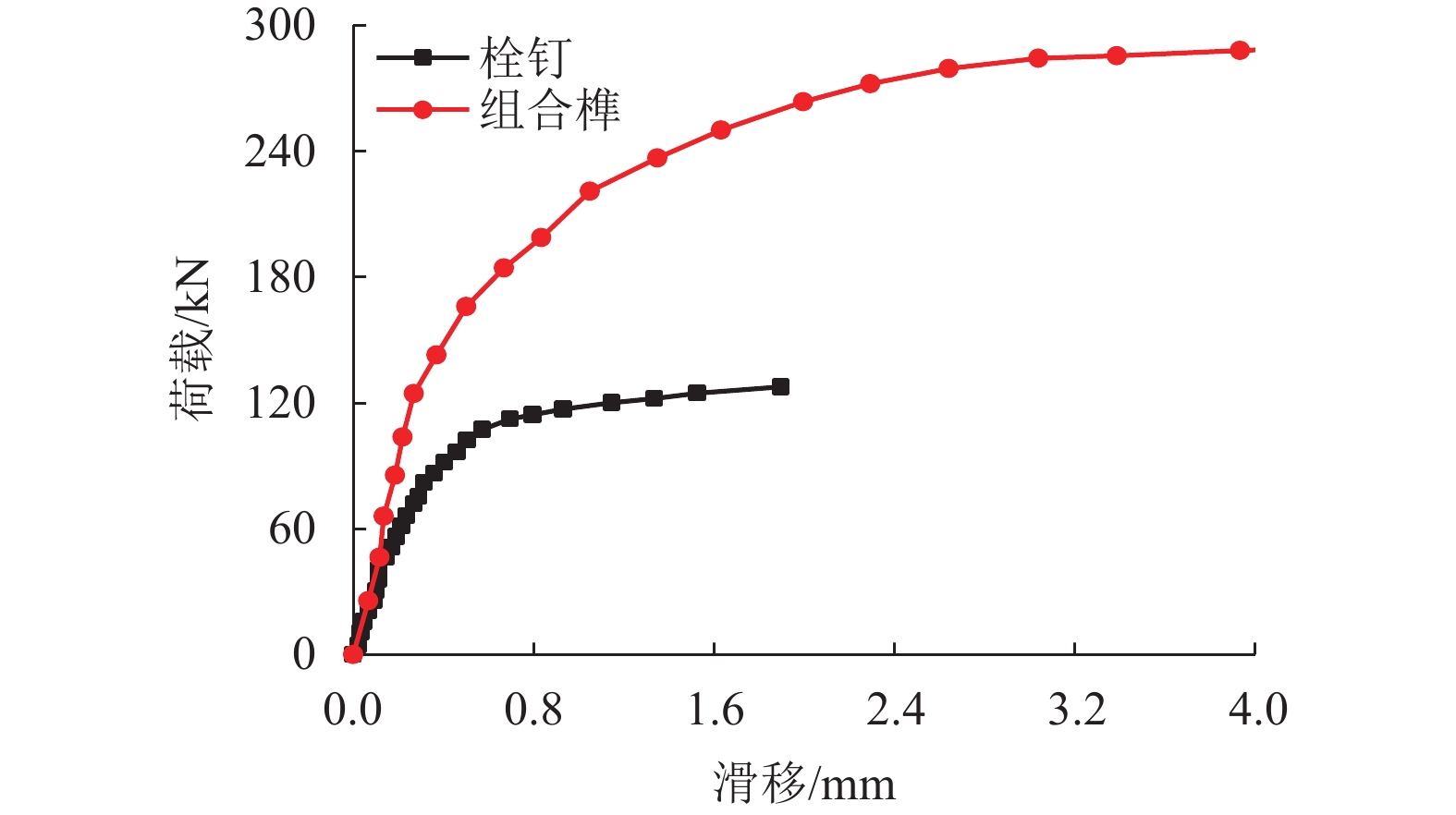

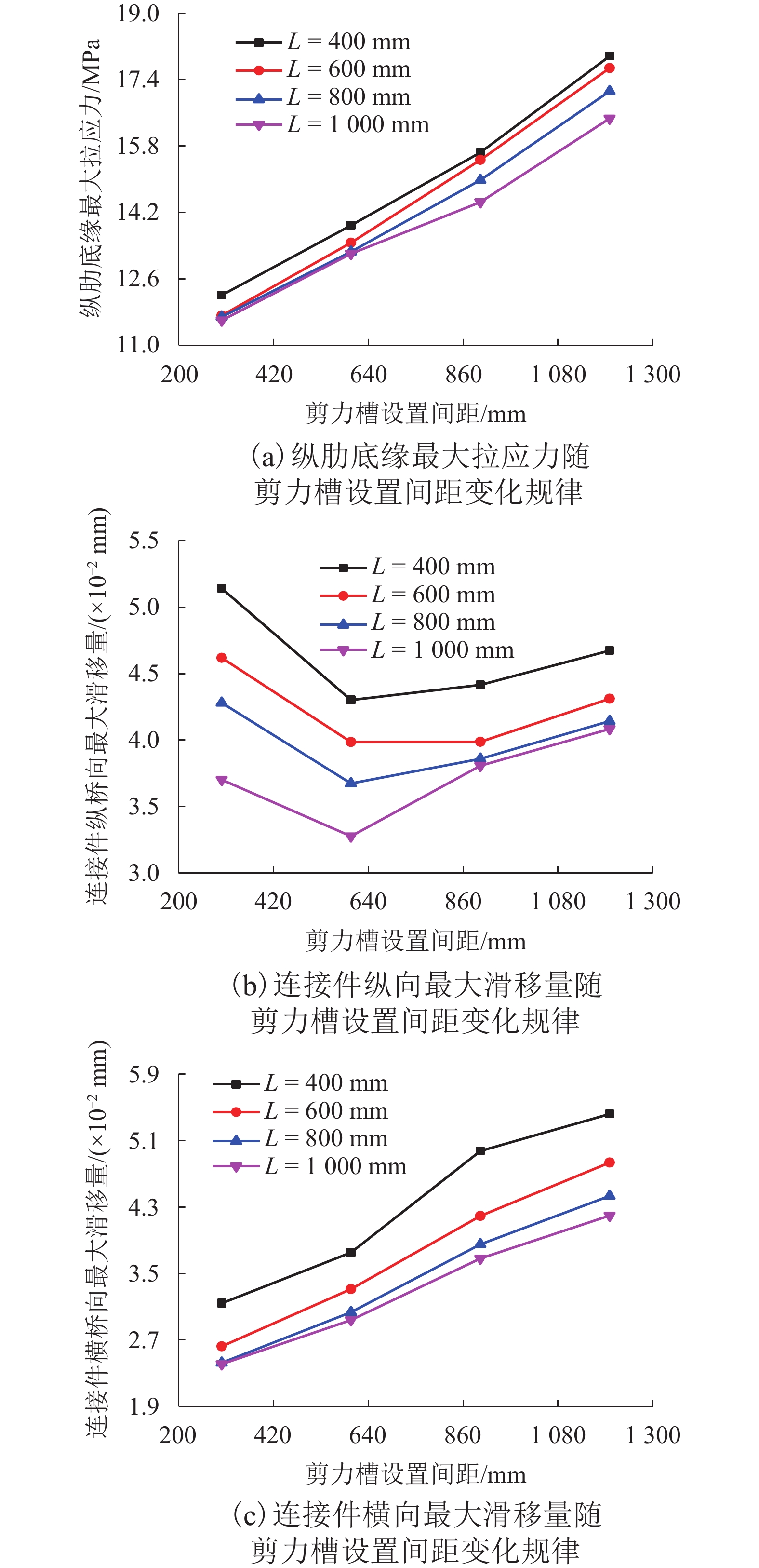

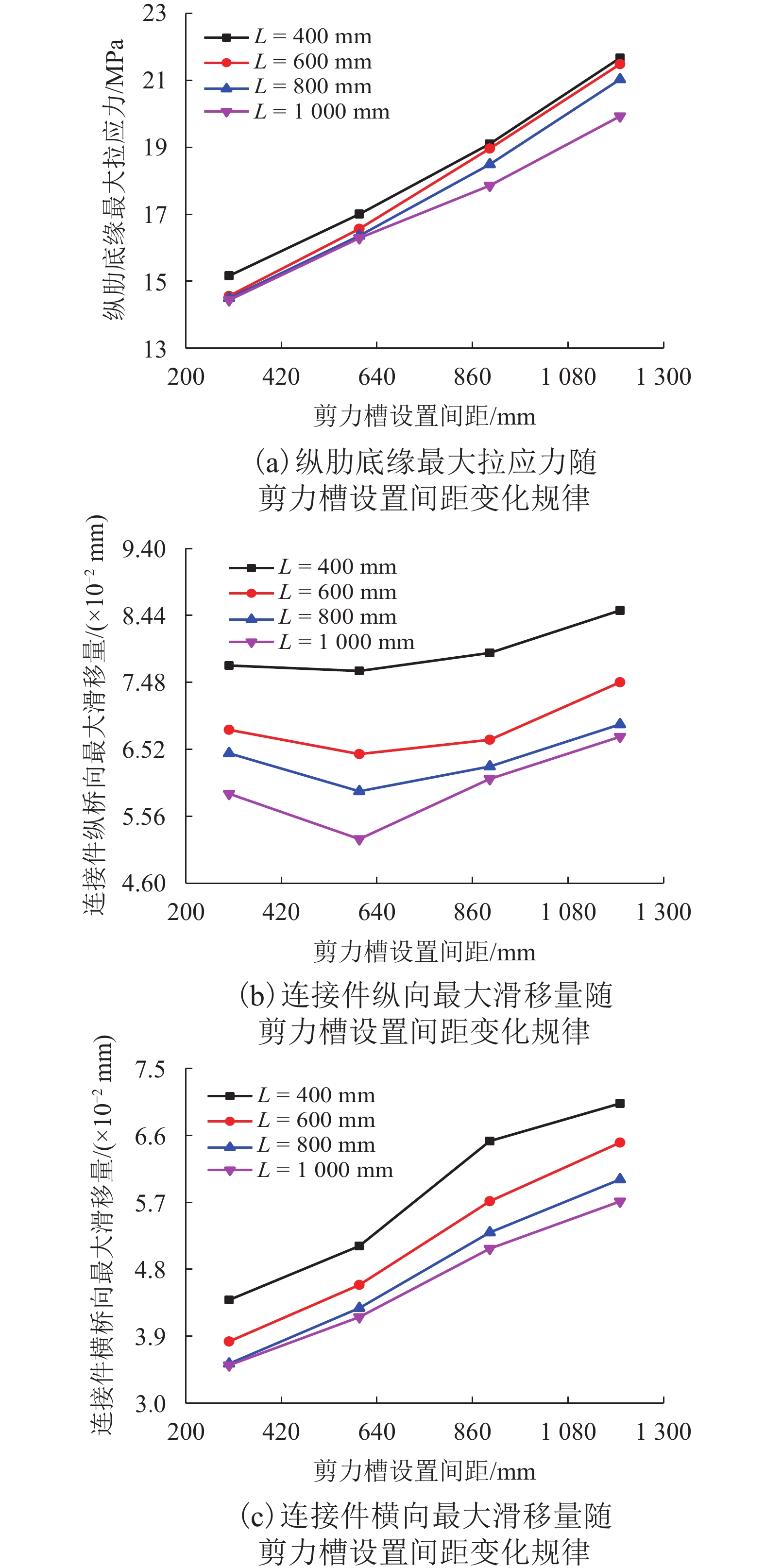

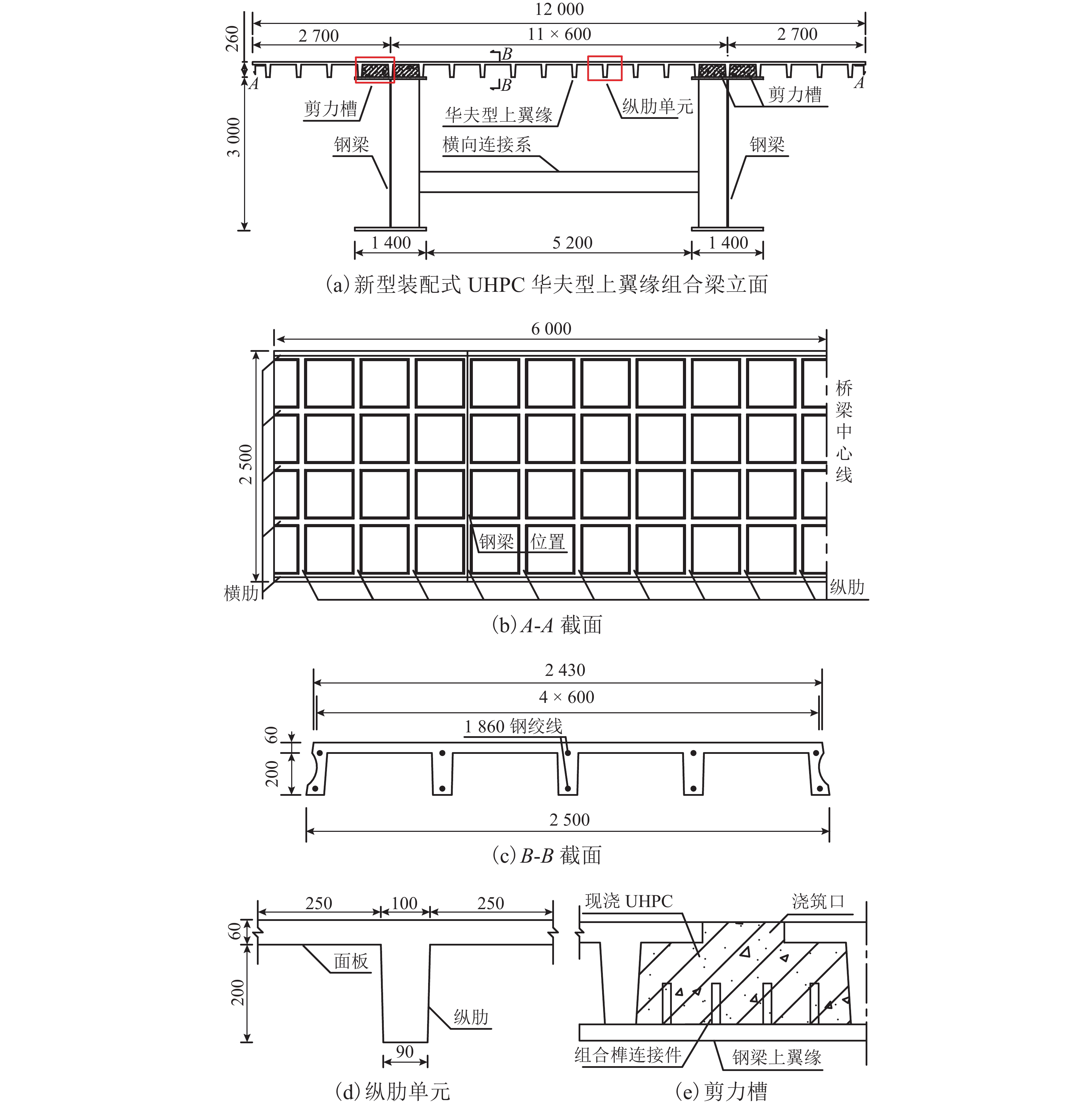

摘要: 为综合解决传统钢-混凝土组合结构中混凝土桥面板自重偏大和负弯矩区易开裂的问题,引入超高性能混凝土(ultra high performance concrete,UHPC)华夫板代替普通混凝土桥面板,提出一种新型组合梁—装配式UHPC华夫型上翼缘组合梁. 以某典型3跨连续梁桥为研究对象,分别建立3跨连续梁整体和中支座区域梁段的有限元模型,研究了不同荷载工况下新型装配式UHPC华夫型上翼缘组合梁的受力性能,分析了UHPC华夫型上翼缘关键设计参数对该新型组合梁力学性能的影响规律,对比研究了组合榫型剪力槽与栓钉型剪力槽对该新型组合梁受力性能的影响. 研究结果表明:在恒 + 活组合作用下,中支座负弯矩段华夫型上翼缘纵肋底缘和面板最大拉应力均小于配筋UHPC的抗拉强度设计值;当UHPC华夫型上翼缘纵、横肋宽90 mm、高200 mm,纵肋间距700 mm,横肋间距600 mm,面板厚60 mm时,UHPC华夫型上翼缘受力较为合理;组合榫型剪力槽更适用于新型装配式UHPC华夫型上翼缘组合梁.Abstract: A novel prefabricated composite girder with the top flange of an ultra-high-performance concrete (UHPC) waffle deck panel in place of a normal concrete deck panel was proposed, to resolve problems associated with the high self-weight and high probability of cracking in conventional steel-concrete composite structures. To investigate the mechanical behaviour and application of the structure in continuous bridges, a whole bridge model and mid-support region girder model of a typical three-span continuous bridge were established by finite element analysis (FEA). The mechanical behaviour of the novel composite girder under various load modes was studied, and the influence of the key design parameters for the UHPC waffle deck panel on the mechanical behaviour of the novel composite girder was analysed. In addition, the influences of the composite dowel-type shear pocket and stud-type shear pocket on the mechanical performance of the novel composite girder were compared. The maximum tensile stress at the bottom of the longitudinal ribs and the top deck of the UHPC waffle deck panel meets the tensile strength limit of reinforced UHPC under the composite action of dead loads and live loads; when the longitudinal ribs and transverse ribs are 90 mm in width, 200 mm in height, 700 mm in the space of the longitudinal ribs, 600 mm in the space of the transverse ribs, and 60 mm in the thickness of the top deck, the UHPC waffle deck panels exhibit better mechanical performance than before. The composite dowel-type shear pocket is more applicable to the novel prefabricated composite girder than the stud-type shear pocket.

-

表 1 材料特性

Table 1. Material property

材料 弹性模量/GPa 泊松比 密度/(kg•m–3) UHPC 60 0.20 2 650 Q345钢 206 0.31 7 850 1860钢绞线 195 0.31 7 850 表 2 华夫型上翼缘各部位应力计算结果

Table 2. The calculated stress at parts of the waffle deck panel

位置 最大应力/MPa 加载工况 纵肋底缘 9.9 纵向加载3、横向加载1 横肋底缘 – 4.3 纵向加载2、横向加载1 面板 8.0 纵向加载3、横向加载1 -

聂建国,陶慕轩,吴丽丽,等. 钢-混凝土组合结构桥梁研究新进展[J]. 土木工程学报,2012,45(6): 110-122.NIE Jianguo, TAO Muxuan, WU Lili, et al. Advances of research on steel-concrete composite bridges[J]. China Civil Engineering Journal, 2012, 45(6): 110-122. 陈宝春, 牟廷敏, 陈宜言, 等. 我国钢-混凝土组合结构桥梁研究进展及工程应用[J]. 建筑结构学报, 2013, 34(增刊1): 1-10CHEN Baochun, MU Tingmin, CHEN Yiyan, et al. State-of-the-art of research and engineering application of steel-concrete composite bridges in China[J]. Journal of Building Structures, 2013, 34(S1): 1-10 聂建国. 钢-混凝土组合结构桥梁[M]. 北京: 人民交通出版社, 2011: 1-18 樊健生,聂建国,张彦玲. 钢-混凝土组合梁抗裂性能的试验研究[J]. 土木工程学报,2011,44(2): 1-7.FAN Jiansheng, NIE Jianguo, ZHANG Yanling. Experimental study of crack resistance of steel concrete composite beams[J]. China Civil Engineering Journal, 2011, 44(2): 1-7. 邵旭东, 胡建华. 钢-超高性能混凝土轻型组合桥梁结构[M]. 北京: 人民交通出版社, 2015: 20-21 樊健生,聂建国. 钢-混凝土组合桥梁研究及应用新进展[J]. 建筑钢结构进展,2006,8(5): 35-39. doi: 10.3969/j.issn.1671-9379.2006.05.005FAN Jiansheng, NIE Jianguo. Progress in research and application of composite steel concrete bridges[J]. Progress in Steel Building Structures, 2006, 8(5): 35-39. doi: 10.3969/j.issn.1671-9379.2006.05.005 聂建国,陶慕轩,聂鑫,等. 抗拔不抗剪连接新技术及其应用[J]. 土木工程学报,2015,48(4): 7-14.NIE Jianguo, TAO Muxuan, NIE Xin, et al. New technique and application of uplift-restricted and slip-permitted connection[J]. China Civil Engineering Journal, 2015, 48(4): 7-14. 聂建国,李一昕,陶慕轩,等. 新型抗拔不抗剪连接件抗拔性能试验[J]. 中国公路学报,2014,27(4): 38-45. doi: 10.3969/j.issn.1001-7372.2014.04.006NIE Jianguo, LI Yixin, TAO Muxuan, et al. Experiment research on uplift performance of a new type of uplift restricted-slip free connector[J]. China Journal of Highway and Transport, 2014, 27(4): 38-45. doi: 10.3969/j.issn.1001-7372.2014.04.006 聂建国. 我国结构工程的未来——高性能结构工程[J]. 土木工程学报,2016,49(9): 1-8.NIE Jianguo. The future of structural engineering in China—high-performance structural engineering[J]. China Civil Engineering Journal, 2016, 49(9): 1-8. 刘永健,高诣民,周绪红,等. 中小跨径钢-混凝土组合梁桥技术经济性分析[J]. 中国公路学报,2017,30(3): 1-13. doi: 10.3969/j.issn.1001-7372.2017.03.001LIU Yongjian, GAO Yimin, ZHOU Xuhong, et al. Technical and economic analysis in steel-concrete composite girder bridges with small and medium span[J]. China Journal of Highway and Transport, 2017, 30(3): 1-13. doi: 10.3969/j.issn.1001-7372.2017.03.001 HABEL K, VIVIANI M, DENARIÉ E, et al. Development of the mechanical properties of an ultra-high performance fiber reinforced concrete (UHPFRC)[J]. Cement & Concrete Research, 2006, 36(7): 1362-1370. GRAYBEAL B A. Material property characterization of Ultra-high performance concrete[R]. Washington D. C.: Federal Highway Administration, 2006 RUSSELL H G, GRAYBEAL B A. Ultra-high performance concrete: a state-of-the-art report for the bridge community[R]. McLean: High Performance Concrete, 2013 BABY F, GRAYBEAL B A, MARCHAND P, et al. UHPFRC tensile behavior characterization:inverse analysis of four-point bending test results[J]. Materials & Structures, 2013, 46(8): 1337-1354. 陈宝春,季韬,黄卿维,等. 超高性能混凝土研究综述[J]. 建筑科学与工程学报,2014,31(3): 1-24. doi: 10.3969/j.issn.1673-2049.2014.03.002CHEN Baochun, JI Tao, HUANG Qingwei, et al. Review of research on ultra-high performance concrete[J]. Journal of Architecture and Civil Engineering, 2014, 31(3): 1-24. doi: 10.3969/j.issn.1673-2049.2014.03.002 李成君,周志祥,黄雅意,等. 装配式组合梁剪力钉抗剪承载力研究[J]. 中国公路学报,2017,30(3): 264-270. doi: 10.3969/j.issn.1001-7372.2017.03.029LI Chengjun, ZHOU Zhixiang, HUANG Yayi, et al. Research on shear resistance of shear studs in prefabricated composite beam[J]. China Journal of Highway and Transport, 2017, 30(3): 264-270. doi: 10.3969/j.issn.1001-7372.2017.03.029 贾俊峰,赵建瑜,张强,等. 后张预应力节段拼装CFST桥墩抗侧力学行为试验[J]. 中国公路学报,2017,30(3): 236-245. doi: 10.3969/j.issn.1001-7372.2017.03.026JIA Junfeng, ZHAO Jianyu, ZHANG Qiang, et al. Experiment on lateral bearing behavior of post-tensioned segmental CFST bridge pier columns[J]. China Journal of Highway and Transport, 2017, 30(3): 236-245. doi: 10.3969/j.issn.1001-7372.2017.03.026 TOUTLEMODE F, RESPLENDINO J, SORRELLI L, et al. Innovative design of Ultra high-performance fiber reinforced concrete ribbed slab: experimental validation and preliminary detailed analysis[C]//Proc. 7th Int. Symp. on Utilization of High Strength/High Performance Concrete. Washington D. C.: [s.n.], 2005: 1187-1206 GARCIA HECTOR M. Analysis of an Ultra-high performance concrete two-way ribbed bridge deck slab[R]. Washington D. C.: Federal Highway Administration, 2007 AALETI S, PETERSEN B, SRITHARAN S. Design guide for precast UHPC waffle deck panel system, including connections[R]. Washington D. C.: Federal Highway Administration, 2013 兰枢灵. 薄壁钢箱梁计算方法研究[D]. 西安: 长安大学, 2011 CLAßEN M, GALLWOSZUS J. Concrete fatigue in composite dowels[J]. Structural Concrete, 2016, 17(1): 63-73. doi: 10.1002/suco.v17.1 罗应章. 钢-混凝土组合梁栓钉剪力连接件的研究[D]. 长沙: 中南大学, 2008 马增. 新型装配式钢——混组合箱梁桥结构设计与试验研究[D]. 南京: 东南大学, 2015 -

下载:

下载: